Steel ladle circumferential weld type ventilating water feeding opening seat block and argon blowing metallurgy method thereof

A technology for nozzle block and ladle, which is applied to metal processing equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of large amount of molten steel pouring, purifying molten steel without removing inclusions, and large amount of pouring water. To achieve the effect of reducing the amount of molten steel pouring, promoting floating and removal, and inhibiting the problem of nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

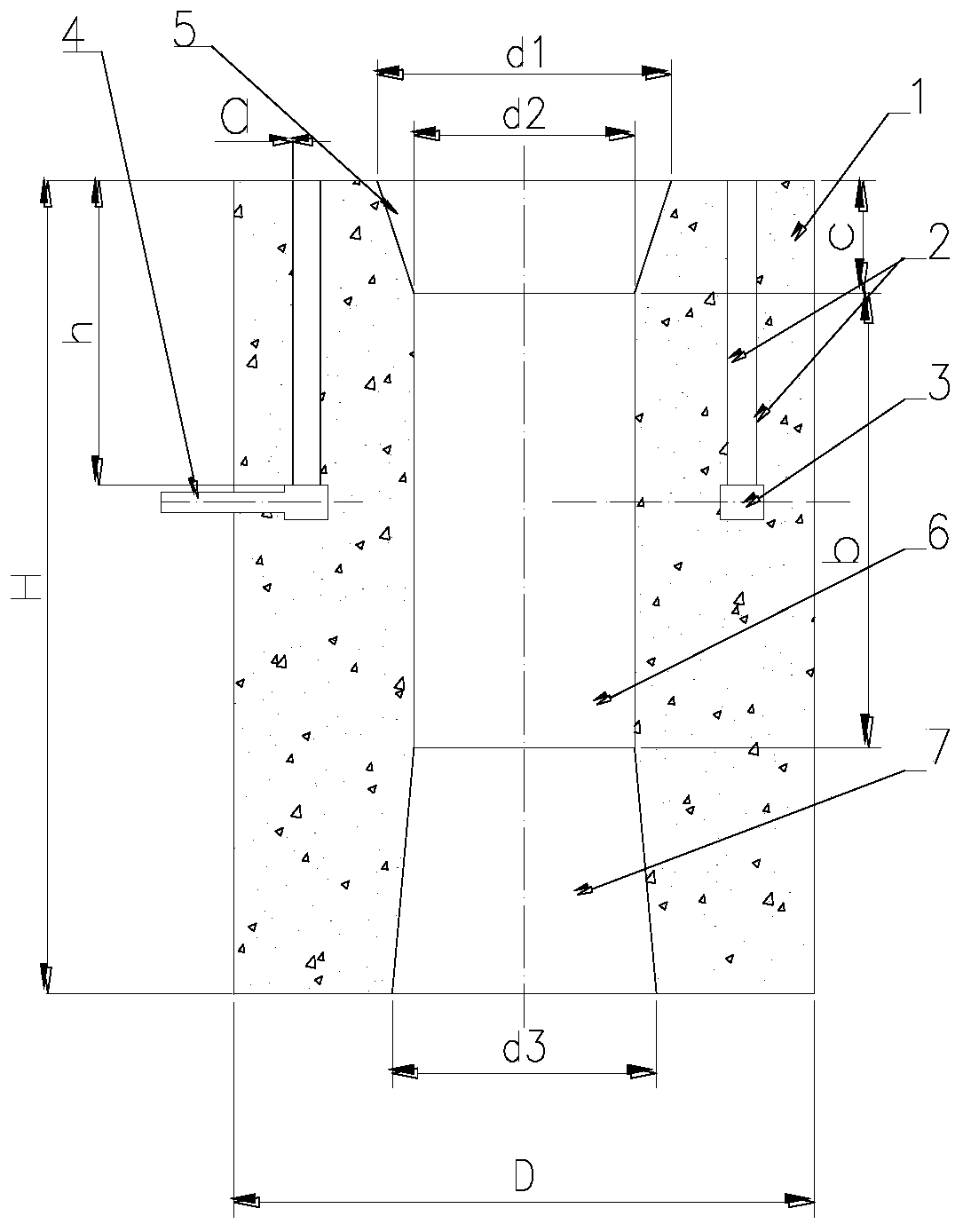

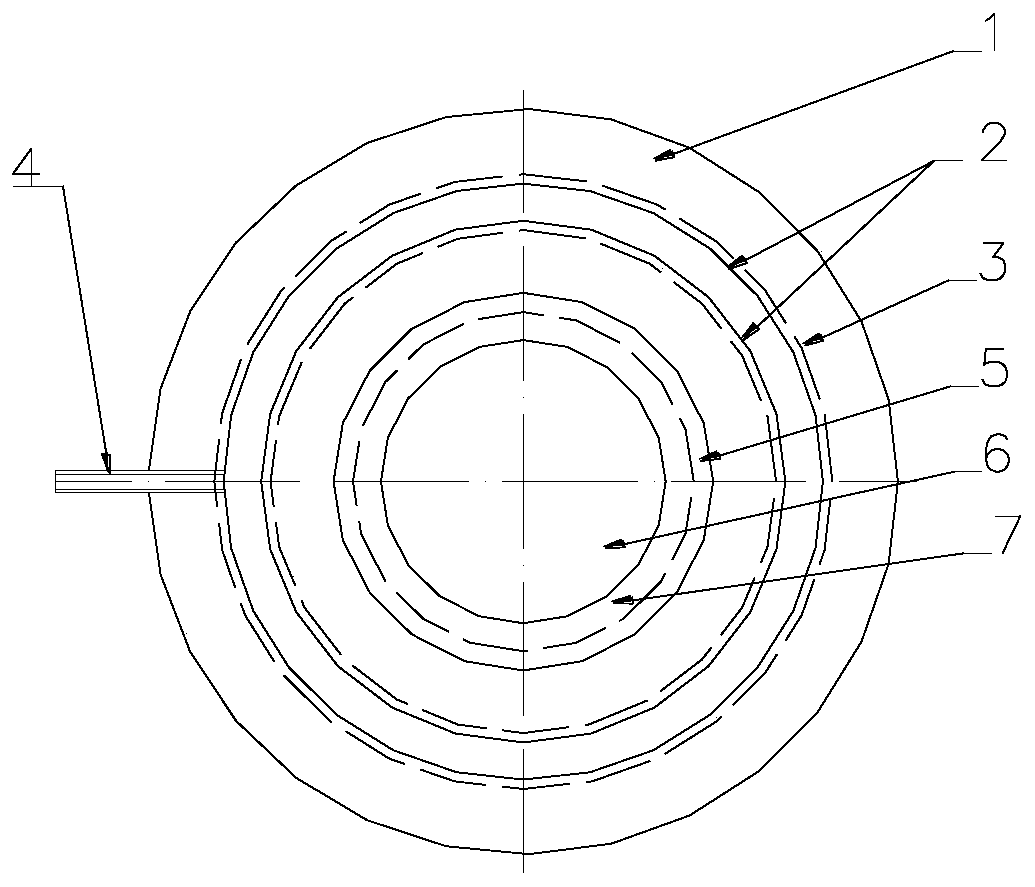

[0039] A ladle ring seam type breathable upper nozzle seat brick, such as Figure 1-Figure 3 As shown, it includes the ladle upper nozzle block body 1, the ring seam 2, the air chamber box 3, and the air intake pipe 4. The middle part of the ladle upper nozzle block body 1 is provided with a flow steel hole 5, a connecting hole 6, and an upper nozzle. Mounting hole 7, the upper surface of the upper nozzle block body 1 of the ladle is provided with a number of annular rings 2 from the upper surface of the upper nozzle block body to the inside of the nozzle block body, and the upper mouth of the ring seam is perpendicular to the upper surface of the nozzle block body. On the surface, the lower opening of the annular seam communicates with the annular air chamber box 3 provided at the bottom of the annular seam, and the side of the air chamber box is connected with an air inlet pipe 4, one end of the air inlet pipe communicates with the air chamber box, and the other end connects ...

Embodiment 2

[0060] As described in Example 1, the difference between the ladle annular seam type breathable upper nozzle seat brick is that:

[0061] The number of the annular seams 2 is 2, the annular seam width a is 1.7 mm, and the annular seam height h is 120 mm.

