Patents

Literature

38results about How to "Prevent shredding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

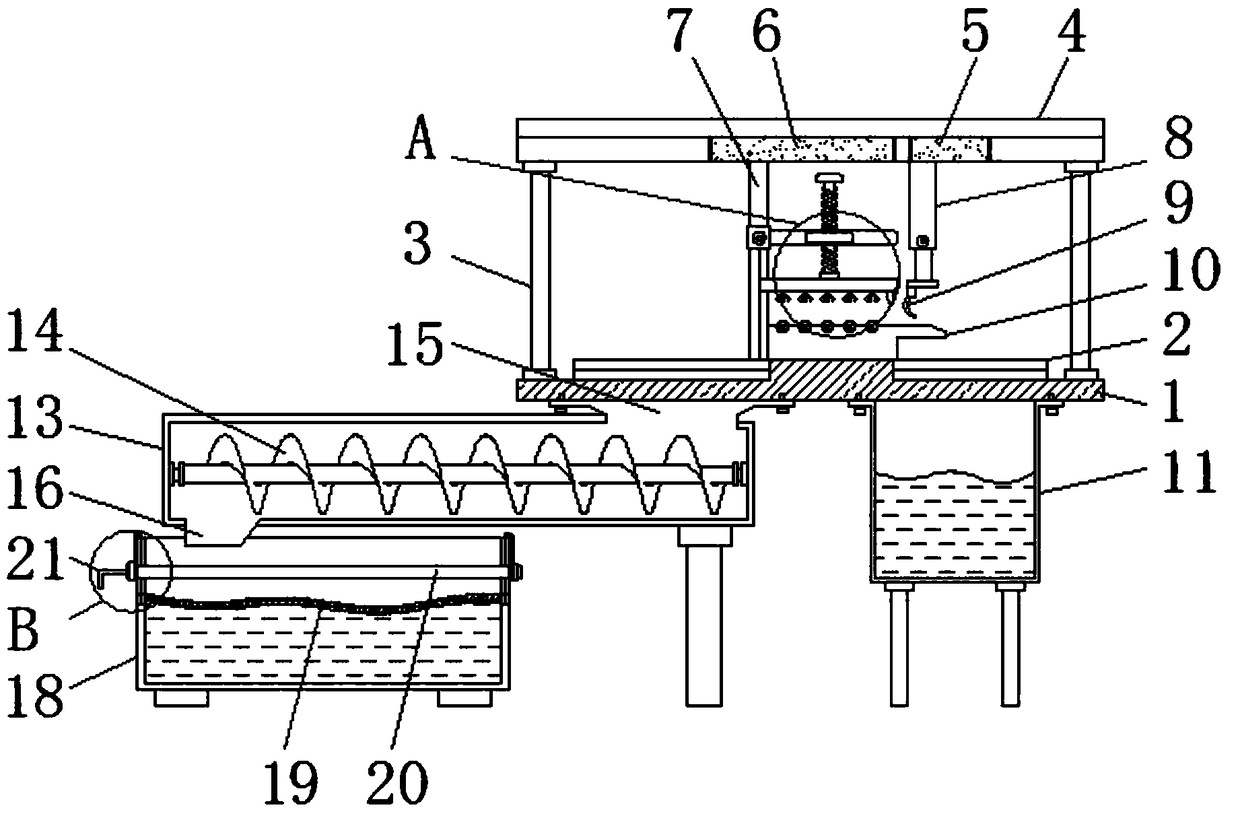

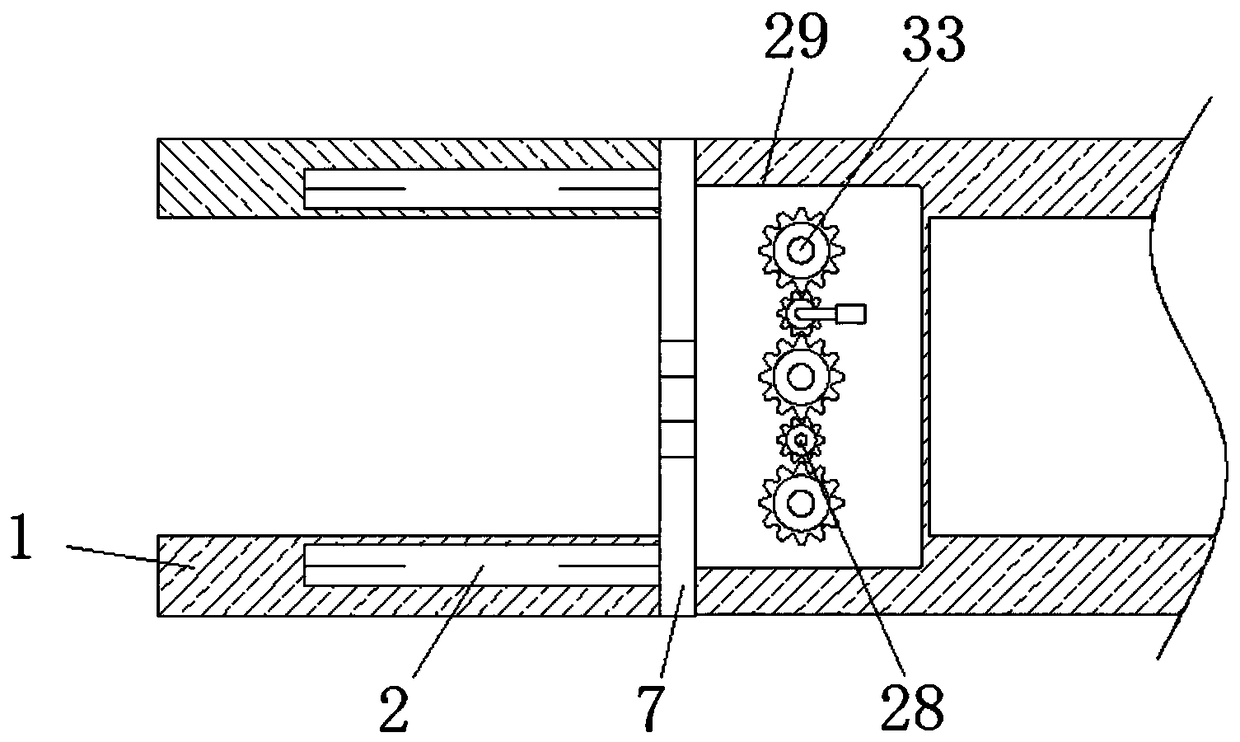

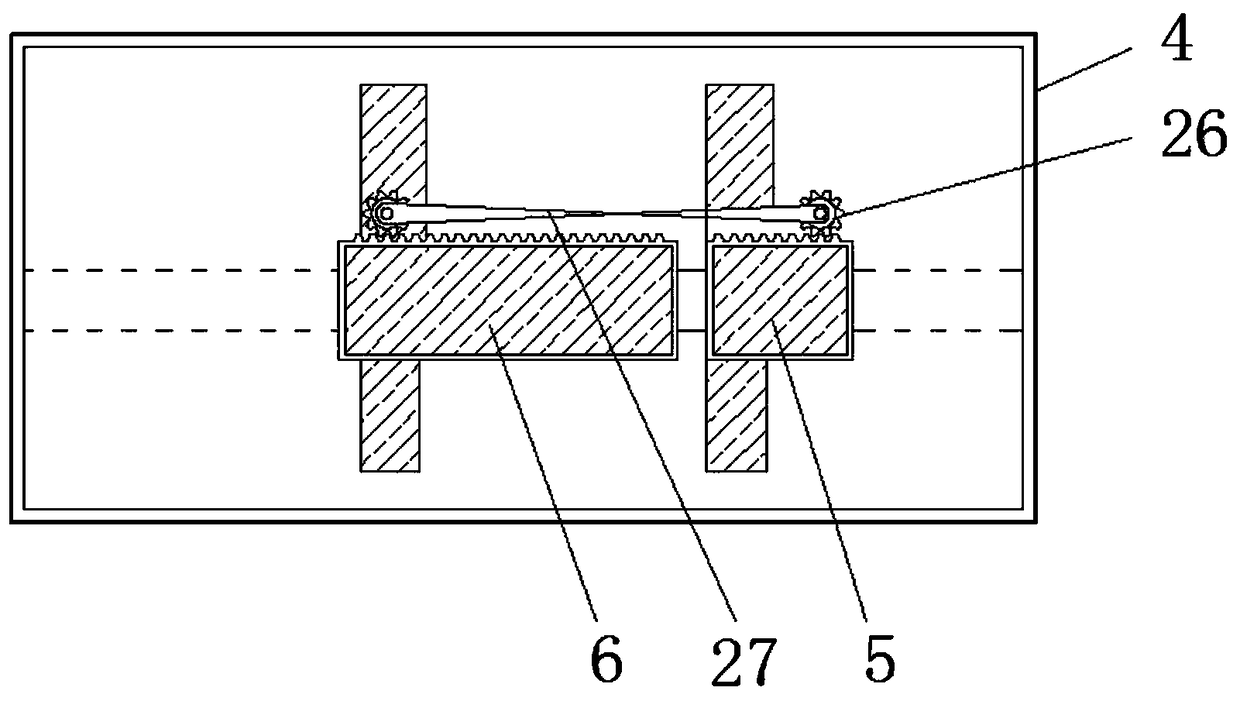

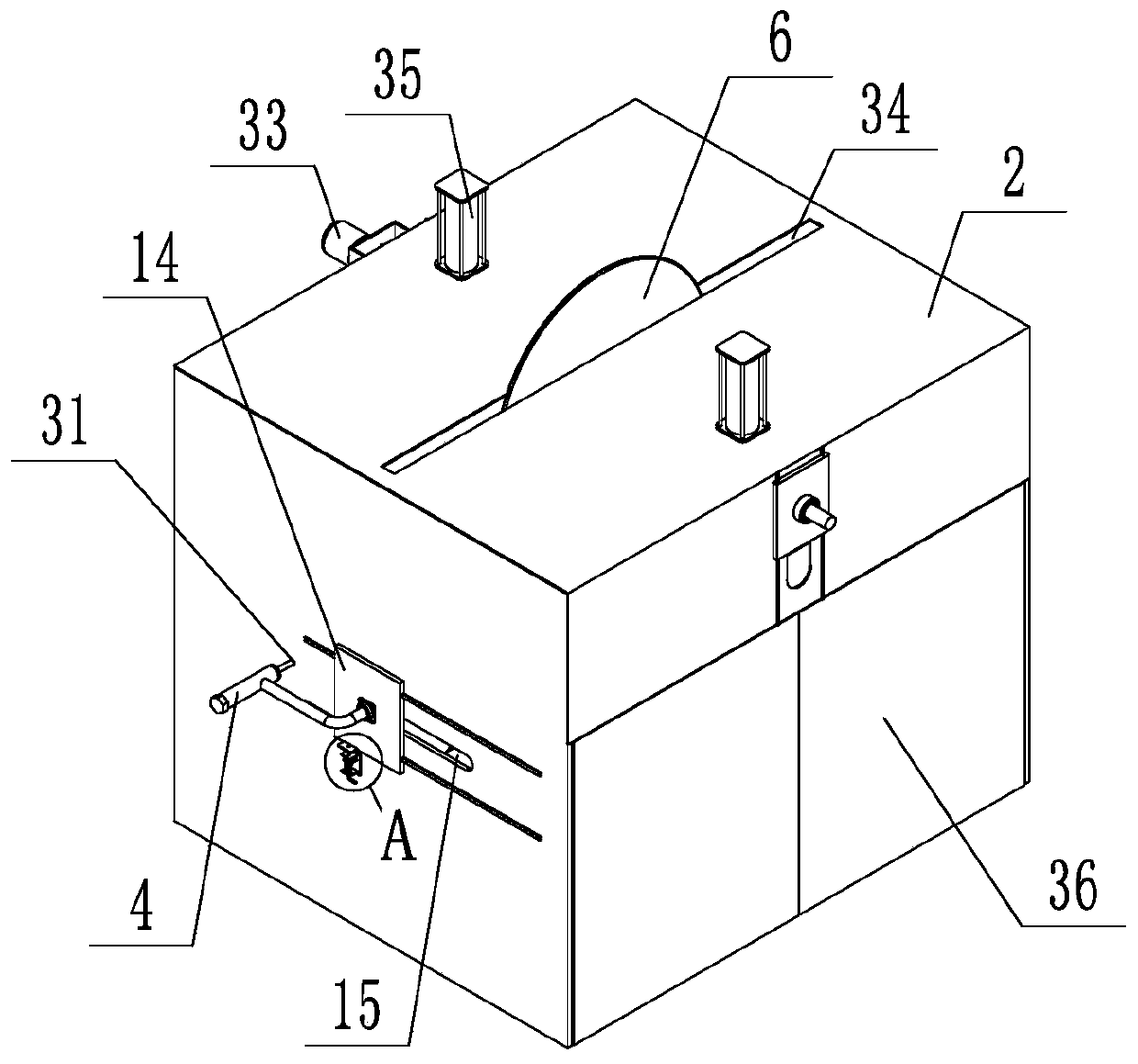

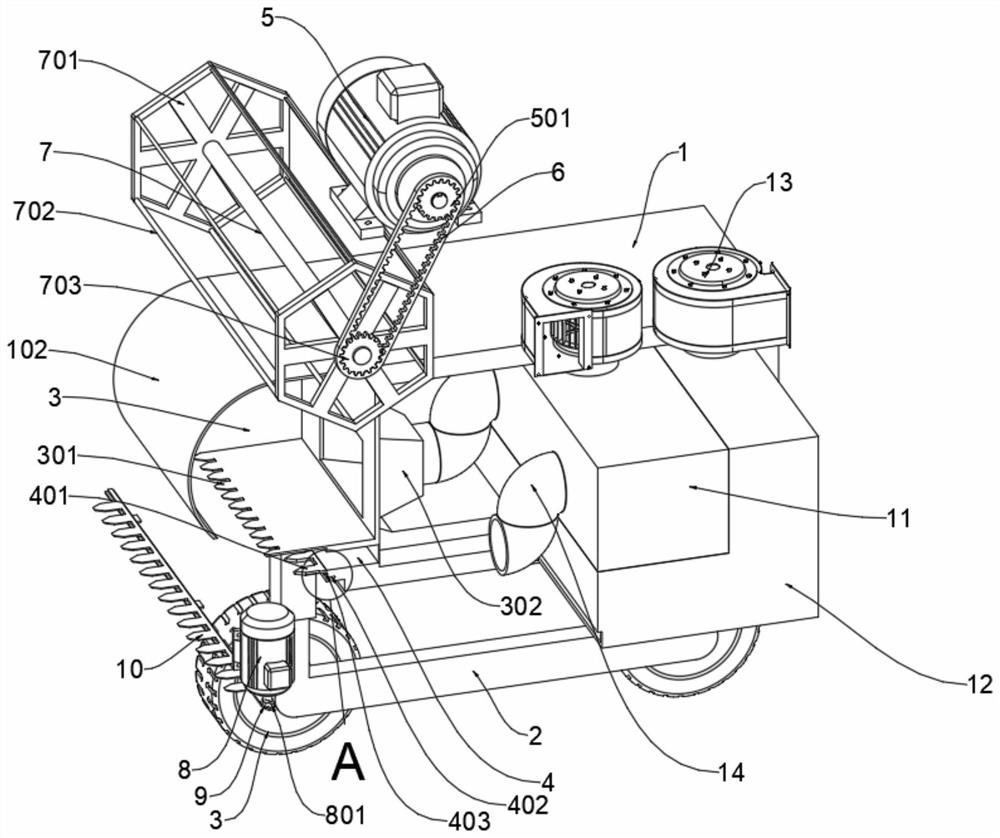

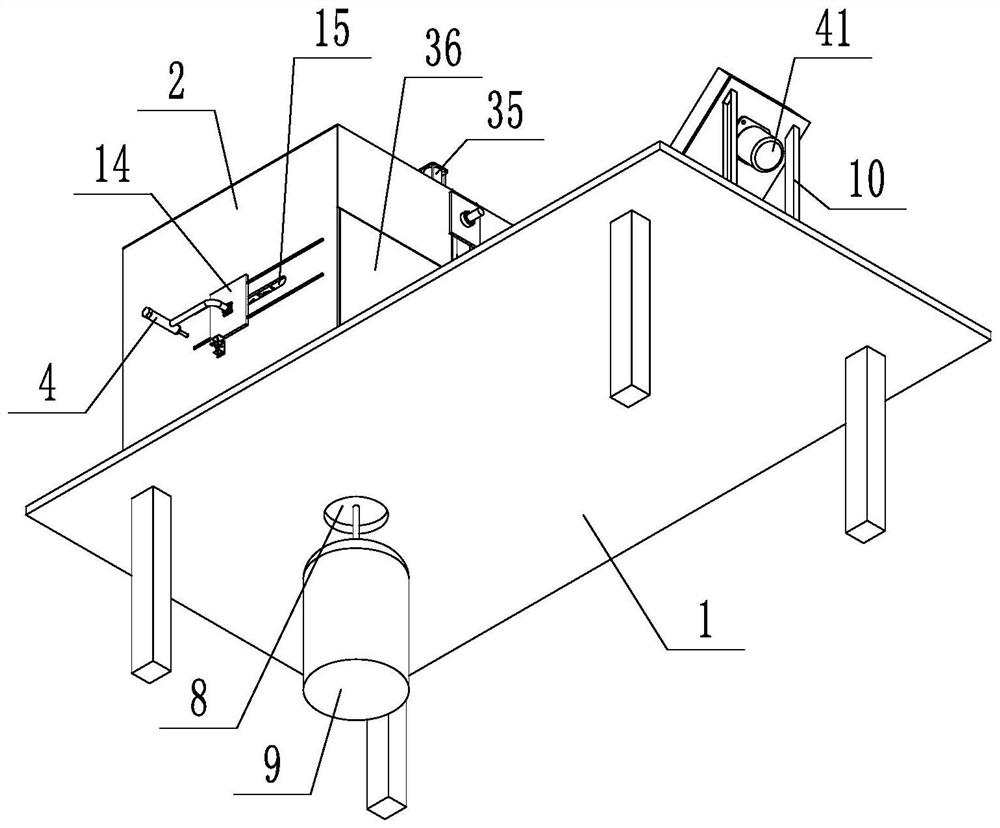

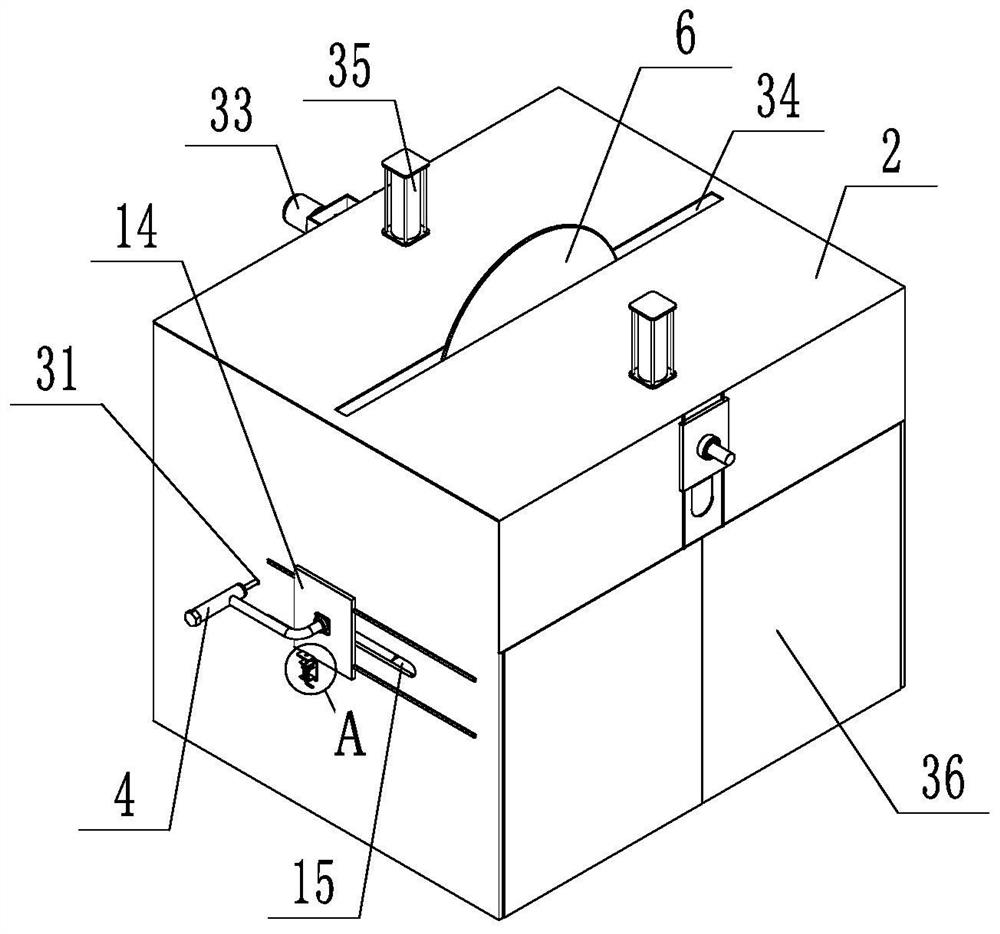

Traditional Chinese medicinal material slicing device

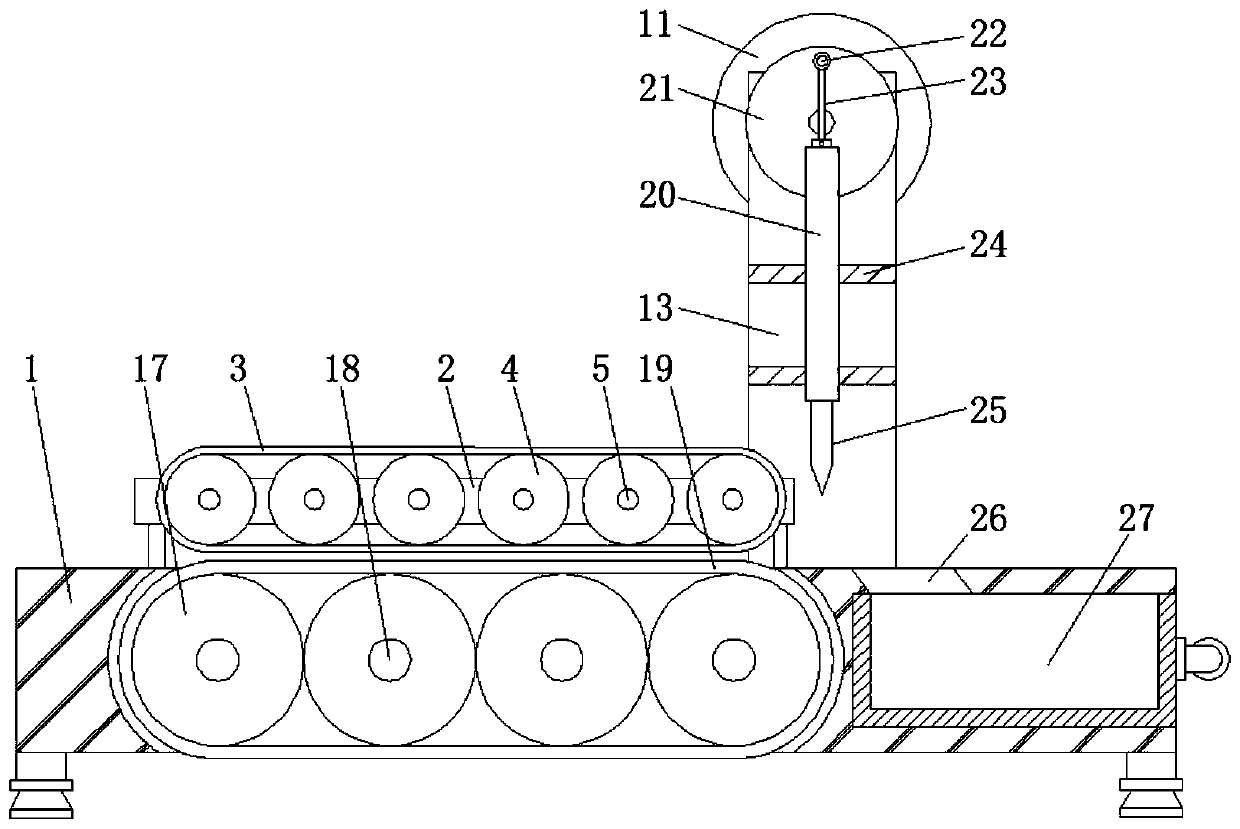

