Method for controlling converter tapping roughing slag through annular converter tapping hole gas blowing

A technology of gas blowing control and tapping hole, which is applied in the field of ring converter tapping hole gas blowing control converter tapping slag, which can solve the problems of difficult on-site operation, large space occupation, instability, etc., and improve the quality of molten steel and yield, improve the yield of molten steel, and the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

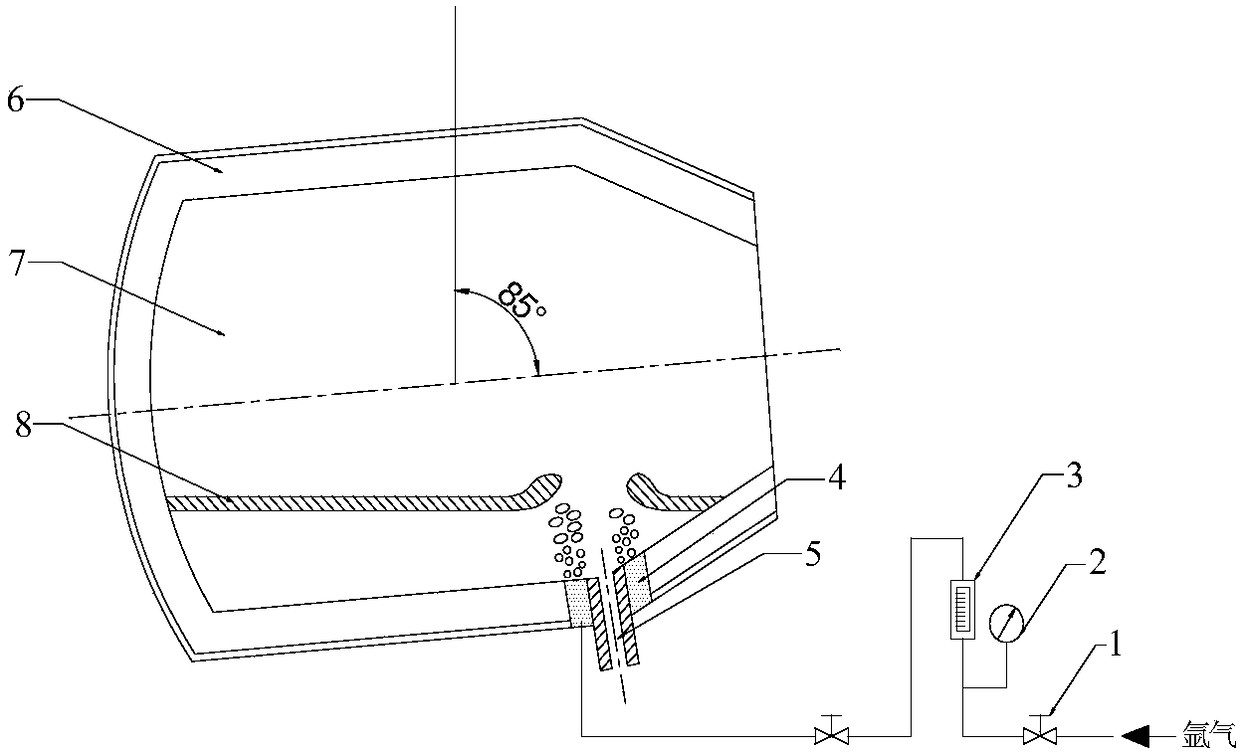

[0024] The converter used in this embodiment is 60 tons.

[0025] The method for controlling the slag in the tapping process of the ring converter by blowing air at the tap hole of the ring converter of the present invention is as follows:

[0026] Step 1: Arrange ring-shaped breathable bricks 4 around the converter tapping hole 5, and the bottom of the ring-shaped breathable bricks 4 is connected to a blowing device; wherein, the gas fed into the blowing device is inert gas or nitrogen; the ring-shaped breathable bricks 4 are set on the converter tapping Around the mouth 5, the upper end surface of the annular air-permeable brick 4 is circular, the width of the annular air-permeable brick 4 is 100mm, and the height of the annular air-permeable brick 4 is the same as the width of the lining of the converter 6;

[0027] Step 2: At the end of the converter tapping process, when the tilting angle of the converter 6 is 85 degrees, the gas is introduced into the molten steel 7 in t...

