Printed circuit board lamination manufacturing process

A printed circuit and board pressing technology, which is applied in the field of printed circuit board lamination process technology, can solve the problems of increasing lamination time, increasing PP cutting and PP replacement times, and low pre-lamination efficiency, so as to reduce the interlayer Slip, reduce the number of PP cutting, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

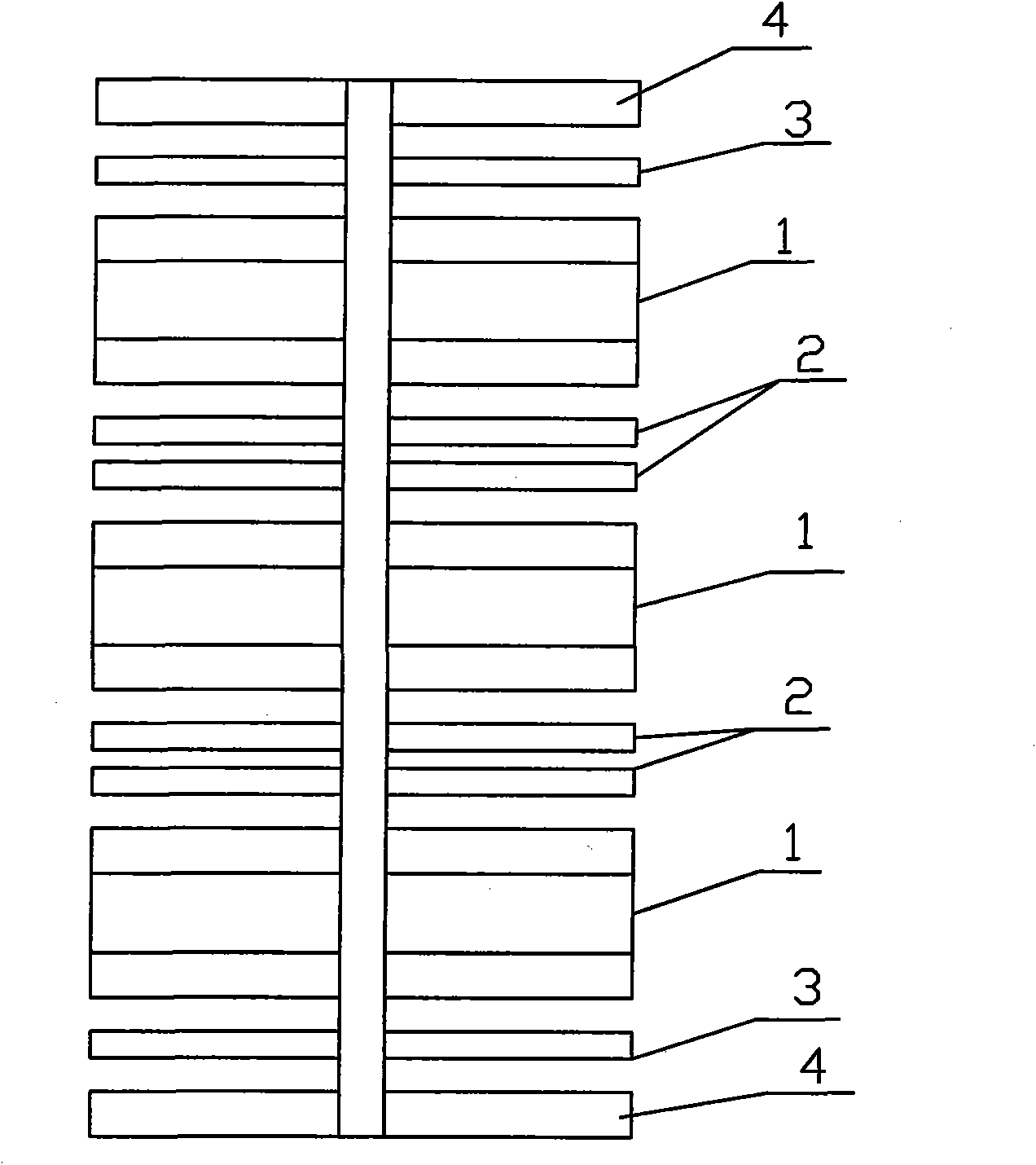

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0019] This example:

[0020] This embodiment provides a printed circuit board lamination process, which includes the following steps:

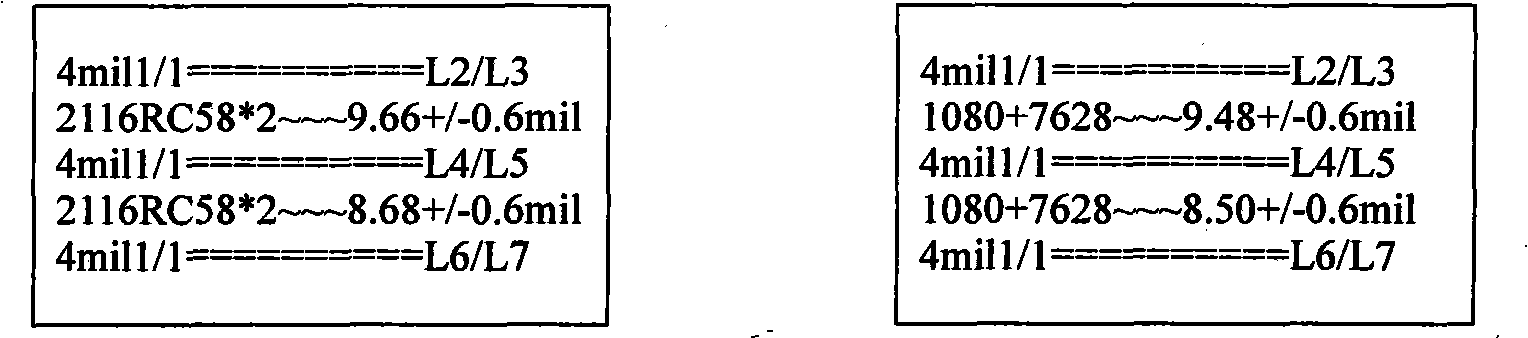

[0021] (1), PP cutting: cut the PP of the same model into several small sheets through the PP slitting machine, and then use the cutting machine to cut it into the size required by the work order, and match it with the inner layer board;

[0022] There is only one type of PP in the PP layer in the new stack, which is more convenient to cut; while in the old stack, the inner layer contains two types of PP, and the PP model needs to be replaced when cutting the original stacked PP, and the replacement process takes about 15 to 20 minutes.

[0023] (2) Front pre-stacking: stack the inner layer board and the cut OK ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com