Ultra-high pressure water jet slotting system and using method thereof

A water jet and ultra-high pressure technology, applied in drilling equipment and methods, mining fluids, earthwork drilling and mining, etc., can solve problems such as low slotting pressure, limited depth of hard coal rock slots, and unsmooth slag discharge, etc., to achieve Effects of increased fluidity, wide application range, and remarkable application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

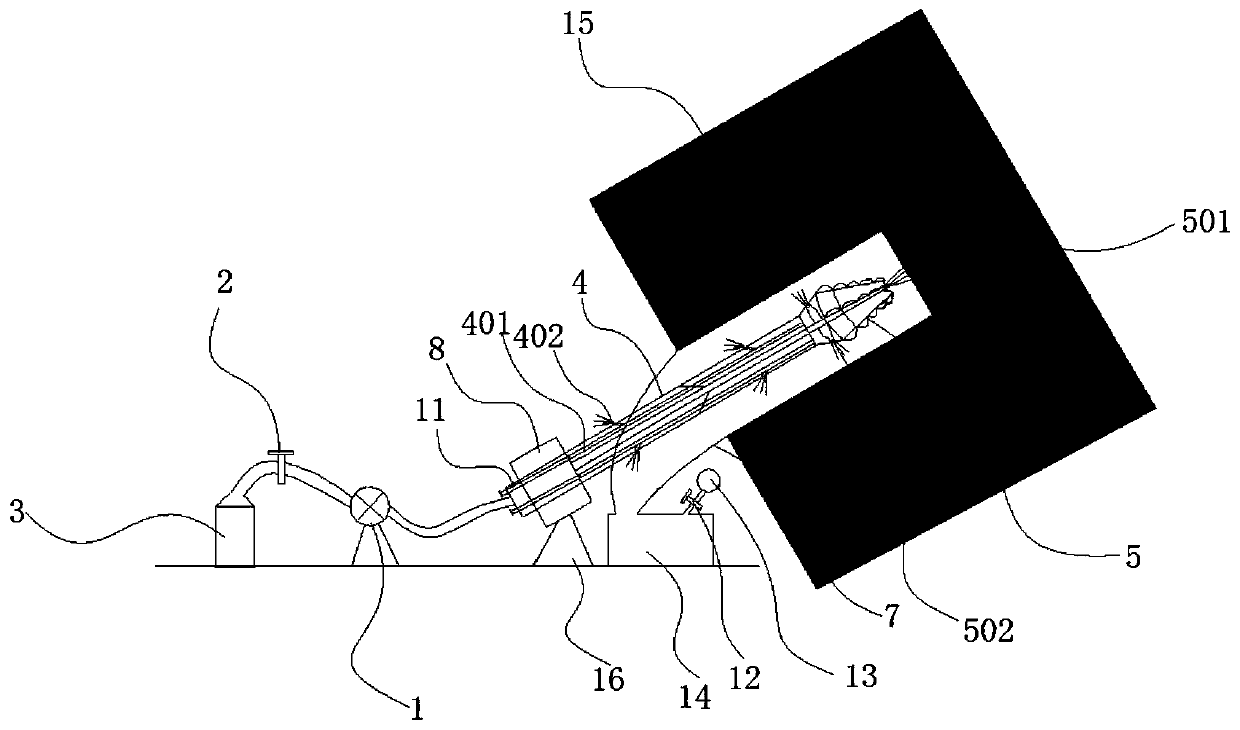

[0045] see figure 1, this embodiment discloses an ultra-high pressure water jet slotting system, including an ultra-high pressure water jet generation system, a drill pipe drilling system, an orifice sealer 7 , an air slag separator 14 and a drilling rig 16 .

[0046] The ultrahigh pressure water jet generation system includes an ultrahigh pressure water pump 1 and a nanofluid storage tank 3. A control valve I2 is provided on the high-pressure pipeline between the ultra-high pressure water pump 1 and the nanofluid storage tank 3 . The nanofluid is a two-phase suspension formed by dispersing nanoparticles into water. The mass fraction of nanoparticles is 0.1-1%. The particle diameter of the nanoparticles is 20-80 nm. Nanofluid wettability improves fluidity of coal cuttings.

[0047] The drill pipe drilling system includes a drill pipe 4 , a drill bit 5 and a water braid 8 . The drill rod 4 is a hollow tube as a whole. Two channels I401 are symmetrically arranged on the pi...

Embodiment 2

[0052] This embodiment discloses a method for using the system described in Embodiment 1 for drilling through layers, using a rotary slotting method, including the following steps:

[0053] 1) According to the drilling design requirements for interlayer gas drainage, determine the drilling location and drilling parameters.

[0054] 2) Open control valve I2, control valve II12 and drilling rig 16. The drill pipe 4 drives the drill bit 5 to drill 1-1.5m into the coal rock layer 15 along the designed drilling angle.

[0055] 3) Turn on the water jet generating equipment and raise the water pressure to 40-50 MPa. After 2 minutes, drilling is carried out to make full use of the water hammer pressure to break the coal body. The radial nozzle 501 forms a high-pressure water jet to impact the coal and rock mass in front to form a cylindrical weak surface. The axial nozzle 502 forms a high-pressure water jet to impact the surrounding coal and rock mass, expanding the diameter of the...

Embodiment 3

[0061] This embodiment discloses a method for using the system described in Embodiment 1 for layer-by-layer drilling, which adopts the method of rotary slotting and flat pulling slotting, including the following steps:

[0062] 1) According to the drilling design requirements for bedding gas drainage, determine the drilling location and drilling parameters.

[0063] 2) Open control valve I2, control valve II12 and drilling rig 16. The drill rod 4 drives the drill bit 5 to drill a certain distance in the coal seam along the designed drilling angle.

[0064] 3) Turn on the water jet generating equipment and raise the water pressure to 40-50 MPa. After 2min, implement drilling. Under the combination of the grinding and drilling of the drill bit 5 and the rotary cutting of the water jet containing nanoparticles, the drill rod 4 drives the drill bit 5 to drill and ream the hole. The nanoparticles adhere to the surface of the coal chips formed by the impact of the high-pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com