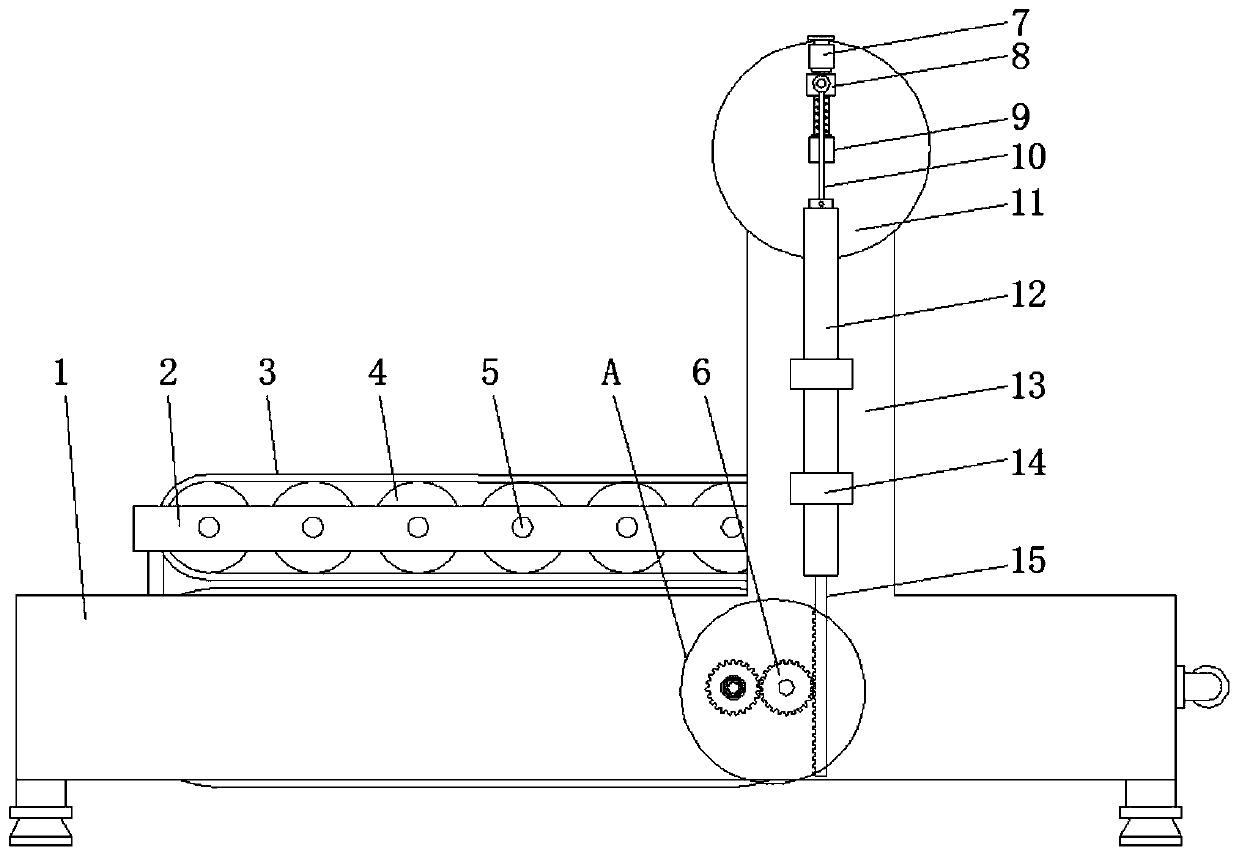

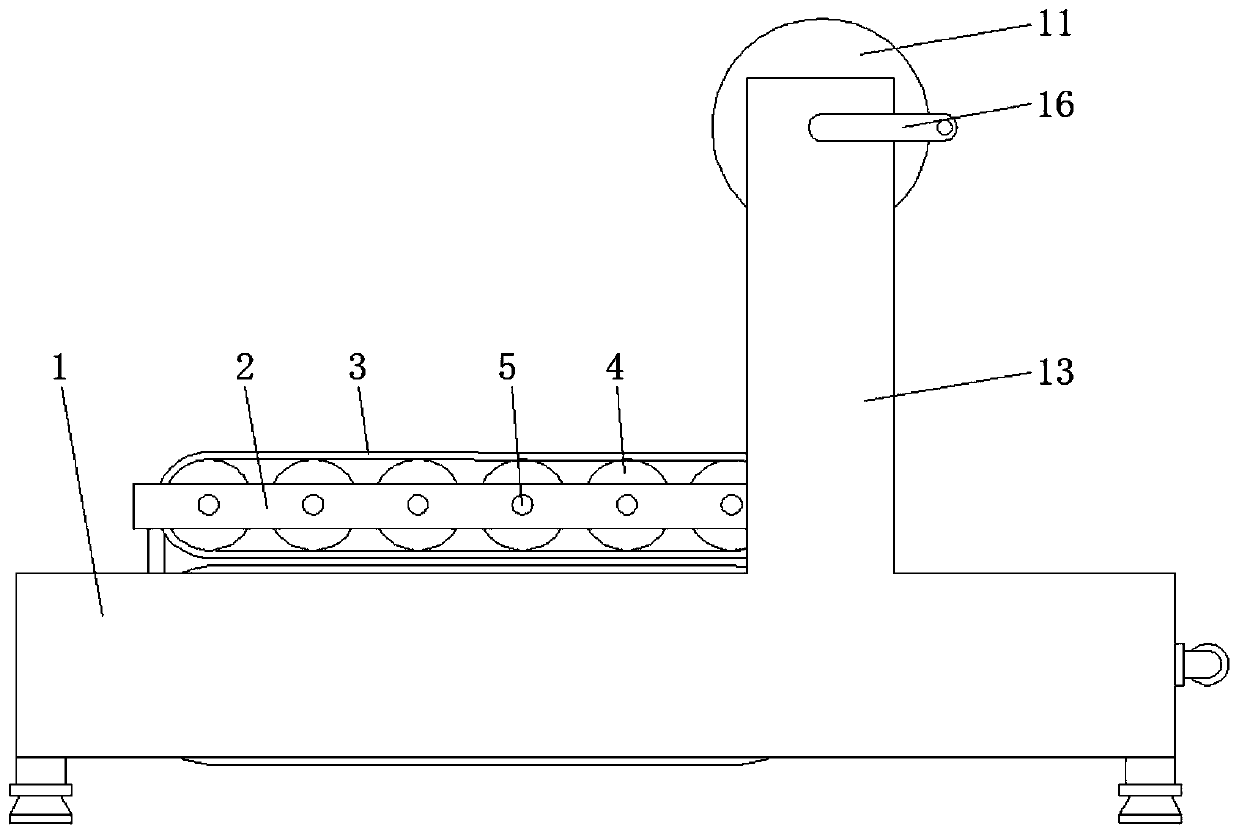

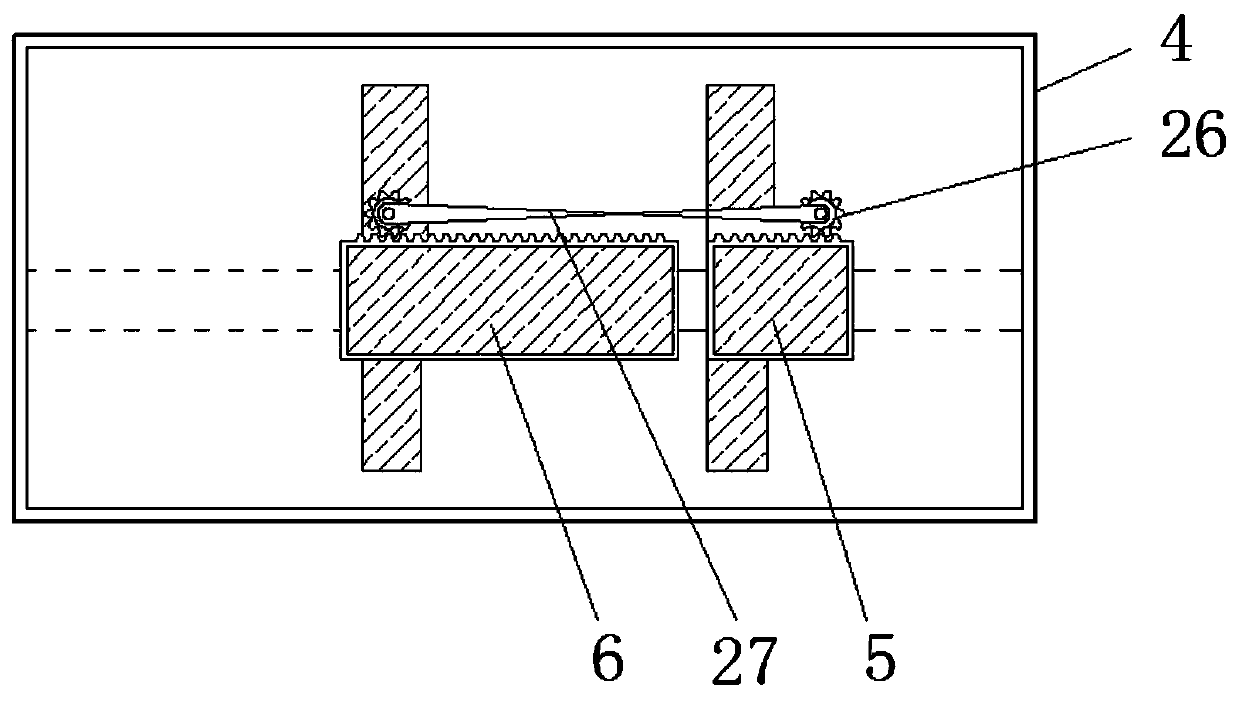

The invention discloses a traditional Chinese medicinal material slicing device which comprises a processing seat, fixed racks, a feeding mechanism, a driving mechanism, a slicing mechanism and a material frame. One end of the processing seat is slidably connected to the material frame, a discharging slot is formed in the processing seat above one end of the material frame, the fixed racks are connected to two sides of the top of the processing seat at two ends of the discharging slot, the slicing mechanism is connected between the fixed racks, the feeding mechanism is connected to the centerof one side of the fixed rack, and the driving mechanism is connected to the outer side of the fixed rack; the slicing mechanism comprises a tool apron, a second rotary wheel, a driving shaft, a second driving rod, a limiting plate and a slicer. The feeding mechanism comprises an upper end transfer part and a lower end transfer part. The driving mechanism comprises a transmission gear, a handwheeland an adjusting part. The traditional Chinese medicinal material slicing device can feed and slice traditional Chinese medicinal materials automatically by operating the handwheel by an operator andcan avoid a phenomenon of surface damage as the traditional Chinese medicinal materials are excessively extruded effectively, so that the integrity of the traditional Chinese medicinal materials is improved.

