Overflow type iron bath slag melting pool and slag removal method thereof

An overflow type and slag technology, which is applied in the petroleum industry, the manufacture of combustible gas, and the mechanical details of gasification devices, etc., can solve the problems of poor fluidity of liquid slag, blockage of slag discharge port, and insufficient temperature, so as to improve operating efficiency and Operational safety, solving poor slag discharge, and ensuring smooth slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

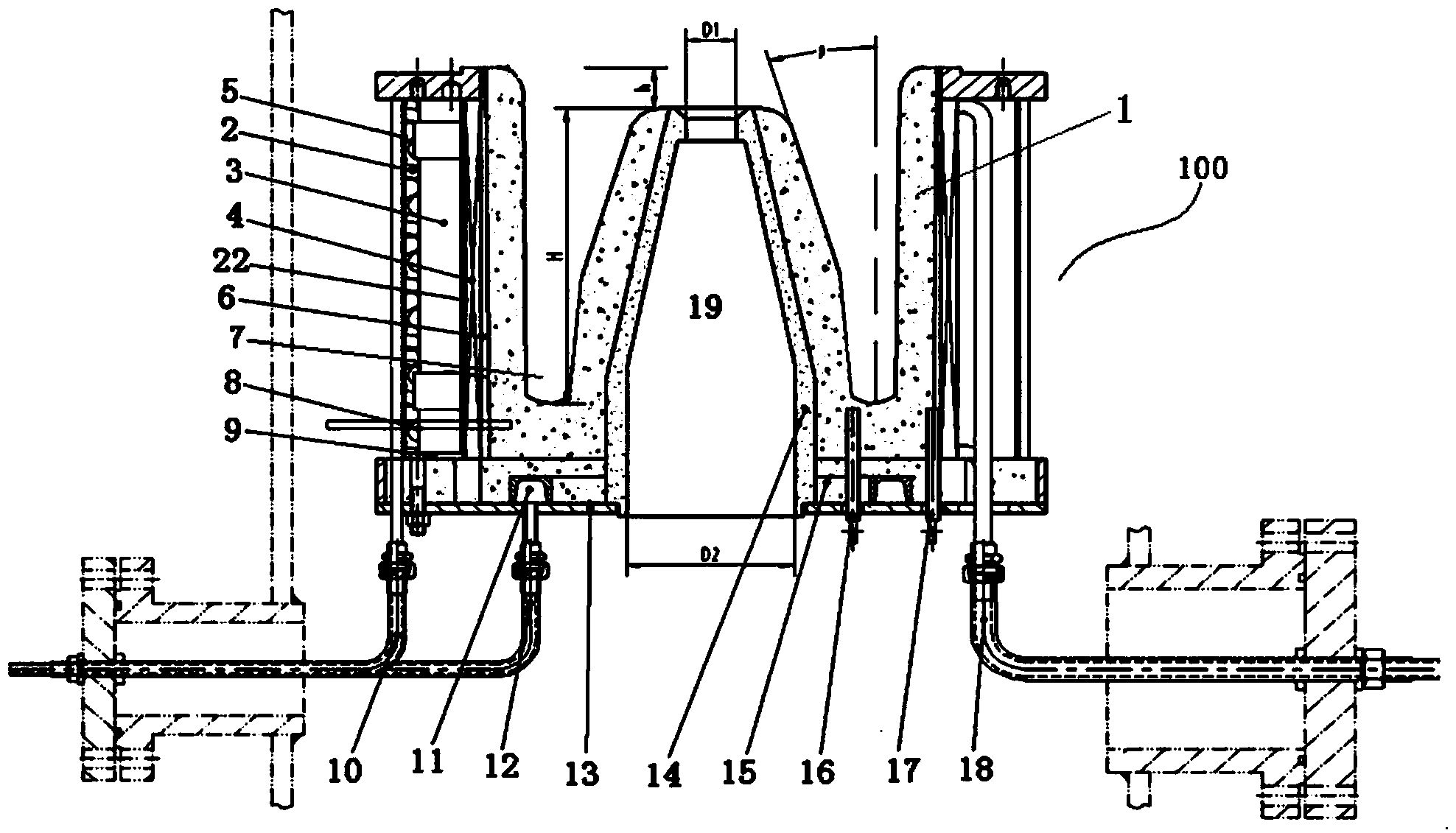

[0024] Such as figure 1 As shown, this embodiment provides an overflow iron bath slag pool 100 with an inner diameter of 3.0 m or less. The slag pool 100 is installed under the furnace body of the slag gasifier, which includes an inverted "M" section Shaped annular furnace lining 1, the middle part of the furnace lining 1 has a hollow conical slag outlet 19, the overflow port at the upper end of the slag outlet 19 is slightly lower than the upper edge of the outer wall of the furnace lining 1 in the height direction, the outer wall of the furnace lining 1 and the slag outlet Form an annular slag pond 7 between 19. An inductor 4 is installed outside the furnace lining 1 for inductively heating the metal iron in the slag pool 7 . A magnetic yoke 3 is installed outside the inductor 4 for shielding the magnetic field generated by the inductor 4 and preventing the external metal components and instruments of the slag pool 100 from being affected by the magnetic field. A water-coo...

