Method for making fruit juice with pulp by using juicer

A juicer and pulp technology, applied in the field of food processing machines, can solve the problems of unsatisfactory juice yield, single fruit juice taste, adaptability adjustment, etc., so as to improve the juicing efficiency and juice yield, the variety of taste, and the rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

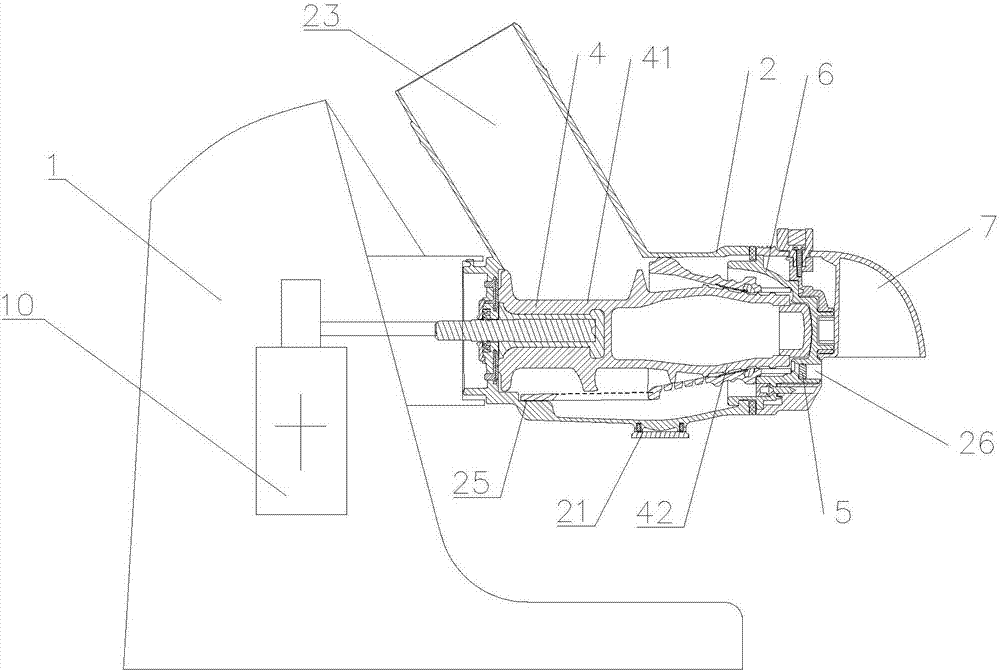

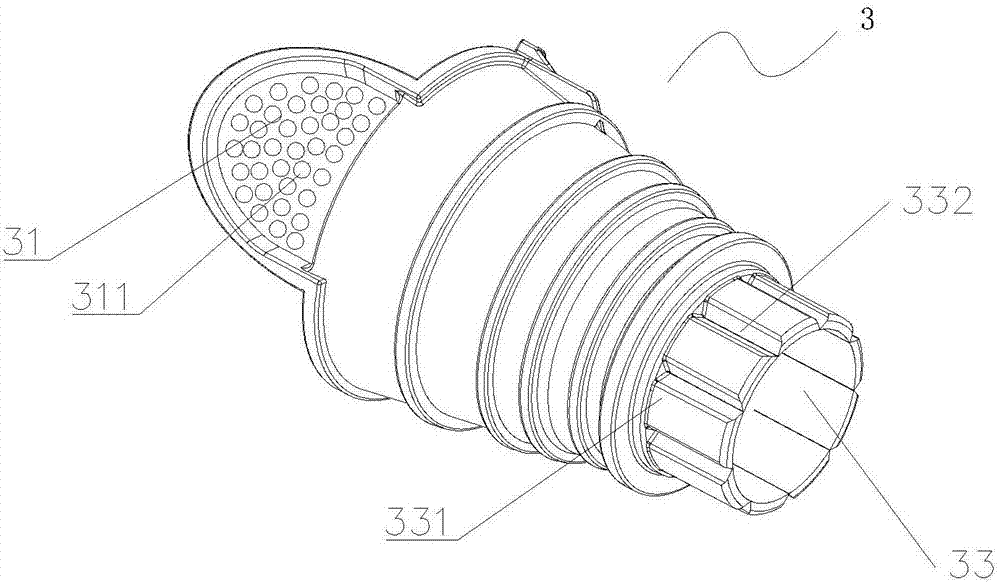

[0048] Such as Figure 1 to Figure 9 As shown, the present invention provides a juice extractor for making pulp-containing juice, and a method for making pulp-containing juice with the juice extractor, the juice extractor includes a machine base 1 connected to the machine base The juice collecting chamber 2, the screw 4 and the extruding barrel 3 arranged horizontally in the juice collecting chamber, the motor 10 is arranged in the base, the screw includes a screw shaft and a screw body from the inside to the outside, the screw shaft and the output of the motor The shafts are mechanically connected. The screw includes a material conveying section 41 and an extrusion grinding section 42 from the front end to the rear end. The extrusion barrel 3 is sleeved outside the extrusion grinding section of the screw 4, and cooperates with the screw to crush the material. Grind and squeeze out the juice. The juice collecting chamber 2 is provided with a juice outlet 21 and a slag outlet 2...

Embodiment 2

[0067] Such as Figure 7 to Figure 9 As shown, the difference between this embodiment and the first embodiment lies in that the structure of the extrusion barrel 3 is different, and correspondingly, the method of making fruit juice containing pulp is also different. In this embodiment, the middle part of