Slag-discharge system of pulverized coal gasification furnace

A gasifier and pulverized coal technology, applied in the field of pulverized coal gasification furnace slag discharge system, can solve the problems that limestone and coal cannot be mixed completely uniformly, local mixing cannot be guaranteed, and uniform mixing is not easy, etc., so as to avoid blocking slag, saving maintenance costs and smooth slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

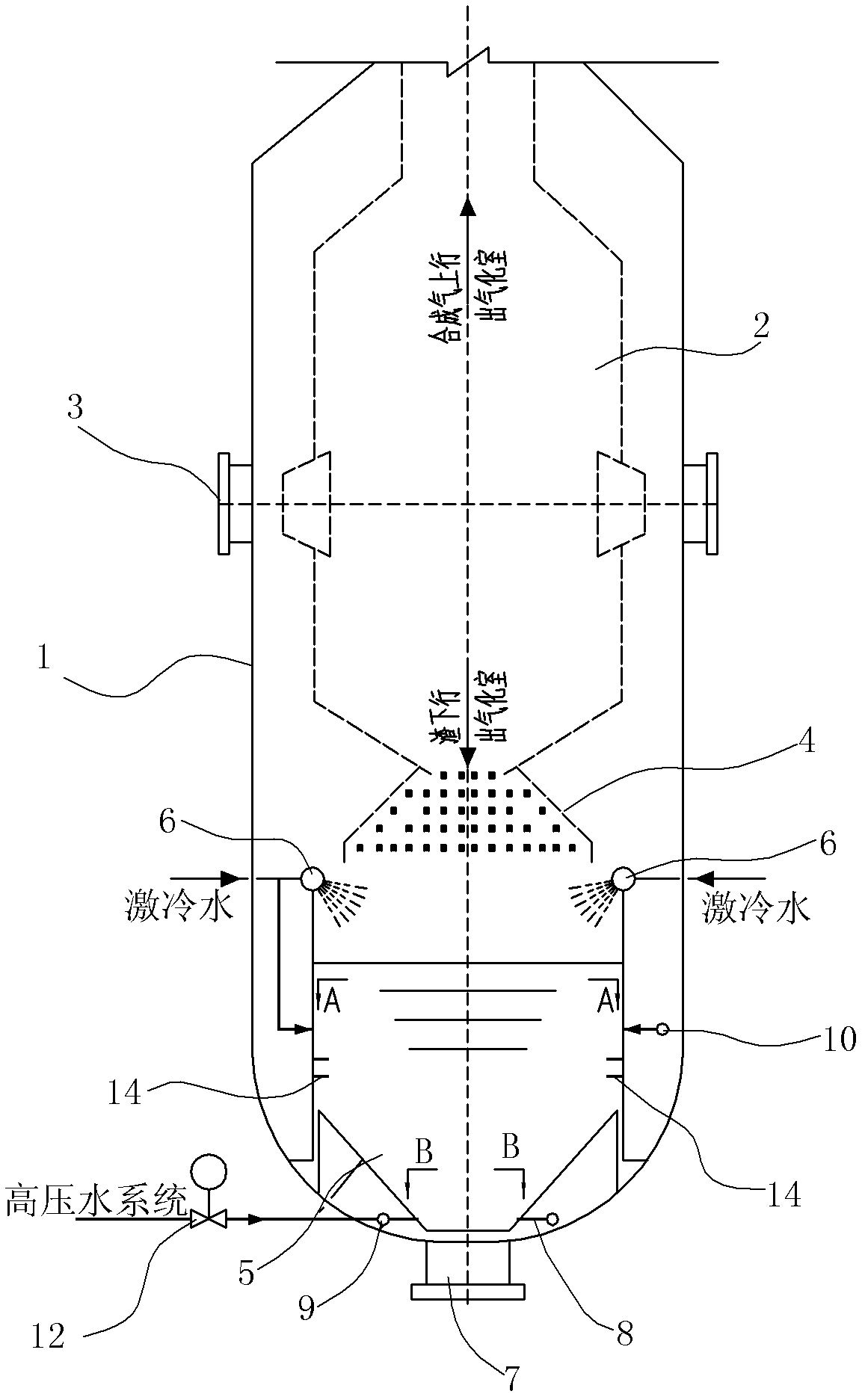

