Patents

Literature

116results about How to "Reduce the number of cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

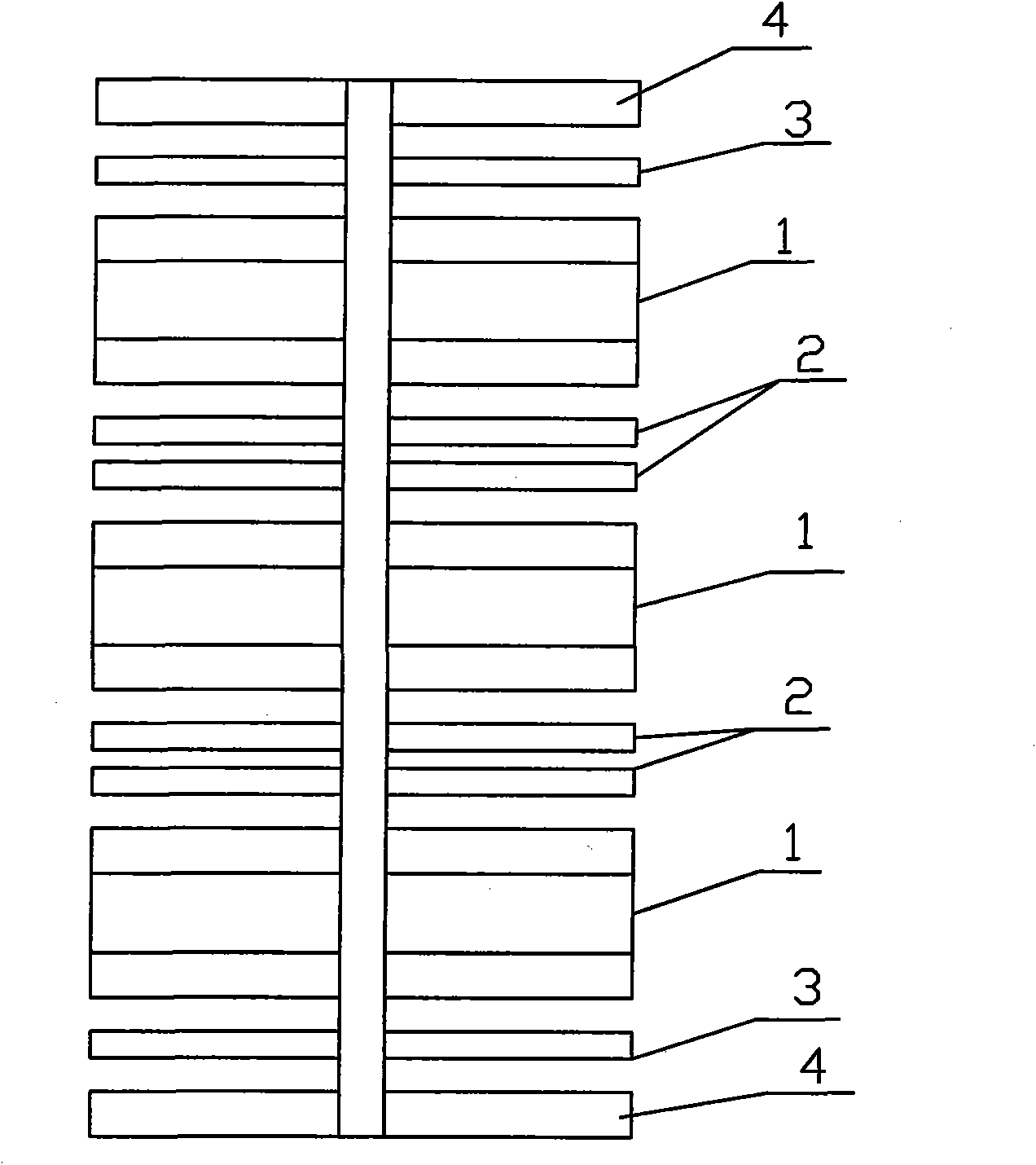

Printed circuit board lamination manufacturing process

InactiveCN101965105AReduce the number of cutsSave time for PP replacementMultilayer circuit manufactureSheet filmEngineering

The invention discloses a printed circuit board lamination manufacturing process. The process is characterized by comprising the following steps of: (1) PP cutting; (2) pre-stacking in advance; (3) riveting; and (4) pre-stacking subsequently. In the process, by the steps, an intermediate film stacked structure of an eight-layer plate or a ten-layer plate in lamination operation adopts two films in the same model number and work staff is more accustomed to stacking the PP in the same model number, so that PP cutting times are reduced and PP replacing time of 15 to 25 minutes can be saved once; pre-stacking efficiency can be improved by about 30 percent by stacking two layers of the PP of the same model number compared with stacking two layers of PP of different model numbers; interlayer slippage is reduced; and production efficiency is improved.

Owner:昆山元茂电子科技有限公司

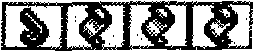

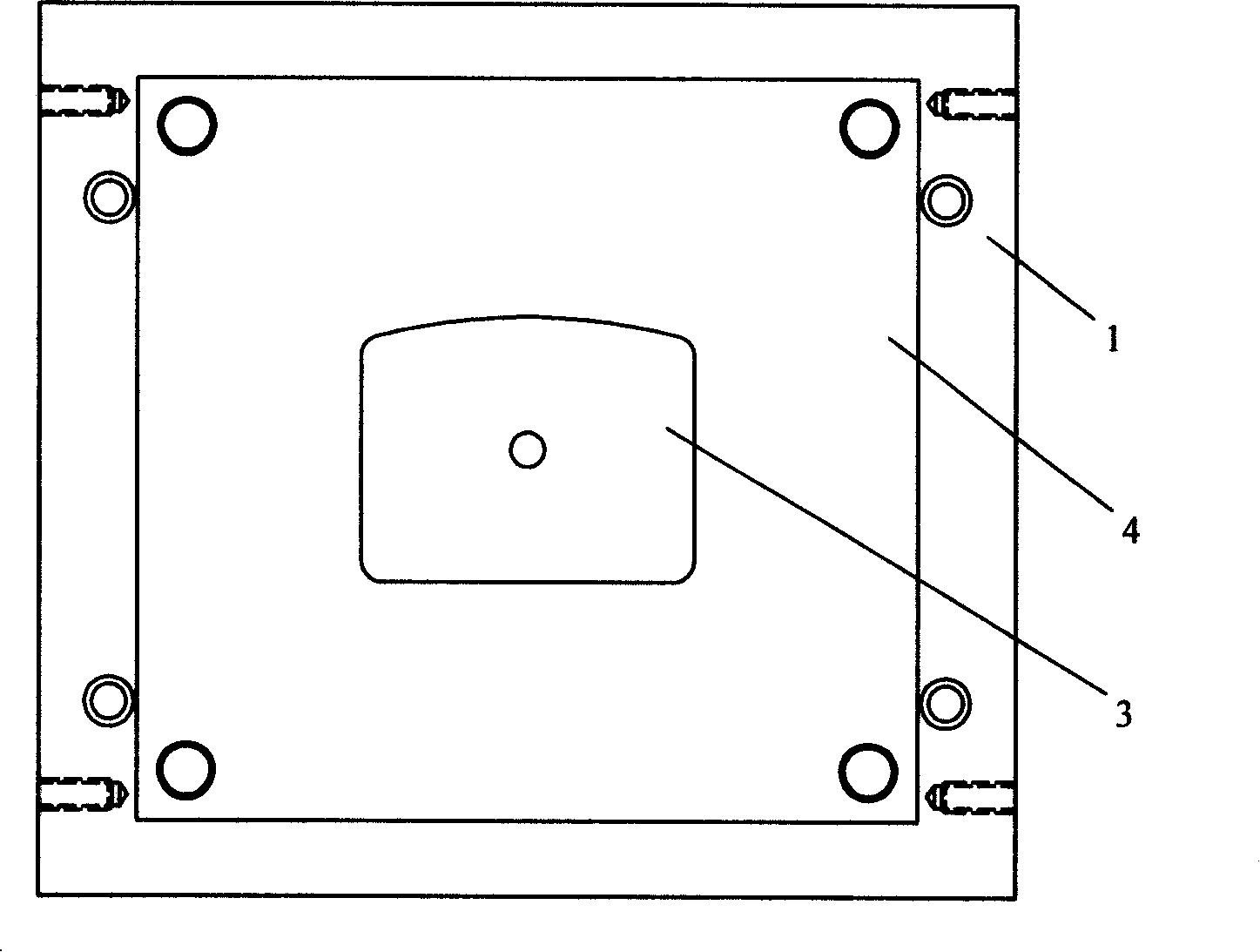

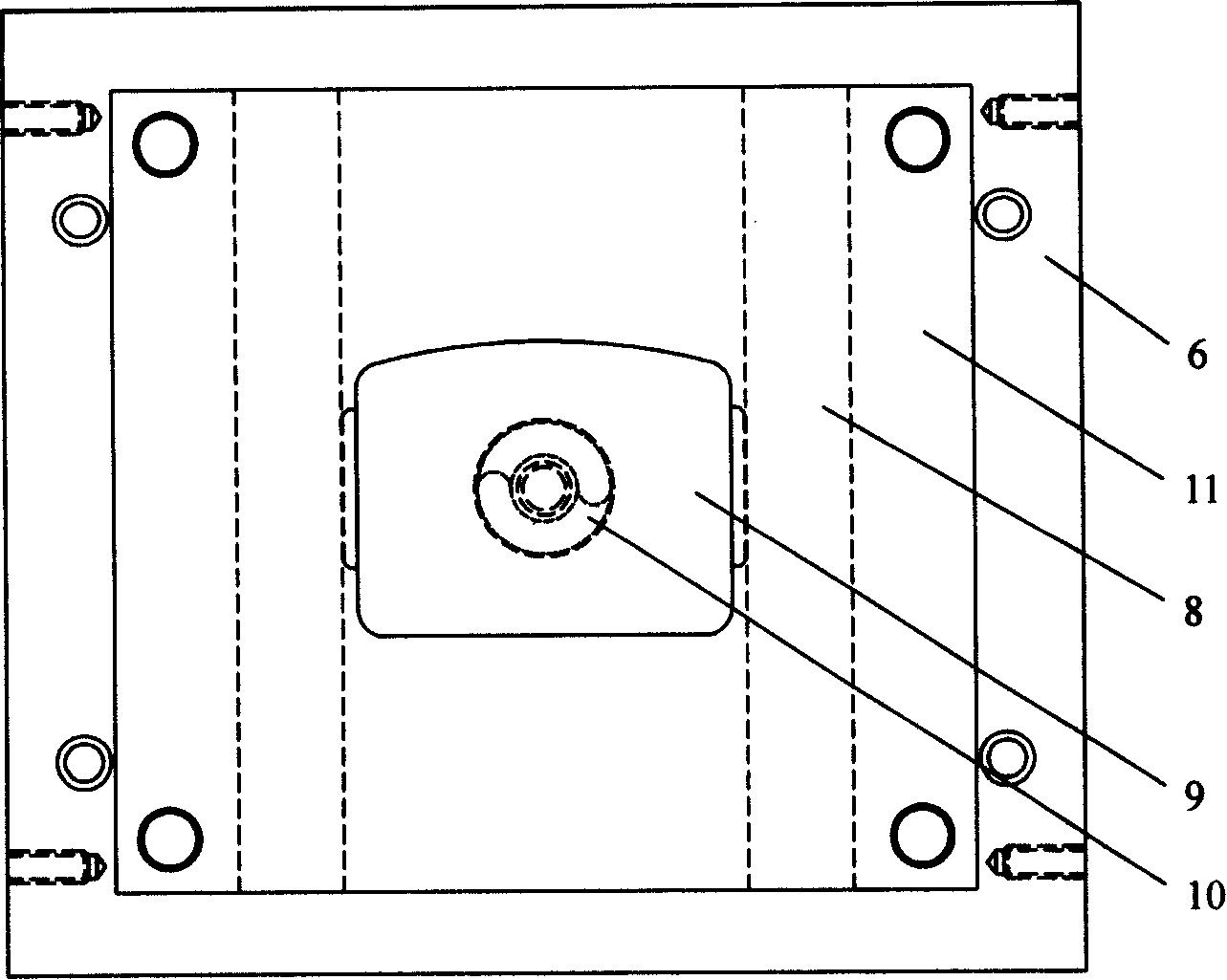

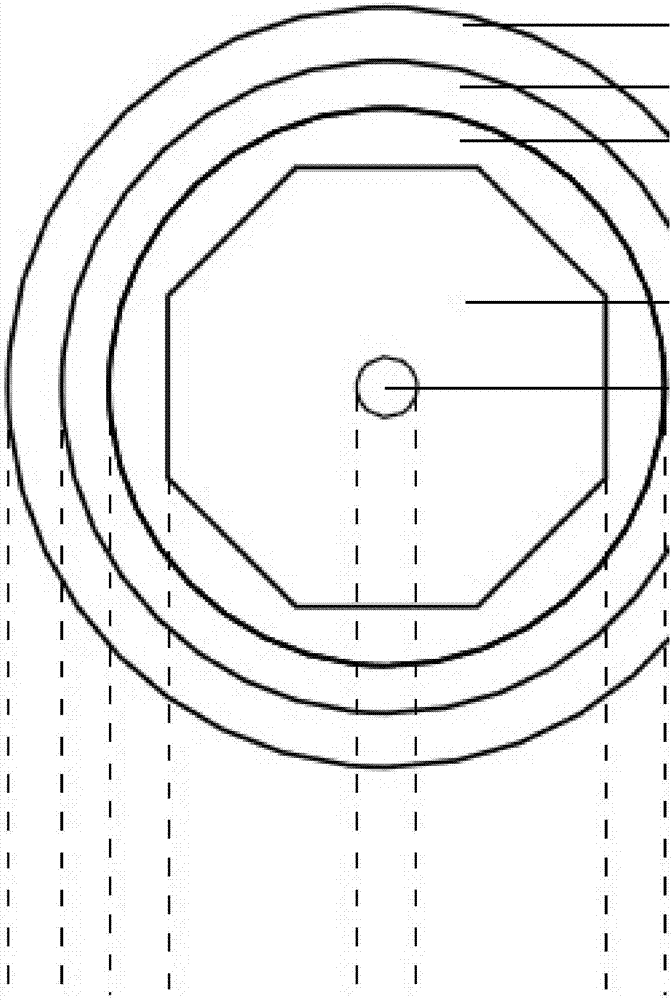

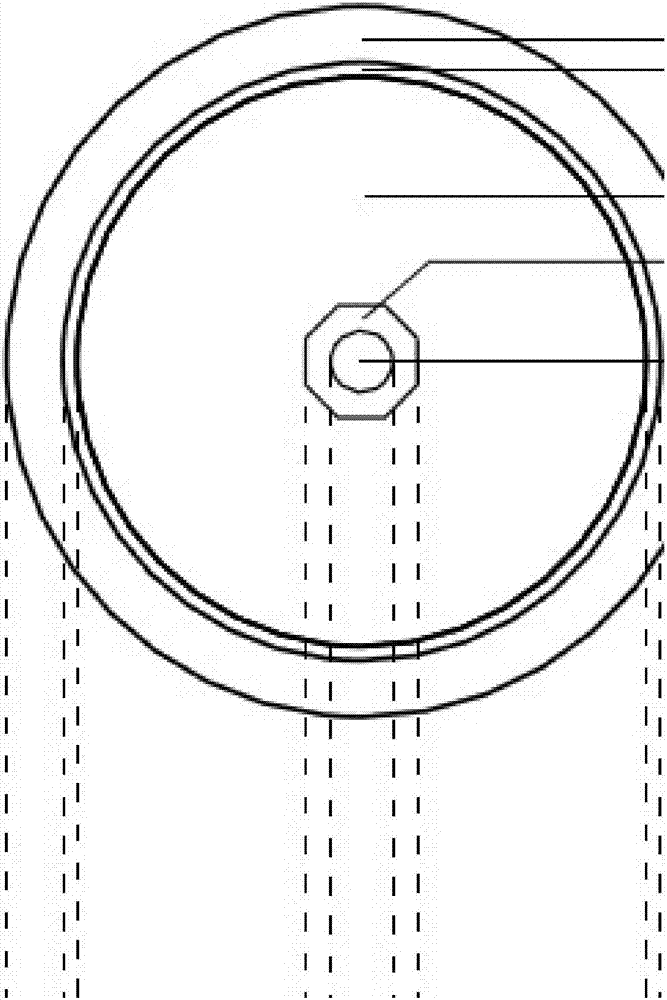

Unsymmetrical stretching forming mould capable of inducing plate material to rebound

ActiveCN101164715ALarge reboundReduce the number of cutsShaping toolsEngineeringMechanical engineering

Owner:BAOSHAN IRON & STEEL CO LTD

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

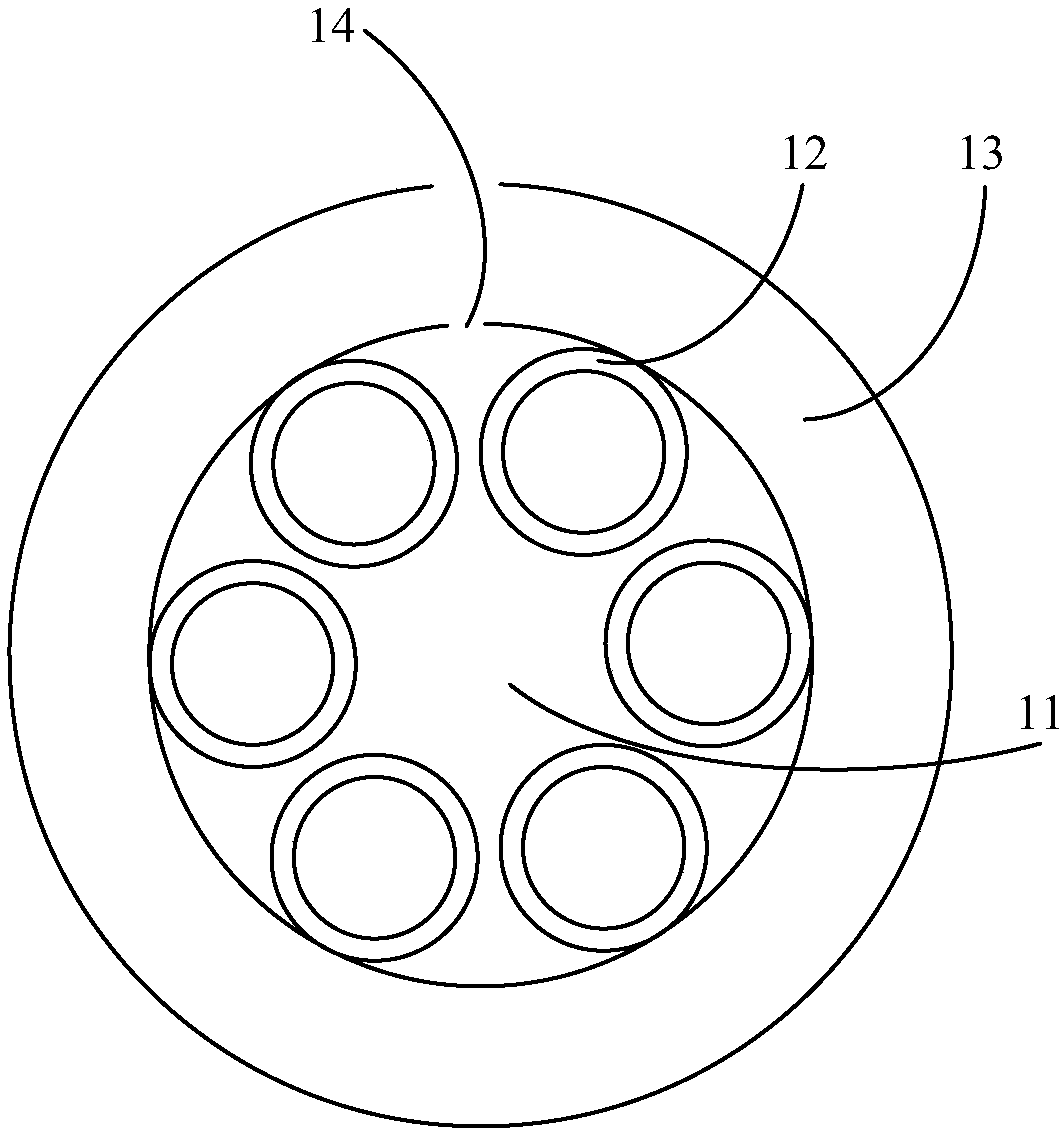

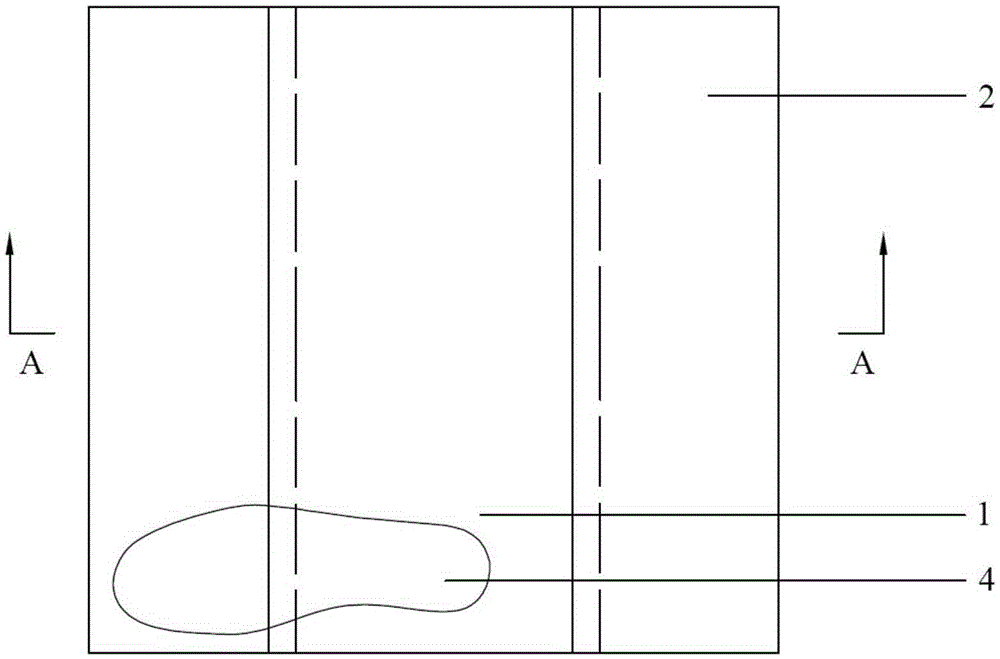

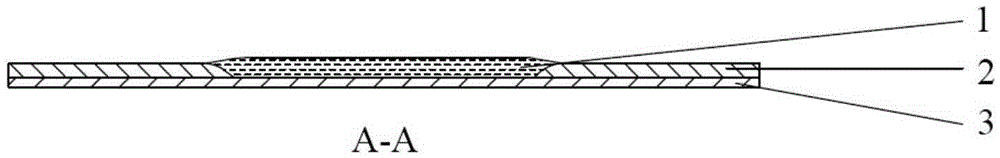

A rare earth doped optical fiber

ActiveCN107329205AIncrease the laser withstand powerReduce light leakageOptical fibre with multilayer core/claddingActive medium shape and constructionFiberRare earth

The present invention discloses a rare earth doped optical fiber. The optical fiber includes a doped fiber core, a first quartz cladding, a second quartz cladding and an organic coating cladding from the inside to the outside. The second quartz cladding has a numerical aperture of 0.1-0.24 relative to the first quartz cladding; and the organic coating has a numerical aperture greater than or equal to 0.35 relative to the first quartz cladding. The optical fiber greatly reduce light leakage of the organic coating cladding, is higher in the reliability of long-term working and longer in usage life.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

