Novel high-flexibility fireproof cable and manufacturing method thereof

A fire-resistant cable, highly flexible technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problem of inability to pass more severe impact + cutting + fire resistance + spray, can not effectively solve the problem of insulation performance, insulation layer and conductor Short circuit and other problems, to achieve the effect of satisfying flexibility and fireproof characteristics, easy maintenance and convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with exemplary embodiments, but the examples should not be construed as a specific limitation to the present invention.

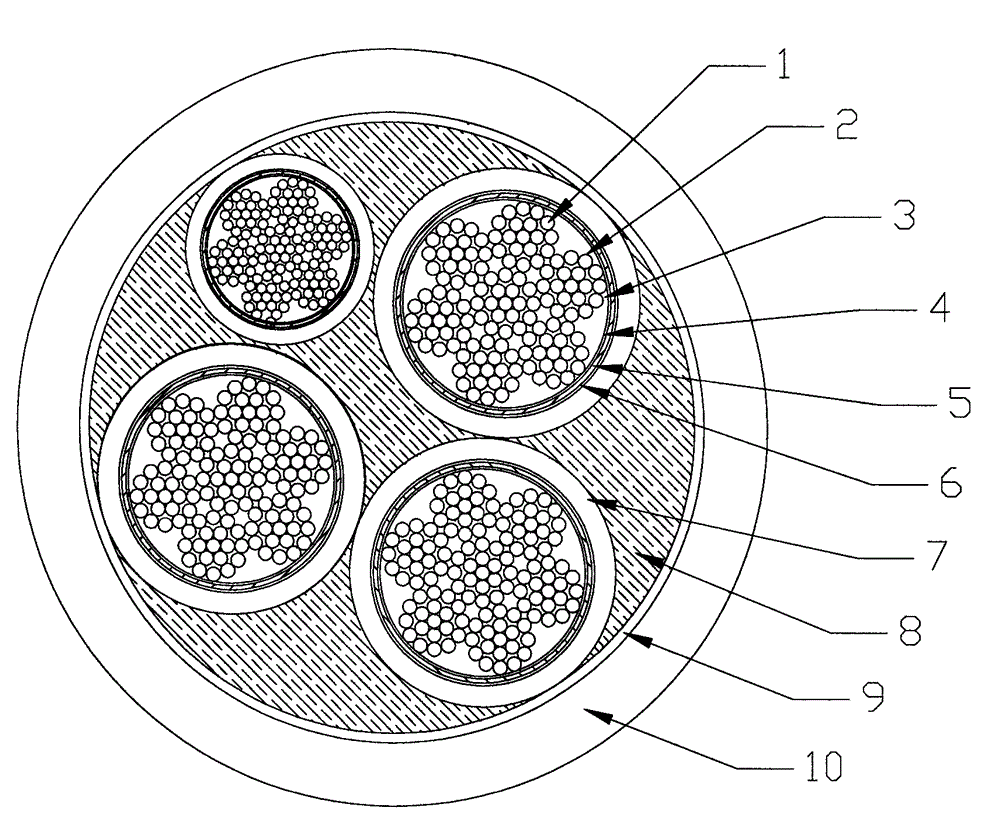

[0020] figure 1 Shown is an embodiment of the present invention, in order to achieve the purpose of high flexibility, the solution that the present invention adopts is: a kind of novel highly flexible fireproof cable, it comprises: flexible or soft structure conductor 3, soft structure protective layer 4, fire-resistant Isolation belt 5, high temperature isolation belt 6, thermosetting low-smoke halogen-free polyolefin or elastomer insulation layer 7, flexible mineral paper rope 8, high-temperature isolation belt 9, low-smoke halogen-free polyolefin or elastomer sheath 10, all There is a soft structure protection layer 4 outside the flexible or soft structure conductor 3, a fire-resistant isolation belt 5 is arranged outside the soft structure protection layer 4, a high-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com