the extruding cylinder is further provided with an intermediate filter part 32, and the pre-filter part 31 and the intermediate filter part 32 are respectively provided with a pre-filter hole 311 and an intermediate filter hole 321, and the intermediate filter part The aperture of the hole 321 is not larger than the aperture of the pre-filter hole 311, the aperture of the pre-filter hole 311 is 1.0mm~1.5mm, the aperture of the middle filter hole 321 is 0.8mm~1.2mm, the filter gap between the bars It is 0.15mm~0.3mm. In this embodiment, the aperture of the pre-filtering hole is 1.2mm. When passing through the pre-filtering part, the material has not been crushed and ground by t...

Embodiment 3

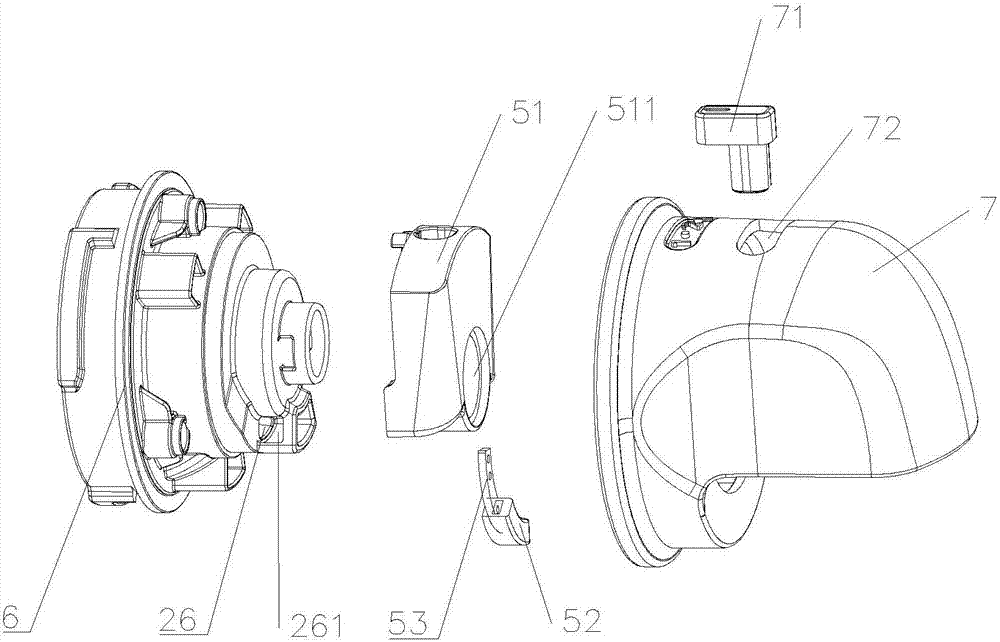

[0074] The difference between this embodiment and Embodiment 2 is that different slag discharge adjustment gears correspond to different juice extraction procedures, different slag discharge adjustment gears are provided on the end cover, and each gear corresponds to a different effective slag discharge area, when the slag discharge adjustment device of the juice extractor is adjusted to a corresponding gear, the control board in the frame controls the juice extractor to output a corresponding juice extraction program. Specifically, the end cover is provided with pulp juice stalls, mixed juice stalls, and pure fresh juice stalls. When the slag discharge adjustment device is adjusted to the pulp juice stalls, the output speed of the motor is 65 rpm—corresponding to the pulp juice squeeze program. 85rpm, the slag discharge adjustment device will fully open the slag outlet or open most of the slag outlet, a large amount of pulp will flow out of the juice outlet with the juice, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com