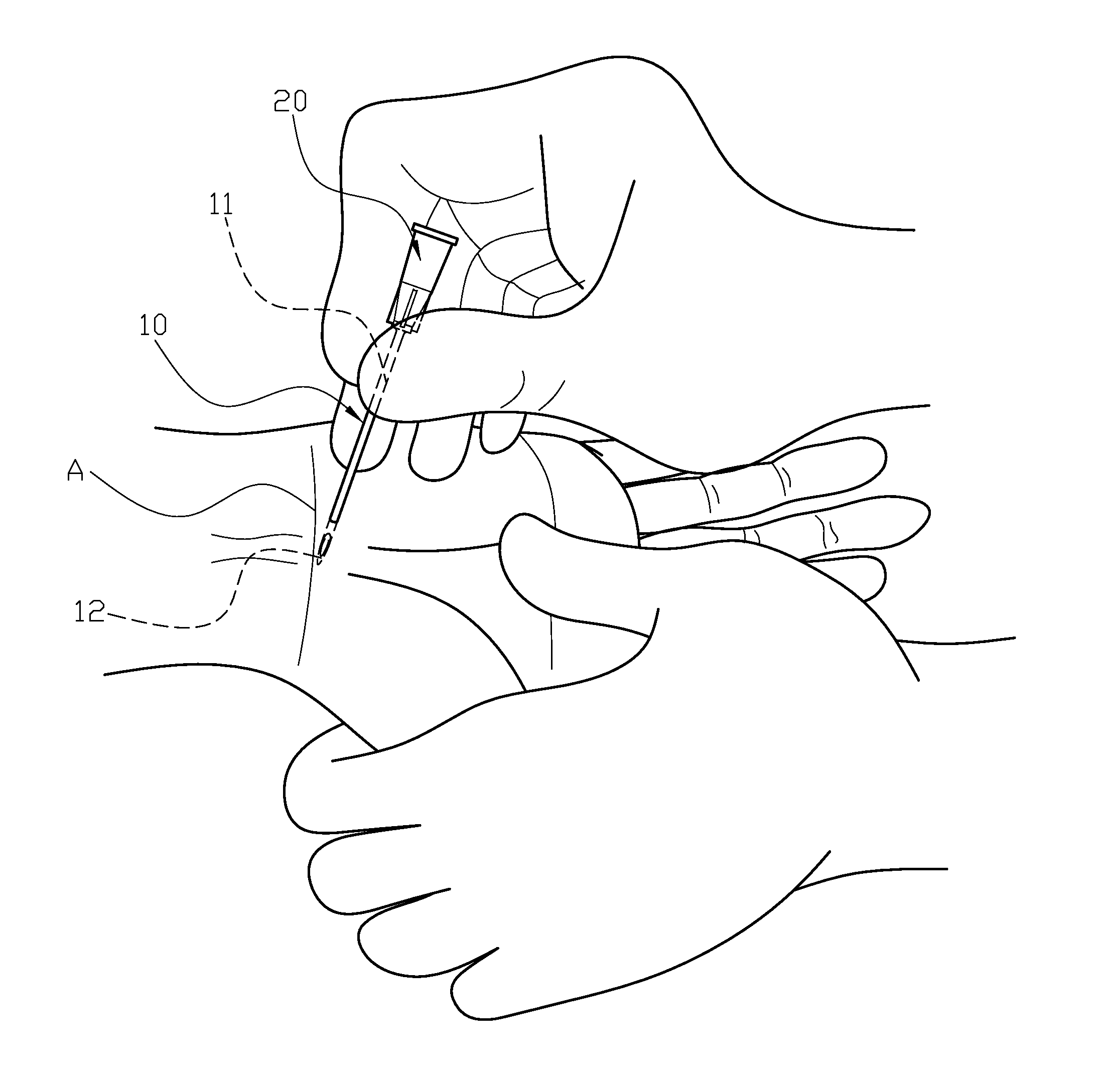

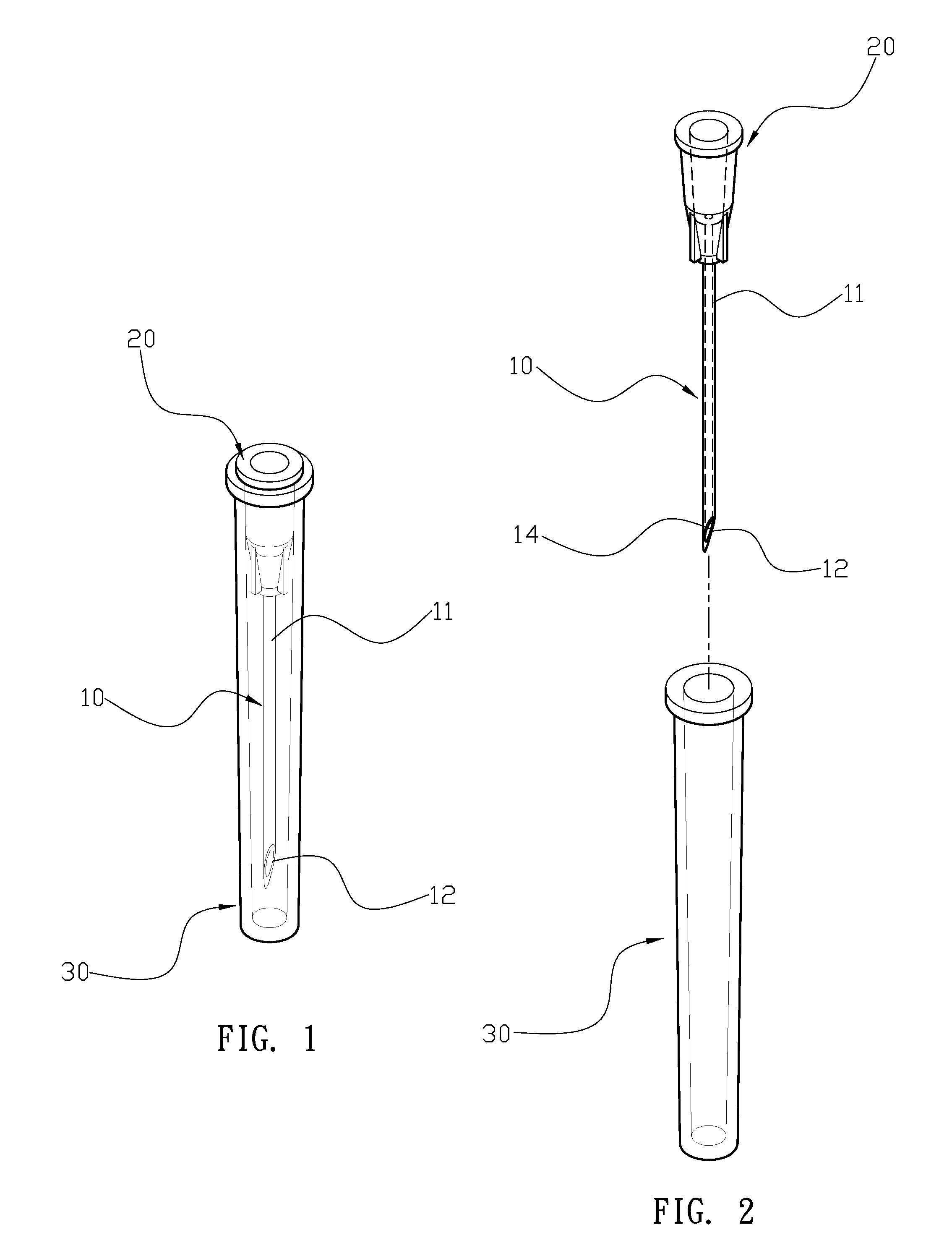

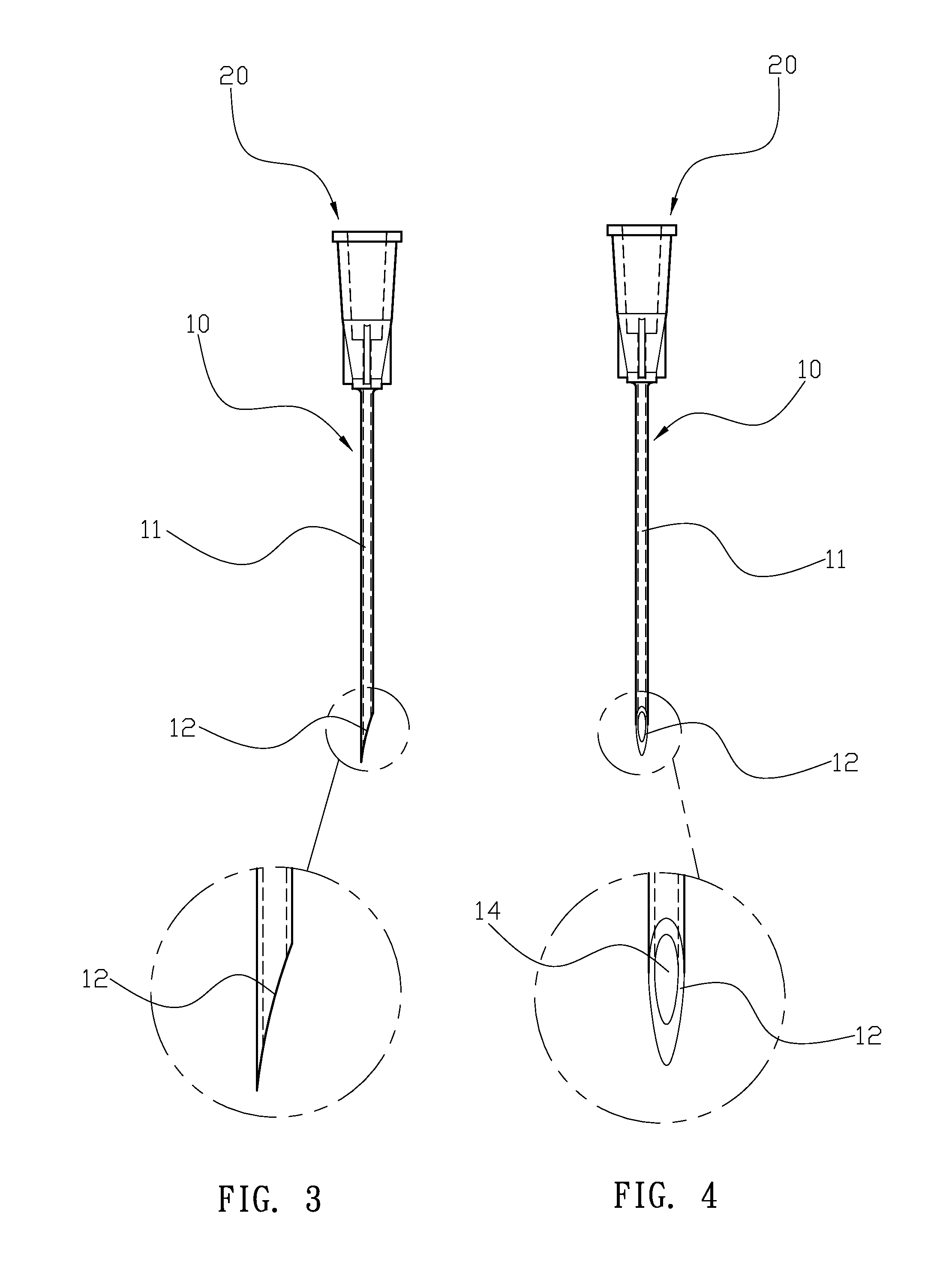

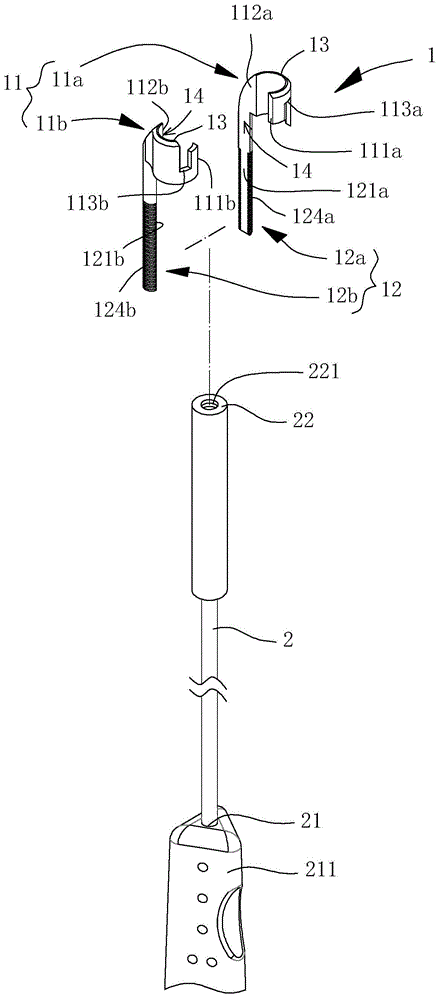

Micro-scalpel used to treat carpal tunnel syndrome

InactiveUS20120029542A1Reduce the number of cutsShorten the timeIncision instrumentsDiagnosticsCTS - Carpal tunnel syndromeCarpal tunnel surgery

A micro-scalpel used to treat carpal tunnel syndrome has an elongated columnar blade, one end of the blade obliquely cut to form a tip, the obliquely-cut surface of the tip sufficiently sharp to pierce and cut skin of a patient. The other end of the blade is connected to a hollow sleeve connector, and the hollow sleeve connector is combined with a handle. The micro-scalpel is oriented perpendicular to a transverse carpal ligament, and swings from its proximal end toward its distal end to cut the transverse carpal ligament, thereby reducing the number of cuts of the blade and saving time for completing the carpal tunnel surgery.

Owner:HUANG CHI YUEN

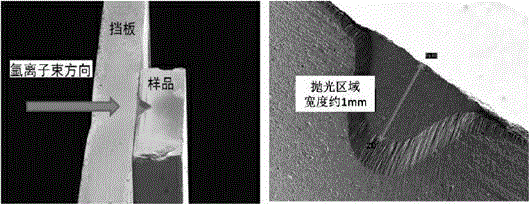

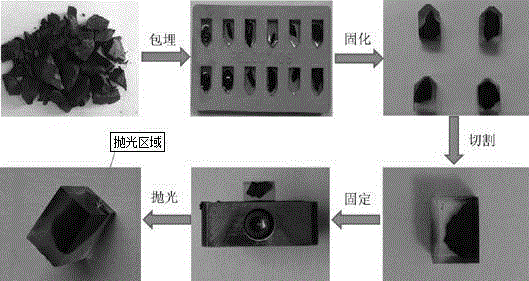

Argon ion polishing/scanning electron microscope analyzing and sampling method for shale samples

InactiveCN105067406ALower profileLower requirementPreparing sample for investigationScanning tunneling microscopeScanning electron microscope

The invention discloses an argon ion polishing / scanning electron microscope analyzing and sampling method for shale samples including fragile shale core samples and rock debris samples. The method comprises steps of embedding, curing, cutting and polishing. By comparison with a traditional argon ion polishing / scanning electron microscope analyzing and sampling method, the analysis range of the samples is widened with the method, the shale core samples which are fragile in the cutting and sampling processes and the shale rock debris samples with smaller sizes can be analyzed, and meanwhile, the success rate of sampling is increased.

Owner:CHINA PETROLEUM & CHEM CORP

Thread turning process

The thread turning process includes the following steps: 1. rough machining of workpiece with rough turning tool; and 2. correcting thread form and eliminating the accumulated error of thread to obtain the required machining precision with finishing tool. The present invention has reduced wear of the finishing tool and raised thread machining precision.

Owner:祁宝栋

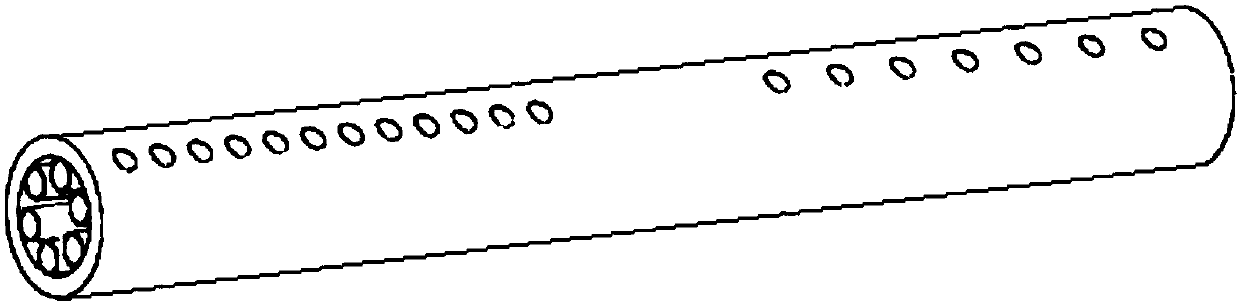

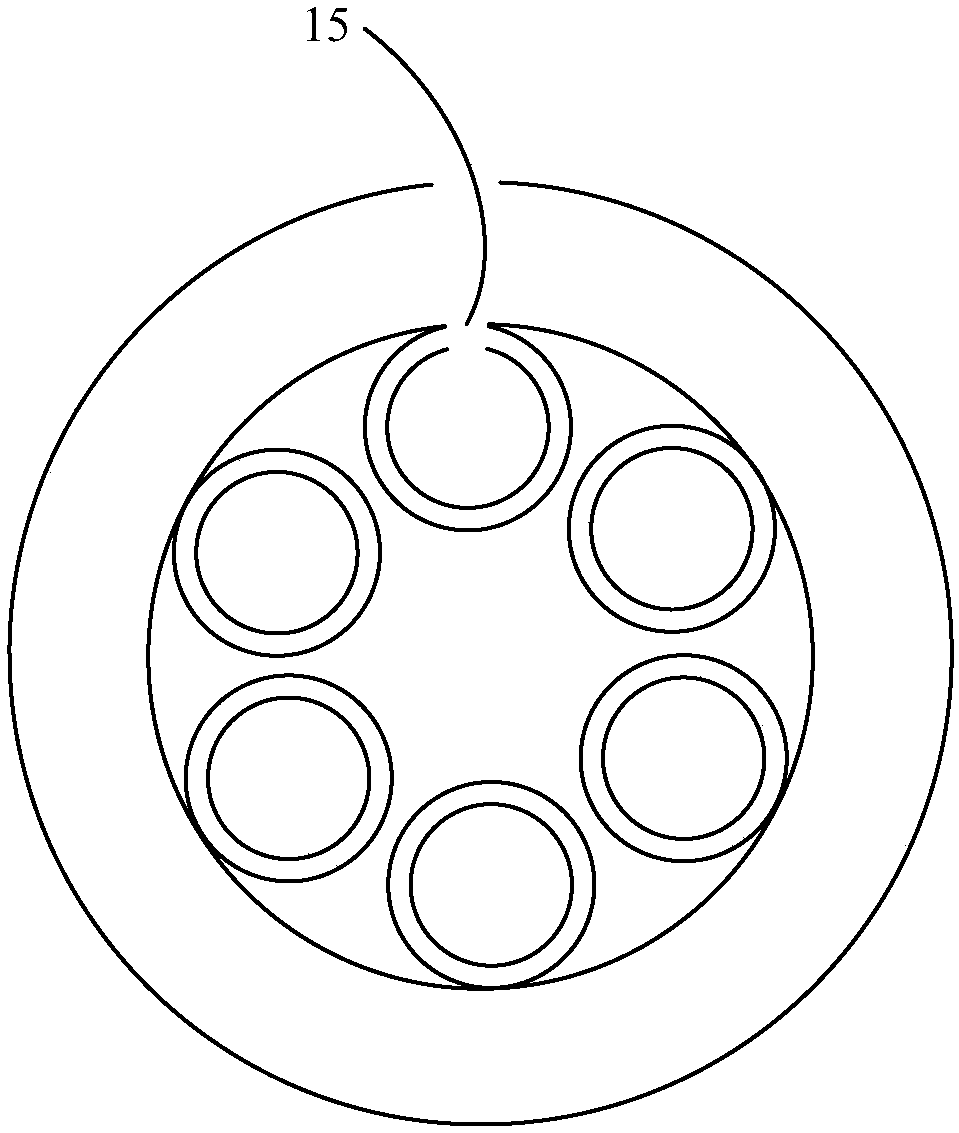

Sensing optical fiber and optical fiber sensing device

InactiveCN107941335AReduce weldingReduce the number of cutsCladded optical fibreOptical waveguide light guideFiberResonance

The invention provides a sensing optical fiber, and the optical fiber is a hollow anti-resonance optical fiber. The hollow anti-resonance optical fiber comprises a cladding region formed by a miniature capillary tube, a hollow tube, and a fiber core region which is surrounded by the cladding region. The hollow tube is disposed at an outer side of the cladding region in a cup joint manner. The refractive index of the fiber core region is lower than the refractive index of the cladding region. Each pre-selection position in each group of pre-selection positions on the side surface of the hollowtube is provided with a through hole, and all pre-selection positions in each group are arranged in the direction of the central axis of the sensing optical fiber. During the detection of various types of to-be-detected substances, the optical fiber can reduce the number of fusing and cutting times of the sensing optical fiber, reduces the workload of detection, and improves the accuracy of a detection result.

