Automatic production line for preparing composite Portland cement

An automated production line, compound silicate technology, applied in cement production, clay preparation equipment, mixing operation control, etc., can solve the problems of poor mixing uniformity of materials and ingredients, poor crushing efficiency, poor applicability of production lines, etc. Efficiency, Improved Applicability, Improved Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Below the attachment in the embodiments of the invention will be clearly and fully described in the technical solutions in the embodiments of the present invention. Obviously, the embodiment described is only a part of the embodiments of the invention, not all the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

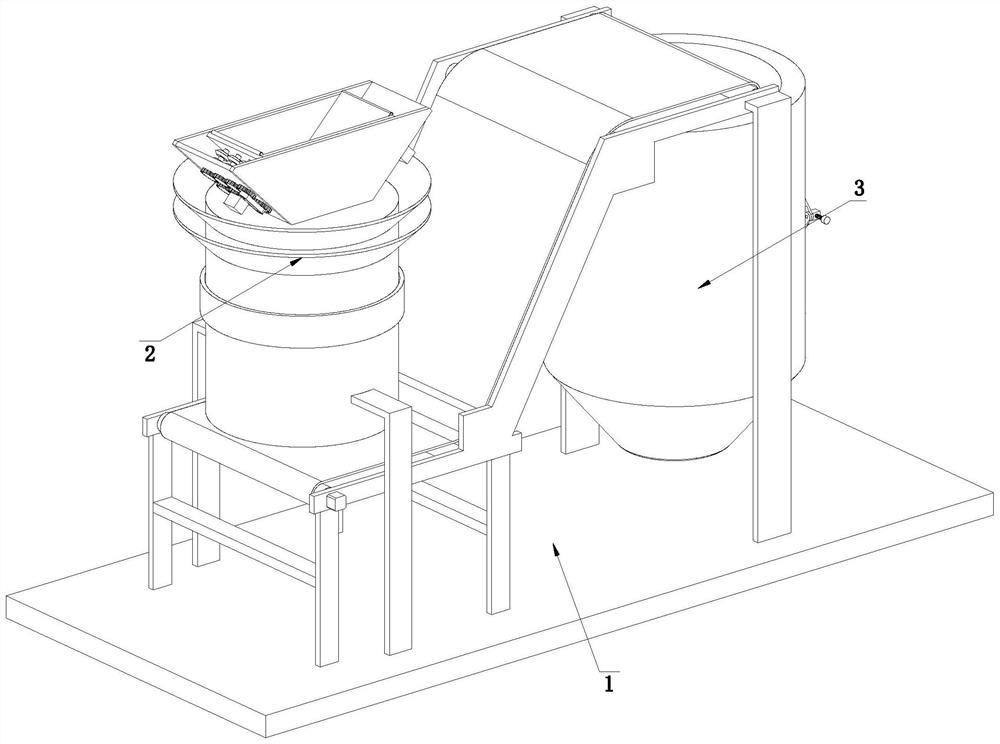

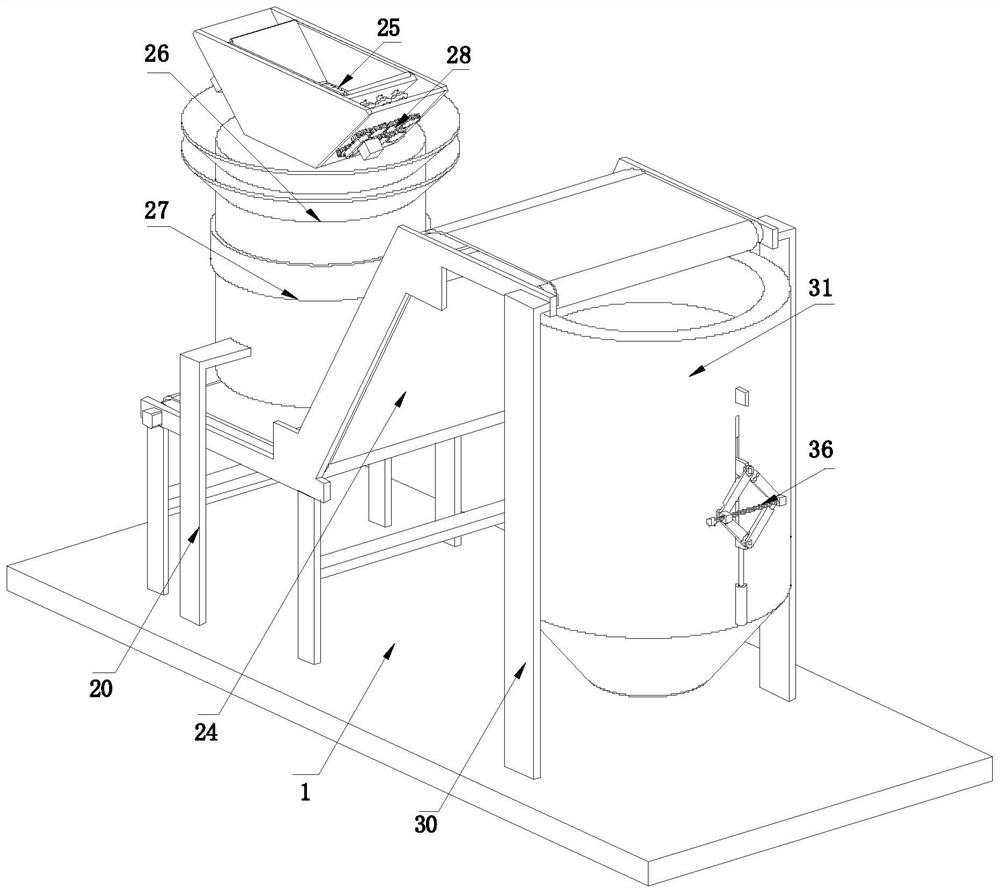

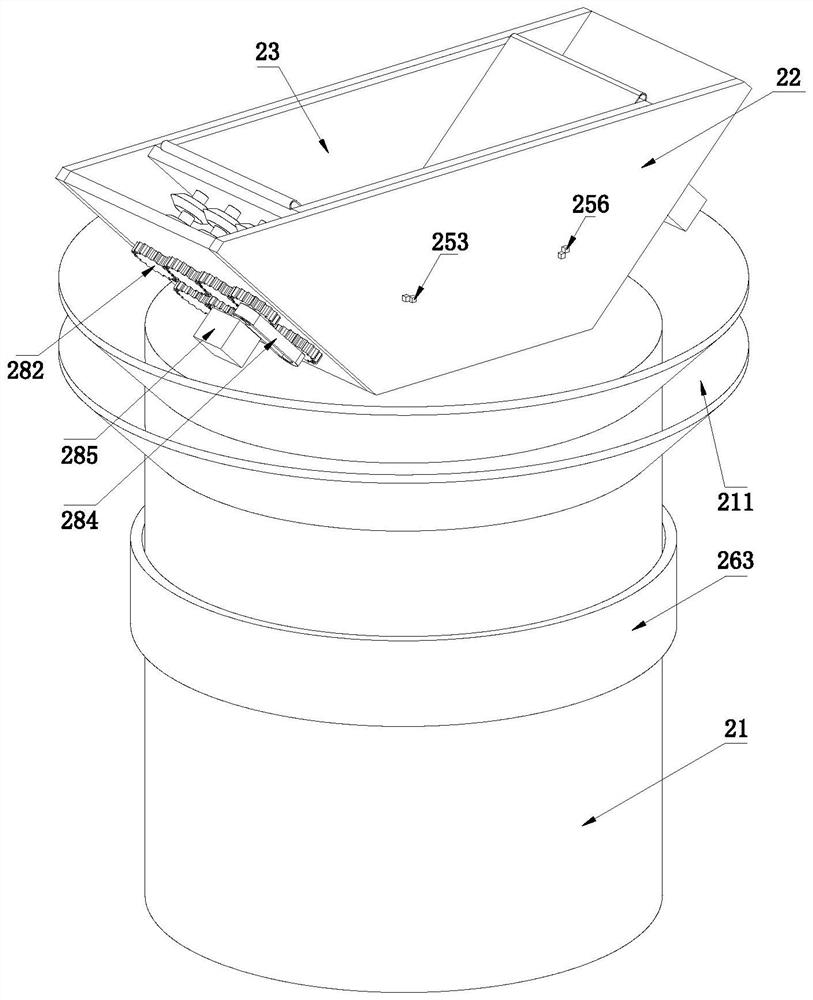

[0035] Reference figure 1 , A composite silicate cement preparation automation production line, including branch board 1, crushing mechanism 2 and feeding mechanism 3. 3. The feeding mechanism 3 is located on the right of the crushing mechanism 2; during the specific work, the operator poured the cement material to make cement into the crushing mechanism 2 for screening and crushing. Mix the material and finally encapsulate the mixed cement raw materials.

[0036] Reference figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com