Owner:吕福杰

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

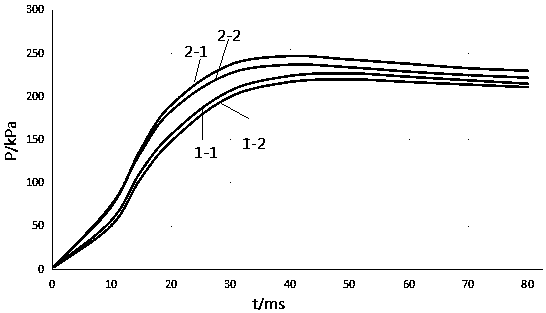

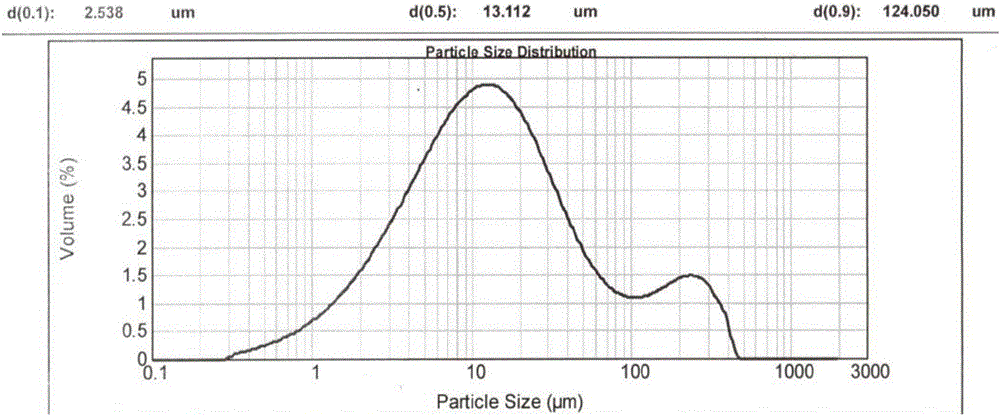

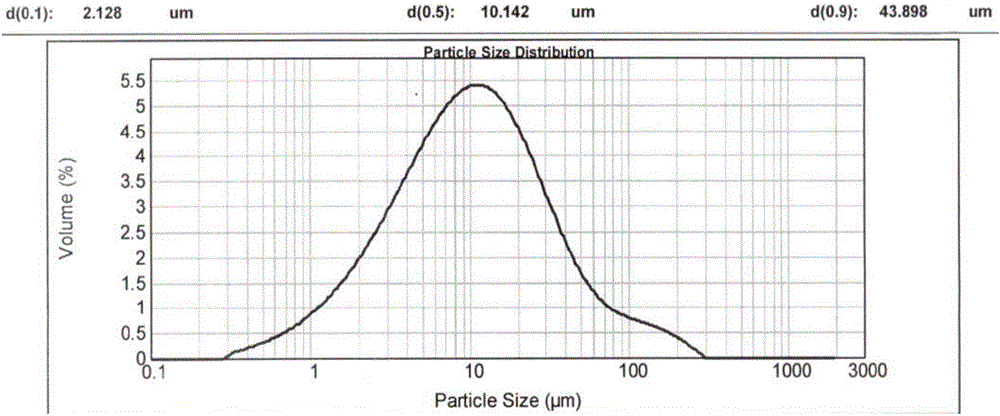

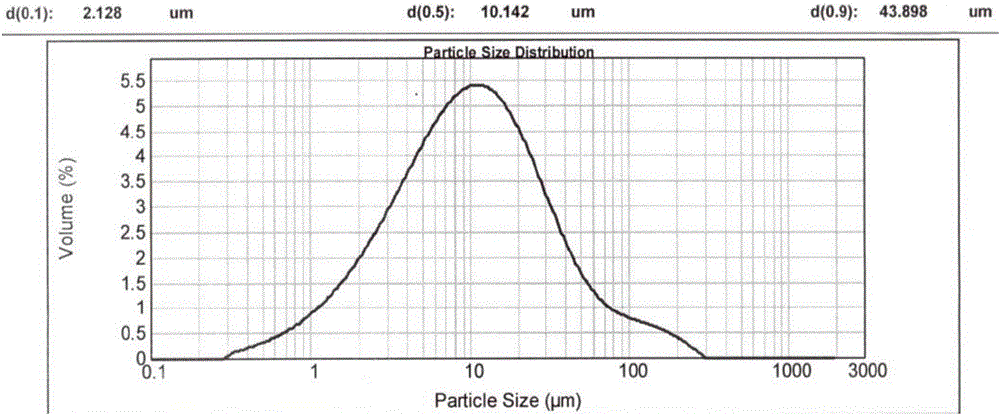

High-burning rate gas generating agent and granulation method thereof

ActiveCN107840772ABurn fasterMeet performance needsExplosivesPressure gas generationCopper nitrateBurn rate

The invention discloses a high-burning rate gas generating agent and a granulation method thereof. The granulation method comprises adding guanidine nitrate, basic copper nitrate, auxiliaries and water into a container, carrying out heating under control of the temperature in a range of 70-90 DEG C, stirring to disperse the mixture through a dispersing device to obtain a uniform mixture, drying the mixture through an atomizing device to obtain dry particles 1, finishing the dry particles 1 to obtain particles 2, drying the particles 2 to obtain particles 3, and tabletting the particles 3. Thehigh-burning rate gas generating agent has a high combustion speed and satisfies the performance requirements of side gasbags to a generating device with special speed requirements. The granulation method can reduce a raw material cost, is free of drying and crushing treatment on raw materials before use, guarantees full contact and mixing of components, improves product stability and consistency,realizes full dissolution of soluble raw materials through a heating dissolution method, utilizes a basket mill and unbaked wet basic copper nitrate to grind and disperse so that a uniform material is obtained, is easy to operate and has high production efficiency.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

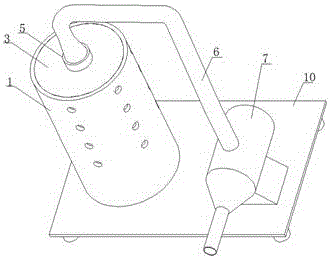

Garlic peeling machine

InactiveCN105725234AEasy to disassemble and cleanPrevent slippingFood treatmentEngineeringFood processing

The invention discloses a garlic peeling machine, which belongs to the field of food processing machinery. The garlic peeling machine includes: a garlic peeling tube, which is used to hold the garlic that needs to be peeled; a motor, which is used to drive the rotation of the garlic peeling tube; a flapping piece, which is fixed inside the garlic peeling tube; , collision occurs between the flapping sheet and the garlic or the garlic to achieve the peeling effect. The beneficial effect of the present invention is that: the garlic peeling machine can quickly peel the garlic and quickly separate the garlic from the garlic skin, the manufacturing cost is low, and the operation is convenient.

