Ultrasonic conical ploughshare type residue-discharging extracting pot

An ultrasonic and extraction tank technology, applied in the field of ultrasonic traditional Chinese medicine extraction equipment, can solve the problems of difficult slag discharge, immature extraction tank structure, impractical solid-liquid separation structure, etc., and achieves the effect of reasonable structure and smooth slag discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

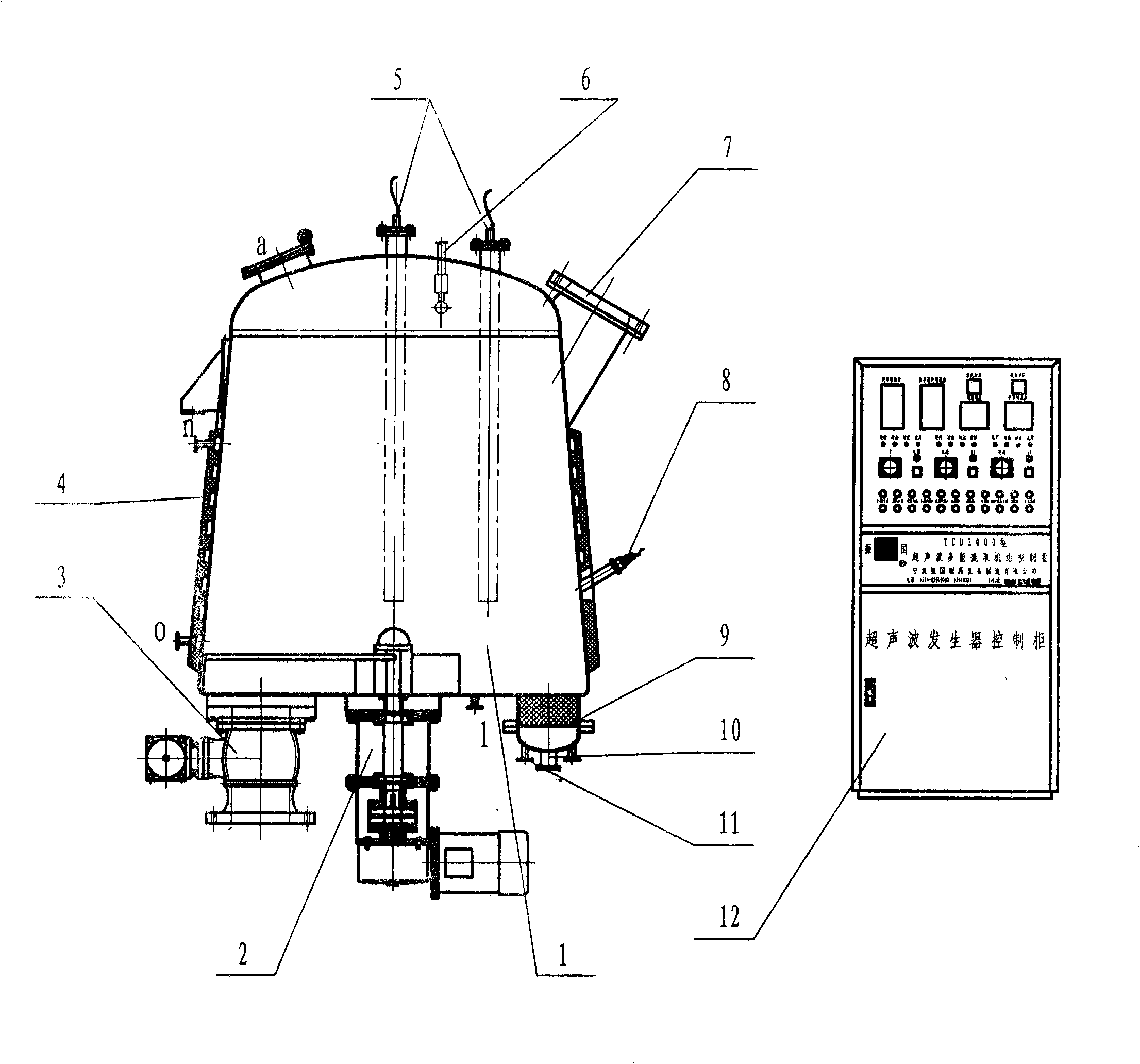

[0012] attached by figure 1 As shown in the figure, an ultrasonic conical three-share type slag discharge extraction tank of the present invention has a conical tank body 1 with a small upper part and a large flat bottom. The phenomenon of bridging and blocking; the tank body is built with a cylindrical high-power ultrasonic transducer 5. The ultrasonic transducer is electrically connected to the ultrasonic generator outside the tank through the wire extending out of the tank body, and the transducer is located in the axis of the tank body. position, the upper end protrudes from the top of the tank and is fixed with the top of the tank; there is also an automatic cleaning device 6 on the top of the tank. The cleaning device is provided with a 360° rotating nozzle. The pipes are connected to each other, and after the pressurized cleaning water is connected, the inner wall of the tank can be automatically cleaned by 360° rotating water spray; a heat exchange jacket 4 is provided...

