Low-temperature chlorination furnace

A chlorination furnace, low-temperature technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of easy crusting and blockage at the outlet of the slag discharge pipeline, large fluctuations in instantaneous slag discharge volume, slag discharge blockage, etc., to avoid Product gas loss, convenient and smooth slag discharge, reliable closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

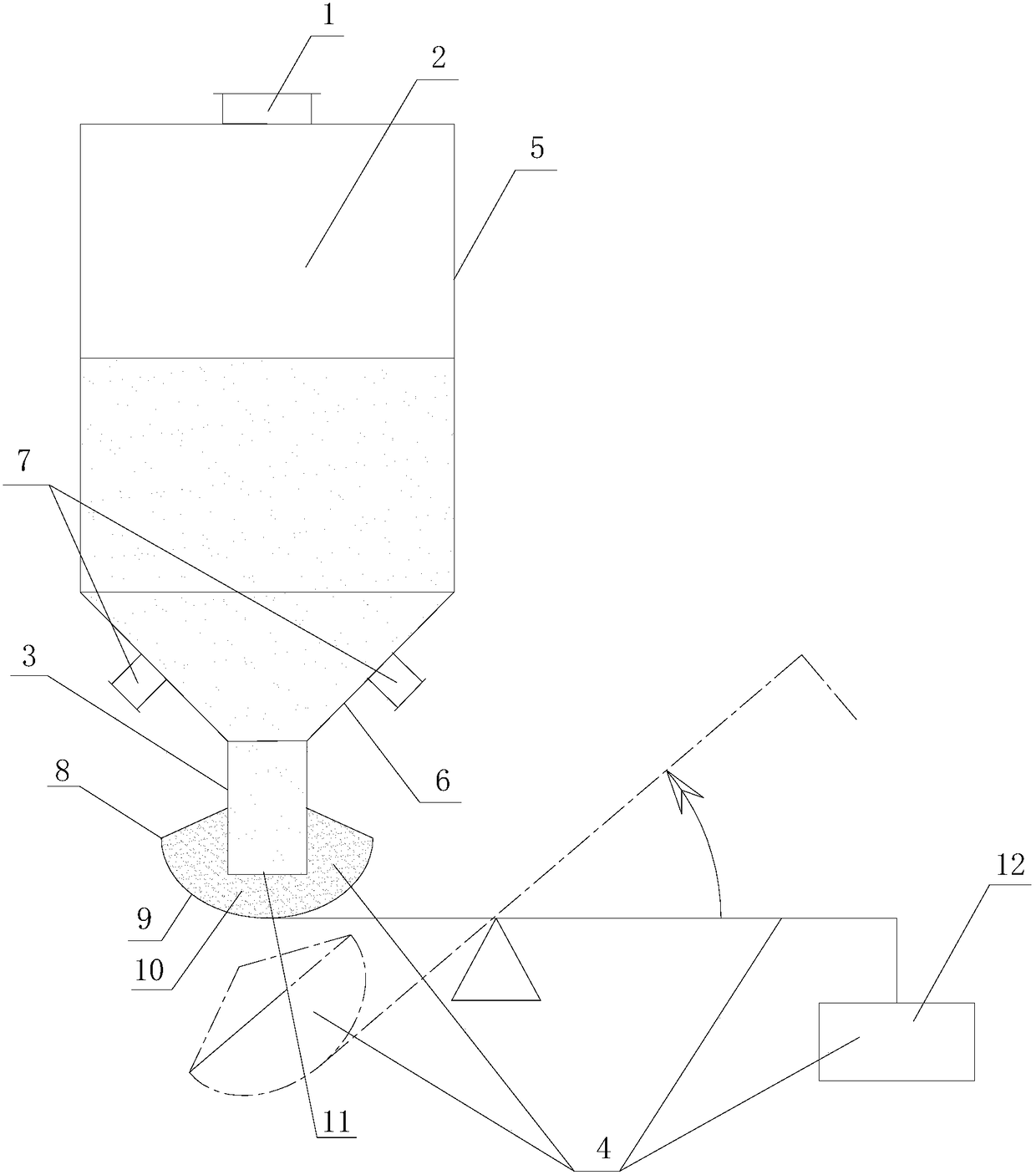

[0026] Such as figure 1 Shown is a low-temperature chlorination furnace provided by the present application, including a low-temperature chlorination furnace body and a lever slagging device. The top of the low-temperature chlorination furnace body has a flue gas outlet, and the bottom is provided with a chlorine gas inlet and a slagging pipe ; The lever slagging device is composed of a lever, a counterweight, a fulcrum and a wide-mouth plugging scoop, and refractory mud is arranged in the wide-mouth plugging scoop; the slag discharge pipeline is arranged at the center of the bed bottom; the thickness of the refractory plugging mud is 15 ~80cm; the diameter of the wide-mouth end of the wide-mouth plugging scoop is 1.5-10 times the outer diameter of the slag discharge pipe; the refractory mud accumulates in the wide-mouth plugging scoop to form a cone, and the cone angle is between 60 and 150°: Chlorine When the furnace is running normally without slag discharge, the slag disch...