Owner:贺灿炎

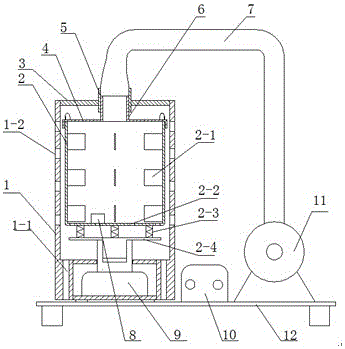

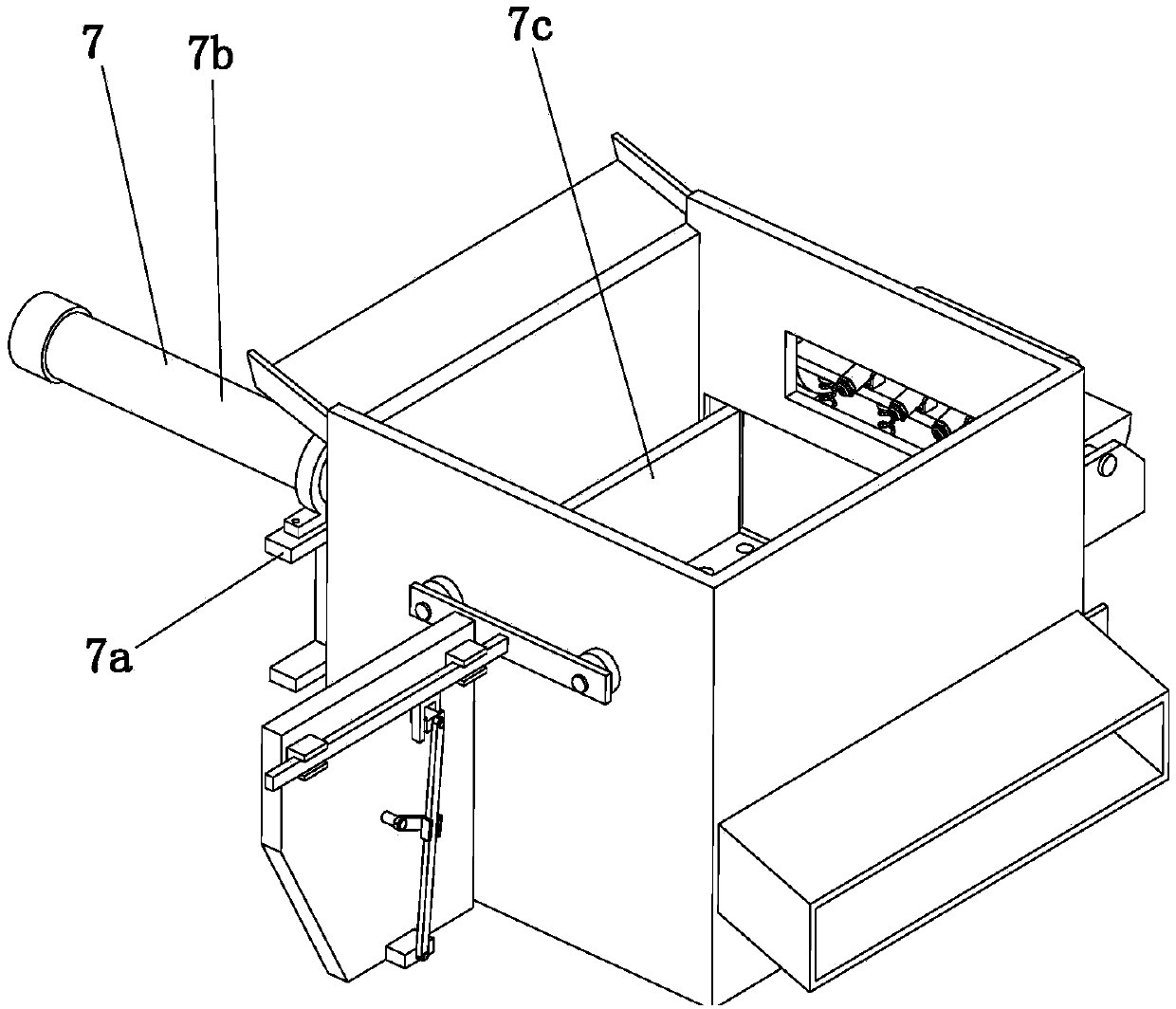

Waste paper disposal device

ActiveCN109653010ASolve the technical problem of sticking to the side wall of the deviceThere will be no sticking phenomenonPaper recyclingPulp bleachingReciprocating motionPulp and paper industry

The invention discloses a waste paper disposal device, and belongs to the field of waste paper disposal. The waste paper disposal device comprises a conveying belt, a waste paper compacting mechanism,a waste paper cutting-up mechanism and a pulp recycling mechanism; the pulp recycling mechanism comprises a recycling box, an adherent paper knocking-off assembly, a waste paper bleaching assembly and a material pushing assembly; a feeding sliding passage is arranged at the left end of the recycling box, a discharging funnel is arranged at the right end of the recycling box, and a closed door which cooperates with the sliding passage is arranged on the discharging funnel. According to the waste paper disposal device, the waste paper cutting-up mechanism can automatically compact and cut up waste paper on the conveying belt, and offset of the waste paper in the cutting process and influence of offset of the waste paper on cutting operation are avoided; the adherent paper knocking-off assembly can make a shock cylinder do reciprocating motion and knock the side wall of the recycling box so that the waste paper can be prevented from sticking to the inner side wall of the recycling box and the influence on cleaning by workers can be avoided, and waste of resources is also avoided.

