Pipe jacking construction technology through water-mud balance

A technology of construction technology and mud-water balance, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems affecting the jacking construction of pipe jacking machines, affecting the construction process, and slow jacking speed, so as to achieve fast construction progress and improved The most unearthed and the effect of reducing land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the description, but the protection of the present invention is not limited thereto:

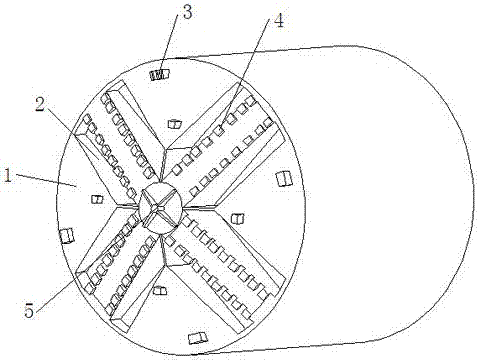

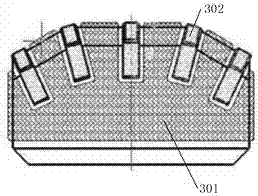

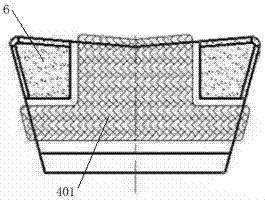

[0032] Such as Figure 1-4 As shown, a pipe jacking construction process using mud-water balance in the present invention, its jacking construction process is as follows: preparation work for jacking construction; equipment installation and debugging; pipe jacking machine out of the hole; Water pipes and various pipelines; jacking until the jacking of a pipe section ends; retract the main jacking jack, remove the water inlet and outlet pipes and various pipelines, and hang the next pipe section; connect the water inlet pipe, water outlet pipe and various pipelines, Jacking; follow this cycle; hang the first relay room and jack it; hoist pipe joints; Pipe joints; follow this cycle until the next relay room is hoisted; pipe joints are hoisted; the first relay room is jacked; the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com