Owner:BEIJING UNIV OF TECH

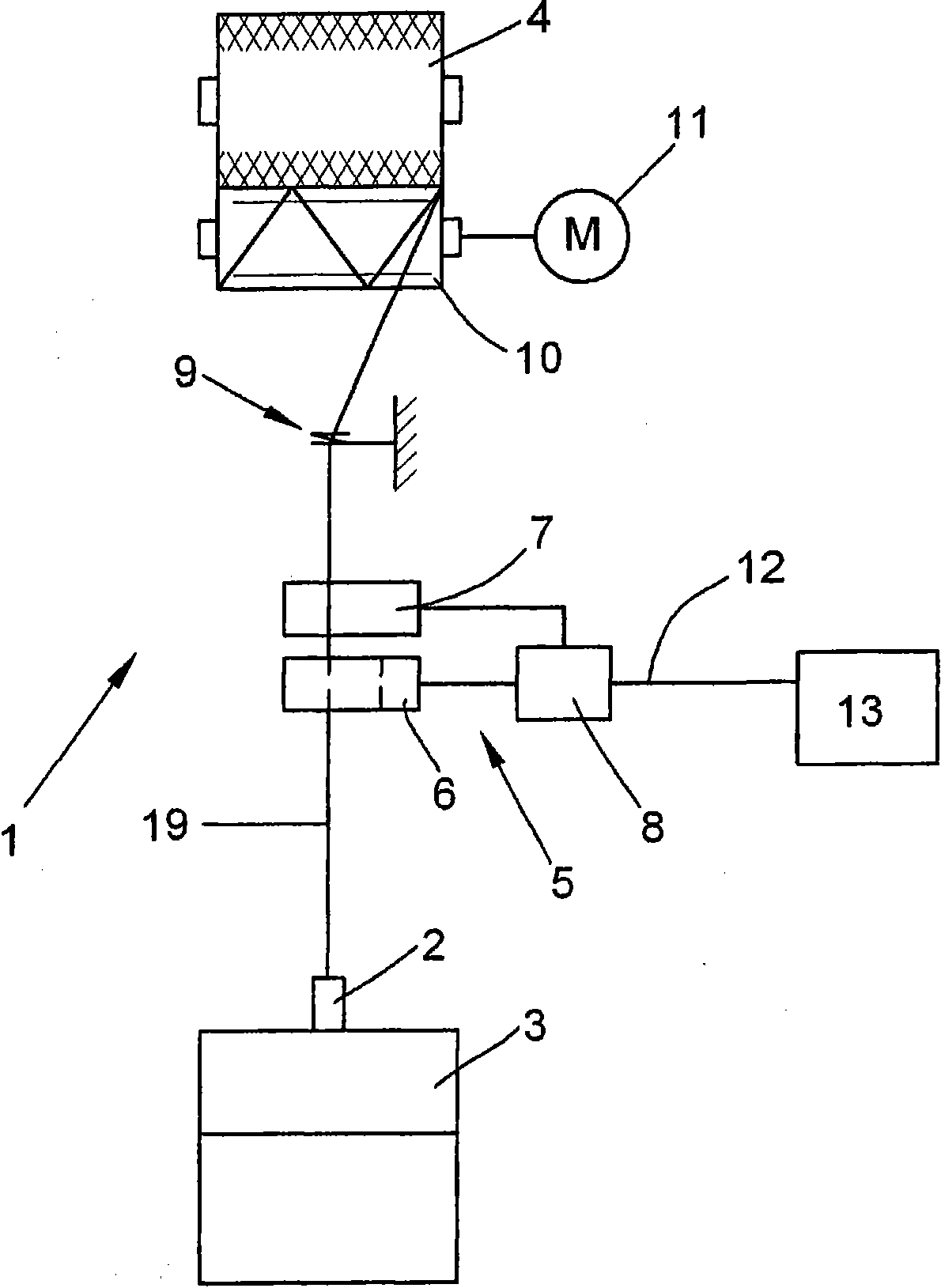

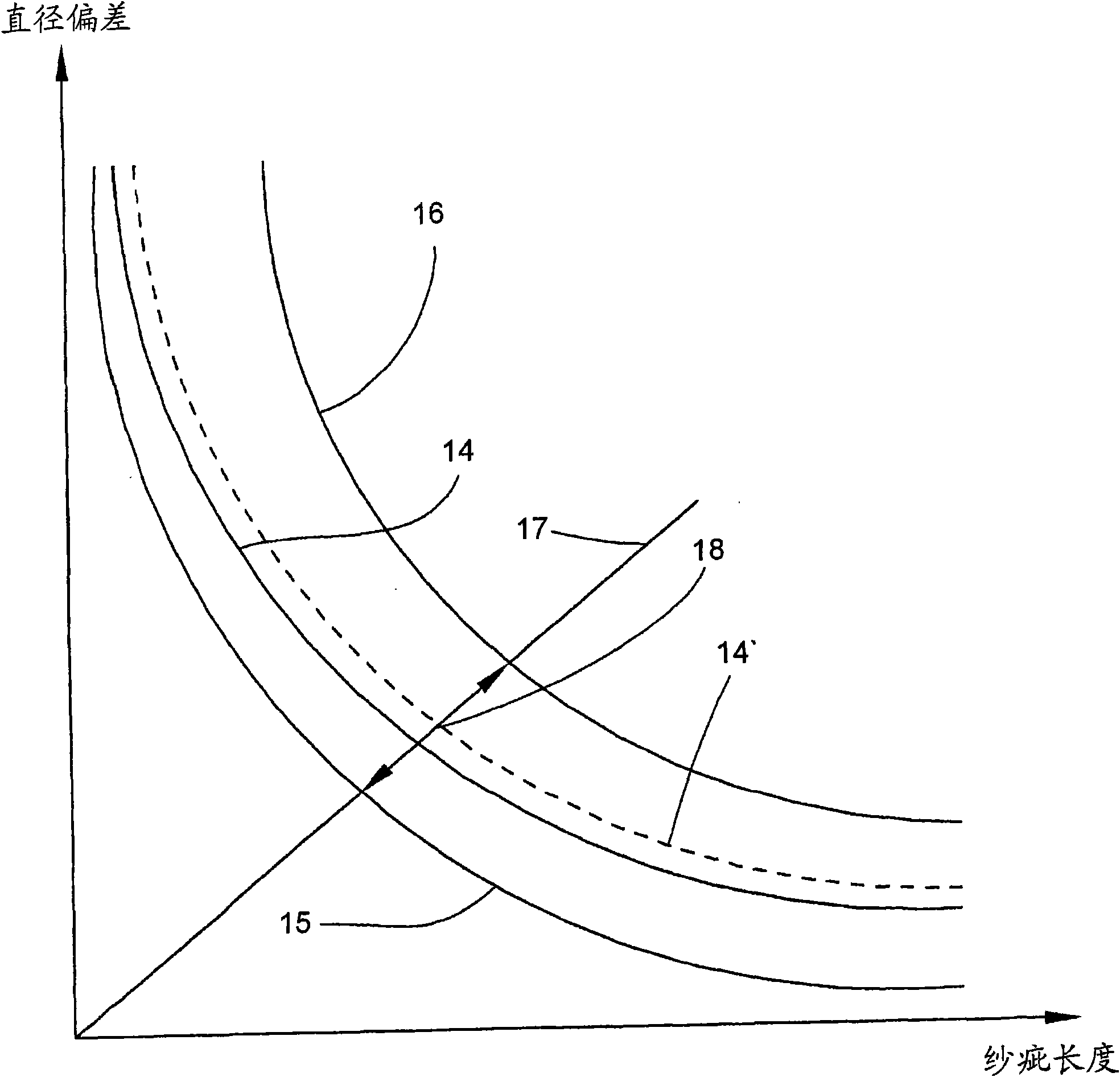

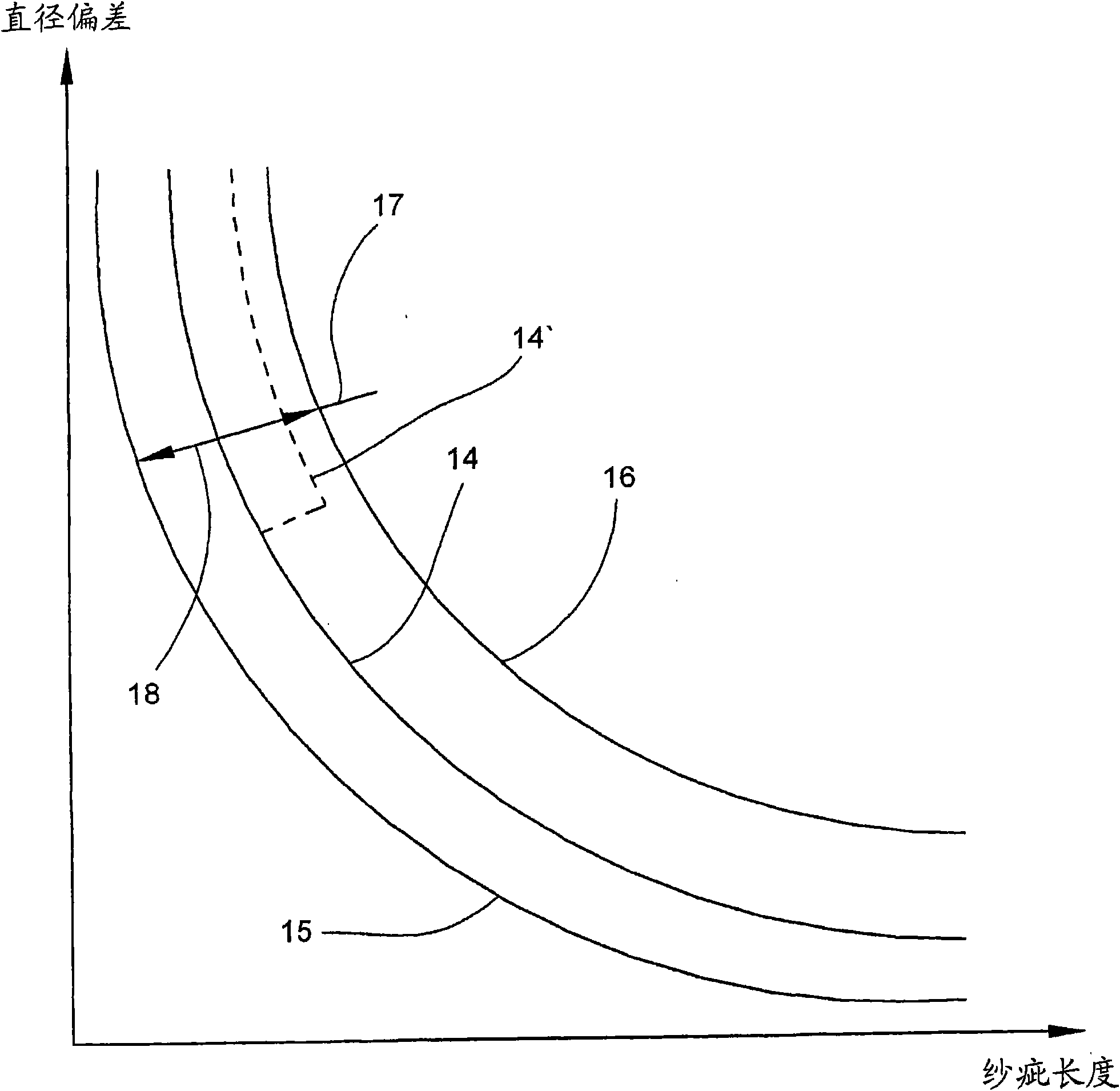

Method for quality monitoring of longitudinally moving yarn at workplace of textile machine

ActiveCN101648660AFlexible and automatic adjustmentLow winding qualityFilament handlingTextiles and paperYarnLower limit

The invention relates to a method for quality monitoring of longitudinally moving yarn at workplace of textile machine manufacturing cross-coil, wherein, the yarn fault is, related to the diameter deviation and longitudinal length of the yarn, estimated in the yarn by aid of an inspecting apparatus and an estimating apparatus, which is realized by comparing the diameter deviation with the clearing threshold value and removing the deviations positioned over the clearing threshold value, wherein, a width is set in a coordinate system for the position of the clearing threshold value and definedby an upper limit and a lower limit, wherein, the fluctuation of the diameter under the lower limit can not be estimated into the yarn fault, while each yarn fault over the upper limit is removed, andbased on the given yarn quality each time on the station, the clearing threshold value is changed in the way that the amount of the yarn fault located between the clearing threshold value and the lower limit and therefore being retained in the yarn can not exceed that of the predetermined yarn fault in the yarn in a unit of length or plane fabric in a unit of length made of the yarn dependent onthe quality.

Owner:SAURER GERMANY GMBH & CO KG

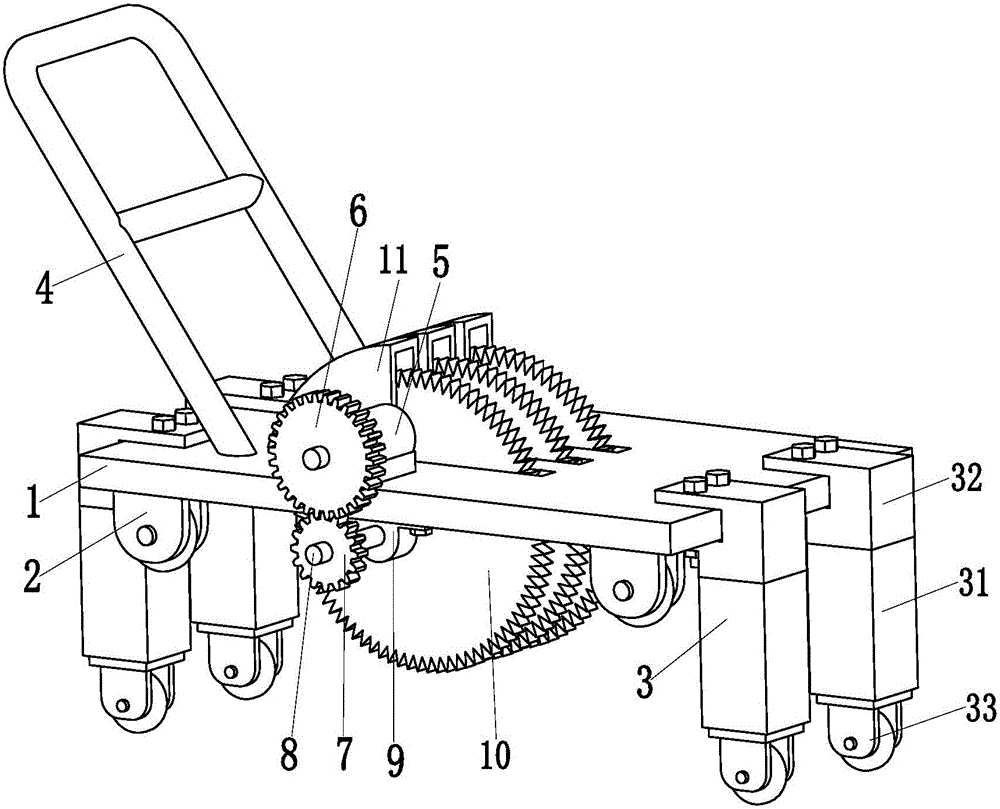

Diameter grading system for rhizome material

InactiveCN103406275AIncrease profitEasy to sort multiple timesCleaningGradingGrade systemEngineering

The invention discloses a diameter grading system for a rhizome material. The system comprises a rack, a rotating conveying chain, multistage rotating rollers and a material conveying device arranged below the multistage rotating rollers, wherein the multistage rotating rollers comprise a fixed roller and a moving roller which are arranged alternately and form a sorting gap; a fixed roller supporting plate and a moving roller adjusting and supporting plate are arranged at two ends of both the fixed roller and the moving roller respectively and arranged on the chain plates on the same side of the rotating conveying chain; the two ends of the fixed roller rotationally move along horizontal friction rails arranged on the rack; a plurality of gap set devices arranged in the conveying direction of the rotating conveying chain are arranged at two ends of the moving roller respectively; the plurality of gap set devices are relatively fixed and connected with the rack and form an integrated flat guide rail after mutually connected; the flat guide rail is arranged obliquely upwards in the material conveying direction; the sorting gap formed between the fixed roller and the moving roller is continuously enlarged in the conveying direction of the rotating conveying chain; a friction wheel fixedly connected with two ends of the moving roller rolls along the supporting surface of the flat guide rail under the driving of the rotating conveying chain.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +2

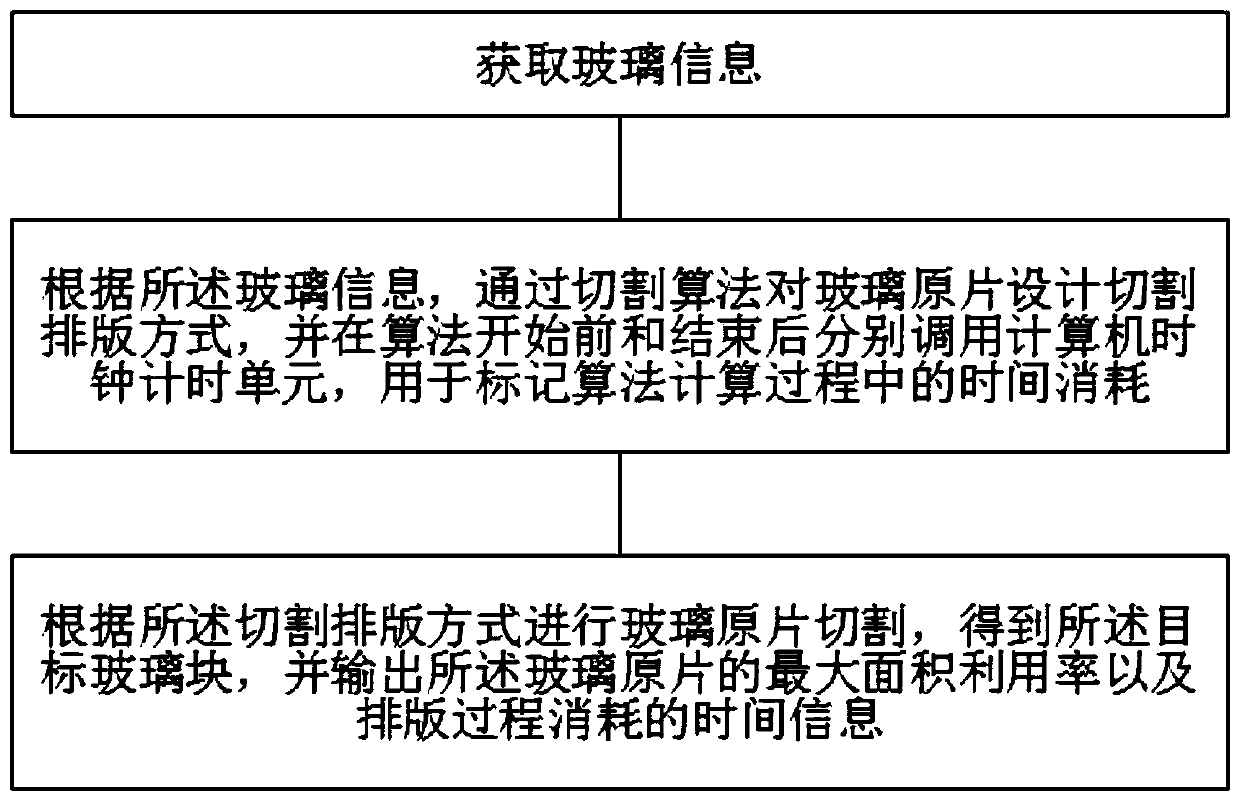

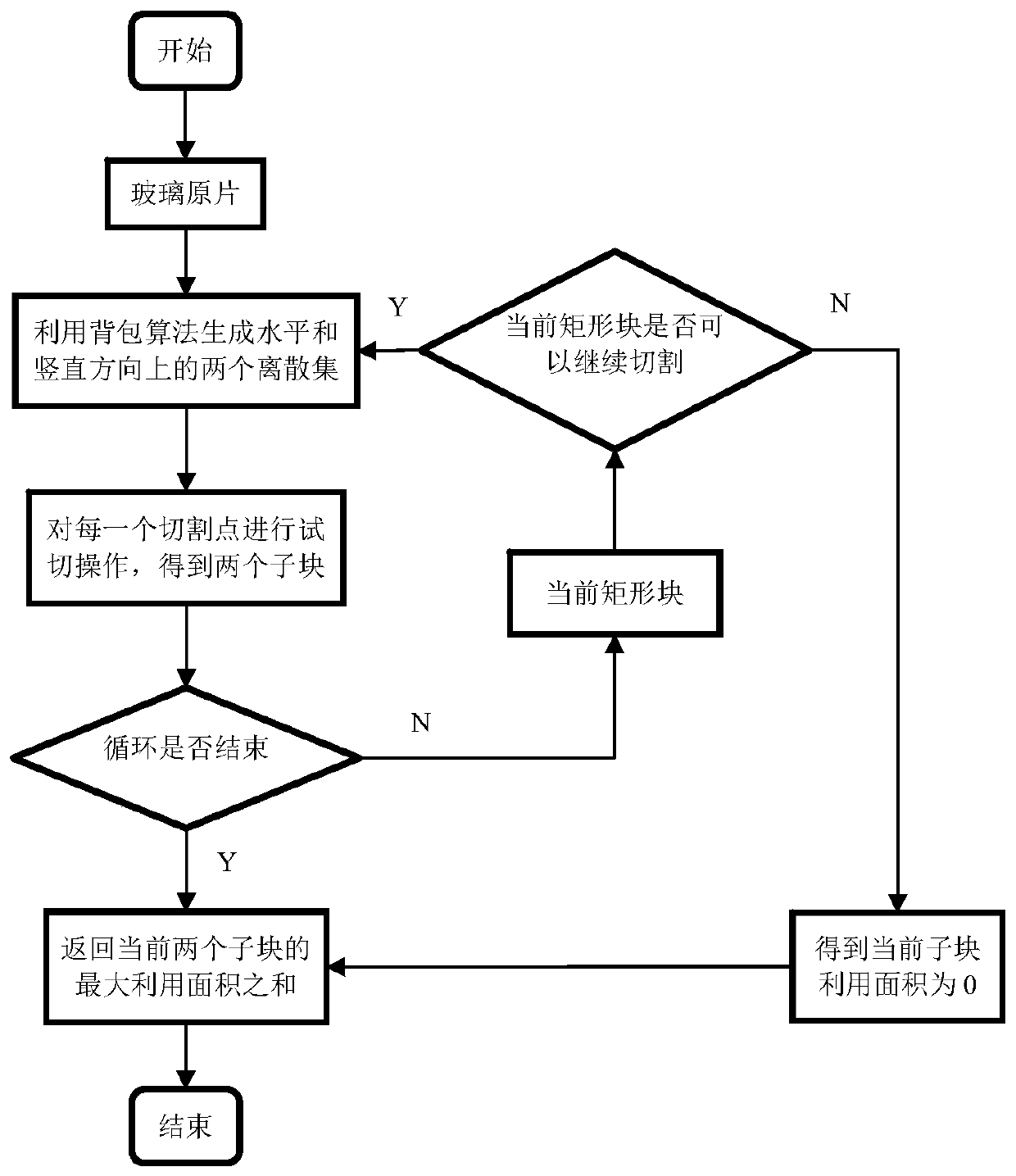

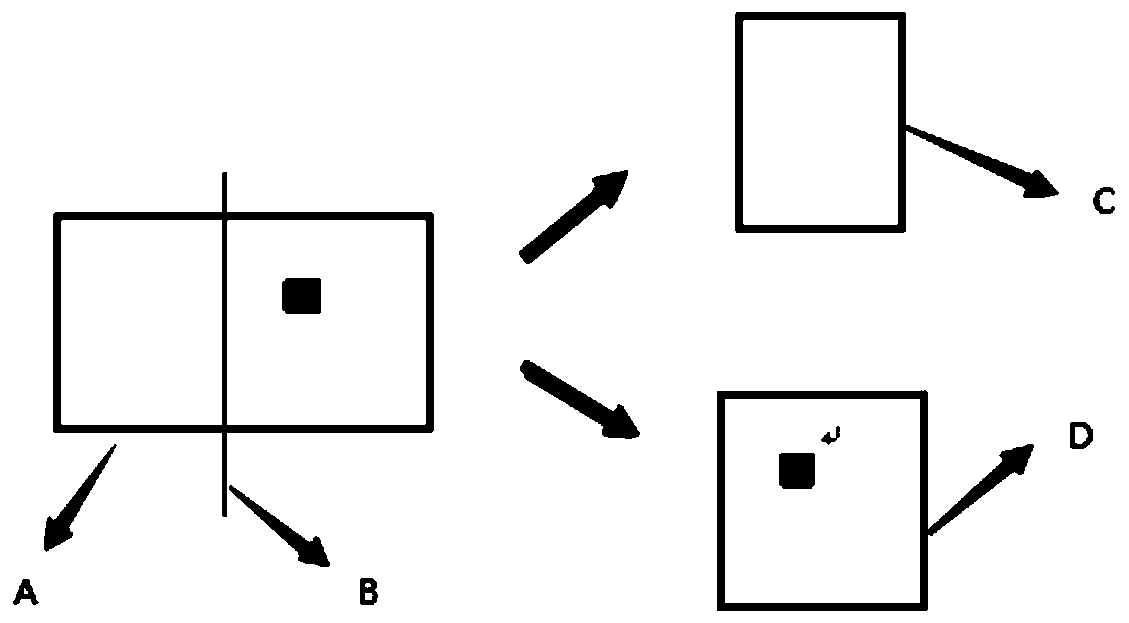

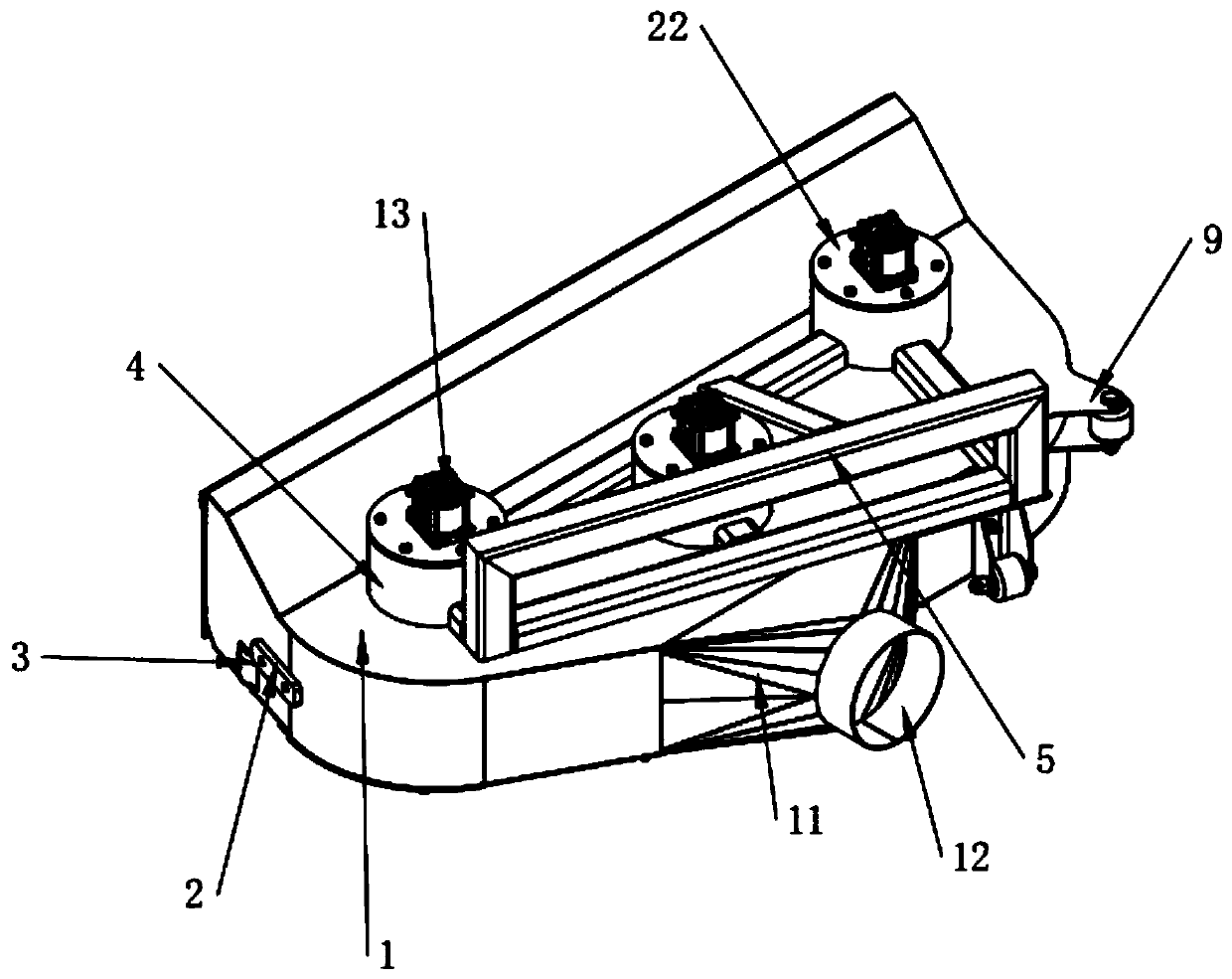

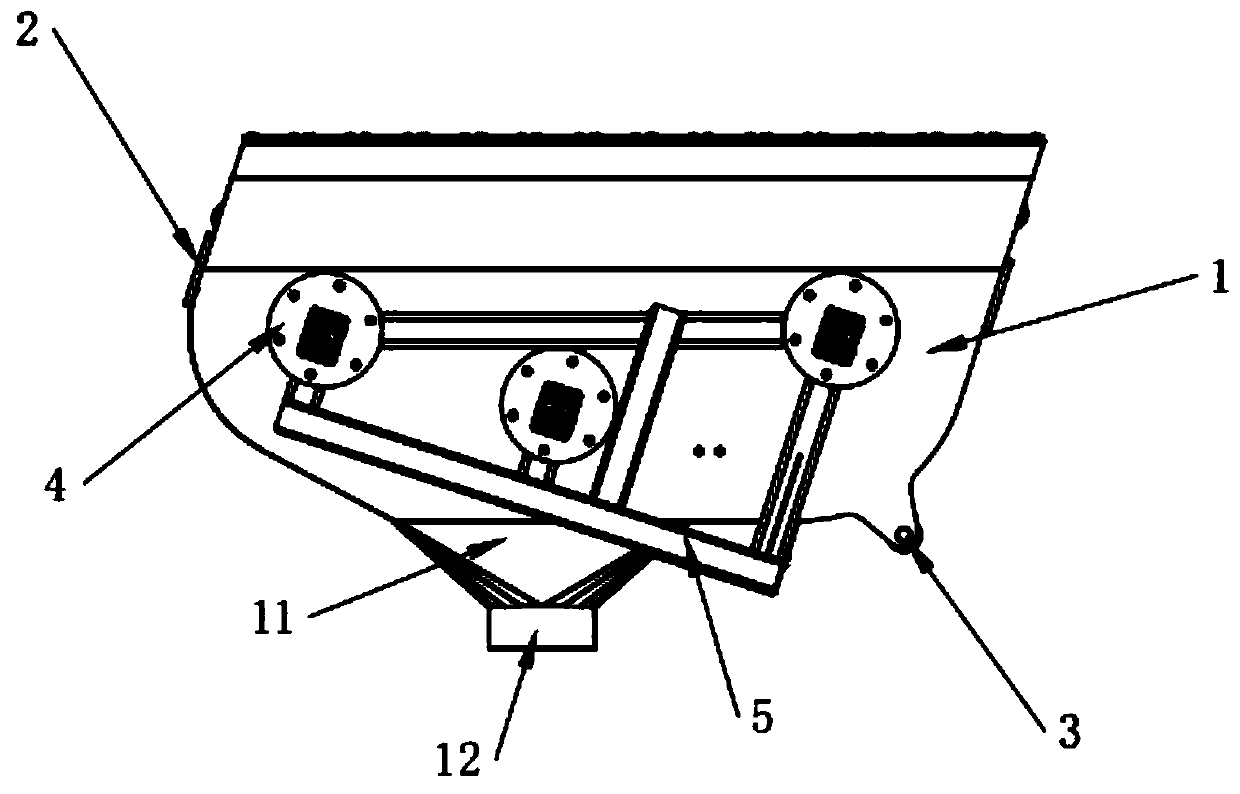

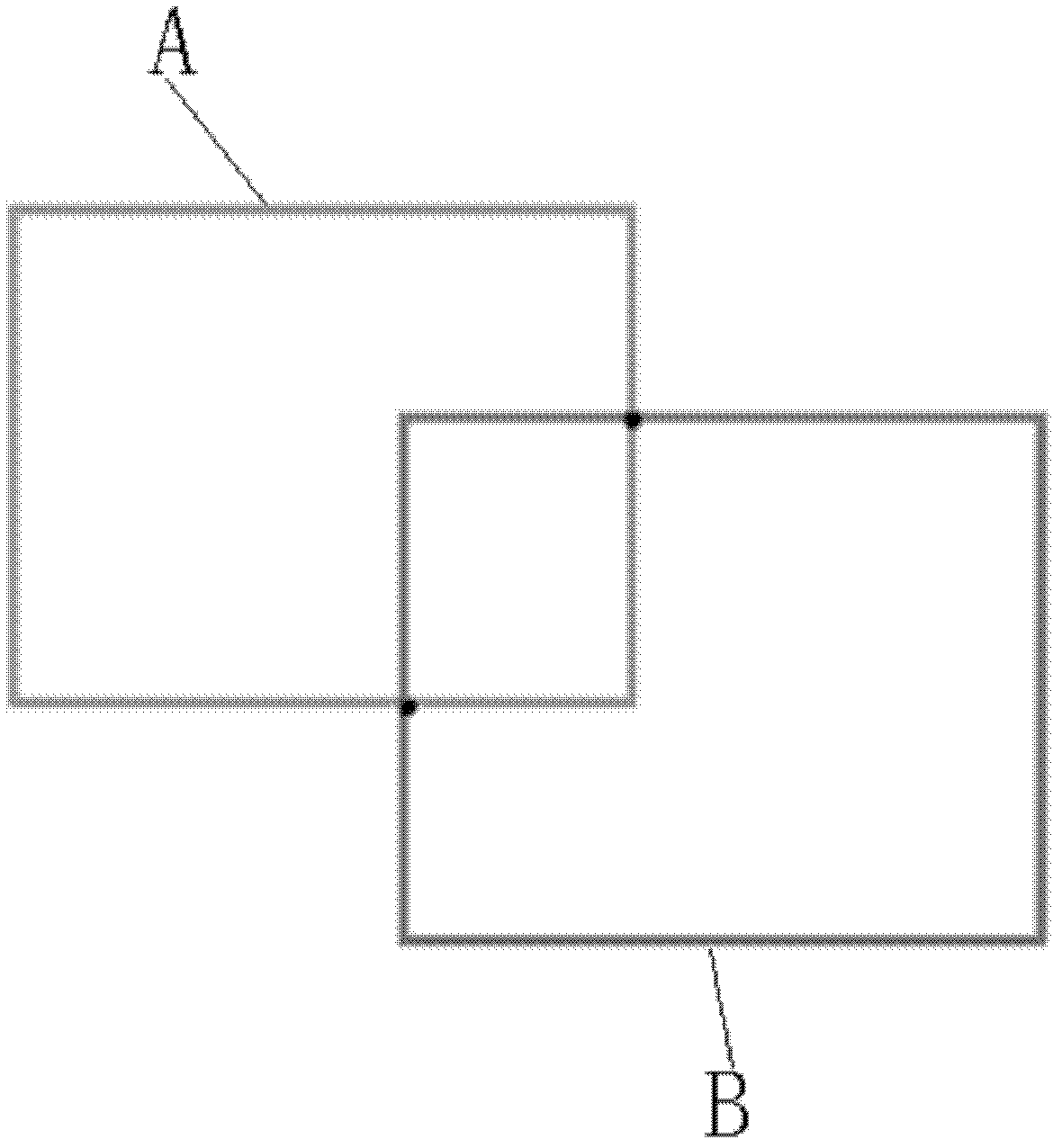

Implementation method of glass cutting optimization technology

ActiveCN111410414AGood segmentation accuracyGood accuracyGlass severing apparatusProcess engineeringGlass manufacturing