Embodiment 2

[0015] In Example 1, the number of groups of the cylindrical high-power ultrasonic transducers 5 set in the tank was changed. Except for one group set at the axis of the tank, they were arranged symmetrically about the axis and separated from the axis by a certain distance. A plurality of cylindrical high-power ultrasonic transducers 5 are arranged at the positions of 5 , and Example 1 is repeated for the rest.

Embodiment 3

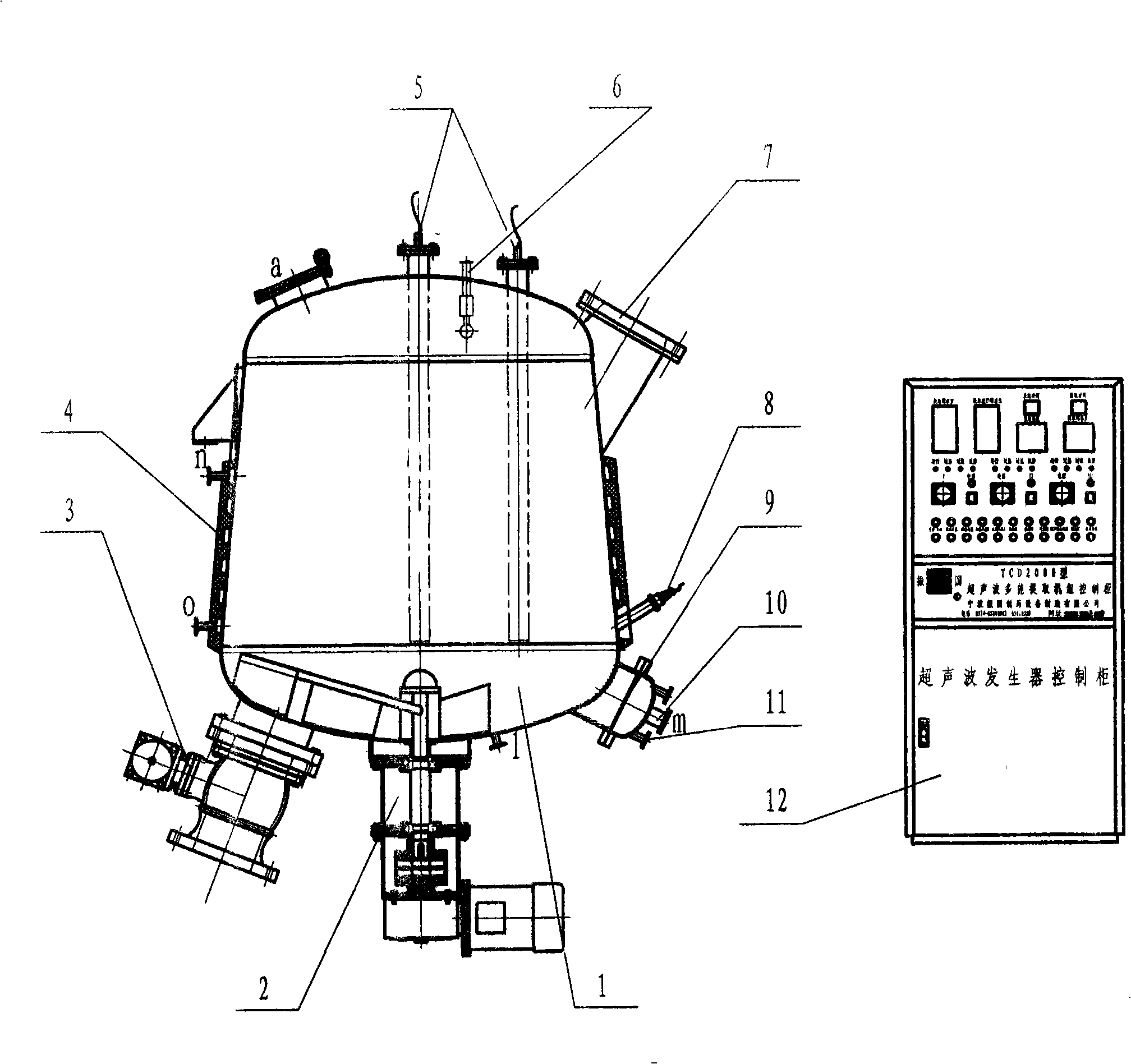

[0017] Depend on figure 2 As shown, in embodiment 1 or 2, the shape of the tank body 1 is changed, the flat bottom of the conical tank body 1 is changed to a tank bottom made with an oval head, and the rows of the left and right sides of the tank bottom are changed. The orientation of the slag port 3 and the solid-liquid separation device 9; the rest repeat Example 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com