Layered iterative layout optimization method considering cutting efficiency and utilization rate

A technology of layered iteration and cutting efficiency, applied in data processing application, prediction, calculation, etc., can solve the problem of less joint optimization of two-dimensional layout and cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

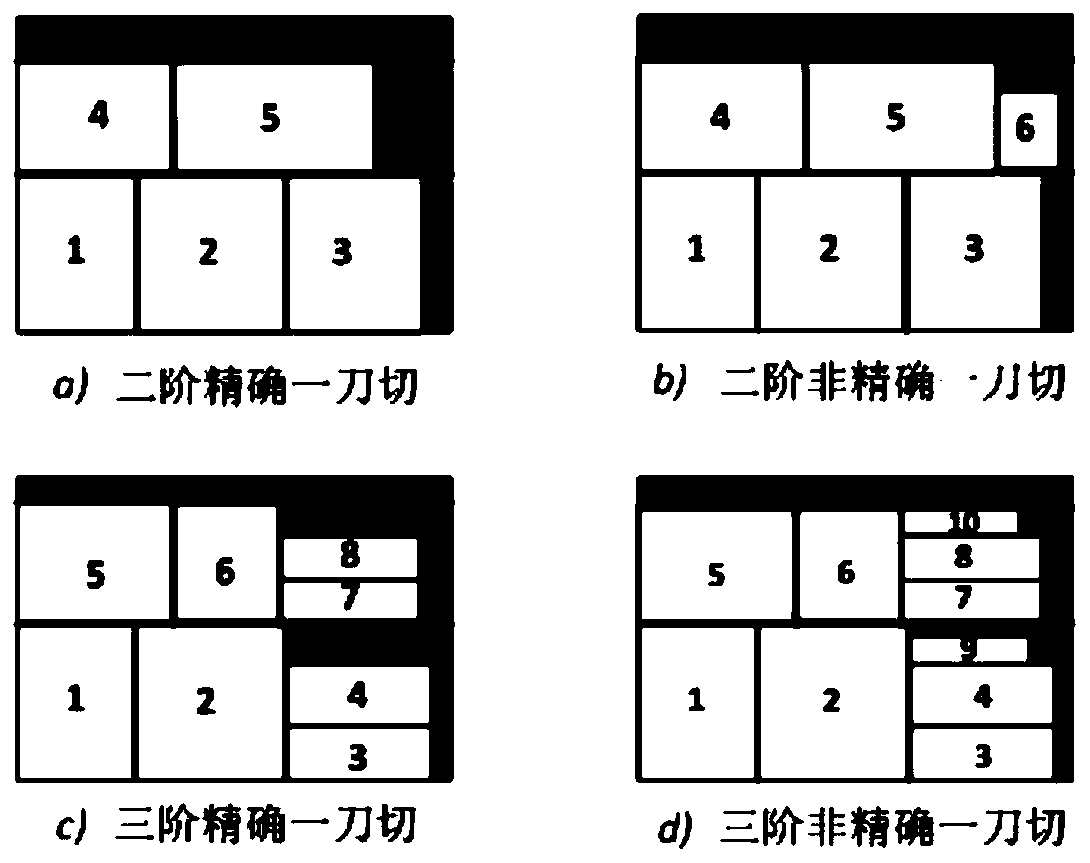

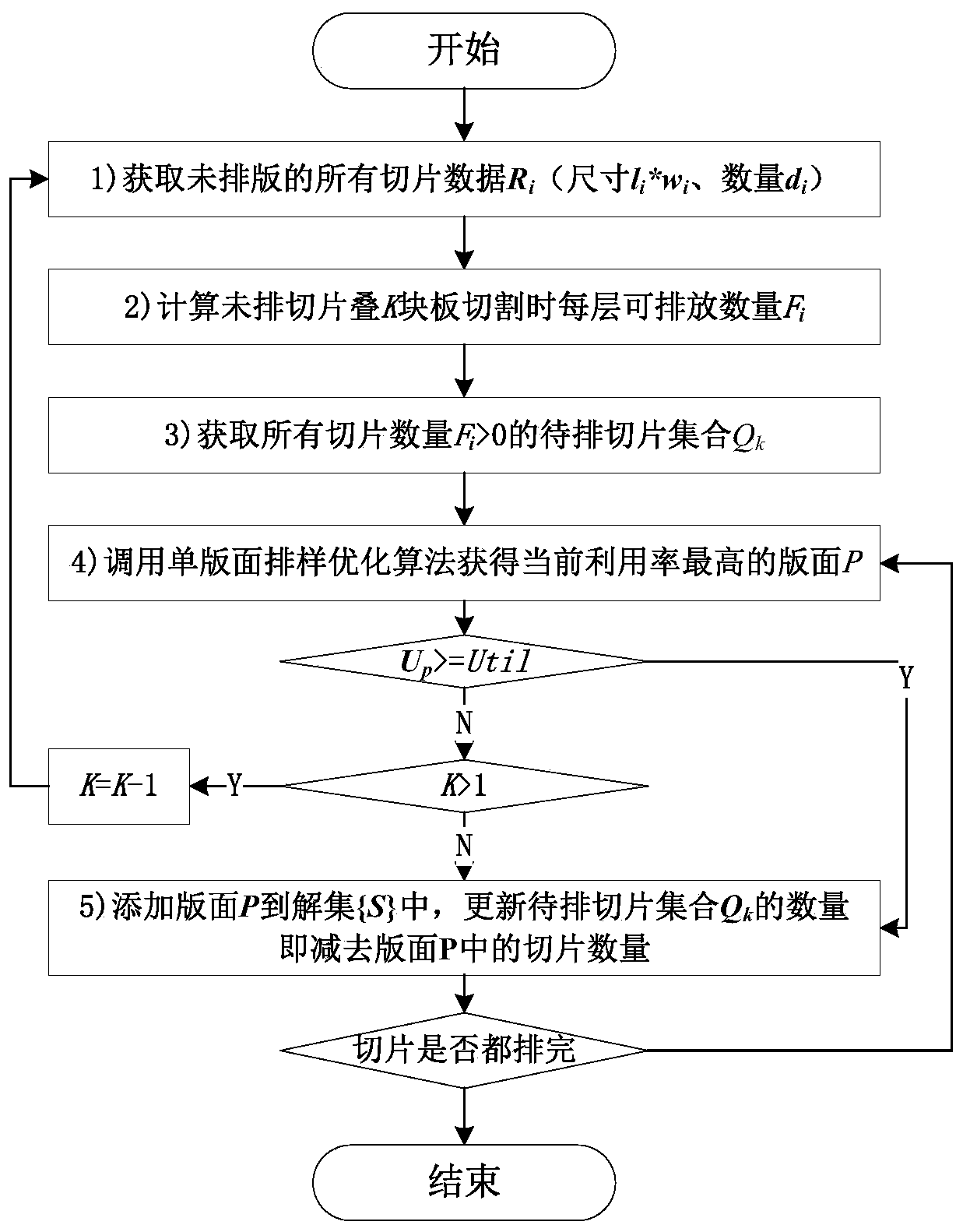

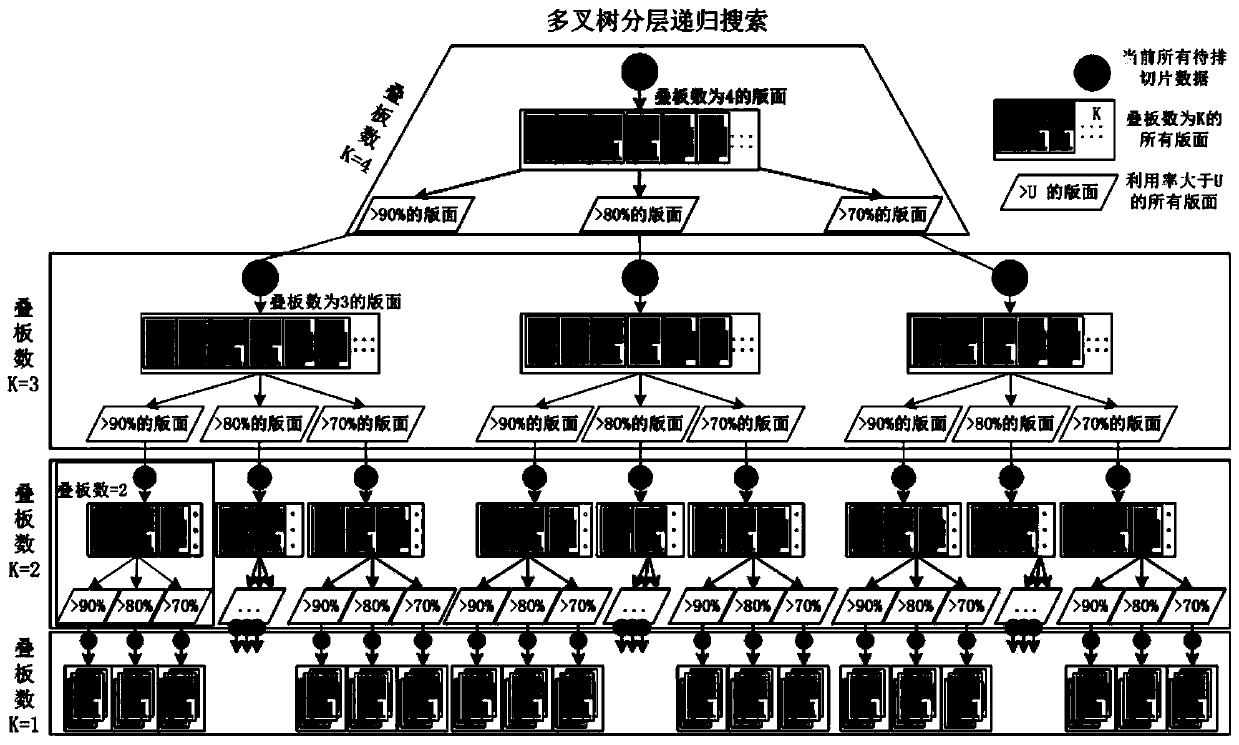

[0046] refer to Figure 1 to Figure 4 As shown, a layered iterative nesting optimization method considering cutting efficiency and utilization rate in this embodiment includes the following steps:

[0047] Model building: combine cutting efficiency and utilization rate to establish a multi-objective optimization model that minimizes total cost;

[0048] Layout optimization: layout optimization is completed based on the recursive algorithm for nesting layout based on the layered number of stacked boards;

[0049] Hierarchical iterative search: multi-tree hierarchical iterative search method based on utilization threshold and set the threshold;

[0050] Parameter analysis and optimization: analyze and optimize the parameters obtained by layered iterative search;

[0051] Computational experiments a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com