The invention discloses an implementation method of a glass cutting optimization technology, which relates to the technical field of glass manufacturing and comprises the following steps: acquiring glass information; according to the glass information, designing a cutting typesetting mode for the original glass sheet through a cutting algorithm, and calling computer clock timing units before and after the algorithm is started and are used for marking time consumption in the algorithm calculation process; and cutting the raw glass sheet according to the cutting and typesetting mode to obtain atarget glass block, and outputting the maximum area utilization rate of the raw glass sheet and the time information consumed in the typesetting process. According to the method, two plates with defects or not can be treated in a classified mode, different cutting strategies are used respectively, the actual production of the glass is combined, the cutting accuracy is guaranteed, the working efficiency is improved, meanwhile, the utilization efficiency of the plate area is improved, and the production cost is reduced.

Owner:JIANGXI UNIVERSITY OF FINANCE AND ECONOMICS

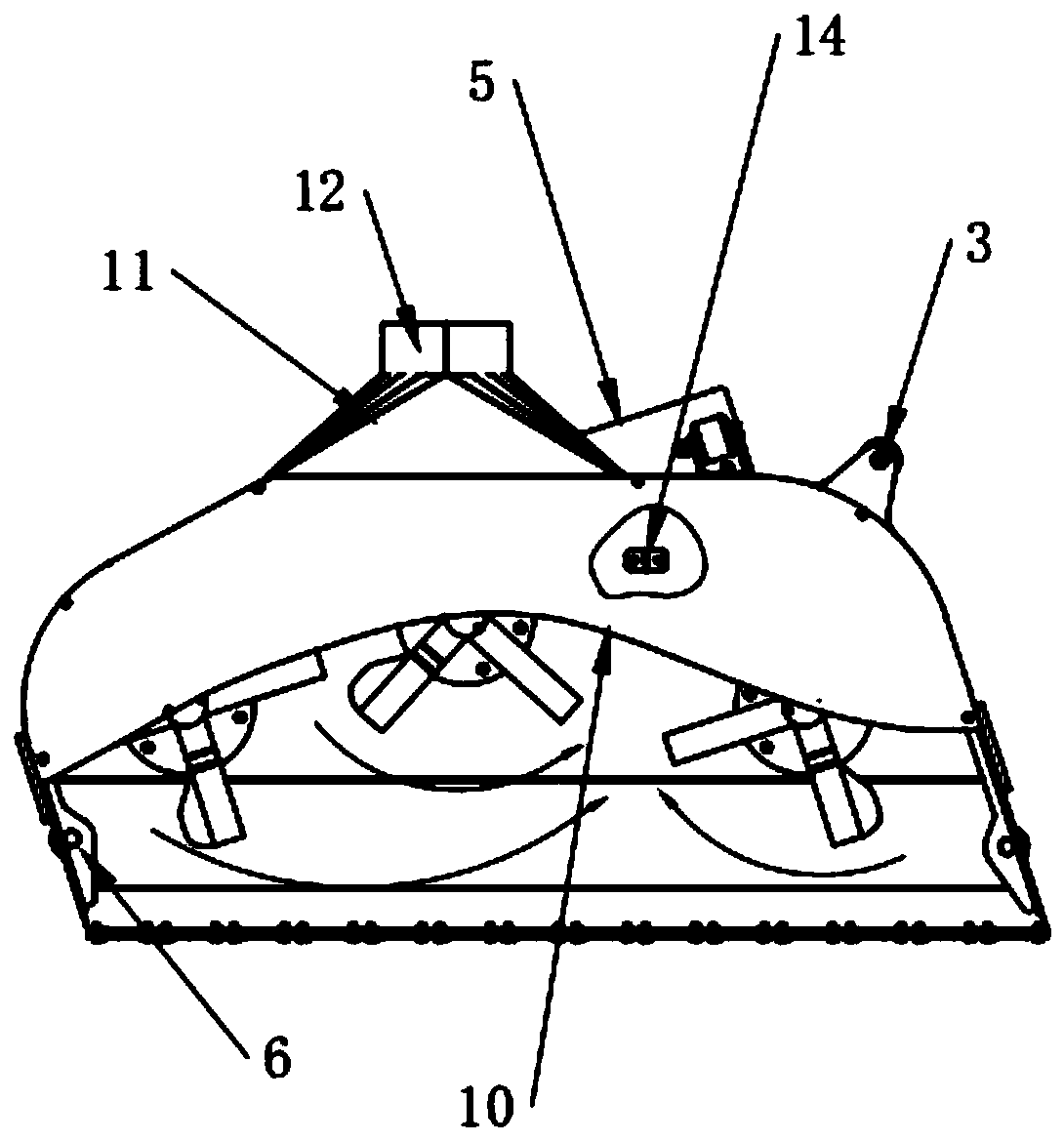

Hedge trimmer head

PendingCN110178571AEnhanced refinement rateIncrease the number of contacts and contact timeHedge trimming apparatusCuttersEngineeringMechanical engineering

The invention discloses a hedge trimmer head, and relates to the technical field of hedge trimmer tools. The hedge trimmer head comprises a casing, one end of the casing is provided with an opening, at least two rotating cutters are installed in the casing, the rotation directions of the two rotating cutters are opposite to each other in the feeding direction, the end face, opposite to the opening, of the casing is provided with a discharging port, and the discharging port is located between the two cutters. The hedge trimmer head solves the problems that in traditional technologies, since multiple cutters are in single contact with hedges for cutting, combined cutting cannot be formed, so that the throwing direction of branches is not fixed, and partial power is wasted; the branches are thrown on a highway pavement under the rotary cutting function of the cutters, and vehicles driven at high speed are influenced; broken branches obtained after trimming need to be manually broken off and cut off for the second time to facilitate bagging.

Owner:广州交投绿化建设有限公司 +2

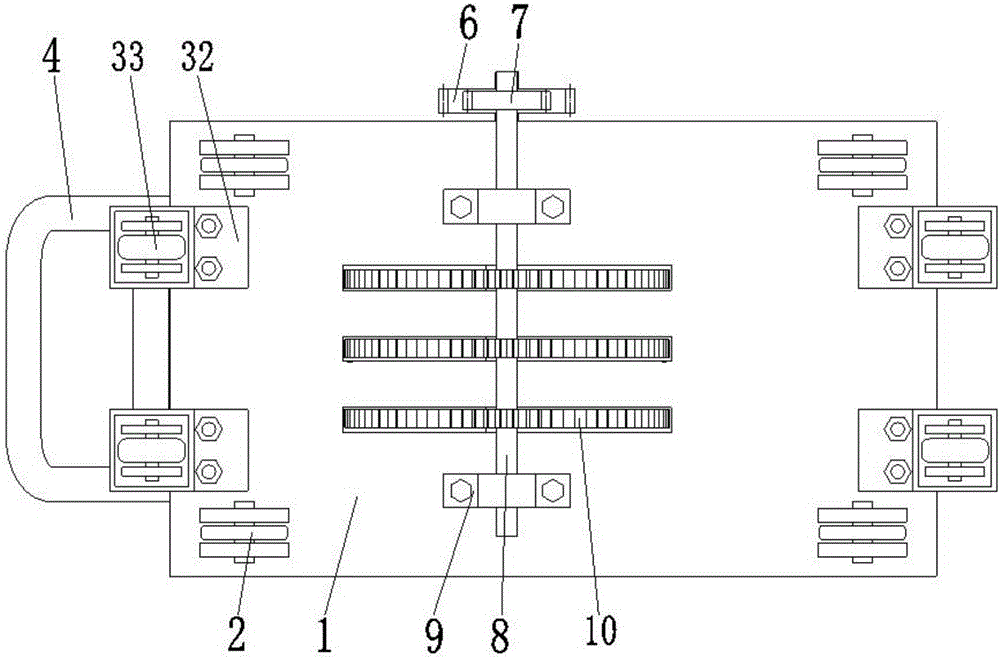

Bituminous concrete cutting device

The invention relates to a bituminous concrete cutting device which comprises a bottom plate. Four first universal wheels are symmetrically installed on the lower end face of the bottom plate. A handrail is mounted at the left end of the bottom plate obliquely. A drive motor is mounted on the front side of the bottom plate through a motor base. A drive gear is mounted on a drive shaft of the drive motor through a key. The drive gear is engaged with a driven gear which is mounted on a rotary shaft through a key. The two ends of the rotary shaft are symmetrically mounted on two support seats through bearings. The two support seats are mounted on the lower end face of the bottom plate through screws. Three cutting blades are evenly mounted on the rotary shaft. Three mud stop frames are arranged at the edges of three cutting ports in the bottom plate correspondingly. According to the bituminous concrete cutting device, the function that a plurality of cutting blades can be used for cutting simultaneously is achieved; the cutting device has the advantages of being short in cutting time, high in cutting speed and working efficiency and the like; and the reciprocating cutting frequency is remarkably decreased, and the labor intensity is relieved.

Owner:高聪聪

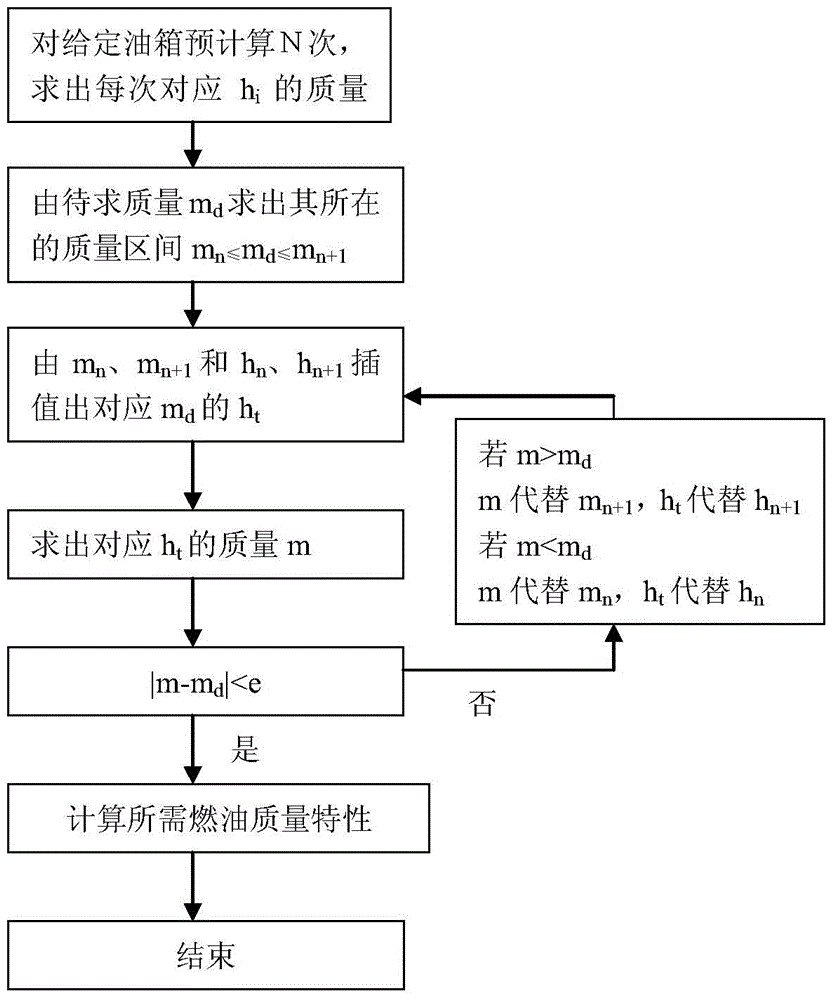

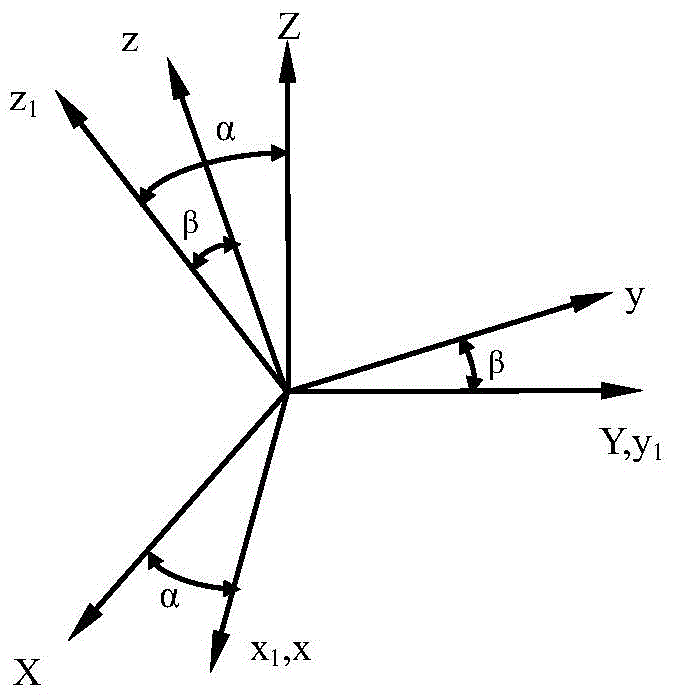

Method for determining fuel quality characteristics of aircraft based on finite element method

InactiveCN105718619AReduce the number of cutsMeet design needsSpecial data processing applicationsSequence designFuel tank

The invention belongs to the technical field of flight vehicles overall design, and especially relates to a method for determining fuel quality characteristics of an aircraft. The invention significantly improves the calculation efficiency of the fuel quality characteristics, and solves the problem of the calculation of the fuel quality characteristics under arbitrary attitude angles. The method can calculate the fuel quality characteristics of fuel in a fuel tank under arbitrary attitude angles. In order to improve the efficiency, an interpolation method is used in a quality characteristic calculation process, the number of cutting of a text format fuel tank file can be reduced from the order of magnitude, the computational efficiency can be improved, and the obtained fuel quality characteristics data satisfy an accuracy requirement. The technology has been successfully applied to the domestic oil consumption sequence design of multiple models and fuel quality characteristics calculation, and the needs of model design can be satisfied.

Owner:AVIC CHENGDU AIRCRAFT DESIGN & RES INST

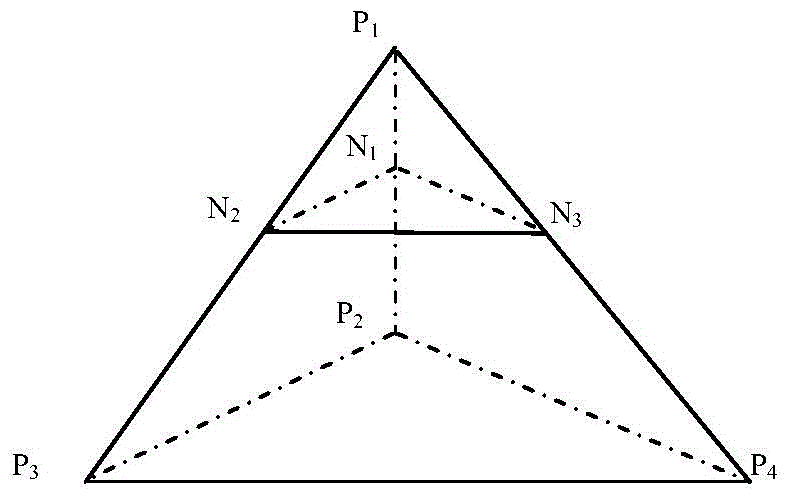

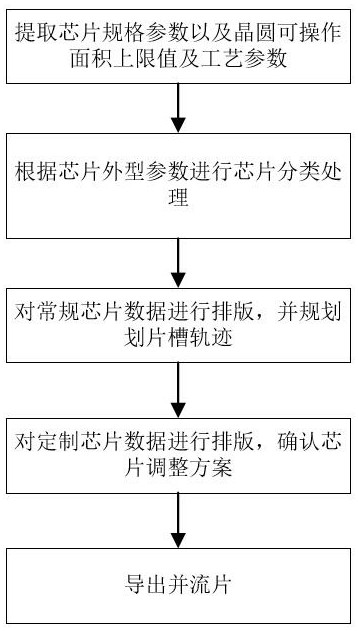

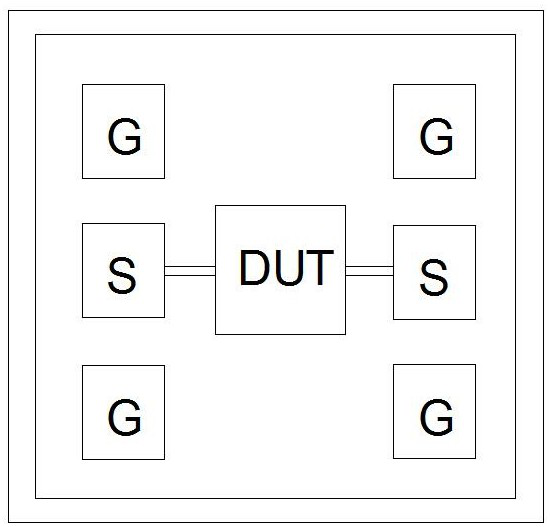

Cutting layout design method suitable for introducing customized chip and chip prepared by cutting layout design method

ActiveCN114548019AGuaranteed cutting efficiencyReduce the risk of secondary cuttingCAD customisation/personalisationSolid-state devicesProgramming languageLayout

The invention discloses a cutting layout design method suitable for introducing a customized chip and a chip prepared through the cutting layout design method, and belongs to the technical field of semiconductors. Chip classification processing is carried out according to chip appearance parameters, and conventional chip data and customized chip data are obtained; performing typesetting calculation according to the conventional chip data and the upper limit value of the operable area of the wafer, and outputting all layout design sketches with penetrating scribing grooves; and performing secondary design on the reserved position in the layout design sketch according to the customized chip data, and outputting a secondary layout design sketch. According to the method, a conventional chip is firstly subjected to typesetting design to obtain a layout design sketch penetrating through a scribing groove, so that the secondary cutting risk is greatly reduced; under the condition that the area is reserved, the scribing groove design of the customized chip is planned, the overall change of the layout design sketch is controlled within the minimum range, and the layout design sketch compatible with the customized chip is obtained on the basis that conventional chip layout is not affected, so that the layout cutting yield and efficiency are guaranteed.

Owner:成都复锦功率半导体技术发展有限公司

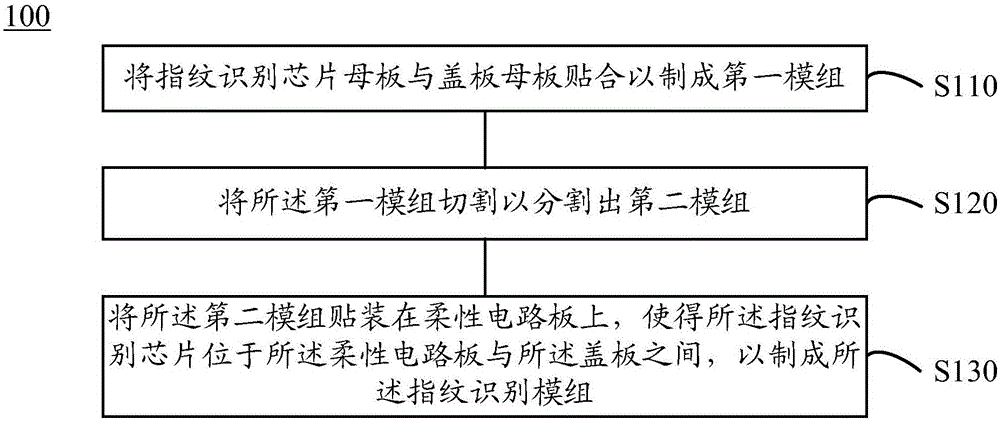

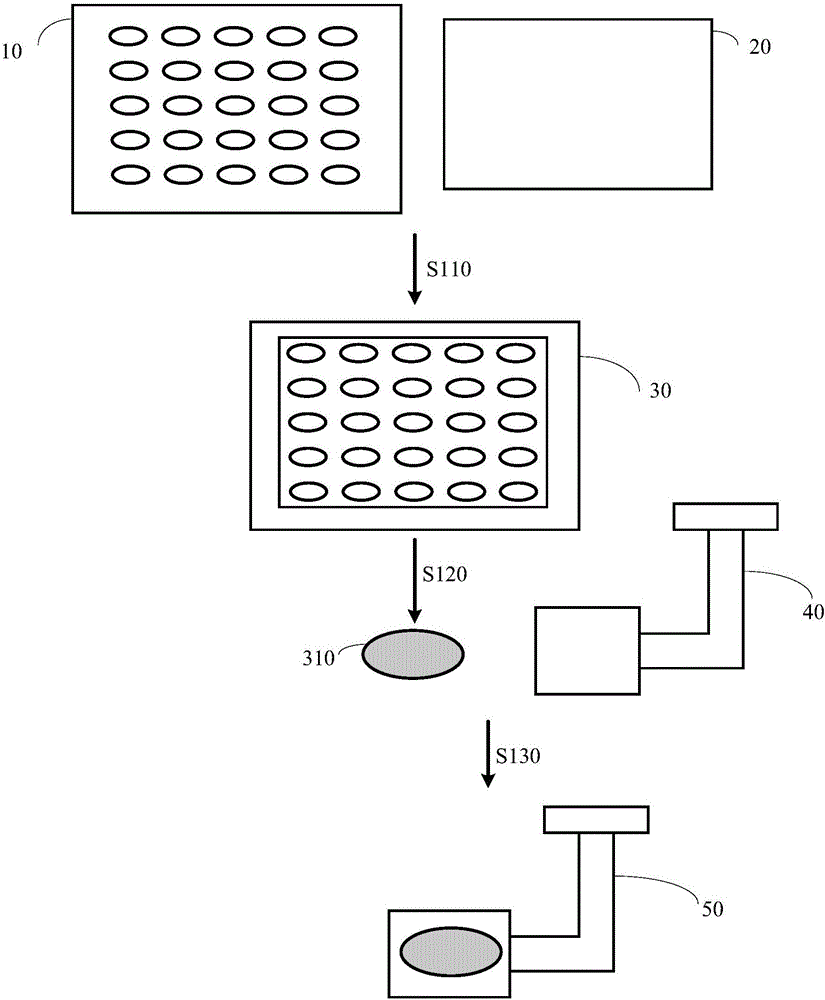

Manufacturing method of fingerprint recognition module

ActiveCN106384105AReduce the number of cutsReduce the number of bondingCharacter and pattern recognitionPattern recognitionFlexible circuits