Embodiment 2

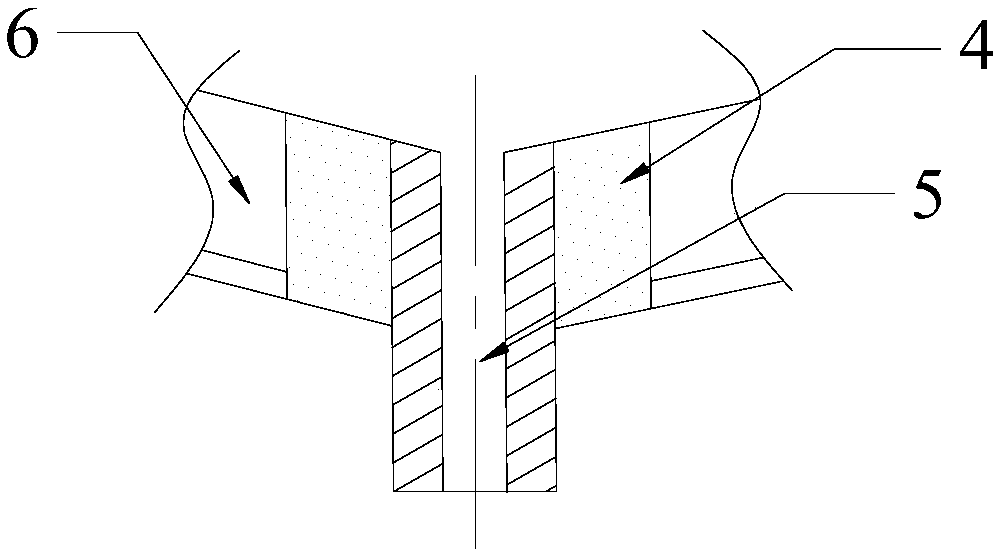

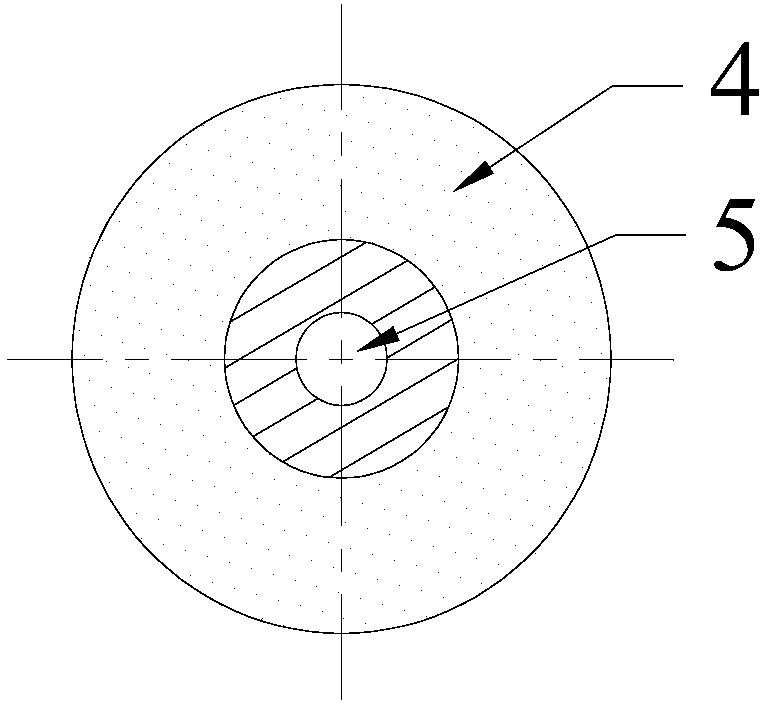

[0031] The converter used in this embodiment is 120 tons. The device process schematic diagram of this embodiment is as figure 2 As mentioned above, the A-A cross-sectional view of its tapping hole and annular breathable brick is shown in 3, and the top view of its tapping hole and annular breathable brick is shown in image 3 shown.

[0032] The method for controlling the slag in the tapping process of the ring converter by blowing air at the tap hole of the ring converter of the present invention is as follows:

[0033] Step 1: Arrange ring-shaped breathable bricks 4 around the converter tapping hole 5, and the bottom of the ring-shaped breathable bricks 4 is connected to a blowing device; wherein, the gas fed into the blowing device is inert gas or nitrogen; the ring-shaped breathable bricks 4 are set on the converter tapping Around the mouth 5, the upper end surface of the annular air brick 4 is circular, the width of the annular air brick 4 is 350mm, and the height of ...

Embodiment 3

[0038] The converter used in this embodiment is 180 tons.

[0039] The method for controlling the slag in the tapping process of the ring converter by blowing air at the tap hole of the ring converter of the present invention is as follows:

[0040] Step 1: Arrange ring-shaped breathable bricks 4 around the converter tapping hole 5, and the bottom of the ring-shaped breathable bricks 4 is connected to a blowing device; wherein, the gas fed into the blowing device is inert gas or nitrogen; the ring-shaped breathable bricks 4 are set on the converter tapping Around the mouth 5, the upper end surface of the annular air-permeable brick 4 is circular, the width of the annular air-permeable brick 4 is 600mm, and the height of the annular air-permeable brick 4 is the same as the width of the lining of the converter 6;

[0041] Step 2: At the end of the converter tapping, when the tilting angle of the converter 6 is 90 degrees, gas is introduced into the molten steel 7 in the converte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com