Muck improving system of multi-cutter tunnel boring machine

A technology for muck improvement and roadheader, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., and can solve the problem of not being able to meet the requirements of multi-cutter roadheader construction, large particle size dregs are difficult to flow to the slag outlet, Local slag affects the excavation and other issues, and achieves the effects of reducing the internal friction angle, enhancing cohesion, and reducing surface settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

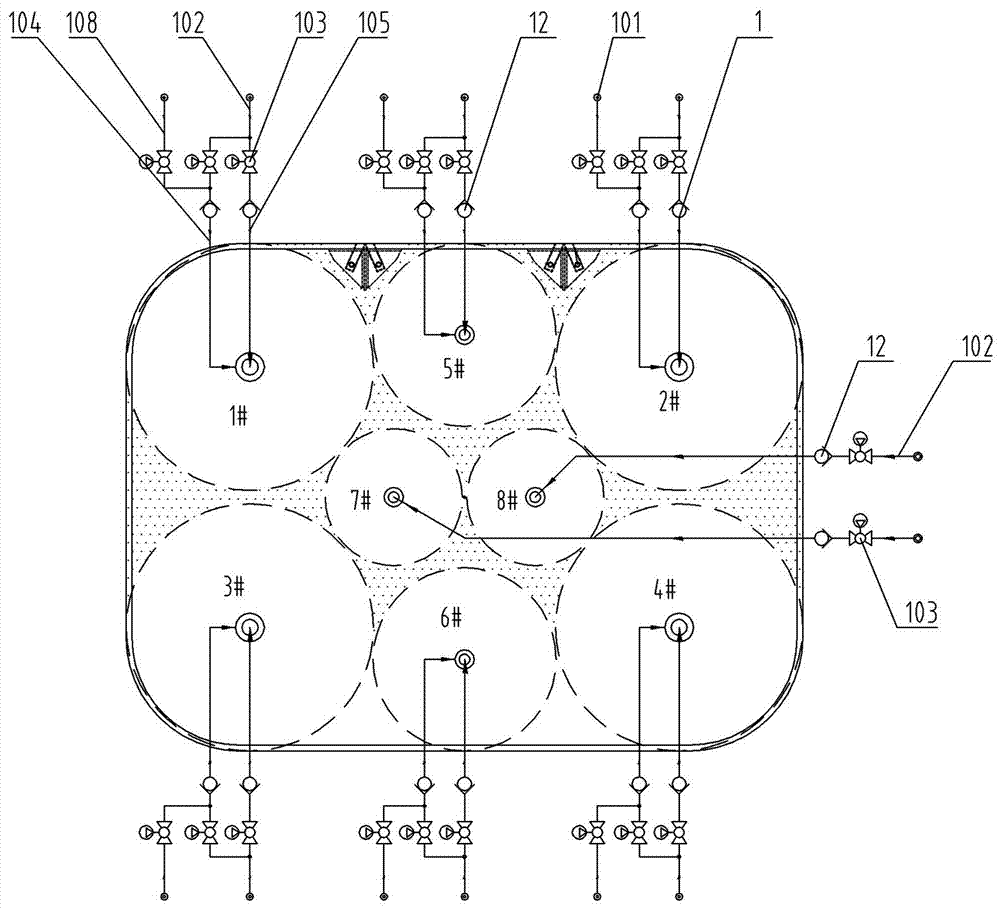

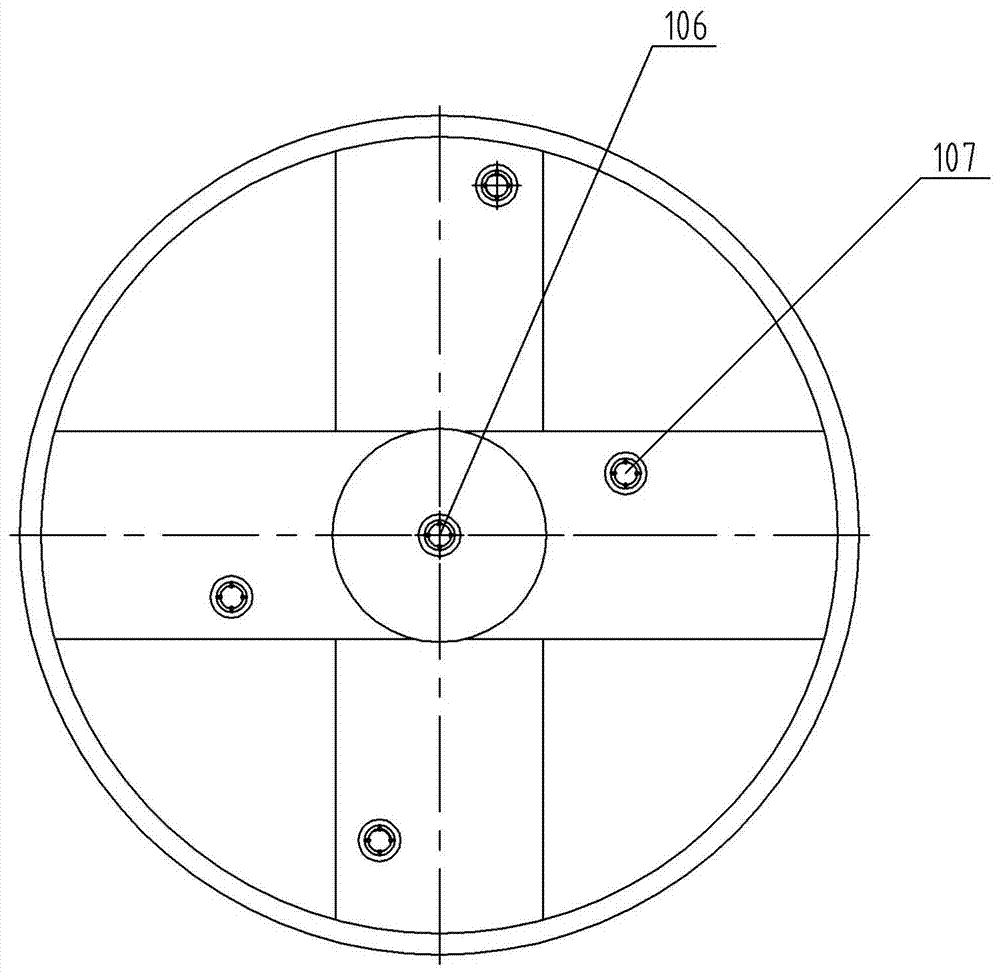

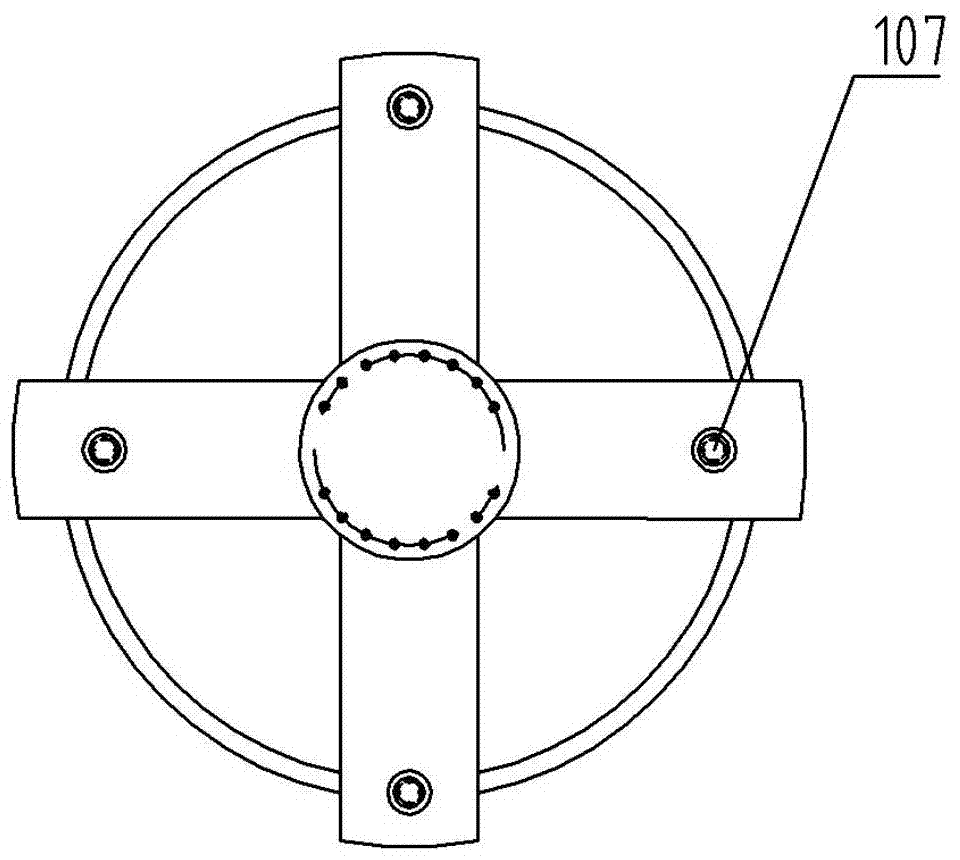

[0038] In the muck improvement system of the multi-cutter header of the present invention, the roadheader is an example of a roadheader with 8 cutter heads, wherein No. 7 and No. 8 cutter heads have a diameter of 1.2m, and each cutter head is provided with 4 nozzles around the cutter head. ; The diameters of No. 1, No. 2, No. 3, No. 4, No. 5 and No. 6 cutter heads are all greater than 1.2m, and each cutter head is equipped with 1 nozzle in the center of the cutter head and 4 nozzles around the cutter head.

[0039] The muck improvement system of the multi-cutterhead roadheader of the present invention includes a cutterhead improvement system 1, a clay injection system 2, an excavation blind area flushing system 3 and a general control mechanism, and the cutterhead improvement system 1 includes a plurality of parallel-connected Cutter unit improvement mechanism. Each cutter head of the multi-cutterhead roadheader is equipped with a set of independent cutter head unit improvement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com