The invention discloses a manufacturing method of a fingerprint recognition module, comprising the following steps: jointing a fingerprint recognition chip motherboard and a cover plate motherboard to make a first module, wherein the fingerprint recognition chip motherboard comprises multiple fingerprint recognition chips arranged in an array, and the cover plate motherboard comprises multiple cover plates arranged in an array; cutting the first module to get second modules, wherein each second module includes the fingerprint recognition chip and the cover plate which are jointed together; mounting the second modules on a flexible circuit board to make the fingerprint recognition chips disposed between the flexible circuit board and the cover plates, so as to get the fingerprint recognition module. By using the manufacturing method of a fingerprint recognition module provided by the invention, the production efficiency can be improved.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

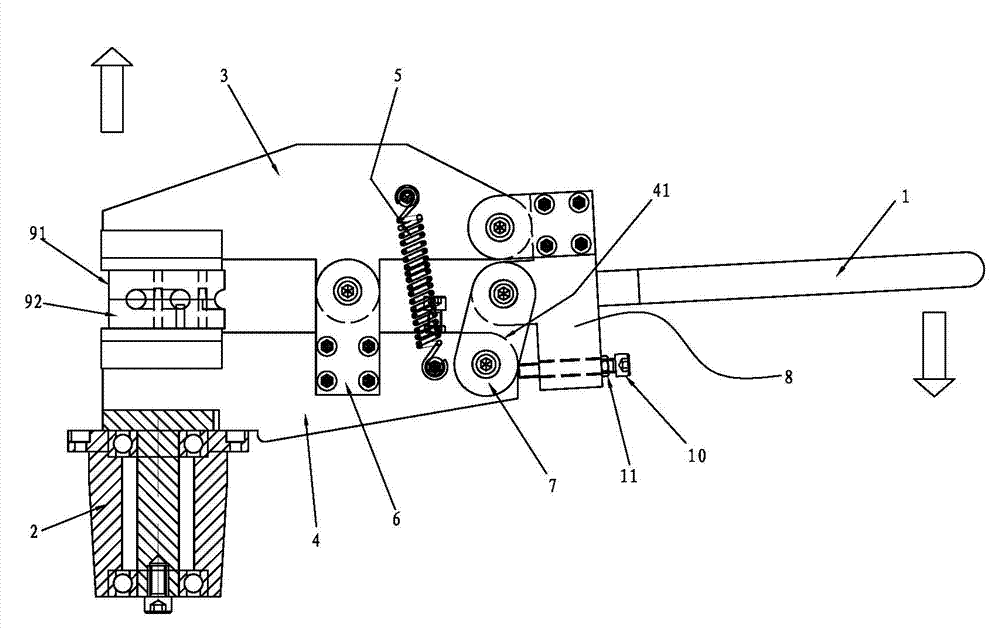

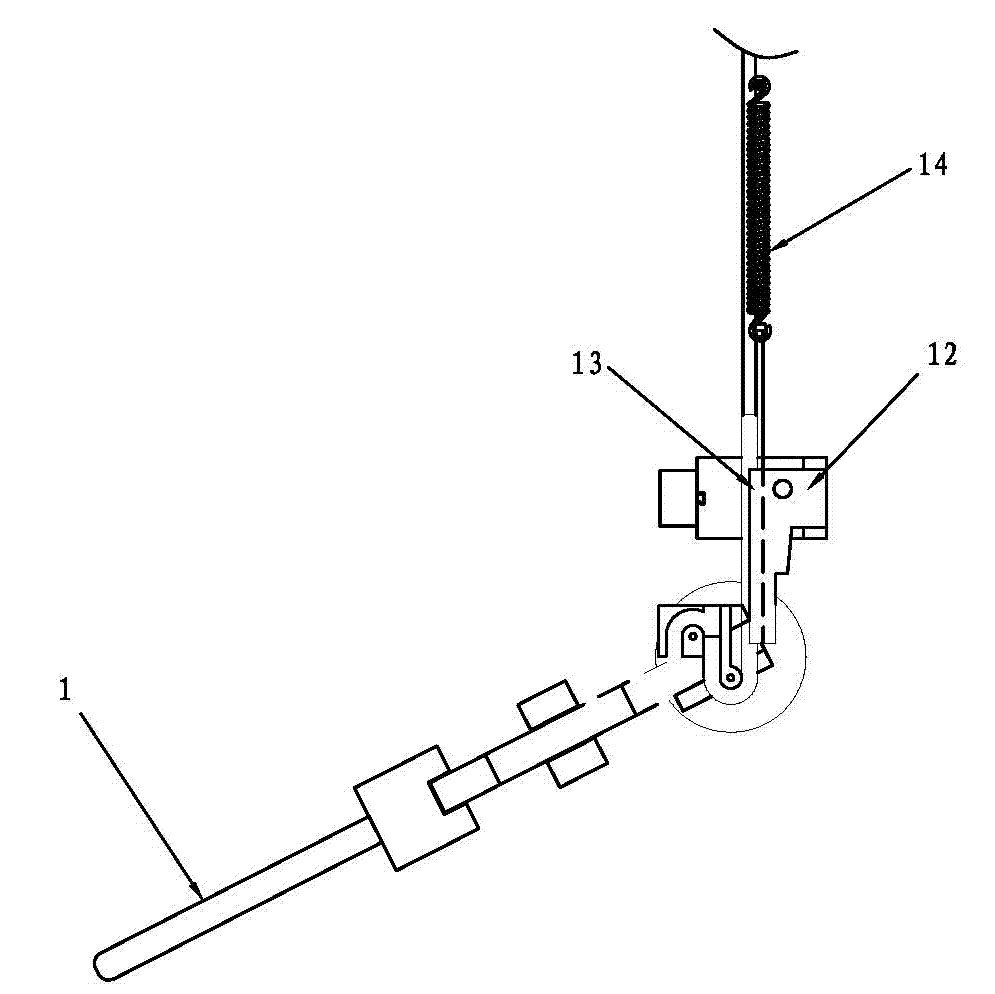

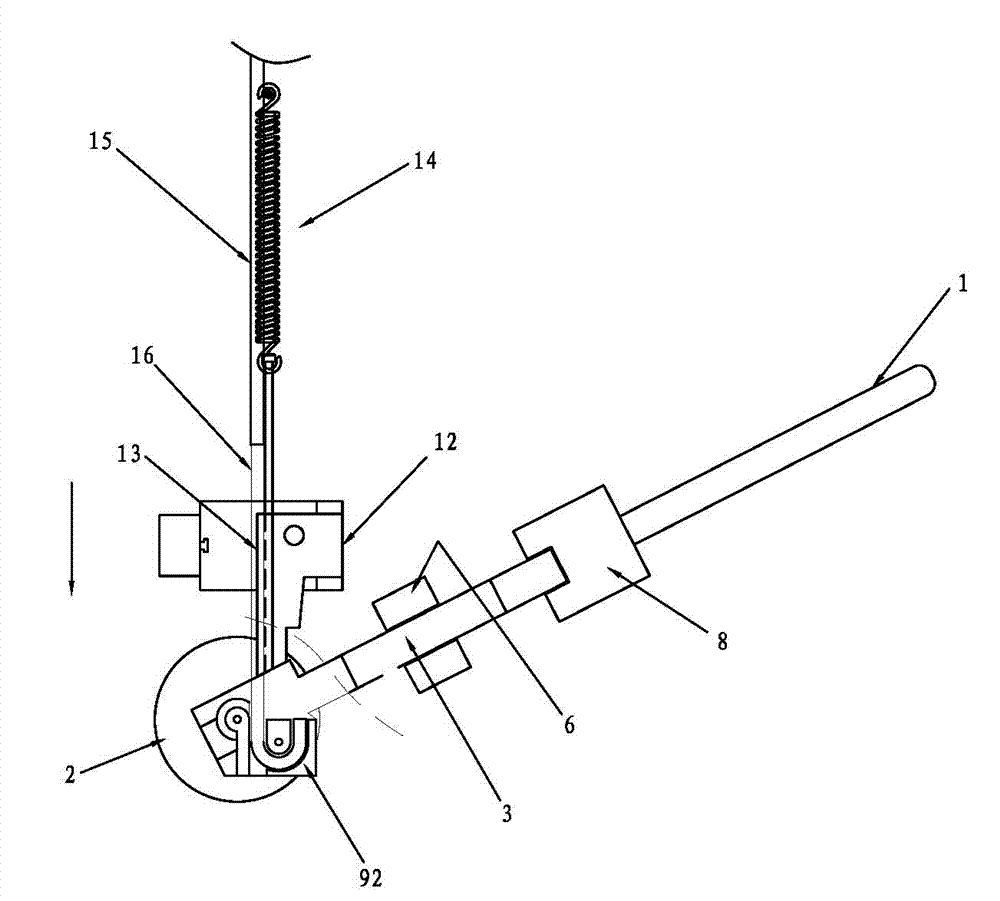

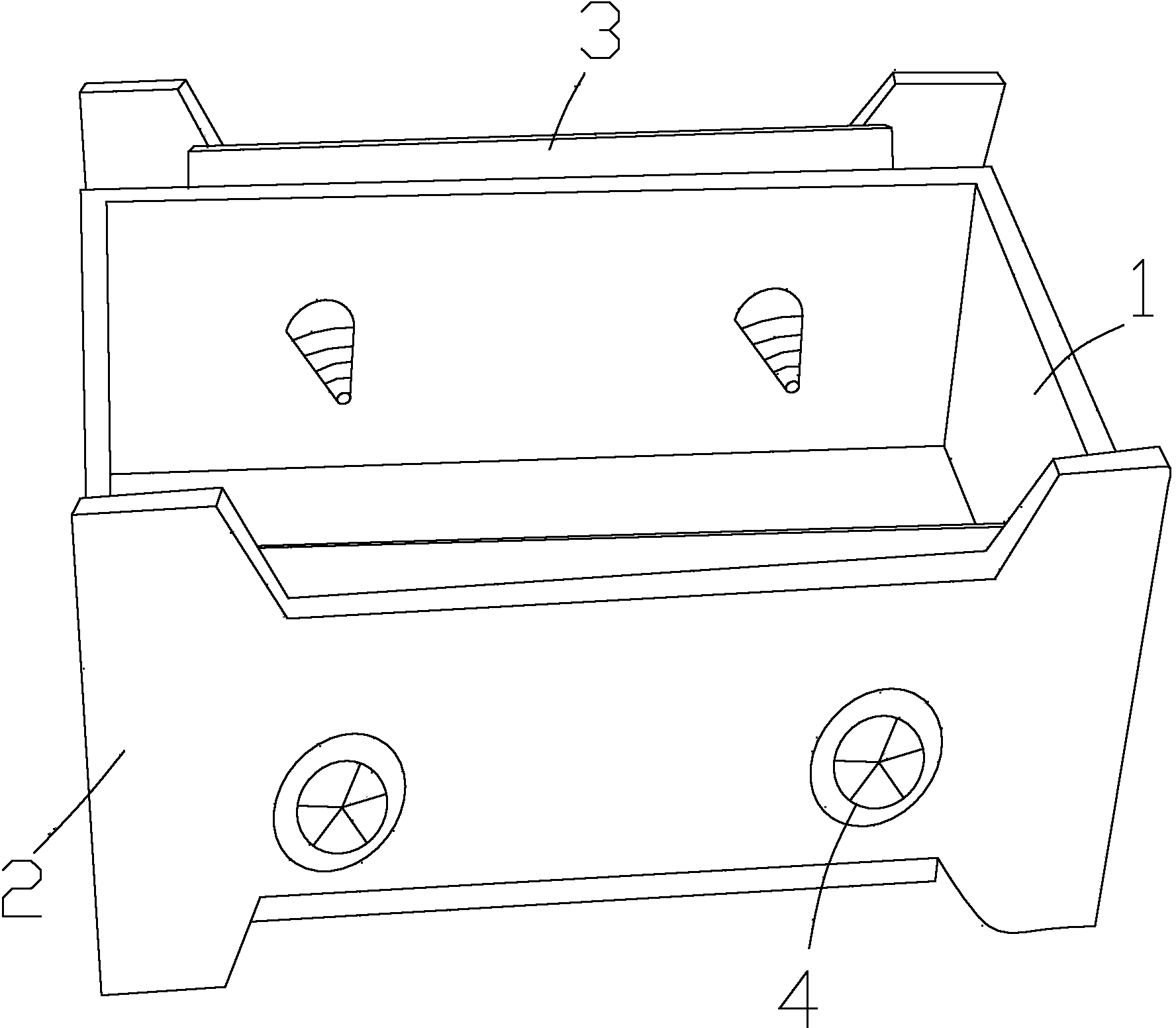

Processing device for U-shaped tubes

The invention discloses a processing device for U-shaped tubes. The processing device for the U-shaped tubes comprises a base, modules, an operating rod and a guiding device and also comprises a rotary support seat, an upper fixture block, a lower fixture block, a tension spring, a support plate, an articulation block and a pressing block, wherein the lower end of the support plate is fixedly connected with the middle part of the lower fixture block; the upper end of the support plate is pivotally connected with the middle part of the upper fixture block; one end of the articulation block is pivotally connected with the other end of the lower fixture block; the other end of the articulation block is pivotally connected with the middle part of the pressing block; the top part of the pressing block is pivotally connected with the other end of the upper fixture block; U-shaped necks, line grooves and tube body guiding locations of the upper module and the lower module are arranged in the manner of image; and the operating rod and the pressing block are fixedly connected. As such a structure is adopted, and a tubular product adopted by the processing device is longer than a tubular product used in the prior art, the cutting time is reduced, and the tubular product is saved. One tubular product with certain length can be processed into a plurality of U-shaped tubes connected with each other, and then, the U-shaped tubes are cut into a plurality of U-shaped tube units at a time. The processing device for the U-shaped tubes has the advantages that the work efficiency is high; scrap materials are reduced; the raw material is saved; and especially for a copper tubular product, the cost is greatly reduced.

Owner:GUANGDONG XIANGJI ELECTRICAL APPLIANCE

Production method and using method of simple carya illinoensis budding knife

The invention relates to the technical field of grafting, in particular to a production method and a using method of a simple carya illinoensis budding knife. The methods can be applied to carya illinoensis as well as to fruit tree grafting and flower and tree grafting. The methods are characterized in that two congruent figure blades are fixed on two sides of a supporter via a firm support to enable length and shape of slices on a stock and a scion to be identical. By using of the budding knife, cutting frequency dung budding can be reduced, working efficiency is improved, two parts cut on the scion and the sock can be ensured to be closely fitted, and grating survival rate can reach above 95% and is increased greatly.

Owner:阜阳市林业科学技术推广站 +1

Three dimensional Boolean calculating method for quantity survey in construction

ActiveCN102662915AReduce the number of cutsImprove stabilityComplex mathematical operationsComputer scienceCalculation methods

The invention discloses a three dimensional Boolean calculating method for quantity survey in construction. First, a subtraction relational expression of members to be calculated is analyzed according to civil engineering calculating rules. Then, for each correlation members in the subtraction relational expression, all segmentation lines between original geometric bodies are calculated according to intersection and overlapping relation of the original geometric bodies; each original geometric body is cut one time according to the segmentation lines, all the facets of the cut geometric bodes are analyzed to obtain the positional relation of the facets relative to the original geometric bodies of the correlation members; the corresponding geometric bodies are calculated by collecting the facets according to the positional relation of facets; and at last, the parameters of the corresponding geometric bodies are analyzed and are substituted in the corresponding formula used for calculating geometrical quantity to obtain geometrical quantity of corresponding geometric bodies. The three dimensional Boolean calculating method for quantity survey in construction improves stability and calculating speed, and can in real time render three dimensional geometric bodies obtained by calculating.

Owner:CHENGDU PENGYE SOFTWARE

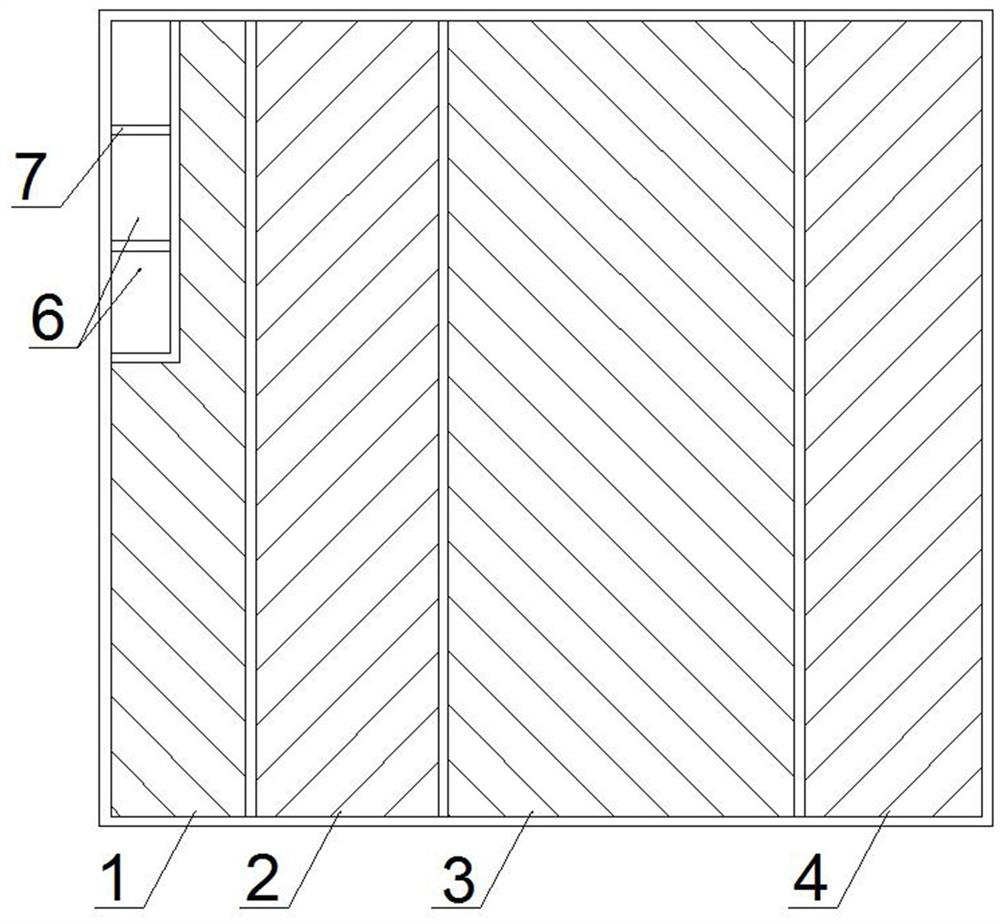

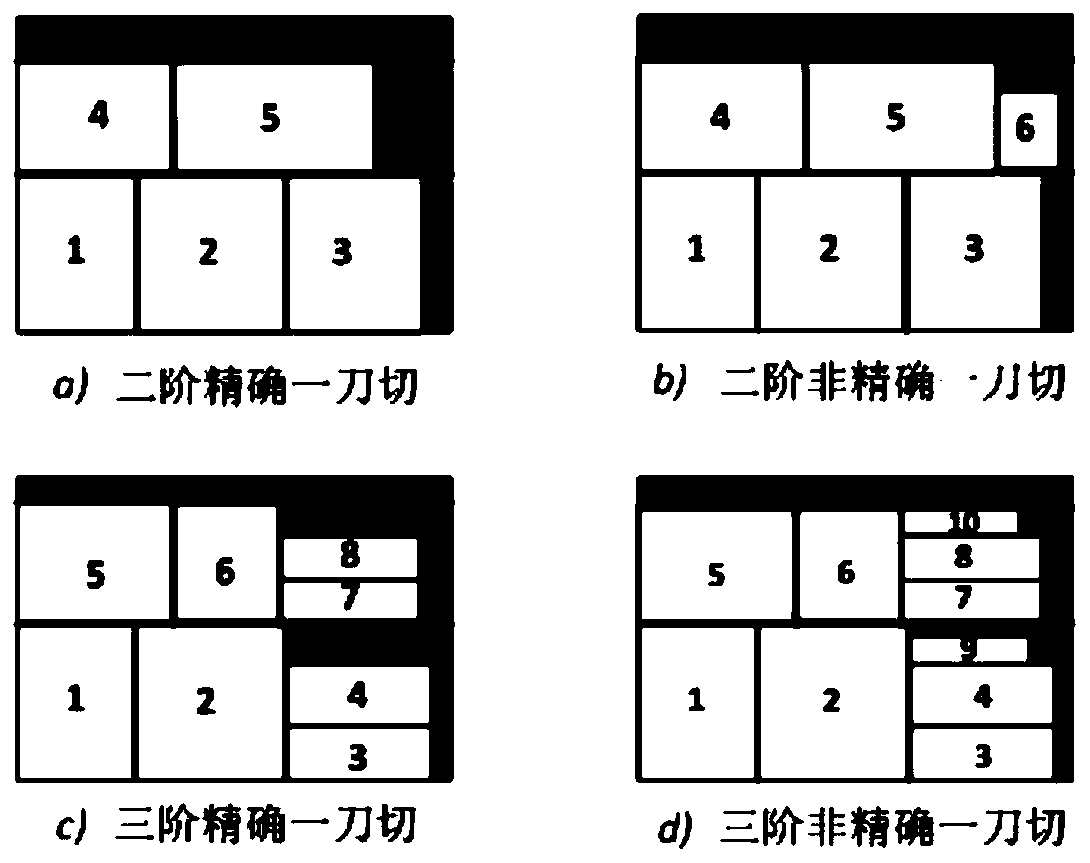

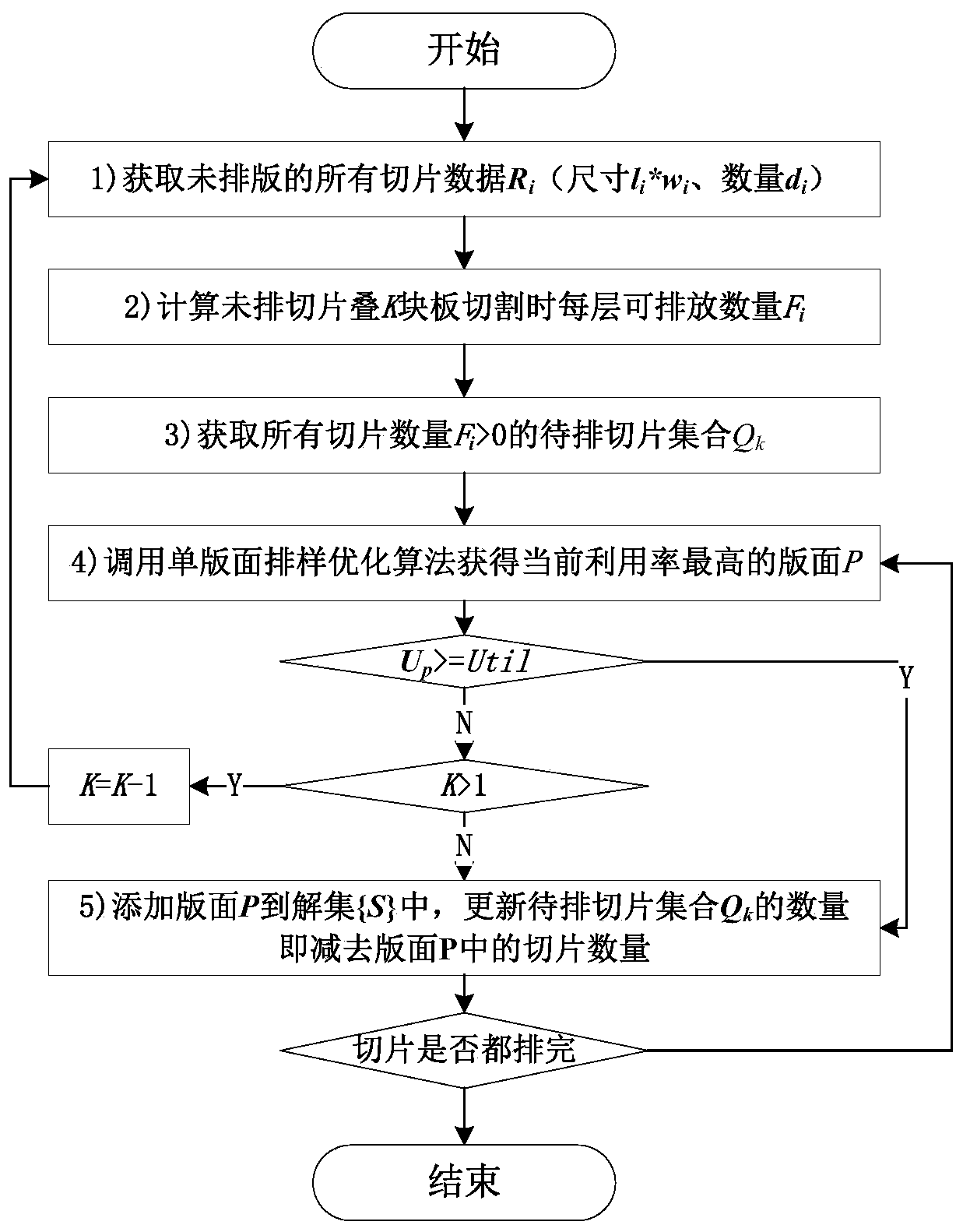

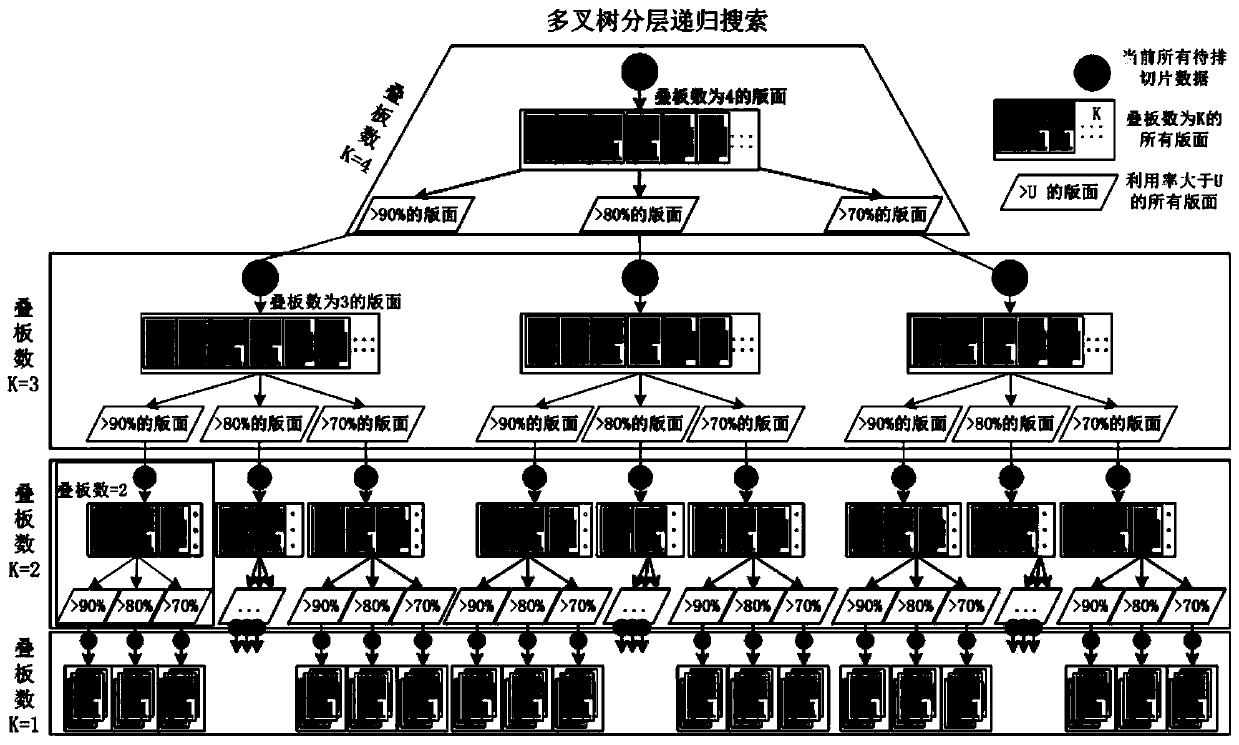

Layered iterative layout optimization method considering cutting efficiency and utilization rate

The invention discloses a layered iterative layout optimization method considering cutting efficiency and utilization rate. The method comprises the following steps: establishing a model: establishinga multi-objective optimization model for minimizing the total cost in combination with the cutting efficiency and the utilization rate; slice typesetting is conducted, specifically, stacked slices are completed through a layout recursive algorithm based on stacked plate number layering; setting a threshold value: setting the threshold value based on a multi-way tree hierarchical iterative searchmethod of a utilization rate threshold value; analyzing and optimizing parameters: analyzing and optimizing the parameters obtained by hierarchical iterative search; calculation experiment and analysis: testing and analyzing through experiments to verify the feasibility and effectiveness of algorithm results; the invention aims to provide the layered iterative layout optimization method considering the cutting efficiency and the utilization rate, the utilization rate of raw materials is improved, batch cutting can be realized, and the cutting frequency and the cutting knife number can be greatly reduced, so that the raw material cost is reduced, the production efficiency is improved, and the total production cost is reduced.