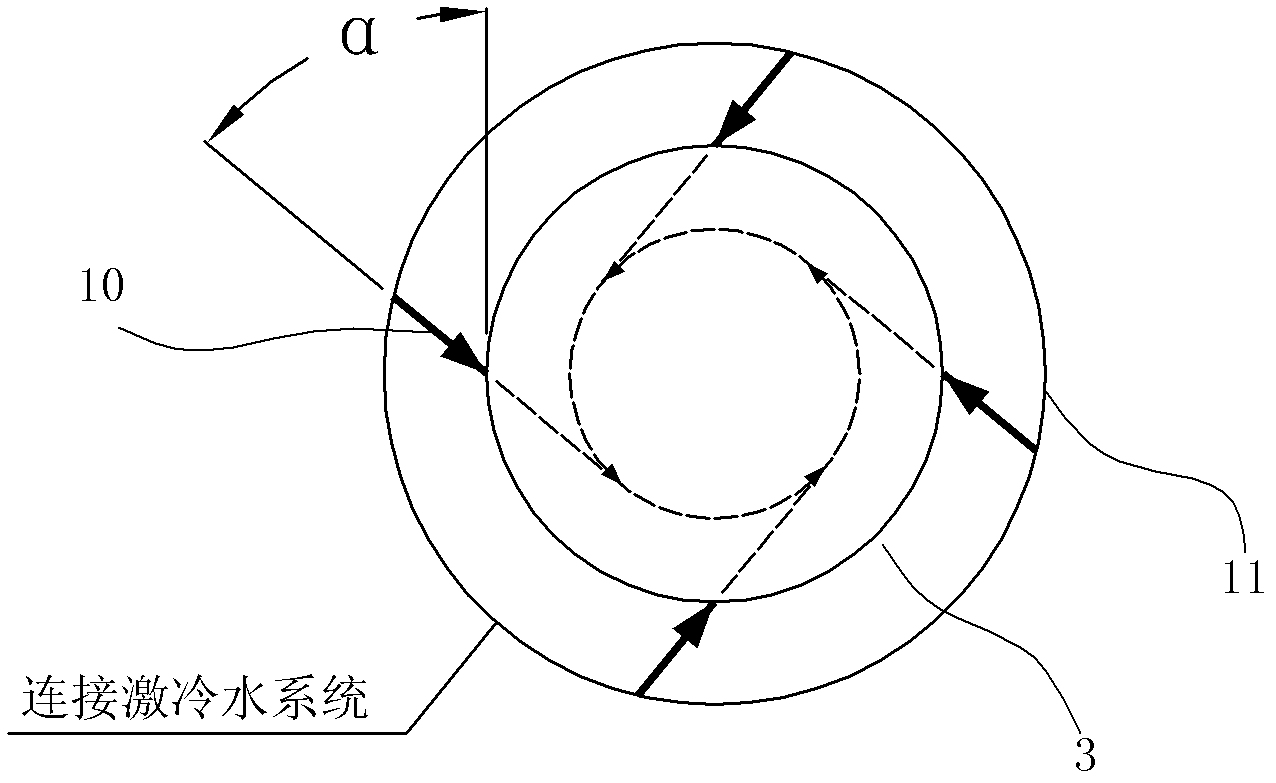

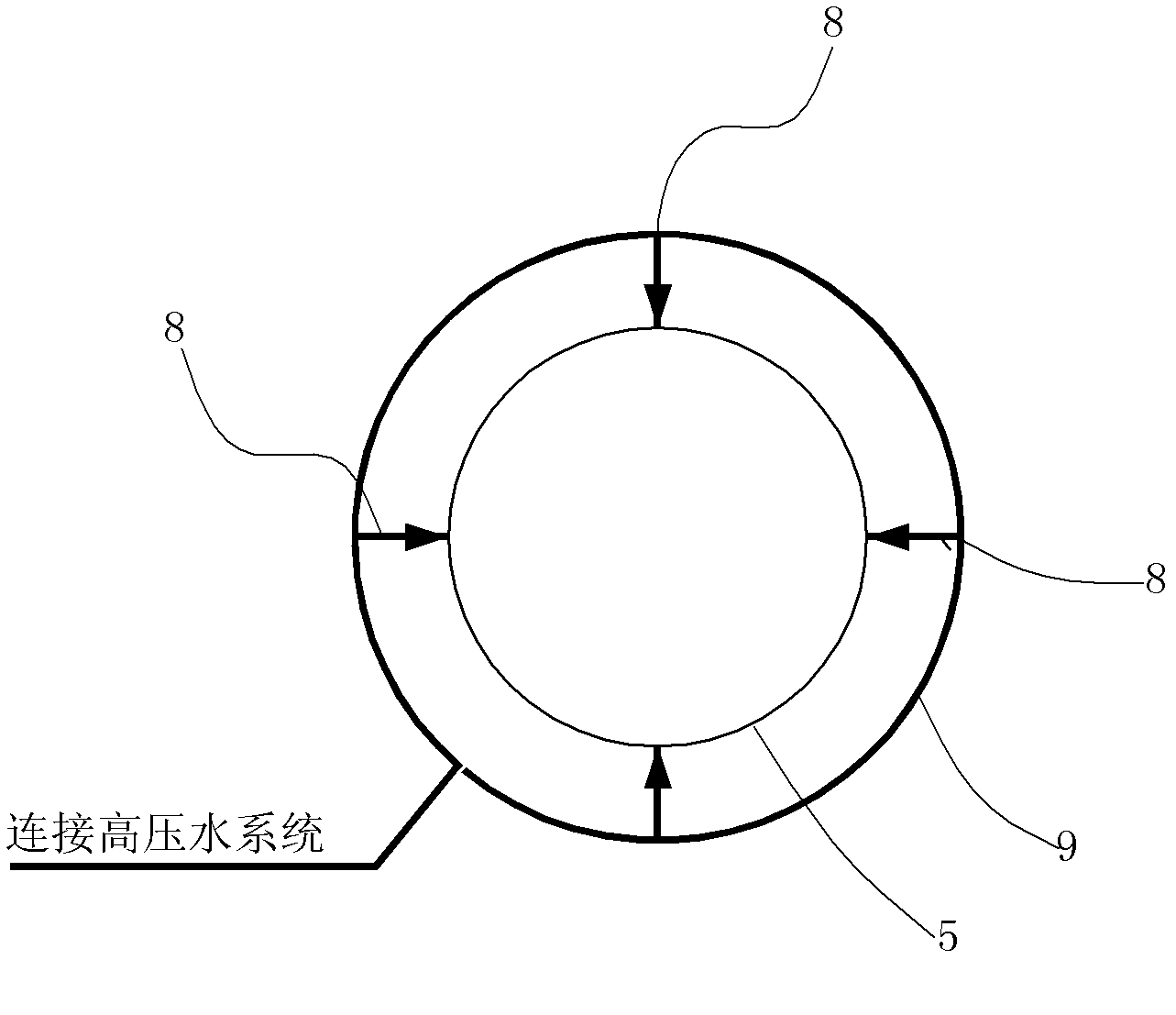

[0022] Such as Figure 1 to Figure 3 As shown, the pulverized coal gasifier slagging system includes:

[0023] The shell 1 is a pressure vessel shell. The middle part of the surrounding wall of the shell 1 is provided with a feed port 13, and the upper part of the shell is provided with a water-cooled wall gasification chamber 2 connected with the feed port 13, and the lower end of the gasification chamber is connected to the outlet. The water wall slag screen 4; the outlet of the slag screen 4 is connected to the material inlet of the slag chamber 3.

[0024] The upper end of the slag chamber is provided with a quenching ring pipe 6 for spraying quenching water to the coal slag entering the slag chamber; the lower end of the slag chamber is connected to the slag outlet 7 arranged at the bottom of the shell through a tapered slag hopper; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com