Tunnel construction unit workstation

A technology for tunnel construction and workstations, applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of long operation time, occupying large tunnel ground space, low operation efficiency, etc., and achieve efficient construction, improve work efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

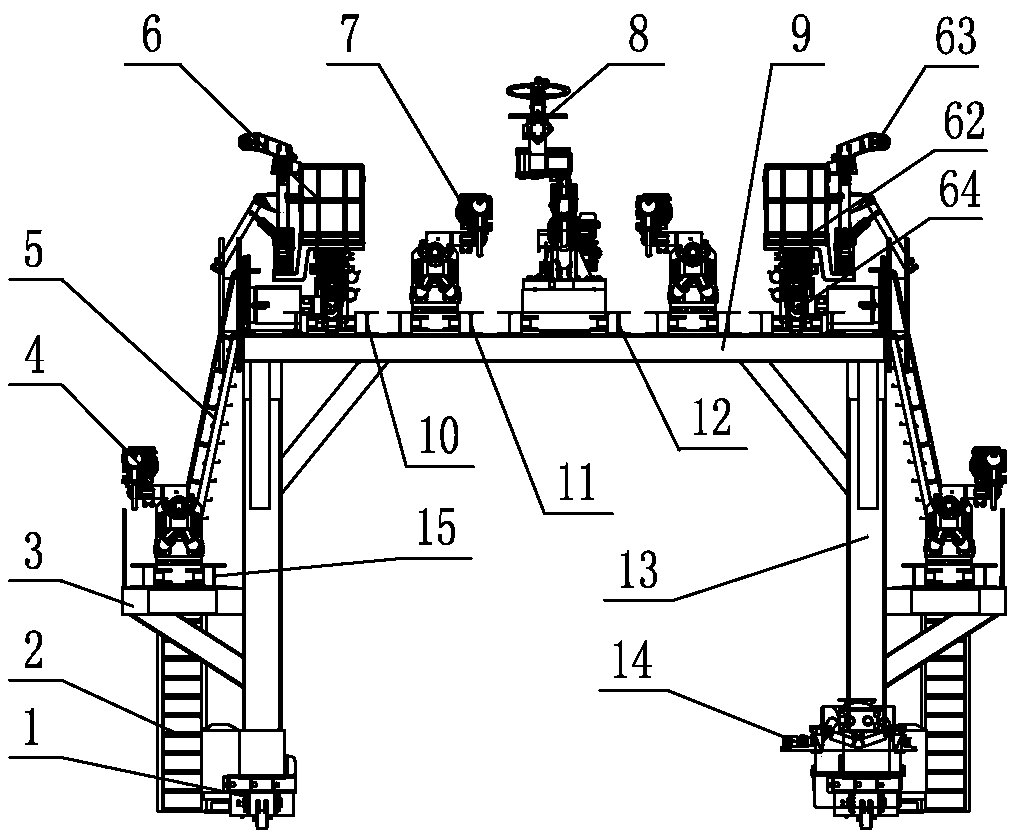

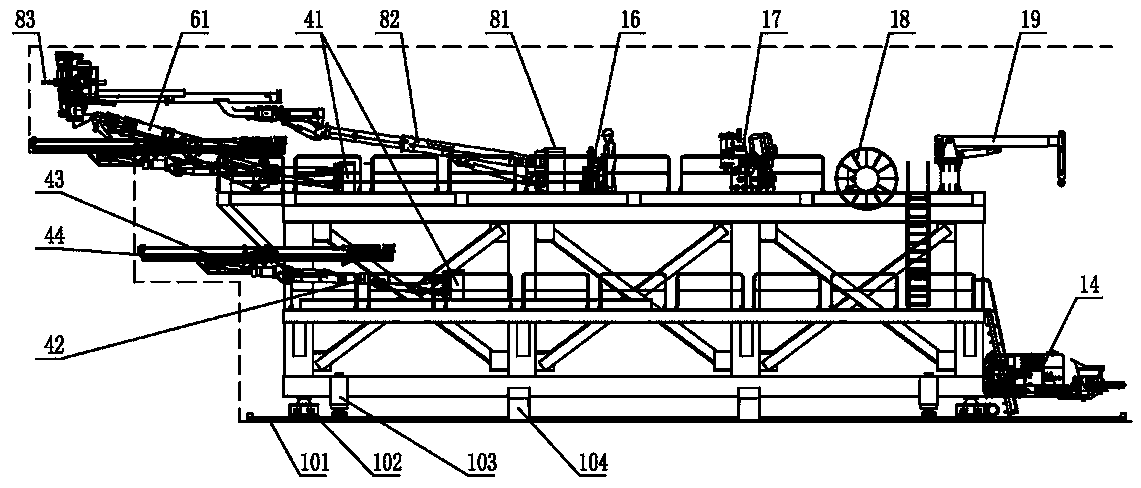

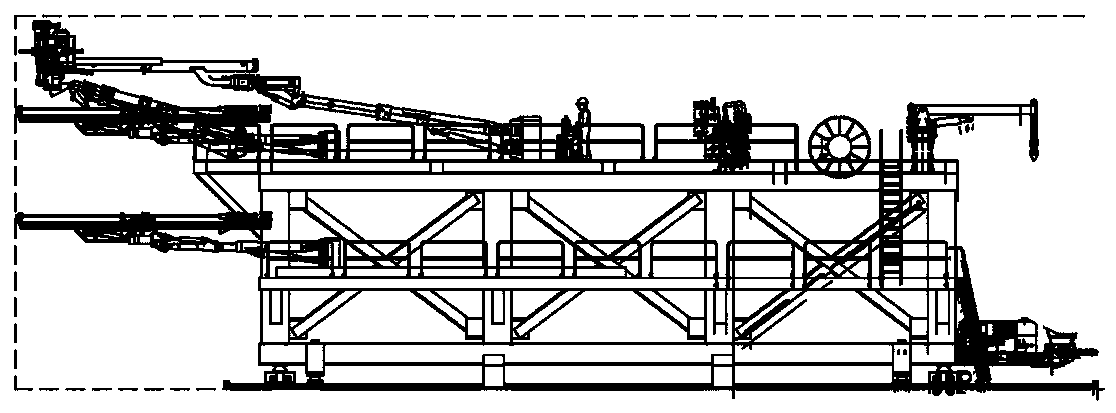

[0028] like figure 1 , figure 2 and image 3 As shown, a tunnel construction unit workstation is mainly composed of a door frame assembly and an automatic walking assembly 1 that drives the door frame assembly to move forward and backward along the tunnel. The main platform 9 is arranged on the top of the auxiliary platform 3 and the door frame 13, an escalator I2 is arranged between the auxiliary platform 3 and the ground, and an escalator II5 is arranged between the auxiliary platform 3 and the main platform 9, so that the staff can reach the platform.

[0029] Two arch chute tracks 10, one wet spray chute track 12 and two drilling chute tracks I11 are fixedly installed side by side on the front of the main platform 9, and the wet spray chute track 12 is arranged in the middle of the door frame 13 , preferably at the longitudinal center position; two arch chute tracks 10 and two drilled chute tracks I11 are respectively symmetrically arranged on both sides of the main pla...

Embodiment 2

[0041] A working station for a tunnel construction crew. The difference between this embodiment and the first embodiment is that: the arch chute track 10 is arranged on the inner side of the drilling chute track I11.

Embodiment 3

[0043] The front end surface of the main platform 9 is flush with the front end surface of the auxiliary platform 3 . Similarly, by controlling the front and rear positions of the arch manipulator 6, the wet spray manipulator 8, the drilling unit Ⅰ7 and the drilling unit Ⅱ4 on the corresponding chute tracks on the main and auxiliary platforms, the excavation by the full-section method and the step method can be satisfied. Excavation requirements, novel structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com