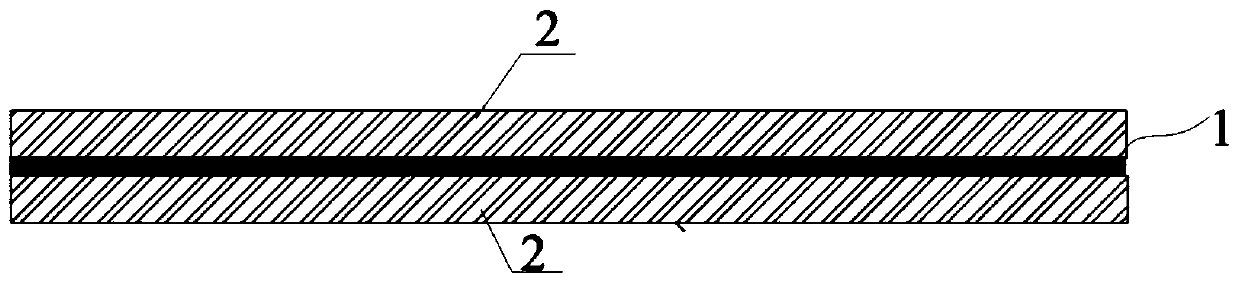

Composite isolating membrane of lithium ion battery and preparation method and application of composite isolating membrane

A technology for lithium-ion batteries and separators, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as inability to ensure the tight fit of composite separator layers, loss of battery capacity, and poor stability of the separator, and achieve Sufficient storage and infiltration, improved cycle life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

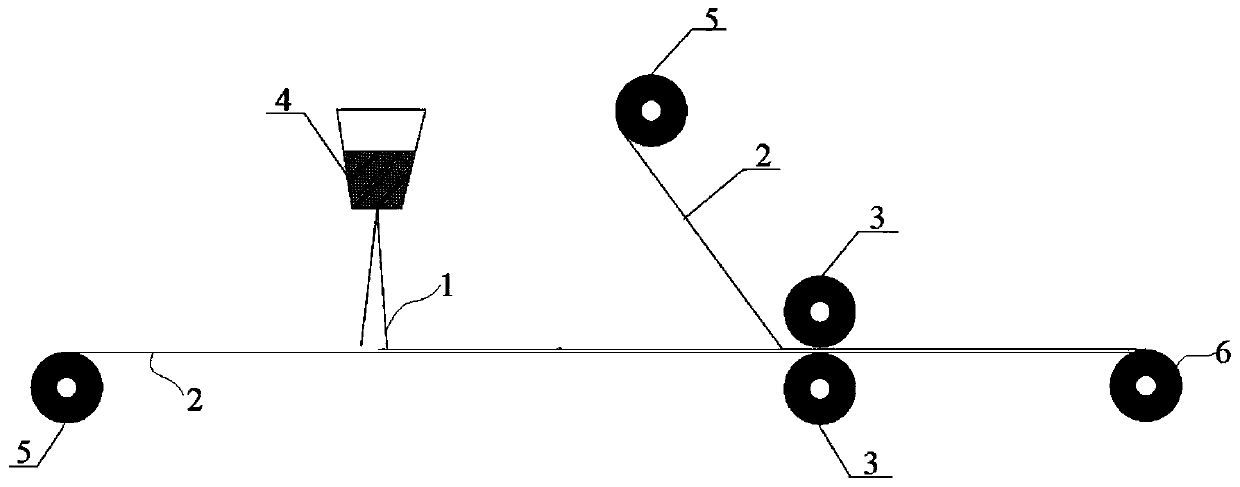

[0050]The invention discloses a preparation method of a lithium-ion battery composite separator, which comprises the following steps:

[0051] 1) Preparation of silicon dioxide modified with double bonds on the surface: take silicon dioxide particles with a particle size of 20-500 nm and a silane coupling agent containing double bonds and place them in ethanol, propanol, propylene glycol, deionized water or toluene, Under the action of a catalyst, reflux at 120°C, and undergo hydrolysis and condensation reactions to prepare silica with double bond modification on the surface;

[0052] 2) Preparation of organic / inorganic hybrid polymer: take the silicon dioxide with double bond modification on the surface prepared in step 1) and put it in a reaction vessel, add solvent cyclohexanone, toluene or N,N-dimethylformaldehyde in sequence Amides, organic functional monomers, and initiators are stirred by magnetic force and reacted in a silicone oil bath at 90°C for 12 to 48 hours. Afte...