Embodiment 2

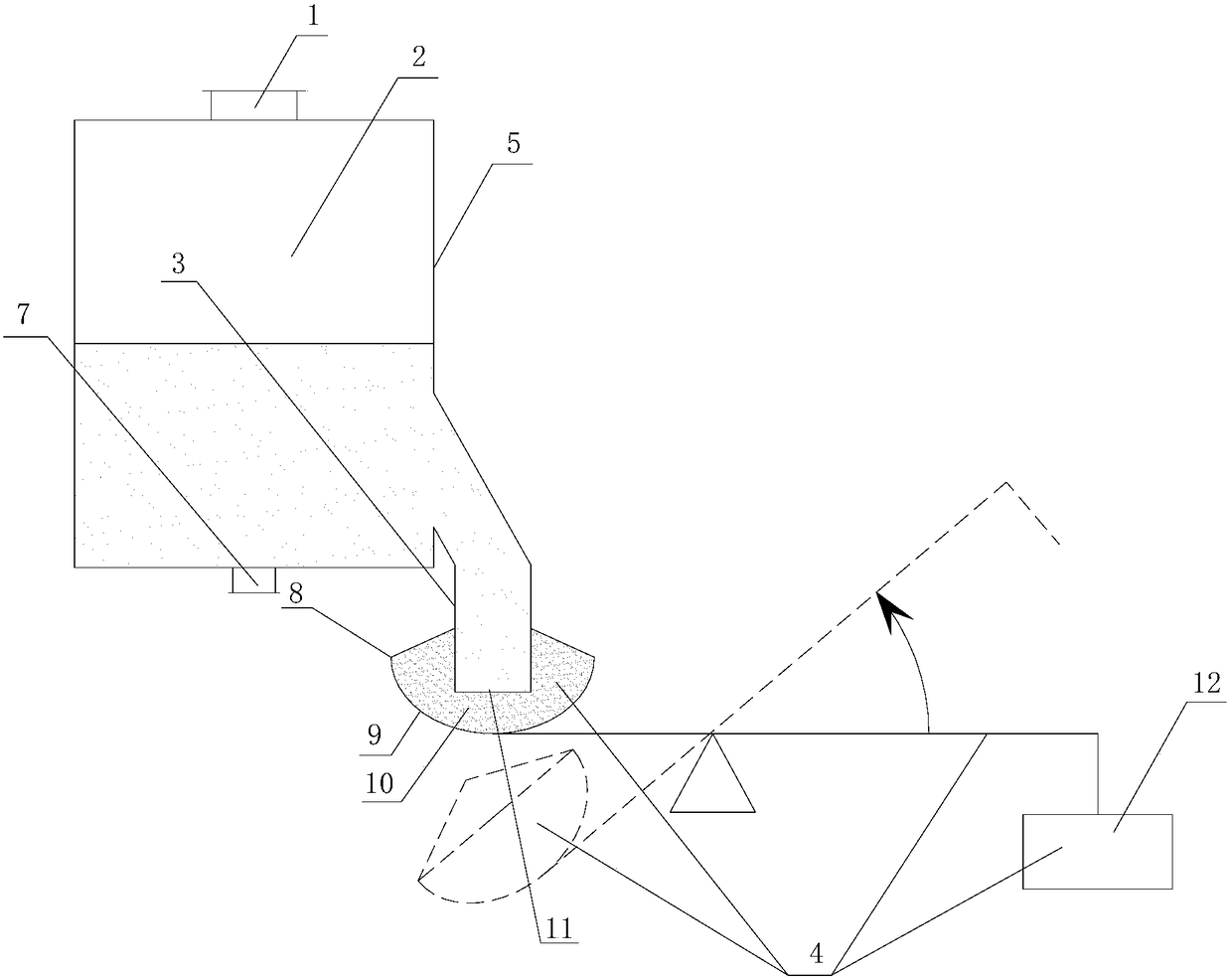

[0037] Such as figure 2Shown is another low-temperature chlorination furnace provided by the present application, which includes a low-temperature chlorination furnace body and a lever slagging device. The top of the low-temperature chlorination furnace body has a flue gas outlet, and the bottom is provided with a chlorine gas inlet and slag removal device. pipe; the lever slag discharge device is composed of a lever, a counterweight, a fulcrum and a wide-mouth plugging scoop, and refractory mud is arranged in the wide-mouth plugging scoop; the slag discharge pipeline is arranged on the bottom wall or middle wall of the bed; the refractory plug The thickness of the mud is 15-80cm; the diameter of the wide-mouth end of the wide-mouth plugging scoop is 1.5-10 times the outer diameter of the slag discharge pipe; the refractory mud accumulates in the wide-mouth plugging scoop to form a cone, and the cone angle is 60-150° Between; when the chlorination furnace is in normal operati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com