Owner:GUANGDONG UNIV OF TECH

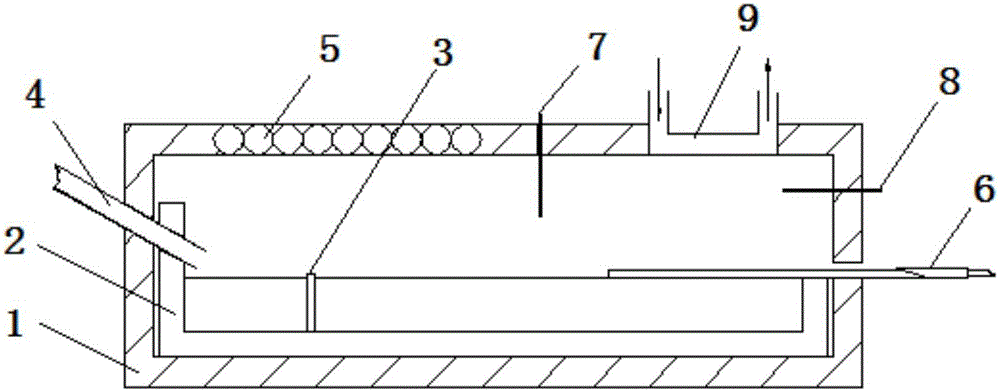

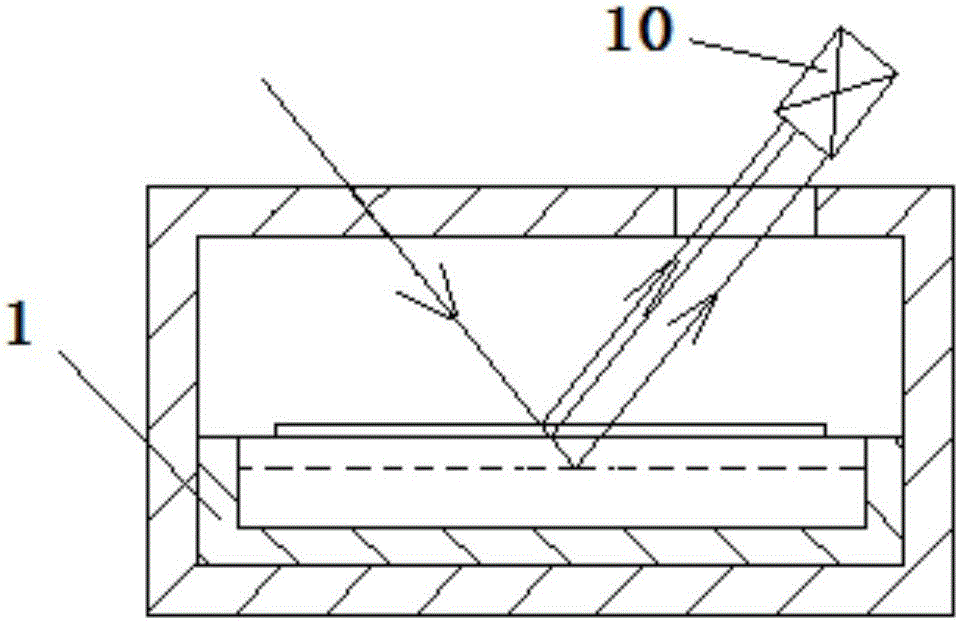

Silicon wafer lifting device and control method thereof

PendingCN106676630AEffective thickness controlEasy to processPolycrystalline material growthBy pulling from meltEngineeringImpurity

The invention relates to a silicon wafer lifting device. The silicon wafer lifting device comprises a heating furnace and a control system, wherein a crucible is arranged in the heating furnace; a heater is fixedly arranged above a melting region; the heating furnace is provided with a feeding tube and an air inlet nozzle; a heat exchanger is fixedly arranged above a main region; a seed crystal bar is connected with a lifting mechanism arranged outside a cabin door; and the heating furnace is further provided with a first pyrometer and a second pyrometer. The control method comprises the following steps: a, adding a silicon material in the melting region of the crucible, and heating and melting the silicon material in the melting region; and b, after seed crystals enter a cavity, enabling the seed crystals to be in contact with melt, maintaining for 3-5 minutes, then starting the heat exchanger, enabling a motor to rotate reversely, enabling the seed crystal bars to move outwards, and enabling the lifting mechanism to move upwards to cut off silicon wafers after the lifting mechanism triggers a limiting switch. The silicon wafers obtained by the method cannot be polluted by the crucible during crystallization, therefore, the content of impurities of the silicon wafers is small, and material loss is expectedly reduced by 50%.

Owner:CHANGZHOU UNIV +1

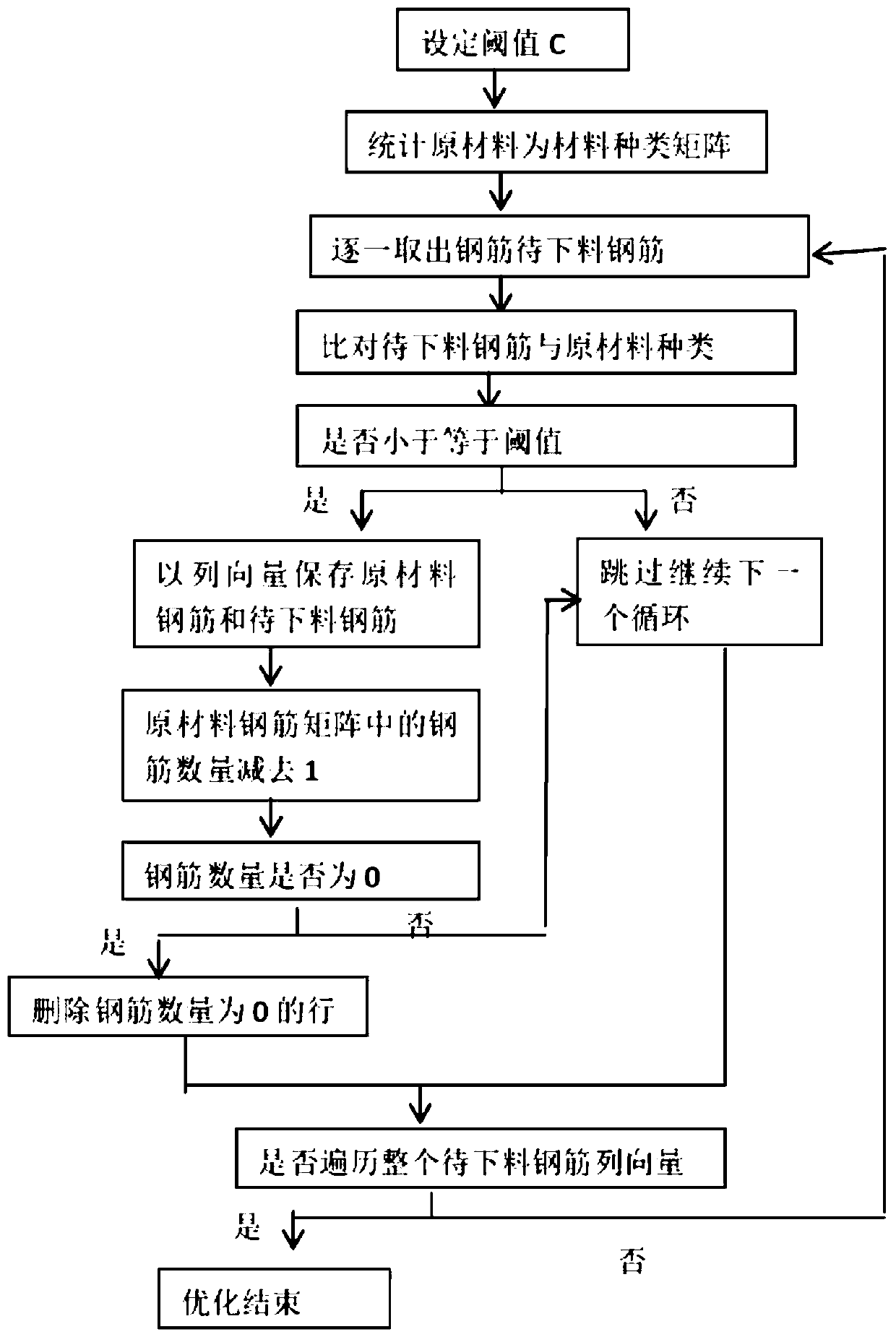

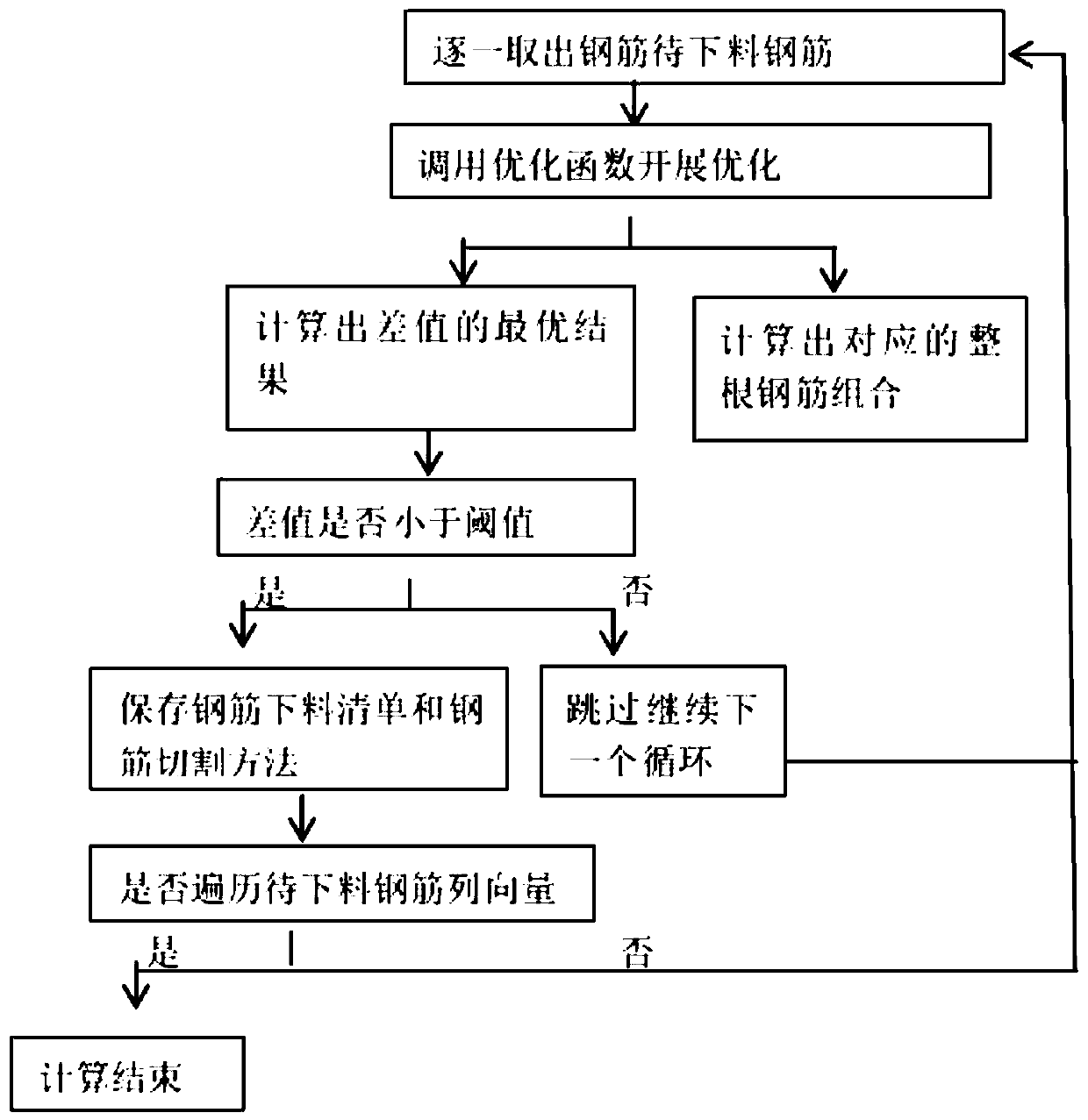

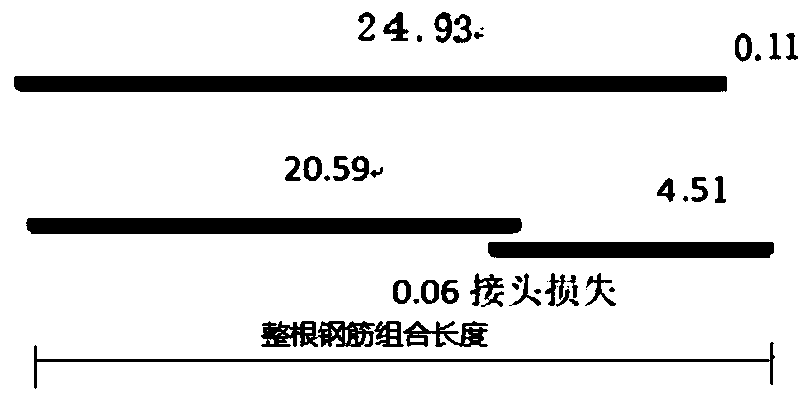

Rebar discharging method

ActiveCN109732021ALow costReduce the number of cutsSpecial data processing applicationsEngineeringRebar

The invention discloses a rebar discharging. The rebar discharging comprises the steps that a raw material rebar combination mode is adopted for blanking, after combination cutting, the effect that the length of the rest raw material rebar is the smallest and not larger than the set threshold value is set as the target, the raw material rebar blanking combination is screened through the intlinprogfunction in matlab, and the result of to-be-discharged rebars and the corresponding raw material rebar blanking combination is output; the effect that after cutting, the length of the rest o-be-discharged rebars is the smallest is set as the target, the raw material rebar blanking combination is solved, the smallest rebar wasting rate is set as the target, the situation that welded joints do notlocated in the girder span serves as the constraint, the situation that the length of each rest to-be-discharged rebar after cutting is at most composed of two rebars is set as the hard constraint, orthe smallest rebar wasting rate serves as the target, the situation that each rest to-be-discharged rebar after cutting is only composed of one rebar serves as the hard constraint, and the blanking combination of the rest to-be-discharged rebars after cutting is obtained through a corresponding lingo model. Through the rebar discharging, the material cost and the manpower cost can be remarkably reduced.

Owner:HUBEI HUAYUE AUTO PARTS

Shoe sole board and production method thereof

InactiveCN105415818APaste effect is firmIncrease productivitySolesLamination ancillary operationsEngineeringWork in process

The invention discloses a shoe sole board and a production method thereof. The production method includes the following steps that a first sole board layer with a certain length, flexible layers with certain length and a second sole board layer with a certain length are cut; the two lateral sides of the first sole board layer are subjected to corner cutting and polished; the lower end face of the first sole board layer, the lower end faces of the flexible layers and the upper end face of the second sole board layer are coated with adhesive layers respectively; the second sole board layer, the flexible layers and the first sole board layer are sequentially pasted together from bottom to top, the flexible layers are pasted to the left side and the right side of the second sole board layer, the first sole board layer is arranged in the middle of the second sole board layer, the two lateral sides of the first sole board layer are pressed on the inner lateral sides of the flexible layers respectively, and a semi-finished shoe sole board is obtained; the semi-finished shoe sole board is pressed to be shaped, and the finished shoe sole board is obtained. By means of the shoe sole board and the production method, the number of mold opening times of the shoe sole board can be decreased, automatic production is facilitated, production cost is reduced, and production efficiency and product quality are improved.

Owner:鹤山市行星鞋类制品有限公司

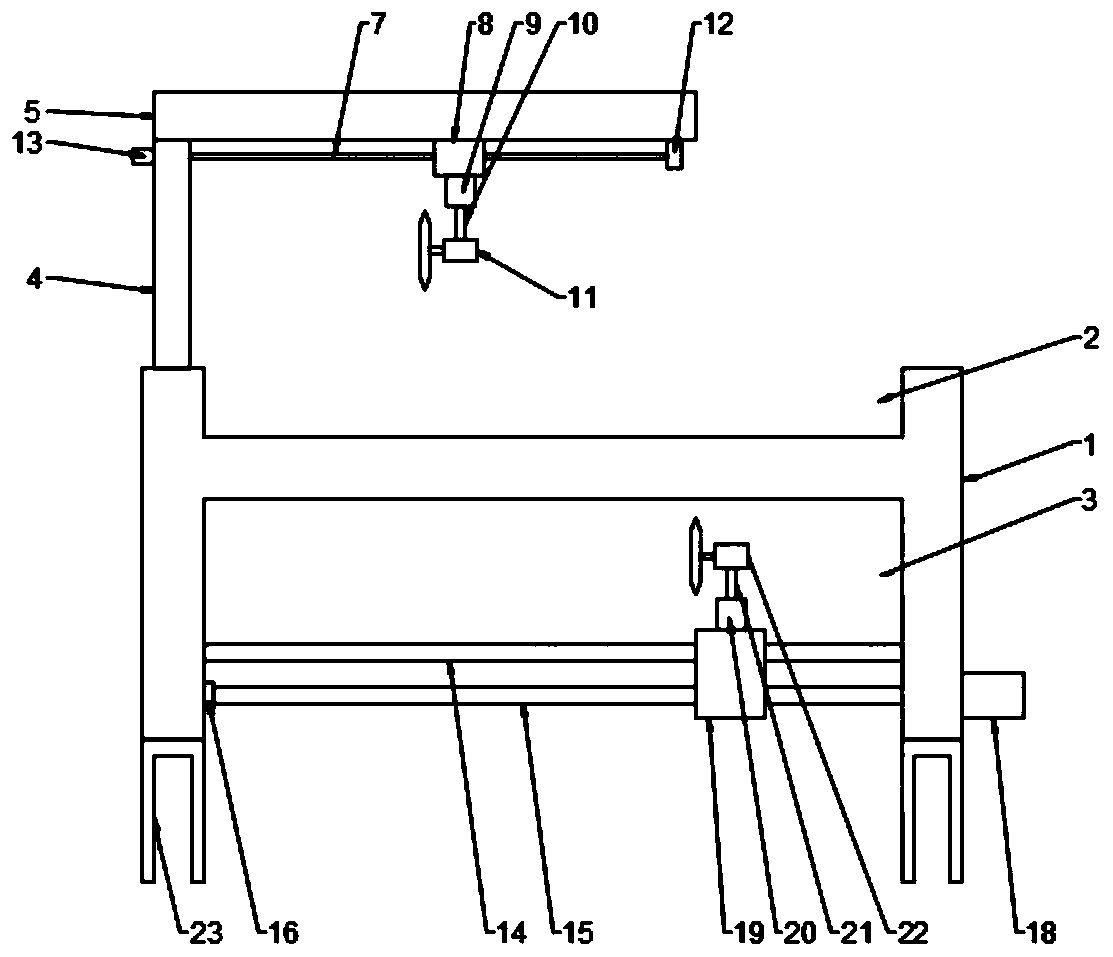

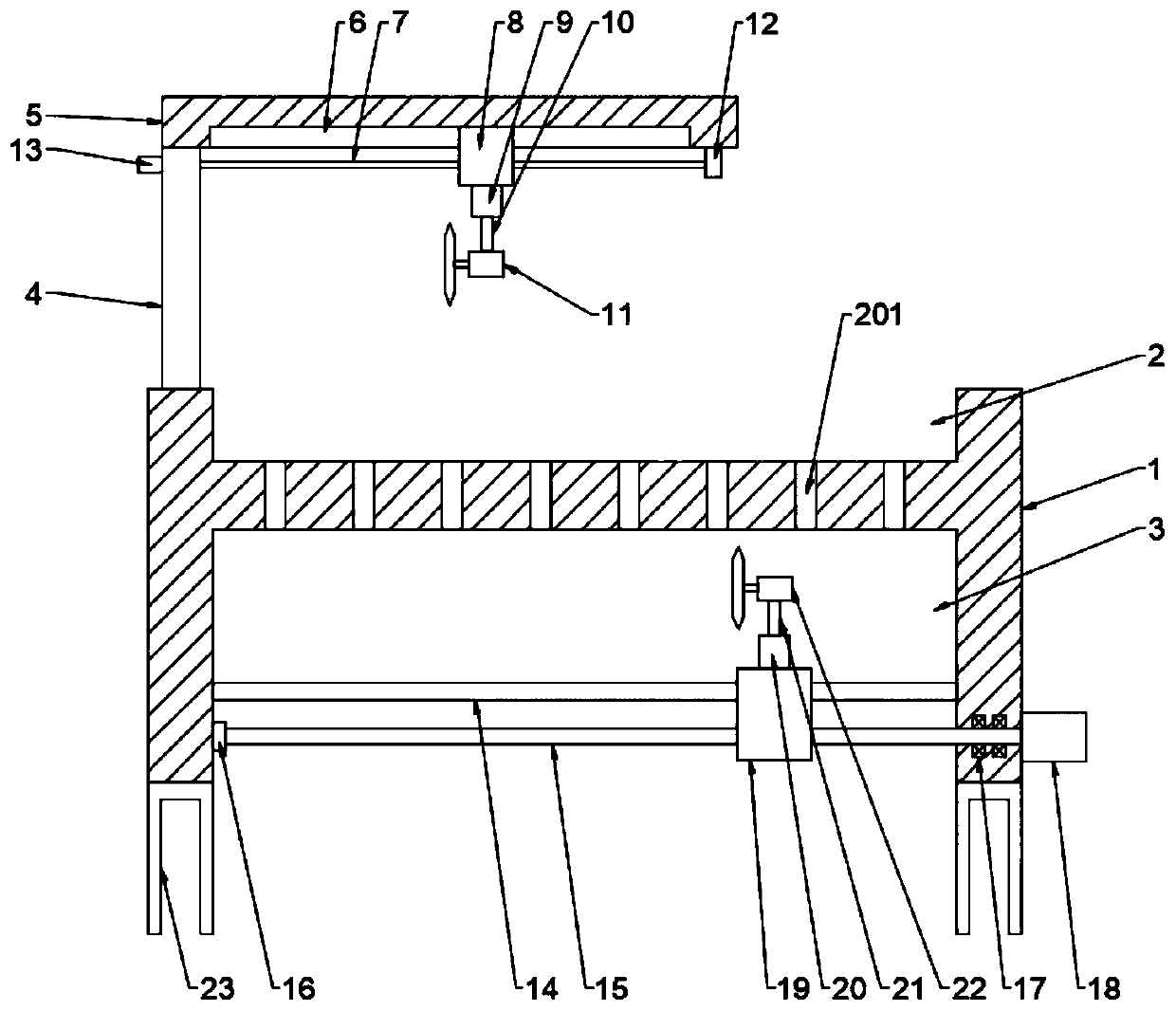

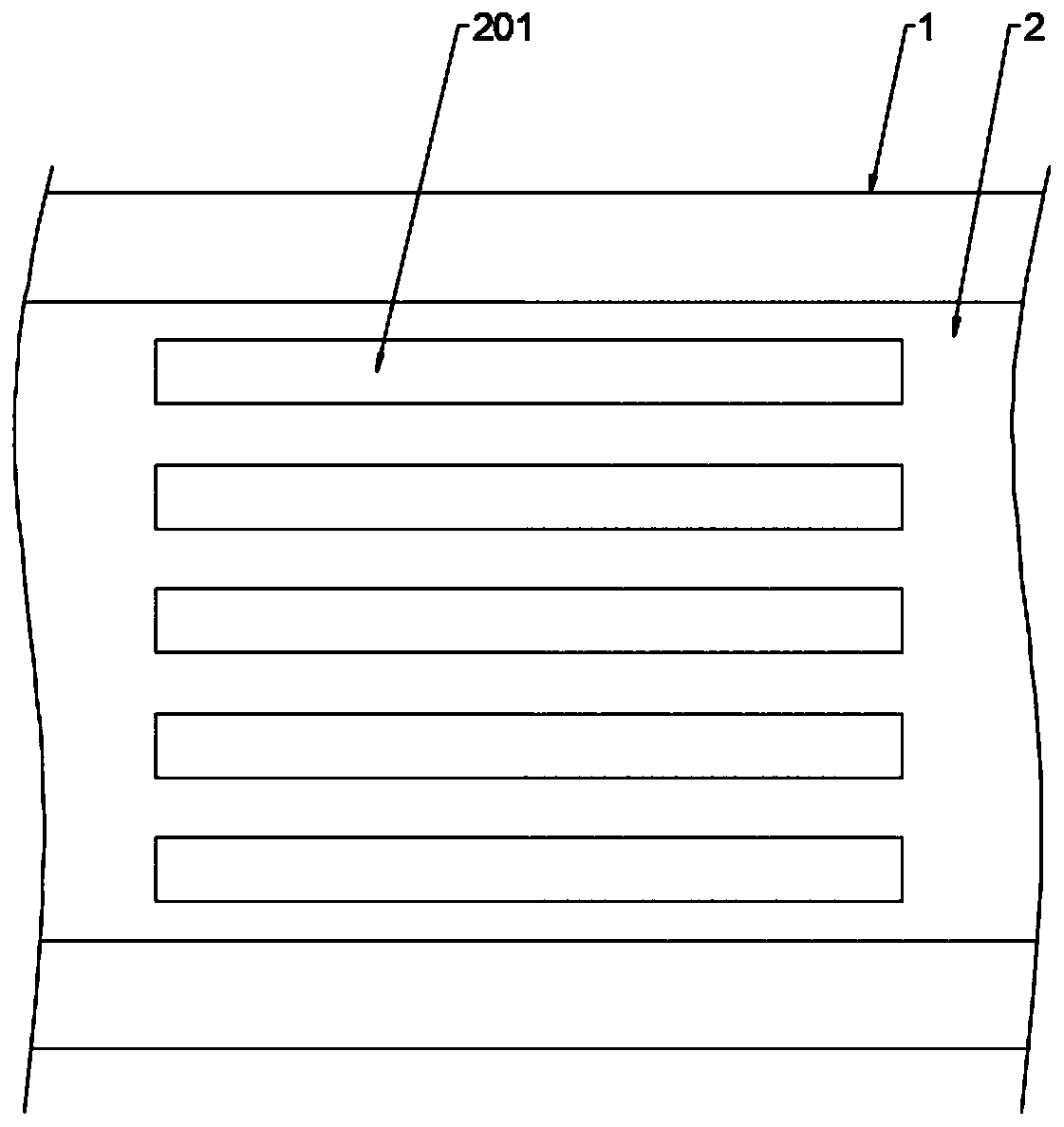

Cutting device used for aluminum alloy sheet material based on cutting space adjusting technology