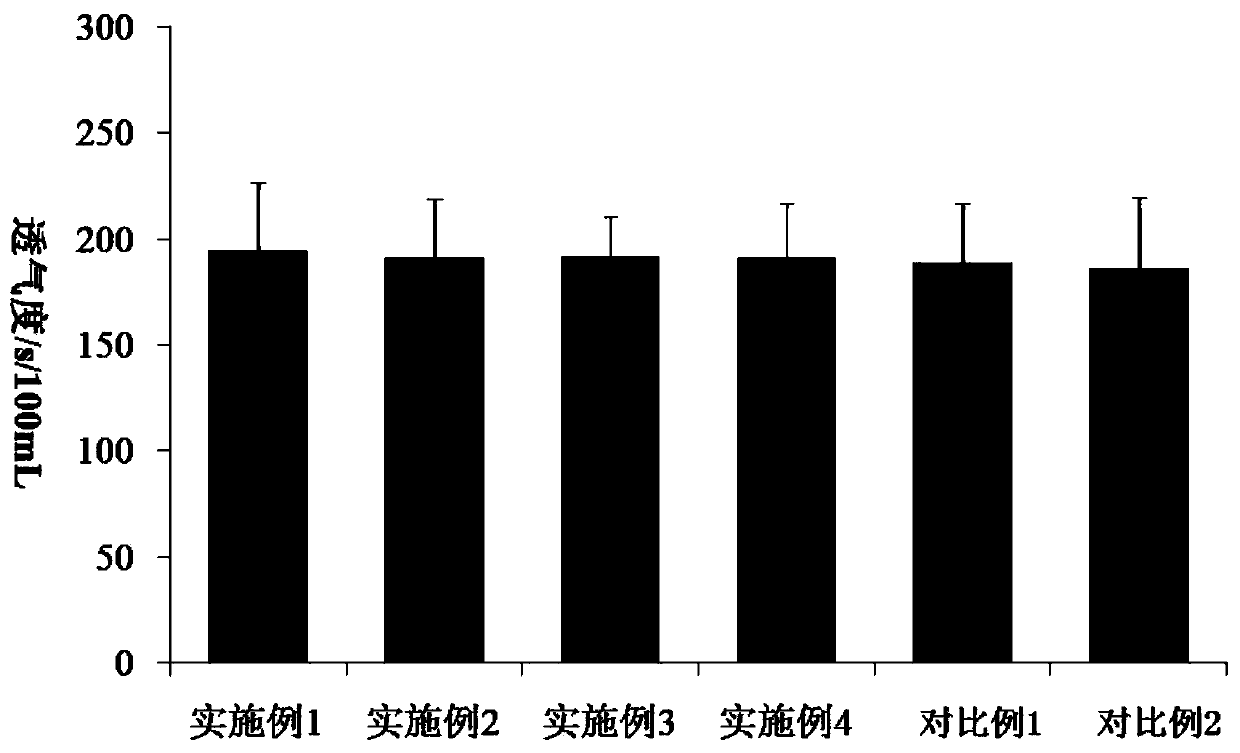

Embodiment 1

[0056] This embodiment discloses a kind of preparation method of lithium-ion battery composite separator, and it comprises the steps:

[0057] 1) Preparation of silica with double bond modification on the surface: take silica particles with a particle size of 200nm and silane coupling agent vinyltrimethoxysilane in toluene, under the catalysis of dilute hydrochloric acid, control the reaction temperature at 120°C Reflux for 12 hours, and undergo a hydrolysis and condensation reaction to obtain silicon dioxide modified with double bonds on the surface;

[0058] 2) Preparation of organic / inorganic hybrid polymer: take the silicon dioxide with double bond modification on the surface prepared in step 1) and put it in a reaction vessel, add solvent cyclohexanone, methyl methacrylate, butyl methacrylate in sequence Esters, using azobisisobutyronitrile as an initiator, reacted in a silicone oil bath at a controlled reaction temperature of 120°C for 12 hours, and then underwent precip...

Embodiment 2

[0062] This embodiment discloses a kind of preparation method of lithium-ion battery composite separator, and it comprises the steps:

[0063] 1) Preparation of silica with double bond modification on the surface: take silica particles with a particle size of 150nm and silane coupling agent vinyltrimethoxysilane in toluene, under the catalysis of dilute hydrochloric acid, control the reaction temperature at 120°C Reflux for 12 hours, and undergo a hydrolysis and condensation reaction to obtain silicon dioxide modified with double bonds on the surface;

[0064] 2) Preparation of organic / inorganic hybrid polymer: take the silicon dioxide with double bond modification on the surface prepared in step 1) and place it in a reaction vessel, and add solvent cyclohexanone, methyl methacrylate, and methacrylate in sequence , using azobisisobutyronitrile as an initiator, reacting in a silicone oil bath at a controlled reaction temperature of 120°C for 24 hours, and then undergoing precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com