Stable impact spanner

A stable wrench technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve problems such as difficulty in grasping the handle, the inability of the sleeve to clamp the bolt stably, and poor stability of the sleeve, so as to improve the operation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

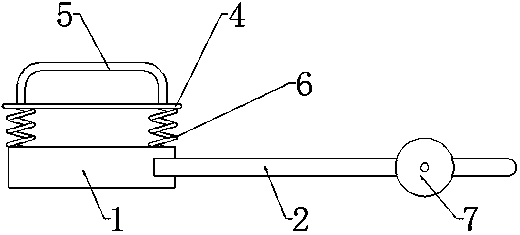

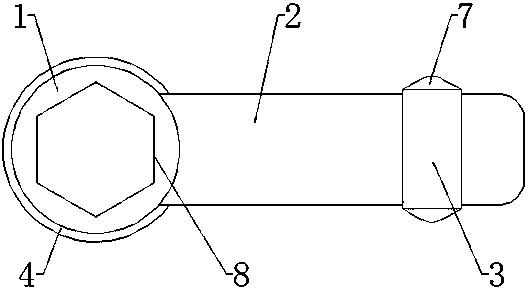

[0015] figure 1 with figure 2 Show the specific embodiment of a kind of stable knocking wrench of the present invention: combine figure 1 with figure 2 , the stable percussion wrench includes a cylindrical sleeve 1, the center of the bottom surface of the sleeve 1 is provided with a regular hexagonal prism bolt hole 8, the size of the bolt hole 8 is the same as that of the bolt head, and the bolt hole 8 can be Cover the head of the bolt so that the sleeve 1 can turn the bolt in the threaded hole.

[0016] Such as figure 1 As shown, the top surface of the sleeve 1 is connected with a disc-shaped pressing plate 4 through two vertically arranged springs 6, the pressing plate 4 is parallel to the top surface of the sleeve 1, the top surface of the pressing plate 4 is provided with a handle 5, and the side of the sleeve 1 A flat plate-shaped handle 2 is vertically provided, and a cylindrical hammering column 3 is arranged on the handle 2. The axis of the hammering column 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com