Friction nanometer power generation sensor array with fabric structure

A sensor array, nano-power generation technology, applied in triboelectric generators, instruments, measuring forces, etc., can solve the problems of complex process, high cost, expensive manufacturing equipment, etc., and achieve simple operation, low cost, and guaranteed reliability and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

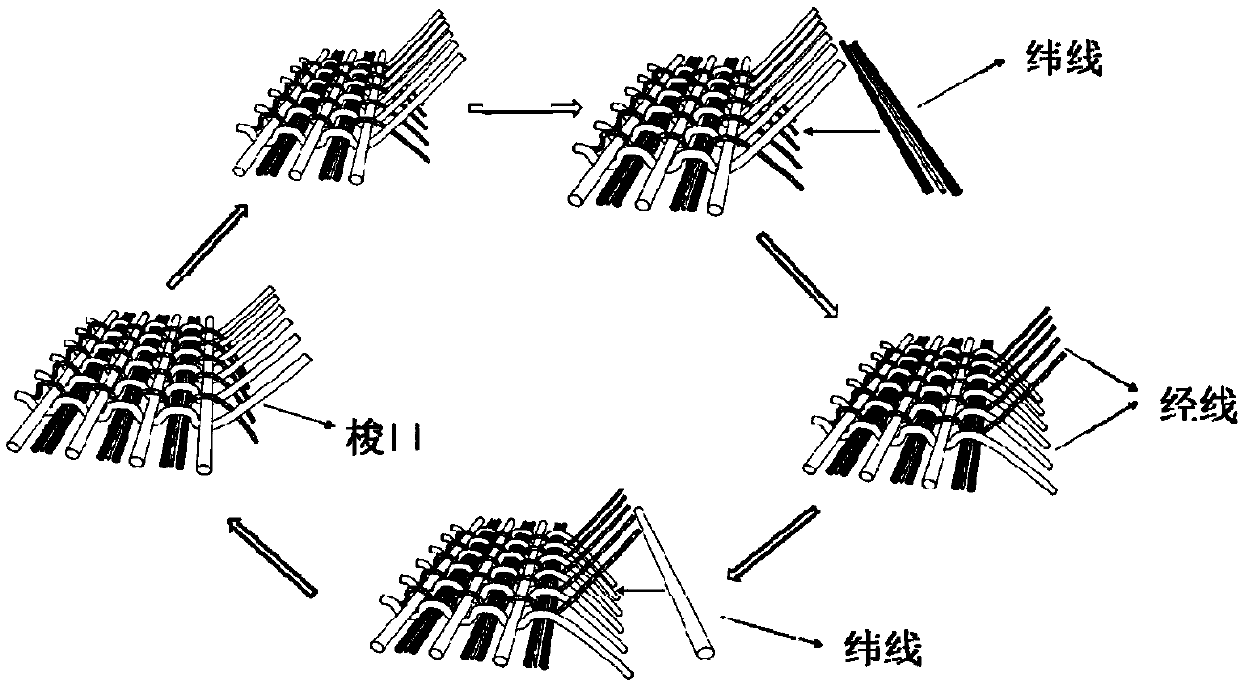

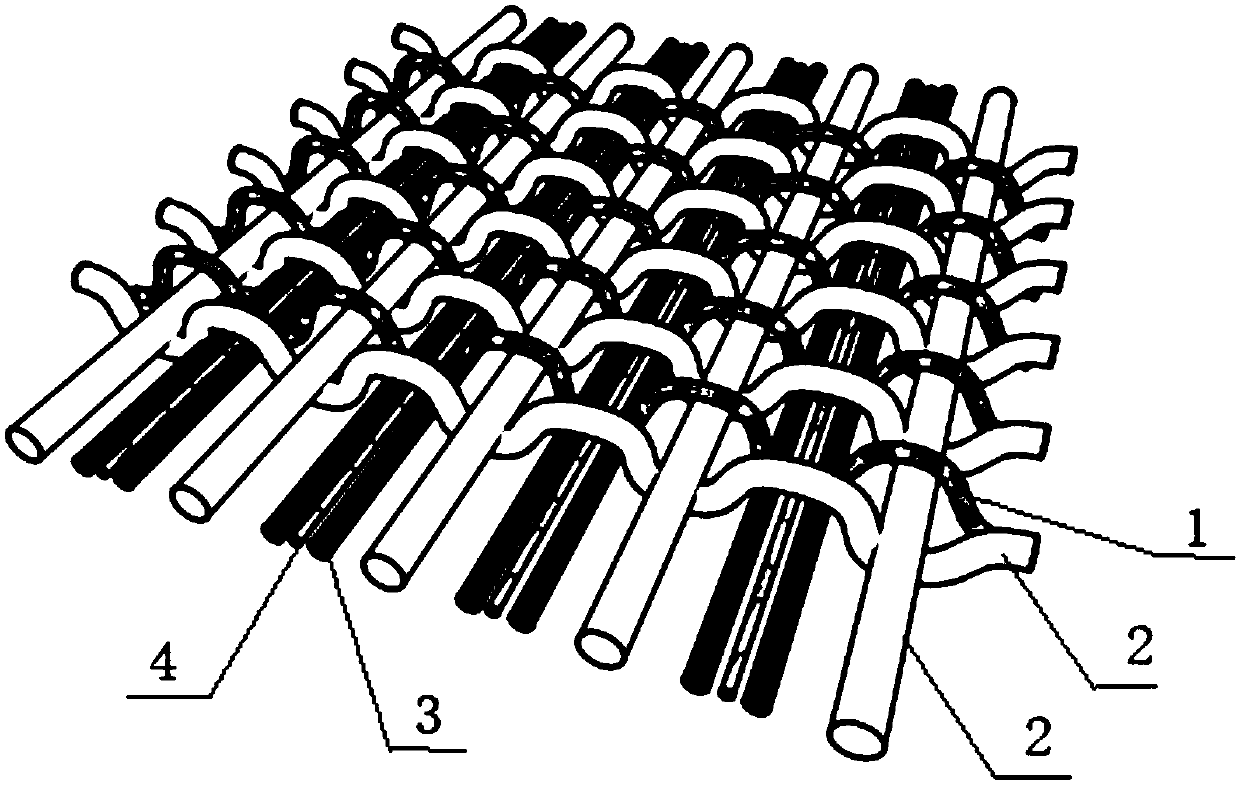

[0035] Example 1 Preparation of triboelectric nano-electric sensing imaging fabric

[0036] Fabrication of highly electrophilic triboelectric fiber electrodes

[0037] Clean the copper wire, dry it naturally, and place it on the surface of the heating table for sintering. Disperse the polytetrafluoroethylene concentrate in ethanol and shake well to obtain a uniformly dispersed suspension. The obtained suspension was sprayed on a single copper wire with a diameter of 0.1 mm to obtain a conductive fiber coated with polytetrafluoroethylene (coating thickness: 0.05 μm). Put the obtained conductive fiber in an oven and heat it for 30 minutes, then take it out, and then you can get the conductive fiber whose surface is wrapped with nano polytetrafluoroethylene film.

[0038] A copper wire with a diameter of 0.1 mm is selected as the low electrophilic triboelectric fiber electrode, and the aspect ratio is greater than 10:1.

[0039] Copper wires with a diameter of 0.1 mm and cloth...

Embodiment 2

[0042] Example 2 Preparation of Flexible Frictional Nano Power Generation Sensing Fabric

[0043] Fabrication of highly electrophilic triboelectric fiber electrodes

