Nondestructive testing accurate knocking device and method thereof

A non-destructive testing and accurate technology, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, generation of ultrasonic/sonic/infrasonic waves, etc., can solve the problem that affects the evaluation results of internal defects of the tested wood, and the non-destructive testing technology is difficult to truly reflect wood etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

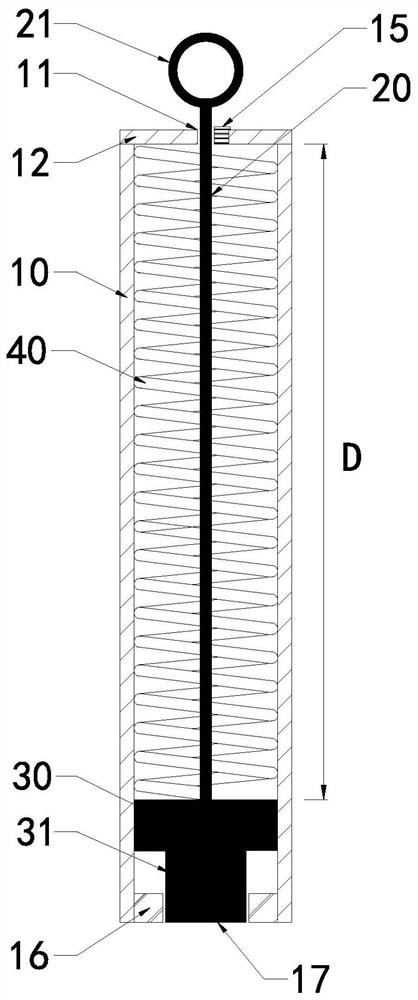

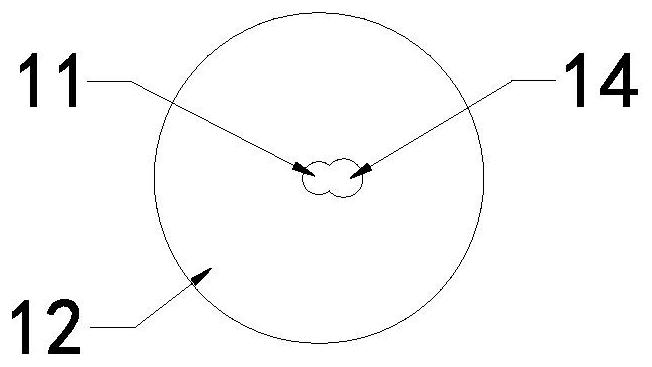

[0034] combine Figure 1 to Figure 4 Illustrate the non-destructive testing precision knocking device of the present invention, it comprises:

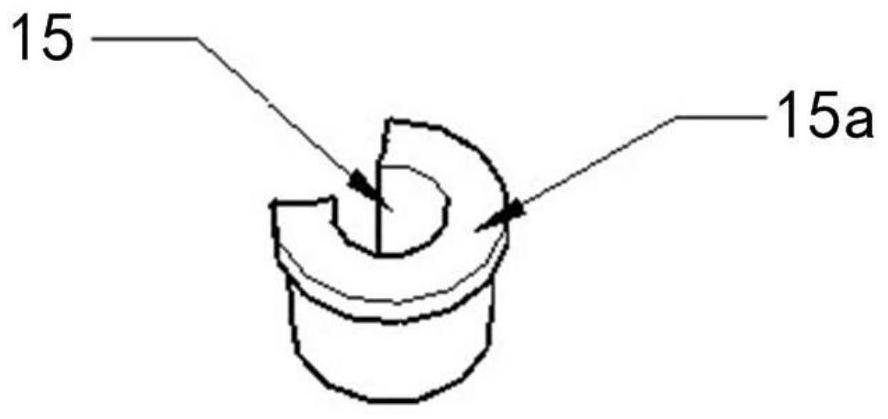

[0035] A cylindrical frame 10, one end of the cylindrical frame 10 close to the detected object (not shown in the figure) is an open end, and the other end is provided with a closed end plate 12;

[0036] Hammer 30, which is arranged in the inner cavity of the cylindrical frame 10 and can slide along its axis, the end of the hammer 30 can be in contact with the detected object located at the open end of the cylindrical frame 10;

[0037] A pull rod 20, one end of the pull rod 20 is hinged to the hammer head 30, the other end of which passes through the end plate 12 and extends out of the cylindrical frame 10, and the outer wall of the pull rod 20 is provided with scales or marks;

[0038] The spring 40 is disposed in the inner cavity of the cylindrical frame 10 and sheathed on the pull rod 20 , and the two ends of the spring 40 respec...

Embodiment 2

[0050] like Figure 5 and Image 6 As shown, the present invention also provides a non-destructive testing precision tapping method, the specific steps are as follows:

[0051] S1: Pull the pull rod 20 to drive the hammer head 30 to move along the cylindrical frame 10 in a direction away from the object to be detected, the spring 40 is compressed by force, and stops pulling when it reaches a certain scale or a specific position of the mark, and determines the striking force;

[0052] S2: Place the stress wave sensor on the top of the object to be detected and determine the knocking point, set the non-destructive testing precision knocking device on the top of the stress wave sensor, and hold the non-destructive testing precision knocking device so that the hammer head 30 is aligned with the knocking point;

[0053] S3: Loosen the pull rod 20, under the action of the spring 40 and gravity, the hammer head 30 moves down along the cylindrical frame 10 and hits the stress wave se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com