Method for treating complex low-grade lead-antimony material by matching dual bottom-blowing furnaces

A low-grade and complex technology, applied in the direction of improving process efficiency, etc., can solve problems such as unclear control conditions of process technology, difficulty in discharging lead from siphon port of reduction furnace, and reduction of slagging times in reduction furnace, so as to increase comprehensive recovery profit, The effect of simple production operation process and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

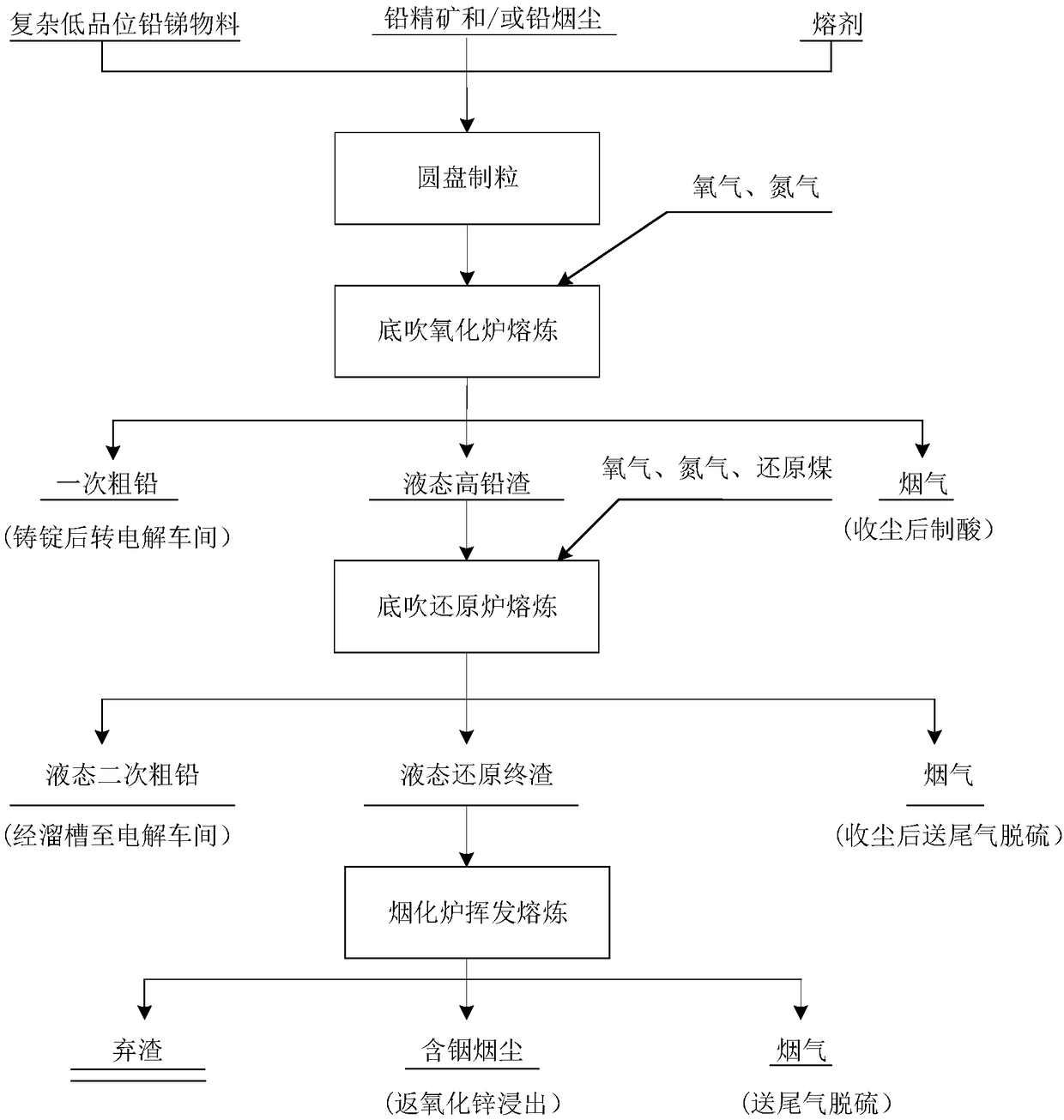

[0019] like figure 1 As shown, a method for processing complex and low-grade lead and antimony materials by using a "double bottom blowing furnace", comprising the following steps:

[0020] The lead concentrate is treated and mixed with zinc leaching slag from hydrometallurgy, silver flotation silver-rich wet mud, lead-antimony ore, lead fume and limestone. Fraction 1.5%; Fe and SiO 2 The mass ratio is 1.3:1; CaO and SiO 2 The mass ratio is 0.3:1. The above mixture is continuously fed into the bottom-blown oxidation furnace after being granulated by the disc, and oxygen and nitrogen are continuously injected from the bottom of the bottom-blown oxidation furnace through the gas spray gun. The nitrogen plays the role of protecting the spray gun. Oxidative smelting is carried out at a high temperature of 1000-1100 °C, and the slag is discharged every 1.25 hours to obtain crude lead, flue gas and liquid high-lead slag. The produced flue gas is sent to the waste heat boiler to re...

Embodiment 2

[0023] like figure 1 As shown, a method for processing complex and low-grade lead and antimony materials by using a "double bottom blowing furnace", comprising the following steps:

[0024] The lead concentrate is processed and mixed with zinc leaching slag, lead-antimony ore, lead fume, and limestone. After batching, the mixture obtained: the mass fraction of Pb is 45%; 2 The mass ratio is 1.2:1; CaO and SiO 2 The mass ratio is 0.5:1. The above mixture is continuously fed into the bottom-blown oxidation furnace after being granulated by the disc, and oxygen and nitrogen are continuously injected from the bottom of the bottom-blown oxidation furnace through the gas spray gun. The nitrogen plays the role of protecting the spray gun. Oxidative smelting is carried out at a high temperature of 1000-1100 ℃, and the slag is discharged every 1.5 hours to obtain crude lead, flue gas and liquid high lead slag, respectively. Acid production, the tail gas of acid production is directly...

Embodiment 3

[0027] like figure 1 As shown, a method for processing complex and low-grade lead and antimony materials by using a "double bottom blowing furnace", comprising the following steps:

[0028] The lead concentrate is processed and mixed with zinc leaching slag from hydrometallurgy, silver flotation silver-rich wet mud, lead-antimony ore, lead fume and limestone. Fraction 4.0%; Fe and SiO 2 The mass ratio is 1.5:1; CaO and SiO 2 The mass ratio is 0.4:1. The above mixture is continuously fed into the bottom-blown oxidation furnace after being granulated by the disc, and oxygen and nitrogen are continuously injected from the bottom of the bottom-blown oxidation furnace through the gas spray gun. The nitrogen plays the role of protecting the spray gun. Oxidative smelting is carried out at a high temperature of 1000-1100 °C, and the slag is discharged every 1.4 hours to obtain crude lead, flue gas and liquid high-lead slag. The produced flue gas is sent to the waste heat boiler to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com