[0044] Clean the silver wire, dry it naturally, and place it on the surface of the heating table for sintering. Disperse the polyvinyl chloride concentrate in acetone and shake well to obtain a uniformly dispersed suspension. The resulting suspension was spin-coated on a single silver wire with a diameter of 0.05 mm to obtain a conductive fiber coated with polyvinyl chloride (coating thickness 20 μm) on the surface. Put the obtained conductive fiber in an oven and heat it for 50 minutes, then take it out, and then you can get the conductive fiber coated with nano polyvinyl chloride film on the surface.

[0045] A stainless steel wire with a diameter of 0.05 mm was selected as the low electrophilic triboelectric fiber electrode, and the length-to-diameter ratio was greater than 10:1.

[0046] The 0.05mm stainle...

Embodiment 3

[0049] Example 3 Preparation of Flexible Frictional Nano-Generation Sensing Array

[0050] Fabrication of highly electrophilic triboelectric fiber electrodes

[0051] Clean the titanium wire, dry it naturally, and place it on the surface of the heating table for sintering. Disperse the polydimethylsiloxane concentrate in ethanol, shake well to obtain a uniformly dispersed suspension. The obtained suspension was sprayed on a single titanium wire with a diameter of 0.2 mm to obtain a conductive fiber coated with polydimethylsiloxane on the surface (the thickness of the coating was 0.10 μm). Put the obtained conductive fiber in an oven and heat it for 60 minutes, then take it out, and then you can get the conductive fiber coated with nano polydimethylsiloxane film on the surface.

[0052] Copper wire manganese-plated composite fibers with a diameter of 0.2 mm were selected as low-electrophilic triboelectric fiber electrodes, and the length-to-diameter ratio was greater than 10:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com