Embodiment 2

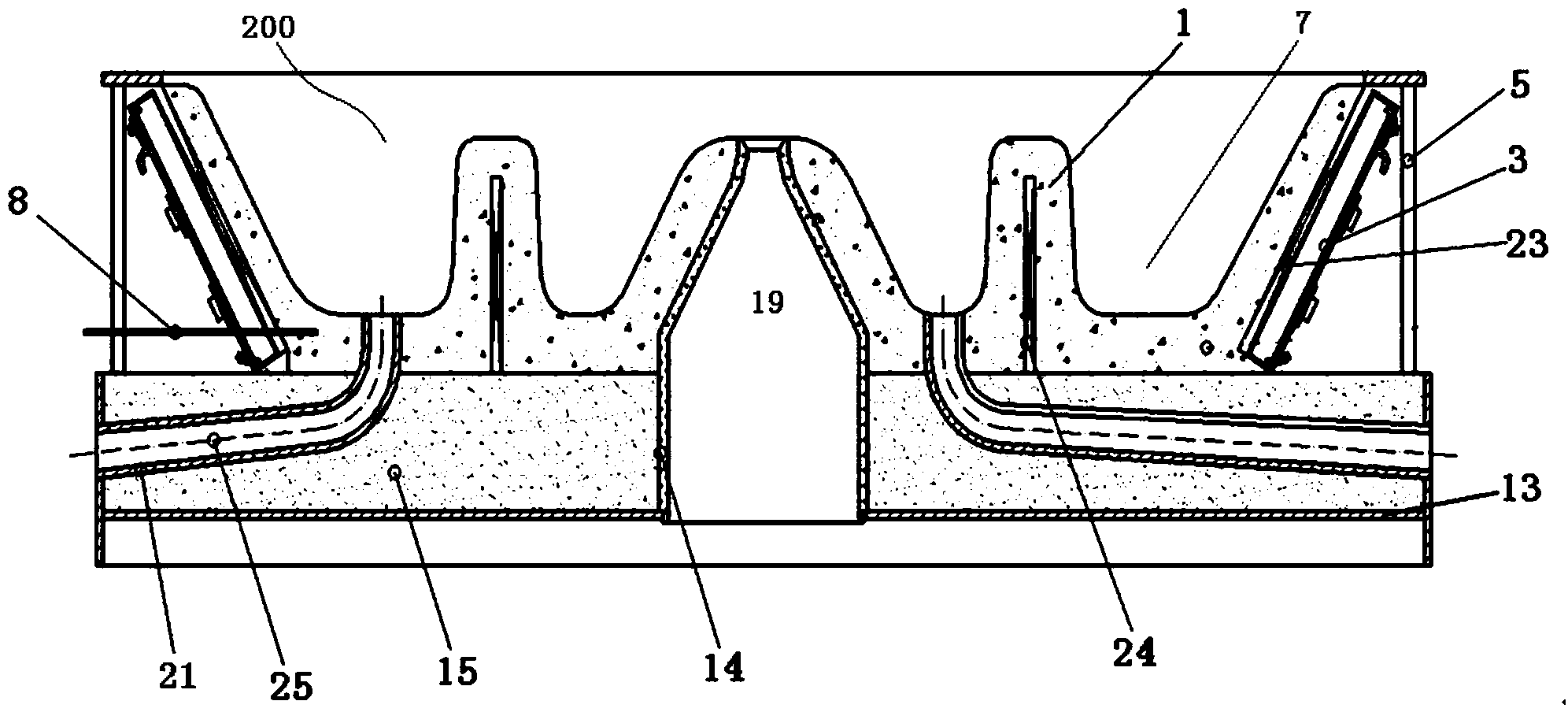

[0036] Such as figure 2 As shown, this implementation provides an overflow iron bath slag pool 200 with an inner diameter of 3.0 m or more. The slag pool 200 is also installed under the furnace body of the slag gasifier, which includes a "W" shaped section The ring-shaped furnace lining 1, the middle part of the furnace lining 1 has a hollow conical slagging outlet 19, the overflow opening at the upper end of the slagging outlet 19 is slightly lower than the upper edge of the outer wall of the furnace lining 1 in the height direction, and the outer wall of the furnace lining 1 is connected to the slagging outlet 19 An annular slag pool 7 is formed between them. Due to the limitation of the electromagnetic induction distance, an integrated annular boss is arranged on the furnace lining 1 inside the slag pool 7. An inner inductor 24 is installed inside the annular boss, and an outer inductor 23 is installed outside the furnace lining 1 to sense Both the device 24 and the induc...

Embodiment 1

[0047] The inner diameter of the overflow iron bath slag pool used in the test is 2.0m, the diameter of the overflow at the upper end of the slag pool is 100mm, and the diameter of the open part at the lower end is 600mm. The angle between the side wall of the slag outlet and the axis of the slag pool is 30°. The depth of the slag pool is 800mm, and the overflow at the upper end of the slag pool is 120mm lower than the outer edge of the slag pool.

[0048] The side wall of the slag outlet is a prefabricated orifice, and the chemical composition of the prefabricated orifice is w(Al 2 o 3 )90%, w(Fe 2 o 3 ) 1.3%, apparent porosity 20%, load softening temperature 1700°C, refractoriness 1790°C, normal temperature compressive strength 65MPa, bulk density 3.2g / cm 3 , specifically brown corundum.

[0049] A layer of furnace lining is poured on the working surface of the slag pool, the thickness of the furnace lining is 80mm, and the chemical composition of the furnace lining is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com