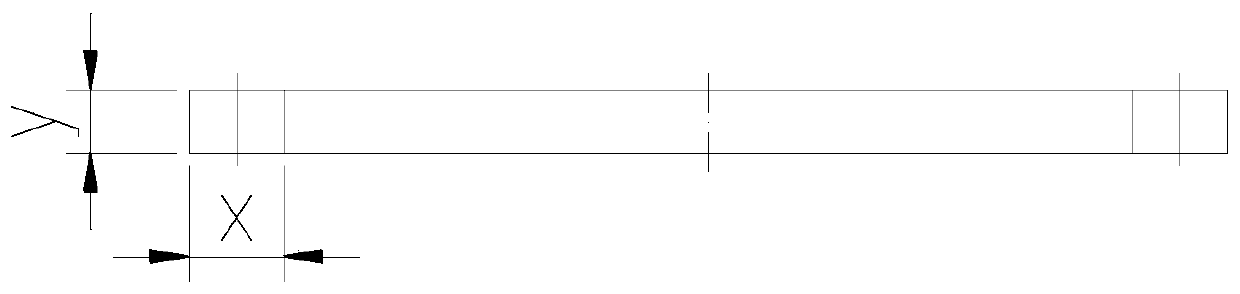

[0062] The air chamber box 3 is in the shape of a ring as a whole, the longitudinal section of the air chamber box is rectangular, the width x of the rectangle is 30mm, and the height y is 20mm.

[0063] Described flow steel hole 5 is circular truncated, and the upper port diameter d1 of circular truncated is 190mm, and the lower port diameter d2 is 140mm, and the height c of circular truncated is 55mm, and described connection hole is cylindrical channel, and the diameter of cylindrical channel and circular truncated The diameter of the lower port is the same, and the cylinder height b is 253mm.

[0064] The upper part of the upper nozzle installation hole 7 is circular truncated, the upper port diameter of the circular pl...

Embodiment 3

[0072] As described in Example 1, the difference between the ladle annular seam type breathable upper nozzle seat brick is that:

[0073] like Figure 7 As shown, the number of the annular seam 2 is 3 rings, the annular seam width a is 1.3mm, and the annular seam height h is 220m.

[0074] The air chamber box 3 is in the shape of a ring as a whole, the longitudinal section of the air chamber box is rectangular, the width x of the rectangle is 50 mm, and the height y is 40 mm.

[0075] Described flow steel hole 5 is circular frustum shape, and the upper port diameter d1 of circular frustum is 210mm, and lower port diameter d2 is 160mm, and the height c of circular frustum is 80mm, and described connection hole 6 is cylindrical channel, and the diameter of cylindrical channel and The diameter of the lower port of the round platform is the same, and the height b of the cylinder is 268mm.

[0076] The upper part of the upper nozzle installation hole 7 is circular truncated, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com