Outburst coal seam circumferential flow supply hole protection and pressure relief sieve pore drill rod

A technology for protruding coal seam and drill pipe, applied in the direction of drill pipe, drill pipe, production fluid, etc., can solve the problem of not being able to lower the hole-protecting screen pipe and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

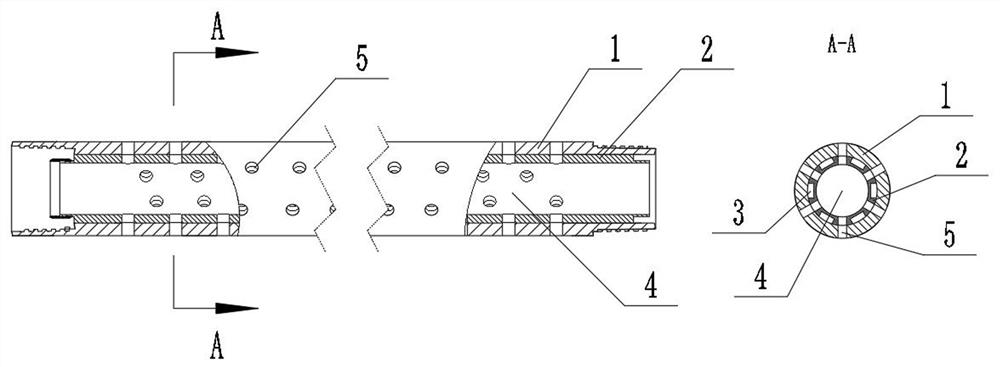

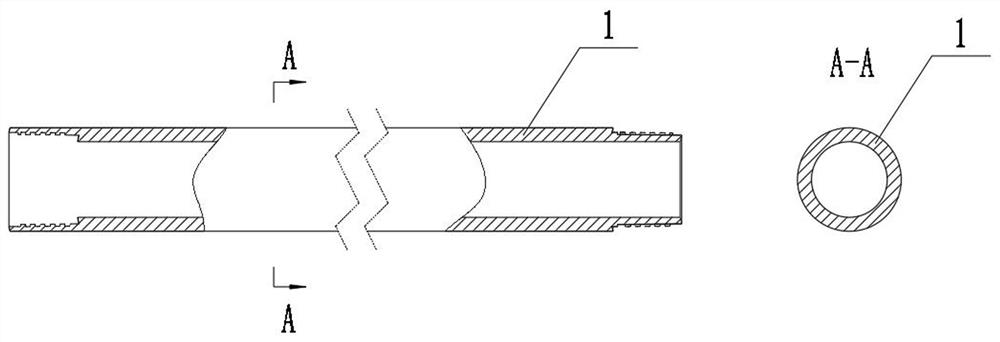

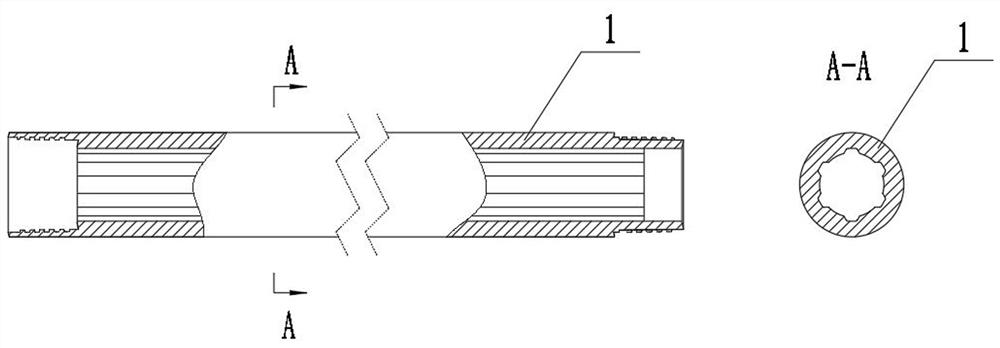

[0056] Such as figure 1 As shown in the figure, a drilling rod for supplying and protecting holes and pressure-relieving screen holes around a protruding coal seam includes a drill rod body, and a plurality of supply and circulation channels for drilling to provide air flow or water flow are arranged in parallel to the axial direction in the circumferential section of the drill rod body. Road 3, the center of the drill pipe body is provided with an inner slag discharge channel 4 with a circular diameter for drilling to provide slag discharge, and the outer surface of the drill pipe body is provided with a slag discharge screen 5 along the radial direction and avoiding the flow channel , The slag discharge screen hole 5 communicates with the inner slag discharge channel 4 .

[0057] The drill pipe body includes an outer tube 1 and an inner tube 2 installed coaxially. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com