Owner:山东天智信息科技有限公司

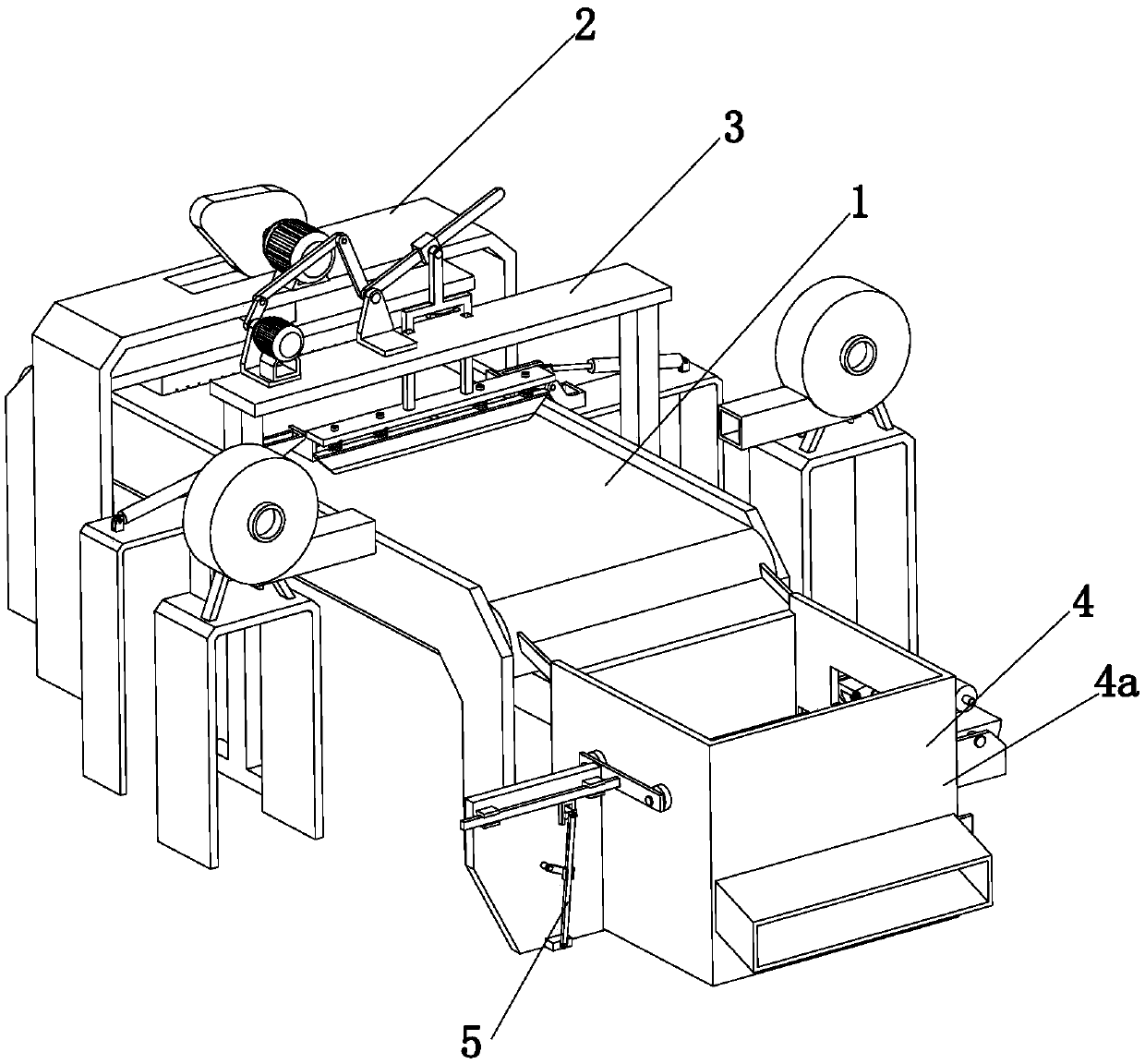

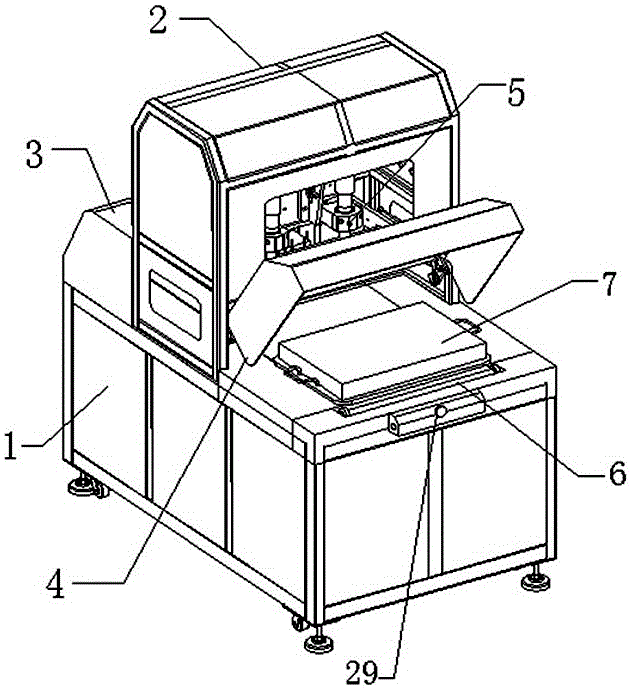

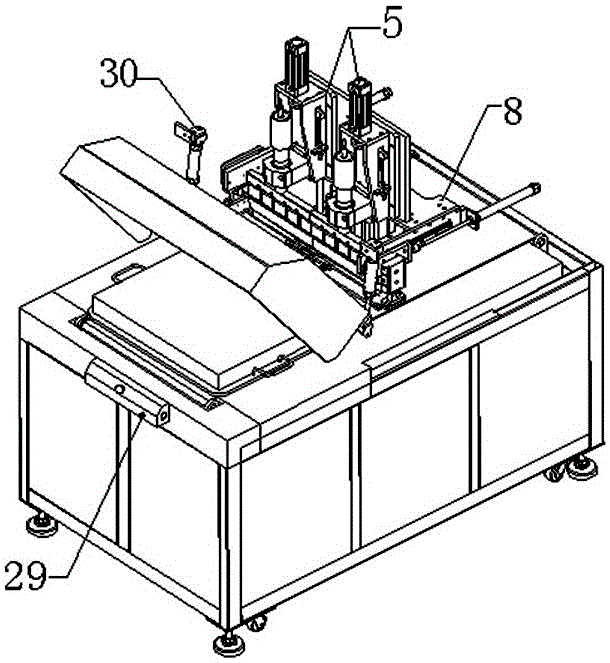

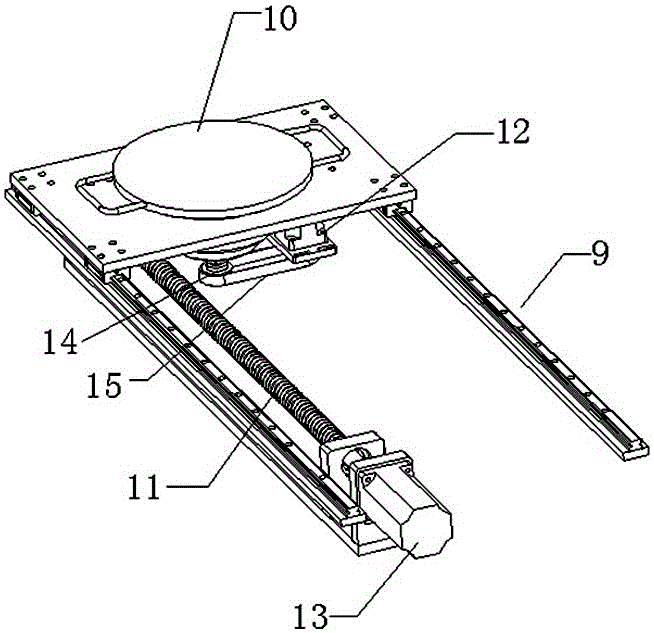

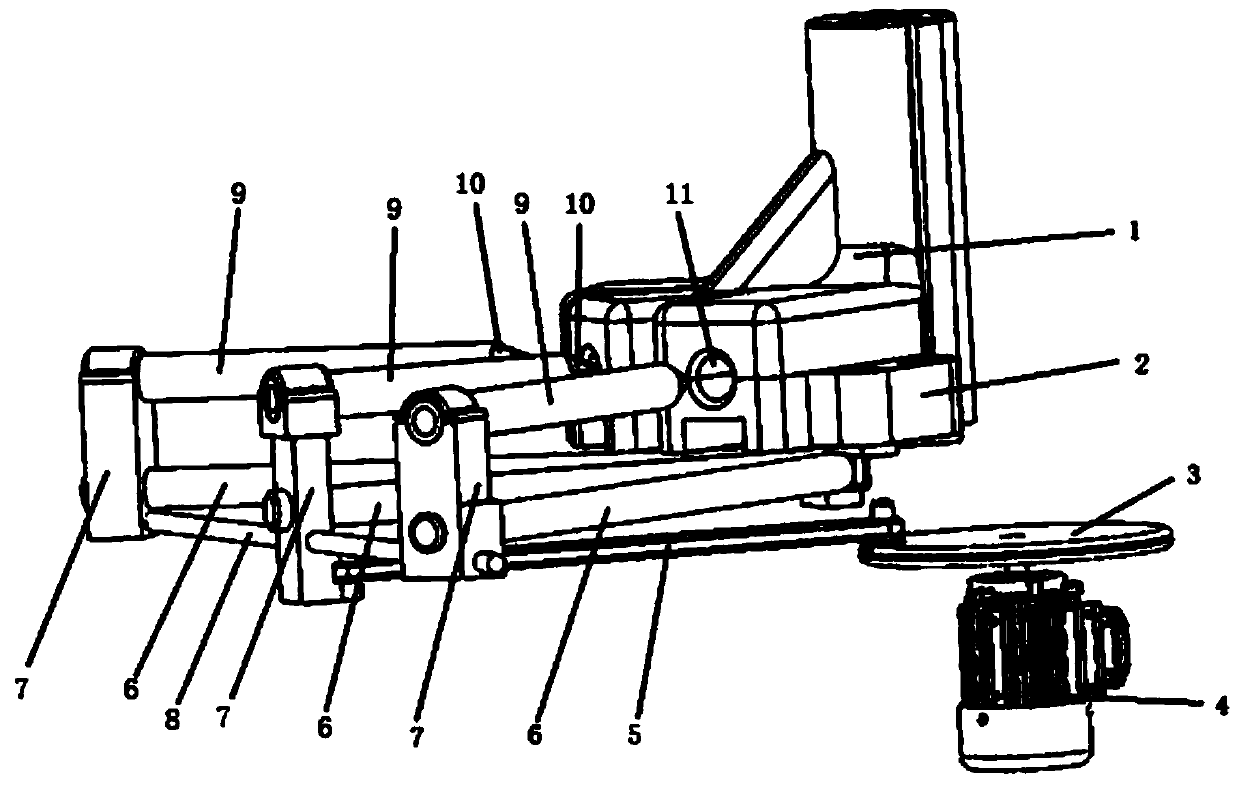

