Production method of thick and large titanium alloy fired mold precision casting

A technology of precision castings and production methods, applied in the direction of molds, cores, mold components, etc., can solve the problems of low quality investment castings, achieve the effects of shortening the production cycle, improving surface quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

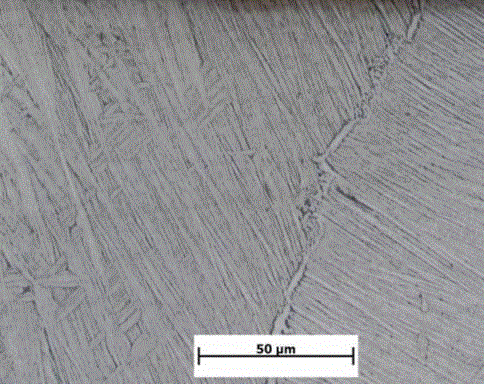

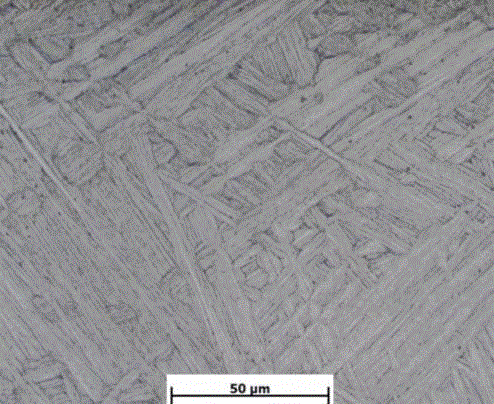

Image

Examples

Embodiment 1

[0055] Example 1: Test object primary pump casing casting

[0056] The first step, wax mold preparation: use the wax injection machine to prepare the wax mold required for production;

[0057] Continuing from the previous step, the second step is wax mold cleaning: use acidic wax mold cleaning solution to clean the wax mold to remove surface oil and debris;

[0058] Continuing from the previous step, the third step is the preparation of the surface layer of the mold shell: the ratio of the surface layer slurry: the mass ratio of 325 mesh yttrium oxide powder to silica sol is 5:1, stir at room temperature 200r / min for 30min, let stand for 50-70min, and wax the mold Stain the wax model with 60-120 mesh yttrium oxide sand after dipping in the slurry, and dry it in a constant temperature and humidity workshop for 24 hours; the temperature in the constant temperature and humidity workshop is 23°C and the humidity is 25%;

[0059] Continuing from the previous step, the fourth step ...

Embodiment 2

[0081] Embodiment 2: The test object is the casting of the mounting bracket

[0082] The first step, wax mold preparation: use the wax injection machine to prepare the wax mold required for production;

[0083] Continuing from the previous step, the second step is wax mold cleaning: use acidic wax mold cleaning solution to clean the wax mold to remove surface oil and debris;

[0084]Continuing from the previous step, the third step is the preparation of the surface layer of the mold shell: the ratio of the surface layer slurry: the ratio of 325 mesh yttrium oxide powder to silica sol is 5:1, stir at room temperature 200r / min for 30 minutes, let stand for 50-70min, and wax the mold Stain the wax model with 60-120 mesh yttrium sand after dipping in the slurry, and dry it in a constant temperature and humidity workshop for 24 hours; the temperature in the constant temperature and humidity workshop is 25°C and the humidity is 40%;

[0085] Continuing from the previous step, the f...

Embodiment 3

[0106] Embodiment 3: The test object is a bracket and a fixed plate

[0107] The first step, wax mold preparation: use the wax injection machine to prepare the wax mold required for production;

[0108] Continuing from the previous step, the second step is wax mold cleaning: use acidic wax mold cleaning solution to clean the wax mold to remove surface oil and debris;

[0109] Continuing from the previous step, the third step is the preparation of the surface layer of the mold shell: the ratio of the surface layer slurry: the ratio of silica sol to 325 mesh yttrium oxide powder is 1:5, stir at room temperature 200r / min for 30 minutes, let stand for 50-70min, and wax the mold Stain the wax model with 60-120 mesh yttrium sand after dipping in the slurry, and dry it in a constant temperature and humidity workshop for 24 hours; the temperature in the constant temperature and humidity workshop is 21°C and the humidity is 35%;

[0110] Continuing from the previous step, the fourth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com