InactiveCN109692994AIncrease profitReduce generationShearing machinesShearing machine accessoriesMachiningMaterials science

The invention provides a cutting device used for an aluminum alloy sheet material based on a cutting space adjusting technology. The cutting device used for the aluminum alloy sheet material based onthe cutting space adjusting technology is particularly used for the technical field of aluminum alloy sheet material machining. The cutting device used for the aluminum alloy sheet material based on the cutting space adjusting technology comprises a seat frame. A cutting groove is formed in the top end of the seat frame, a plurality of cutting holes are uniformly formed in the inner cavity bottomwall of the cutting groove, a vertical column is arranged on the left side of the top end of cutting groove, a horizontal beam is arranged at the top end of the vertical column, the horizontal beam isprovided with a first feeding mechanism, the first feeding mechanism is provided with a first cutting mechanism, a bottom groove is formed in the bottom end of the seat frame, a second feeding mechanism is arranged in the bottom groove, and the second feeding mechanism is provided with a second cutting mechanism. According to the cutting device used for the aluminum alloy sheet material based onthe cutting space adjusting technology, an upper lead screw is matched with a sliding groove, and thus the position of the first cutting device is adjusted; and meanwhile a lower lead screw is matchedwith a sliding rod, so that the position of a second cutting device is adjusted, thus the cutting space distance is adjusted, two or three aluminum alloy sheet materials with the same specification can be cut at the same time, two or three aluminum alloy sheet materials with the different specification can also be cut at the same time, thus the cutting time can be greatly lowered, and the cuttingefficiency is improved.

Owner:戎珊珊

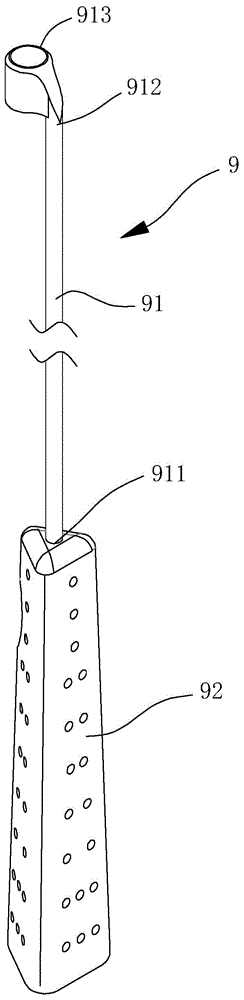

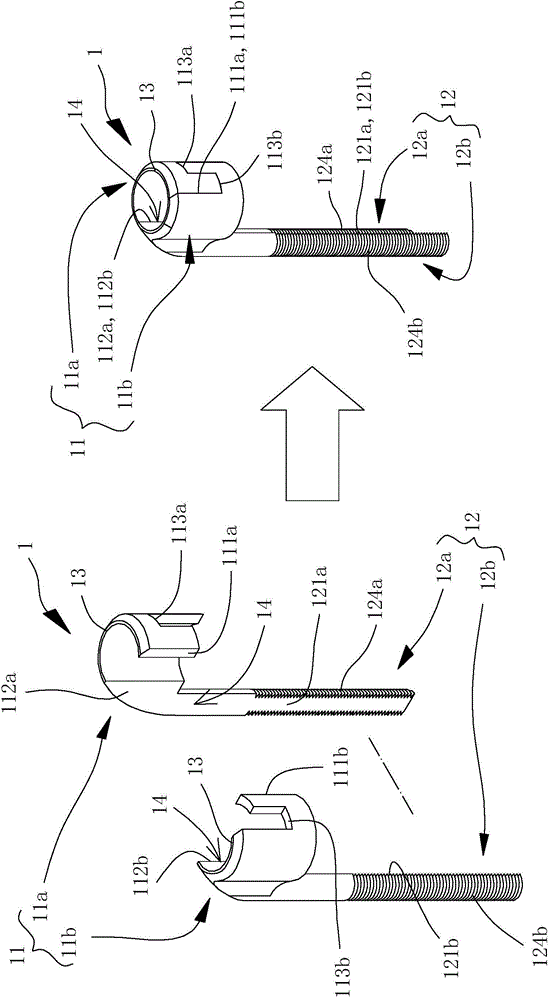

Tendon detacher

ActiveCN106137329AReduce infection rateReduce the number of cutsIncision instrumentsTendon stripperEngineering

A tendon detacher comprises a detaching part and a rod, wherein the detaching part comprises a ring body and at least one combining piece, the ring body is combined with the combining pieces, the ring body is provided with a blade part and a separating part, the separating part separates the ring body into a plurality of parts, the rod is provided with a holding end and a combining end which are opposite, and the combining end is combined with the combining pieces of the detaching part. With the aid of the separating part, the ring body can be separated into a first ring main body and a second ring main body, the first ring main body and the second ring main body can be combined oppositely so that tendon can be located in the ring body of the detaching part, the number of incisions caused in surgery can be reduced, and the effect of reducing surgery complications is achieved. In addition, the tendon is naturally connected to a bone without using too many fixing devices, and the effect of increasing surgery convenience is achieved.

Owner:E DA HOSPITAL

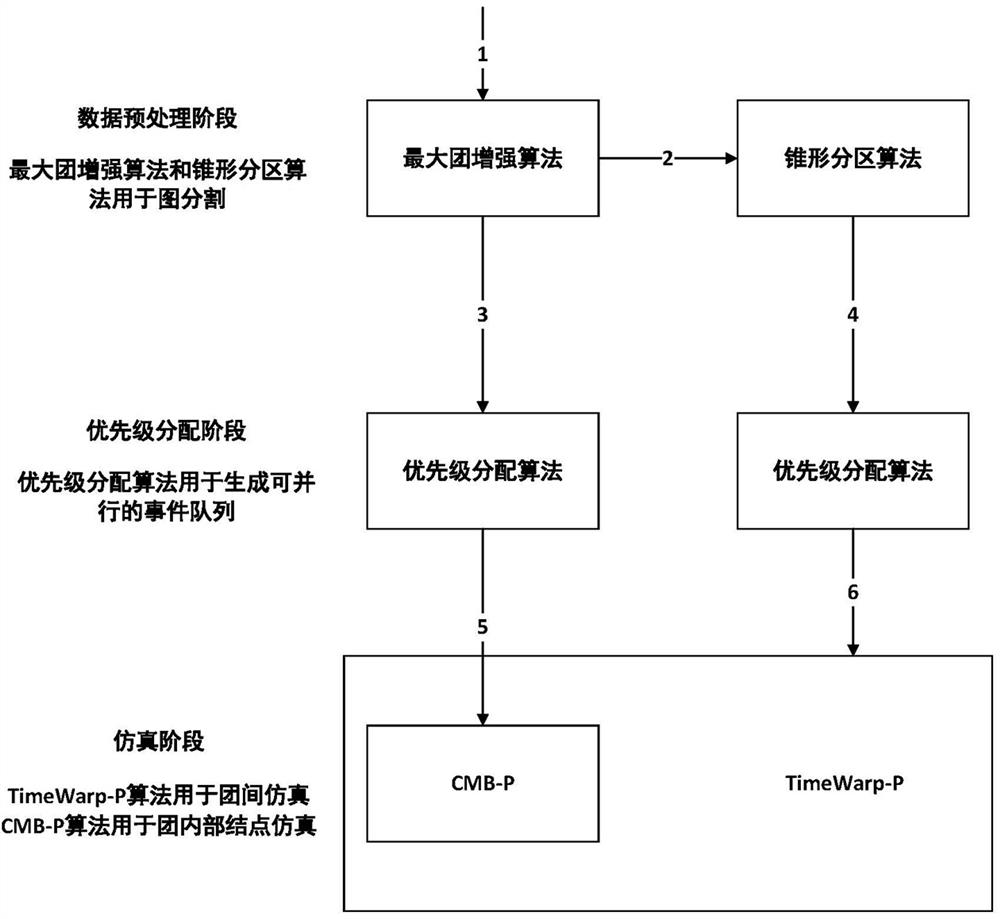

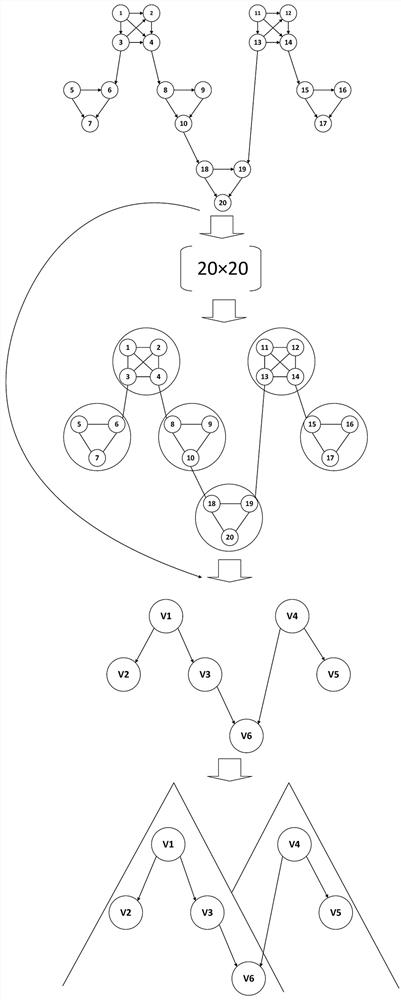

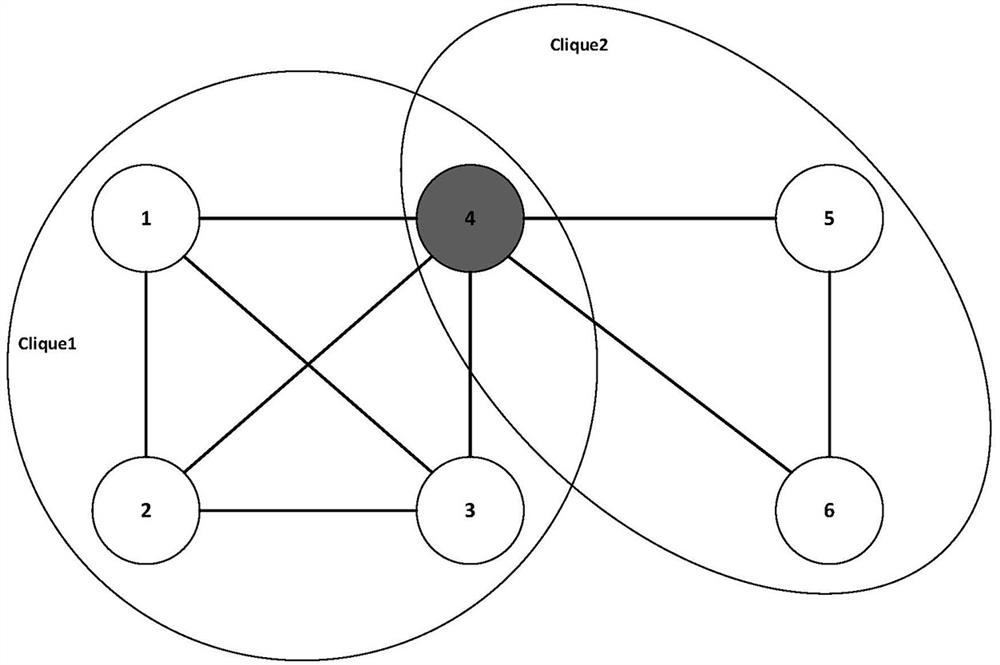

Parallel simulation processing method of gate-level circuit and computer readable storage medium

PendingCN113095022AReduce the number of cutsAvoid inconvenienceComputer aided designSpecial data processing applicationsAllocation algorithmParallel processing

The invention discloses a parallel simulation processing method of a gate-level circuit and a computer readable storage medium. The parallel simulation processing method of the gate-level circuit comprises the following steps: based on an adjacent matrix of the gate-level circuit, segmenting a graph corresponding to the gate-level circuit into a plurality of clusters by adopting a first preset segmentation algorithm; taking each cluster as a superpoint, and packaging data of each superpoint by adopting a first data structure; on the basis of a superpoint diagram formed by all the superpoints, dividing all the superpoints into a plurality of partitions capable of being processed in parallel by adopting a second preset segmentation algorithm, and packaging partition data by adopting a second data structure; generating a cluster priority event queue between clusters and a node priority event queue in the clusters by adopting a preset priority distribution algorithm on the basis of the super-point data and the partition data; and simulating the gate-level circuit according to a simulation sequence defined by the priority event queue. According to the invention, the simulation efficiency of the gate-level circuit can be effectively improved, and the simulation complexity of the gate-level circuit is reduced.

Owner:SHENZHEN STATE MICRO TECH CO LTD

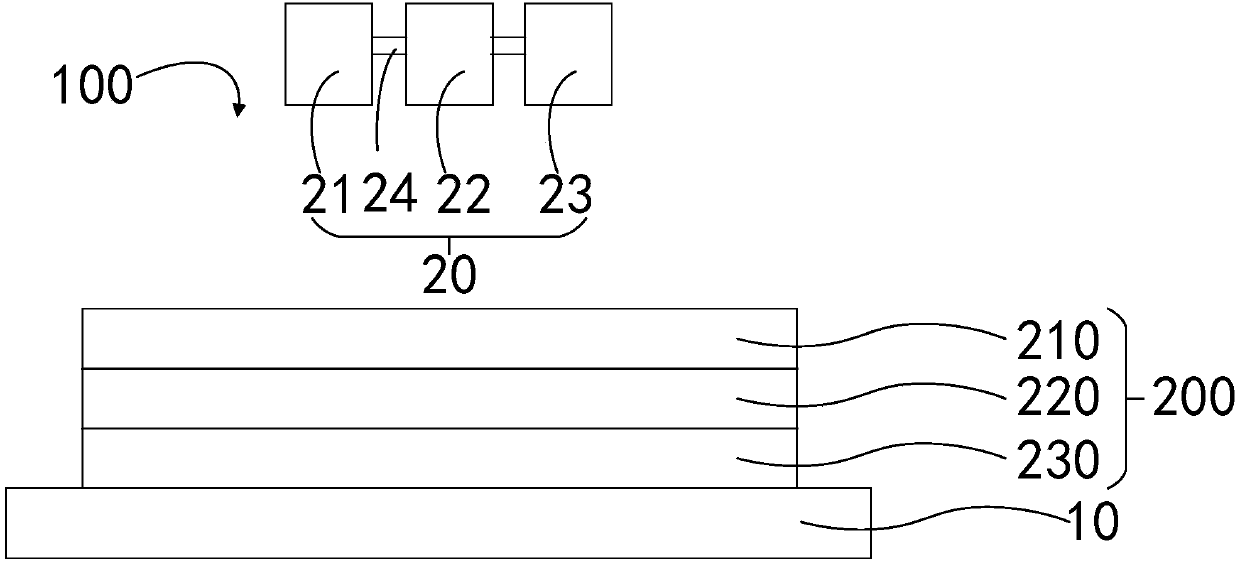

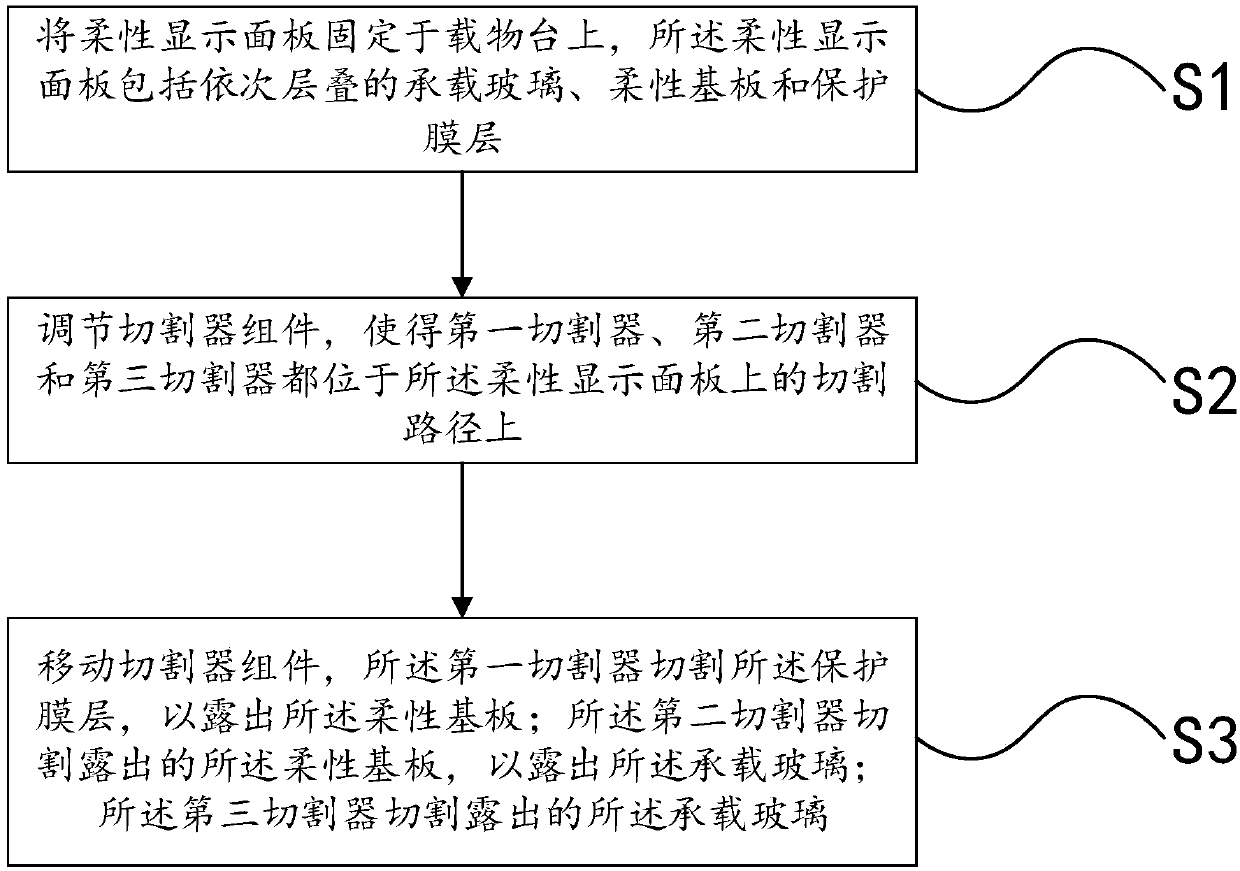

Cutting device and cutting method

InactiveCN107900530AImprove the cutting methodReduce the number of cutsMetal working apparatusLaser beam welding apparatusFlexible displayLaser

The invention provides a cutting device used for cutting flexible display panels. The cutting device comprises an object table and a cutter assembly, wherein the object table is used for bearing the flexible display panel, and the cutter assembly is arranged on the upper portion of the object table; the cutter assembly comprises a first cutter, a second cutter and a third cutter, wherein the firstcutter, the second cutter and the third cutter are transversely and coaxially arranged on the same straight line, the first cutter, the second cutter and the third cutter are used for sequentially cutting different layers of the flexible display panel in the thickness direction so as to achieve cutting-off of the flexible display panel, and at least two of the first cutter, the second cutter andthe third cutter are laser cutters. According to the cutting device, multiple cutters are adopted for simultaneously cutting different layers of the flexible display panel in the thickness direction,the number of cutting is decreased, and the cutting efficiency is improved. The invention further provides a cutting method.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

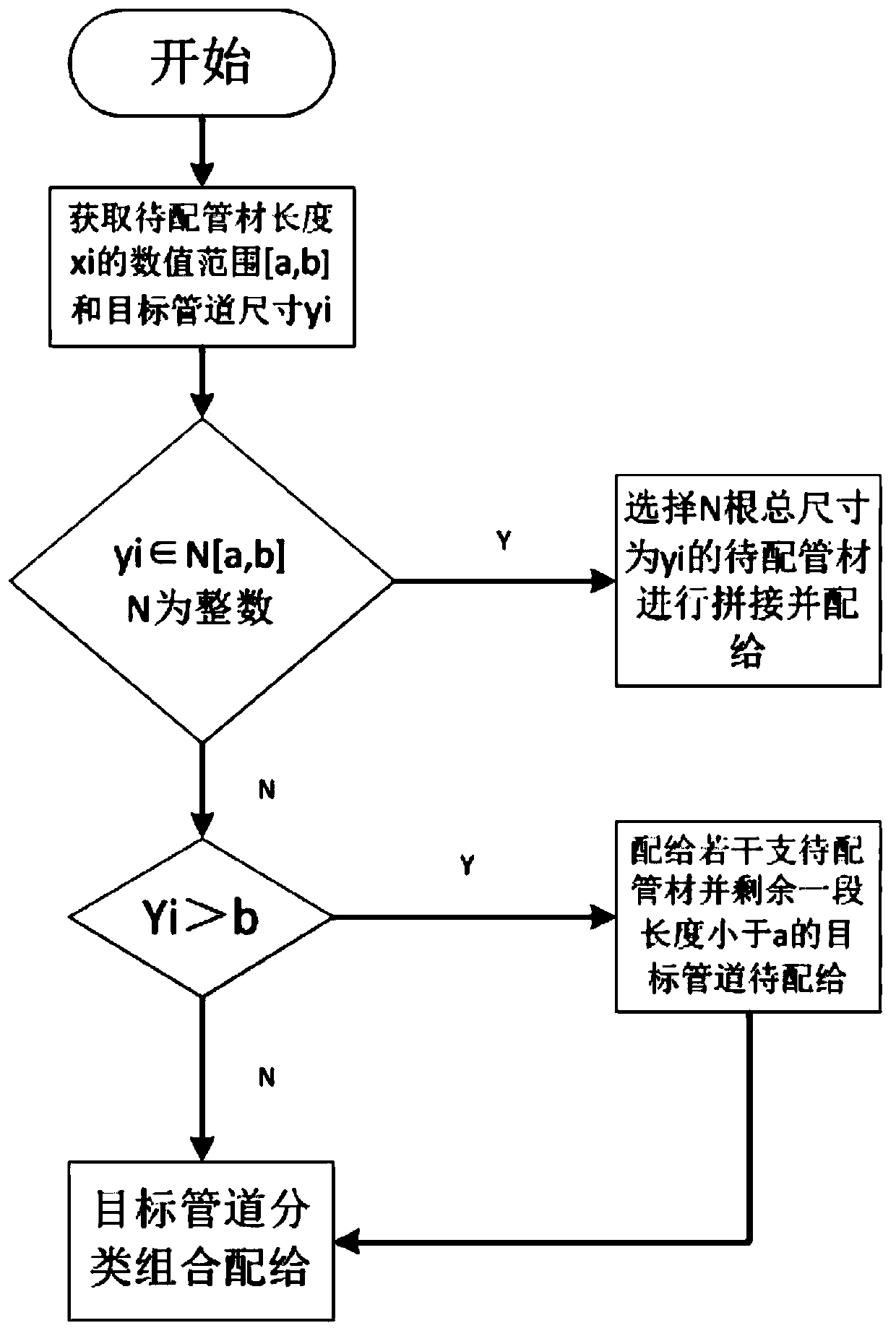

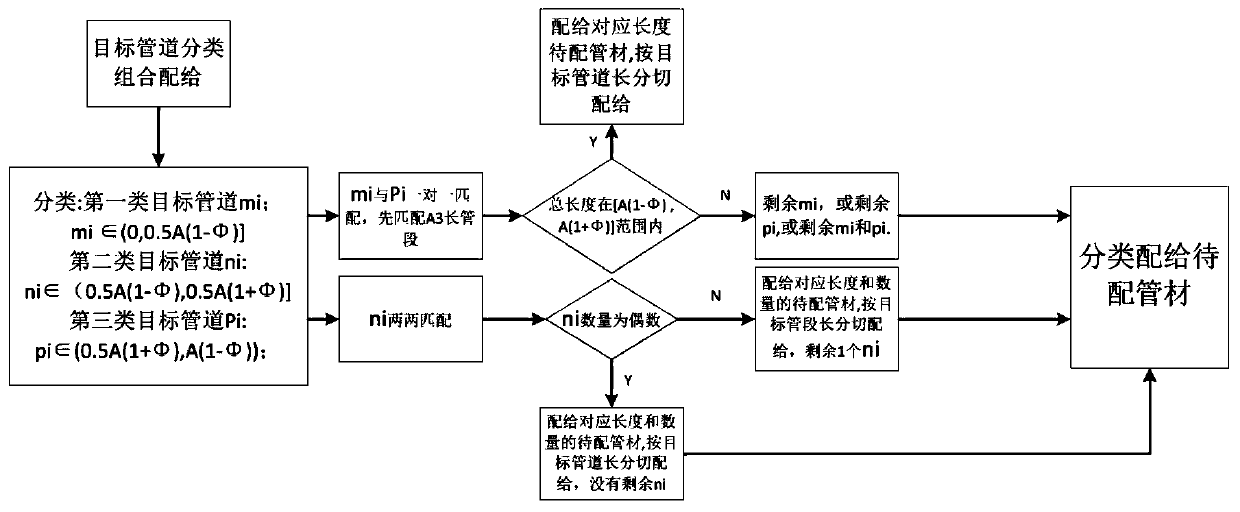

Optimization method for pipe discharging

ActiveCN110516834AReduce the number of cutsIncrease profitForecastingCharacter and pattern recognitionLower limitEngineering

The invention provides an optimization method for pipe discharging. The method comprises the steps of obtaining a length range of a to-be-matched pipe and a target pipeline, wherein the length of thetarget pipeline is integral multiples of the length of a to-be-matched pipe; taking the to-be-matched pipes with the corresponding number and length to be matched, wherein the size is greater than theupper limit of the to-be-matched pipe length and the length of the target pipeline is not within the range of integral multiples of the length of the to-be-matched pipe; taking the to-be-distributedpipes with the corresponding number and length to be distributed, and remaining a target pipe with the length smaller than the lower limit of the to-be-distributed pipes. In this way, the pipes distributed to the target pipe are all the whole pipes. The number of spliced pipes and the cutting frequency of the pipes are reduced. Losses are reduced. The utilization rate of the pipes is increased. All the target pipelines smaller than the lower limit of the length of the to-be-matched pipes are classified and combined. The target pipelines with the total length reaching integral multiple of the length of the to-be-matched pipes after combination are cut and matched according to the corresponding number and length. Useless pipe excess materials are reduced. The utilization efficiency of the pipes is improved, and the pipe discharging mode is optimized.

Owner:HUADIAN HEAVY IND CO LTD

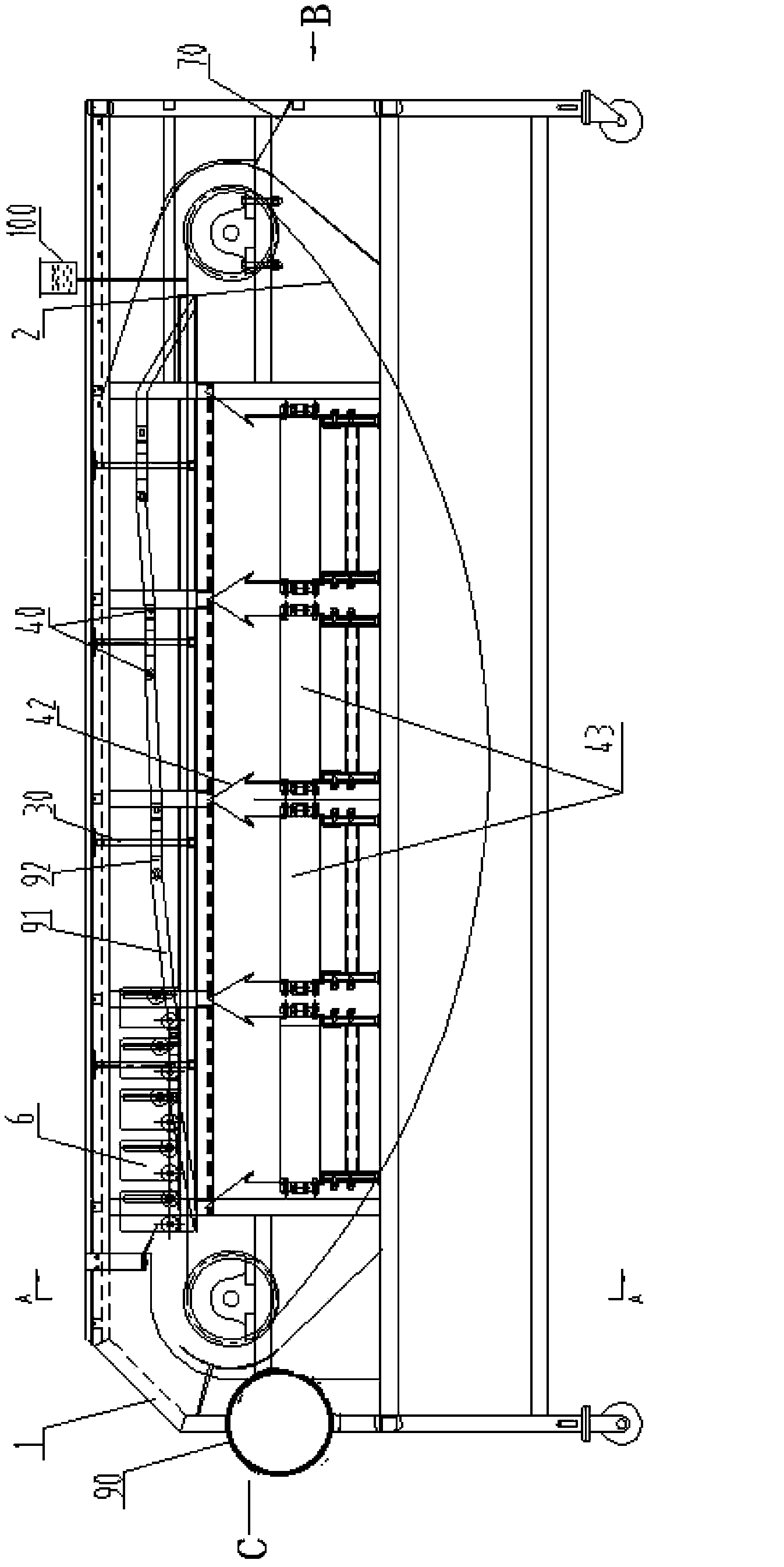

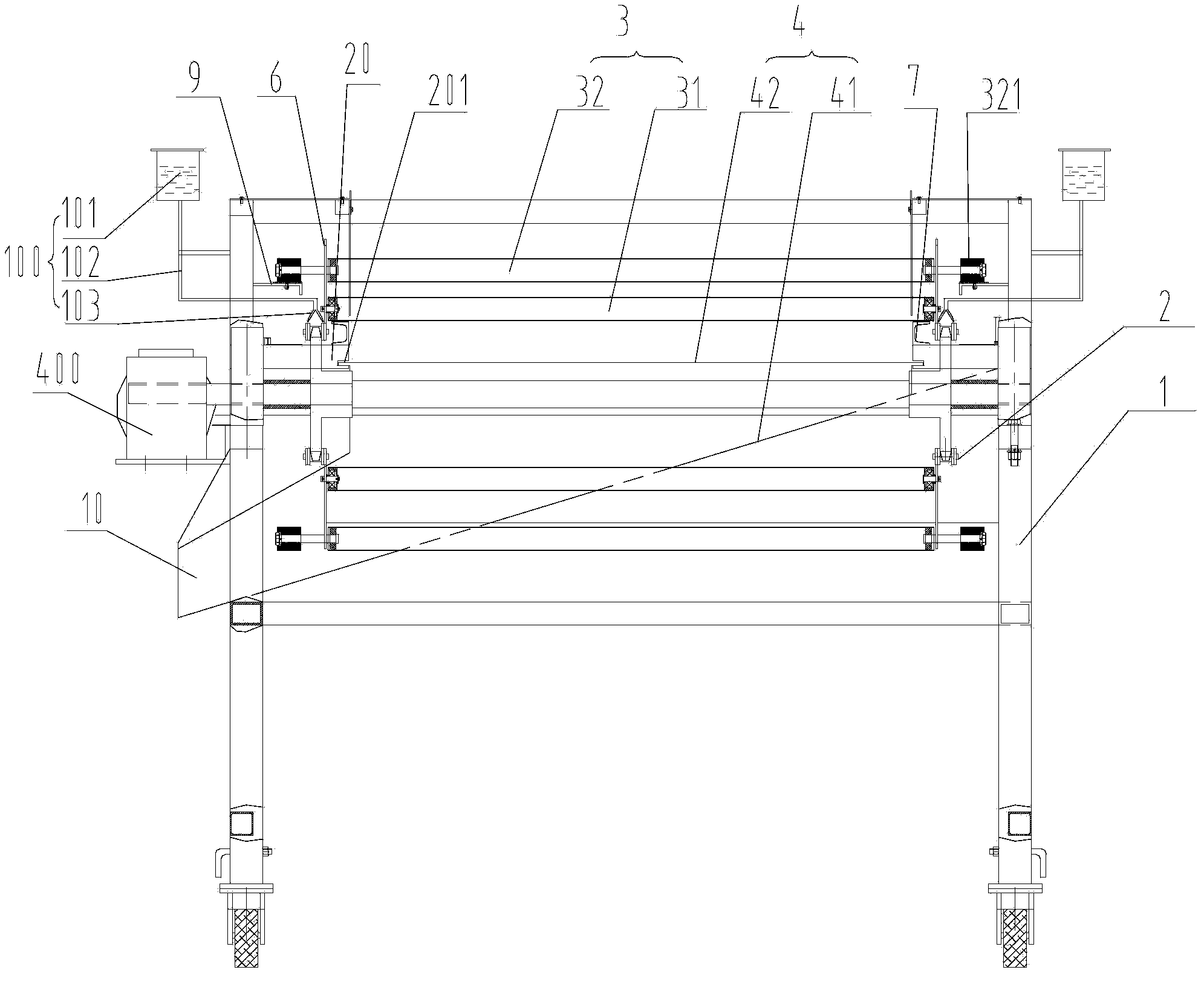

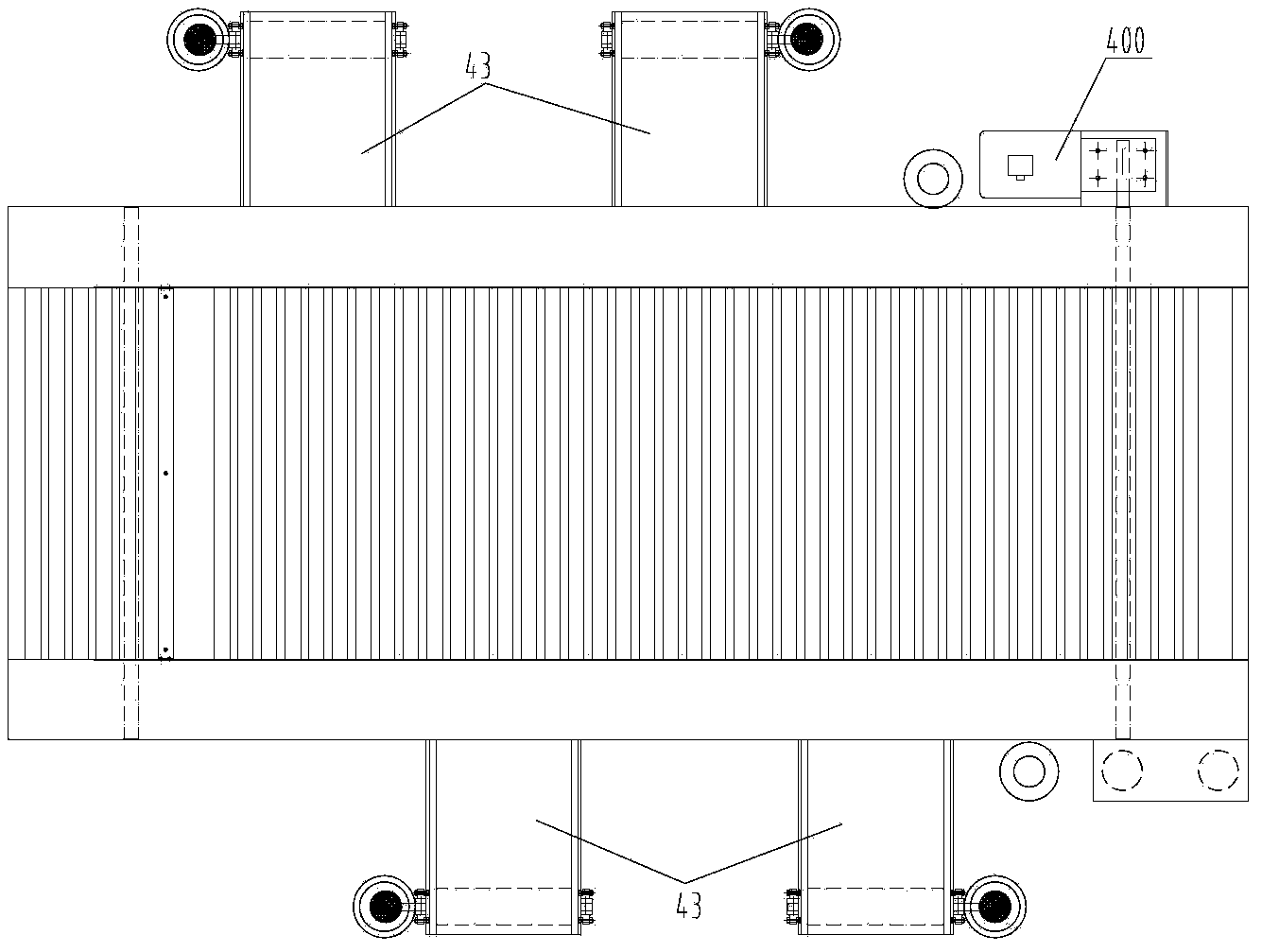

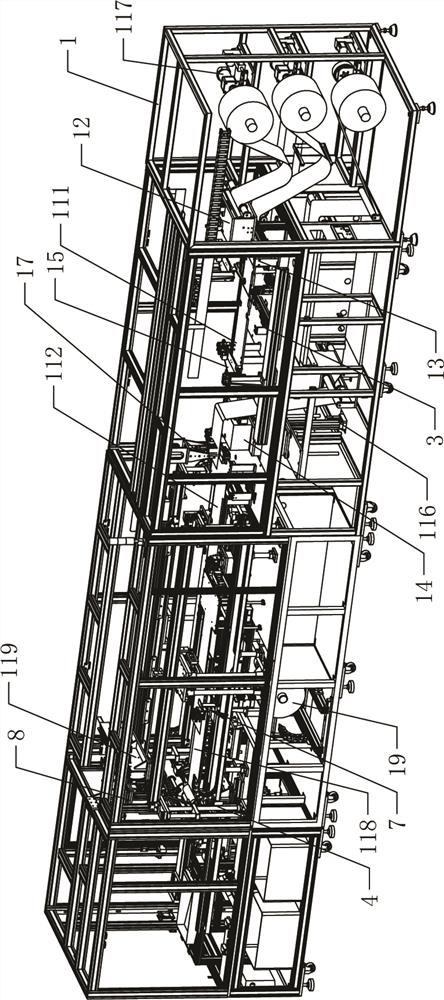

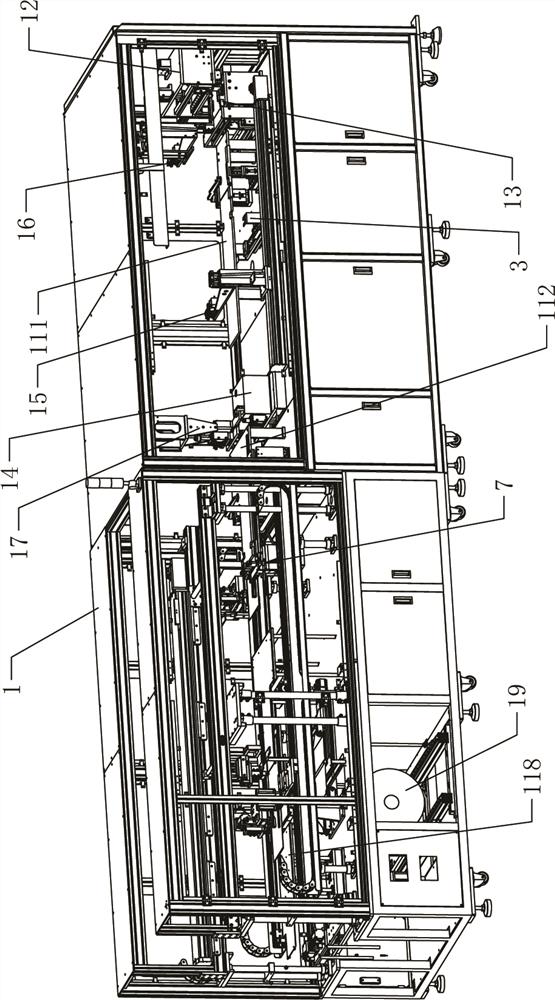

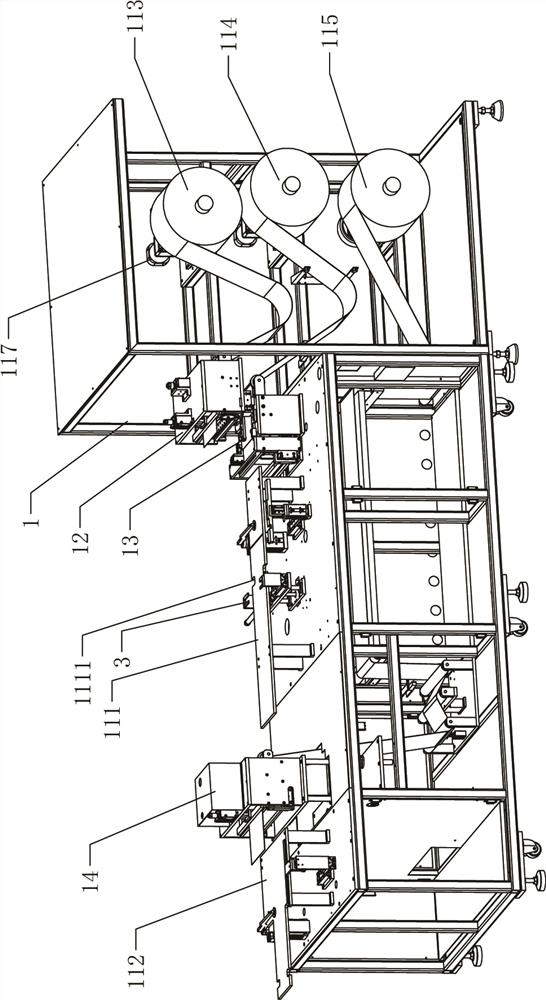

Full-automatic production equipment for RO membrane filter element and processing technology of RO membrane filter element

ActiveCN113304615AReduce the number of cutsPrevent slippingReverse osmosisRobot handProcess engineering

The invention discloses full-automatic production equipment for RO membrane filter elements and a processing technology of the full-automatic production equipment. The full-automatic production equipment comprises a rack, a first placement table top and a second placement table top, and the rack is provided with a feeding mechanism, a laminating mechanism and a rolling mechanism; the feeding mechanism comprises a separation net feeding and cutting device, a membrane feeding and cutting device, a flow guide cloth feeding and cutting device and a central pipe clamping and rotating device; the laminating mechanism comprises a first manipulator, a second manipulator, a third manipulator and a folding device; the rolling mechanism comprises an oblique insertion feeding device, a welding device, an outer-layer flow guide cloth feeding device and a film pasting device, and the rack is further provided with a translation conveying device. The invention has the following advantages and effects: the scheme utilizes a new mechanical structure, the whole processing process does not need manual participation, the automation degree is higher, each process can realize continuity, high efficiency and labor saving, and the processing is convenient; the membrane, the separation net and the flow guide cloth can be stacked in sequence, and the stacking sequence is not prone to errors.

Owner:宁波市奥特曼自动化设备有限公司

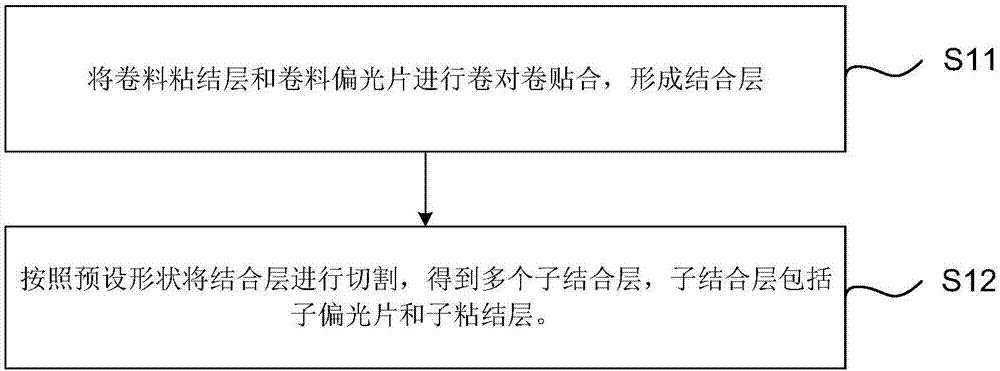

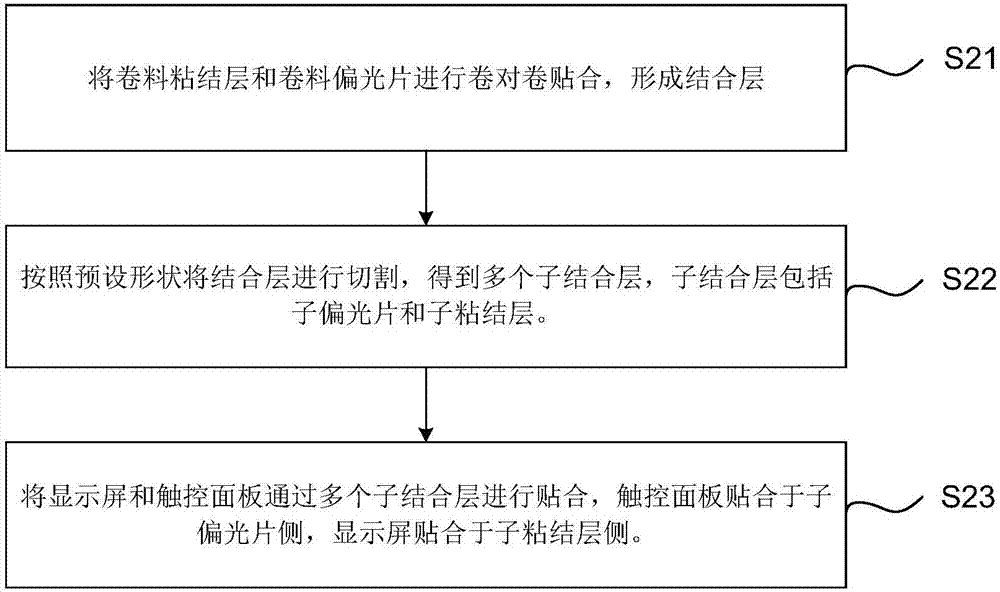

Screen lamination method and display screen

InactiveCN107984872AReduce the number of cutsHigh material utilizationLamination ancillary operationsLaminationPolarizerEngineering

The embodiment of the invention discloses a screen lamination method and a display screen. The method comprises the following steps: performing roll-to-roll lamination on a roll adhesive layer and a roll polarizer so as to form a binding layer; and cutting the binding layer according to a preset shape so as to obtain a plurality of binding sub-layers, wherein the binding sub-layers comprises sub-polarizer and adhesive sub-layers. Apparently, the roll adhesive layer and the roll polarizer are subjected to roll-to-roll lamination in the screen lamination process, and the laminated binding layeris cut to obtain the plurality of binding sub-layers, so that the overall cutting frequency is reduced. Moreover, the adhesive sub-layer in each binding sub-layer does not need a reserved material fordischarging wastes, so that the material utilization rate is increased, the complexity of the lamination process is reduced, and the lamination efficiency is greatly increased.

Owner:TRULY OPTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com