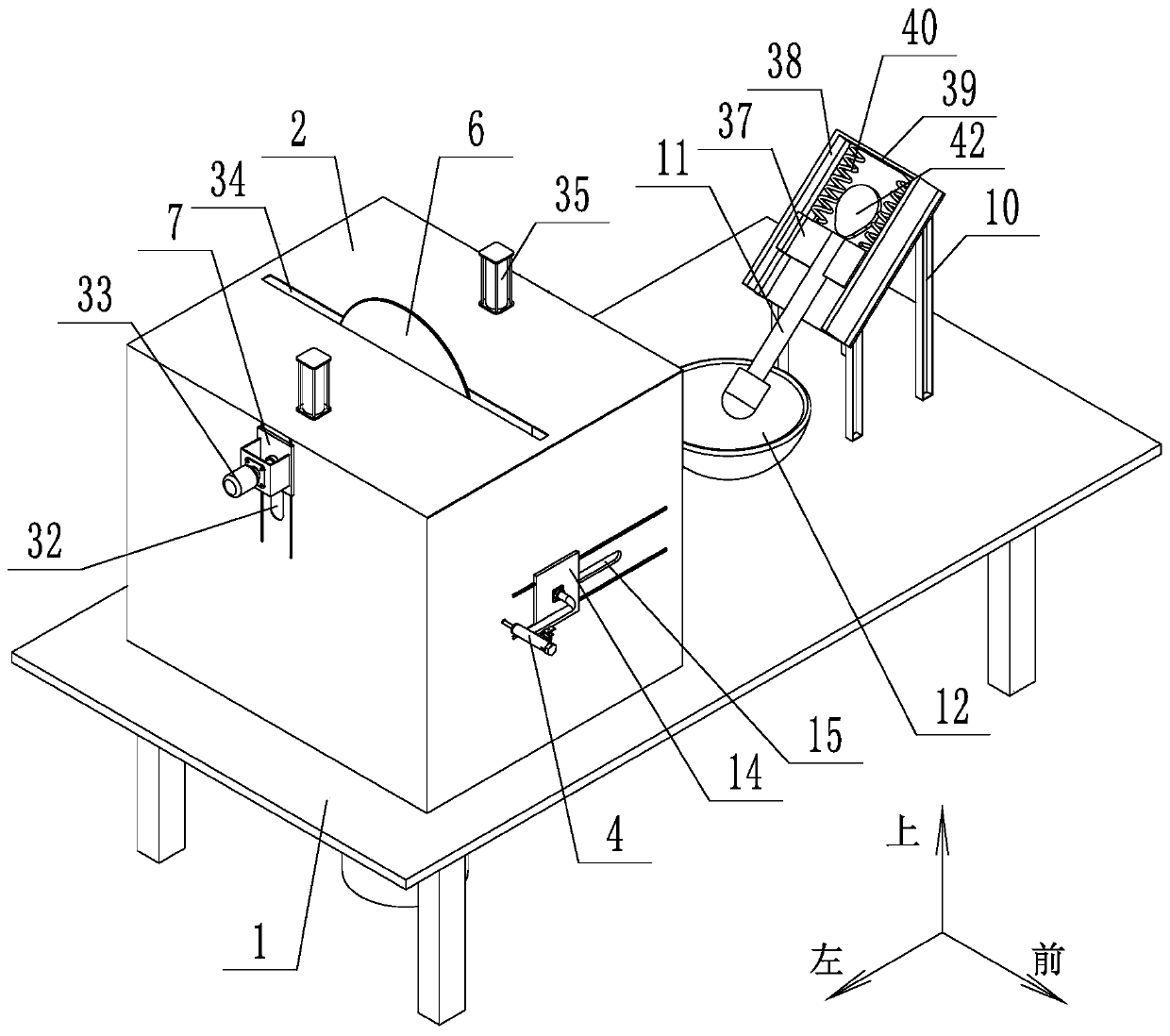

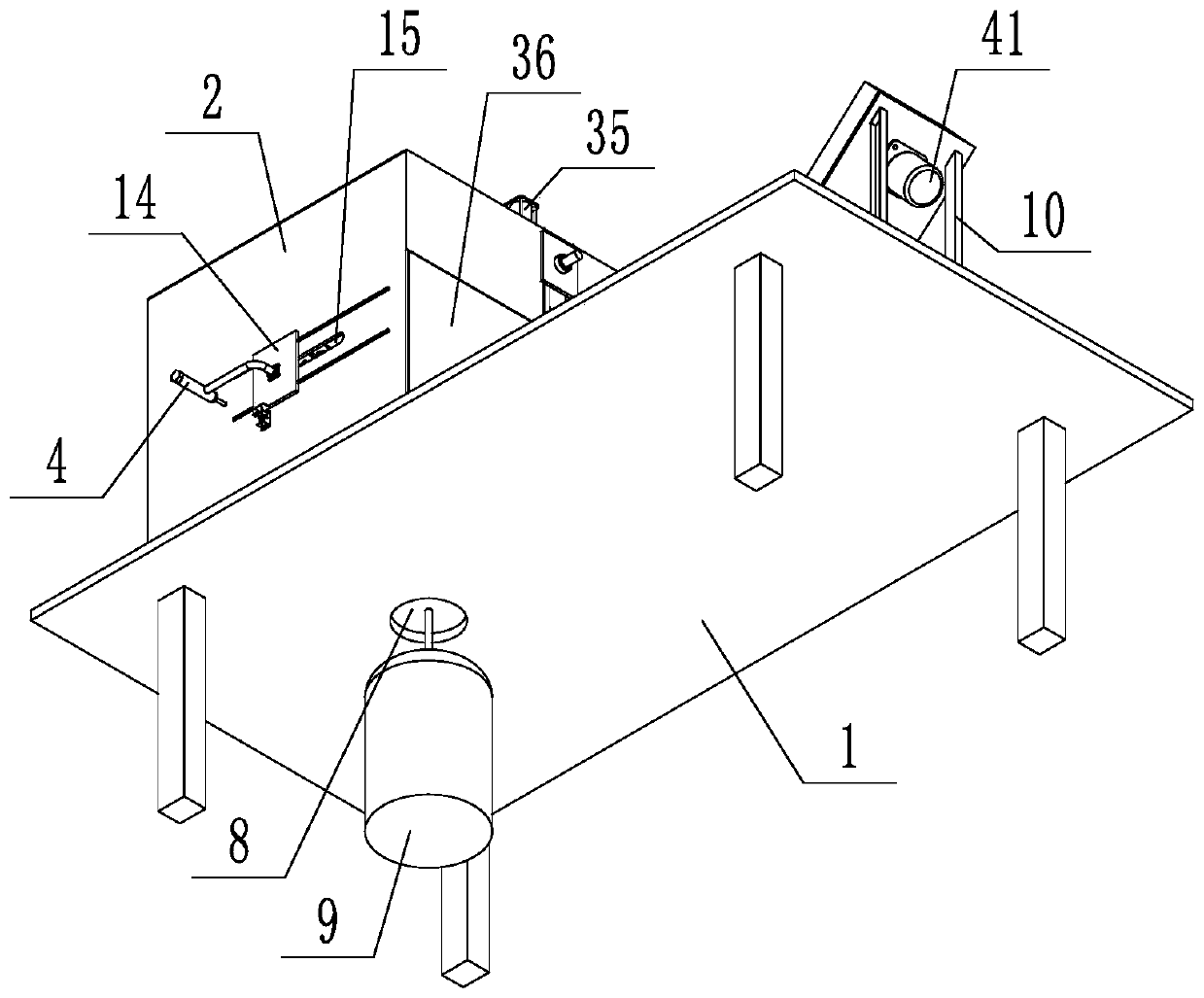

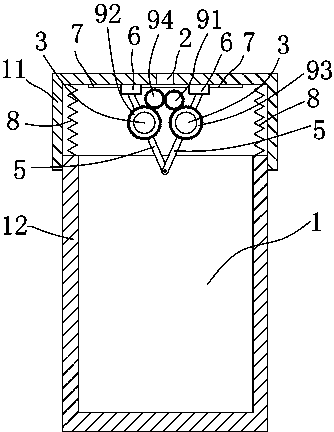

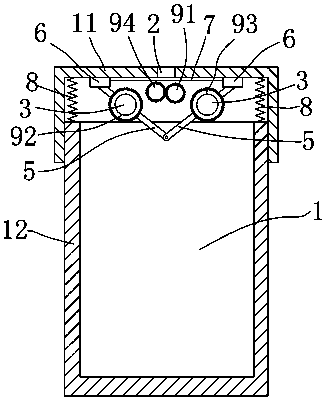

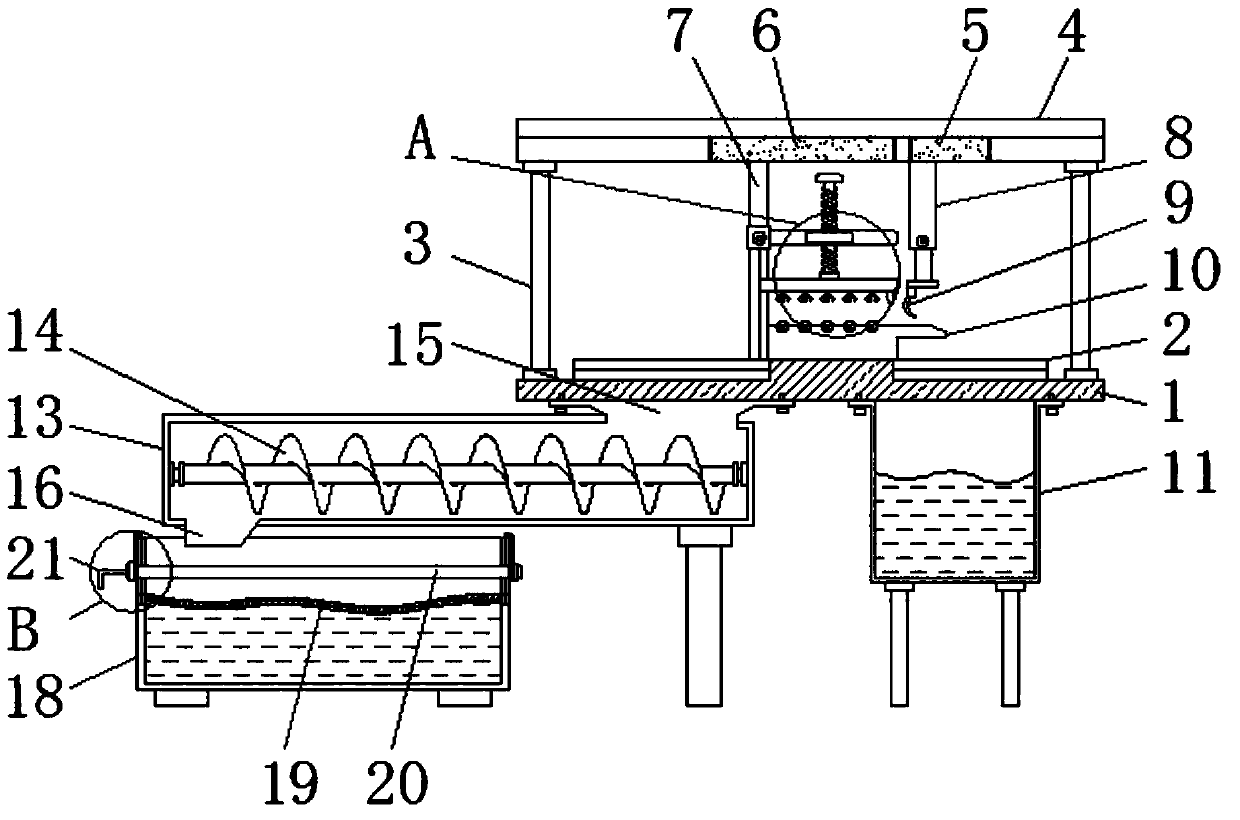

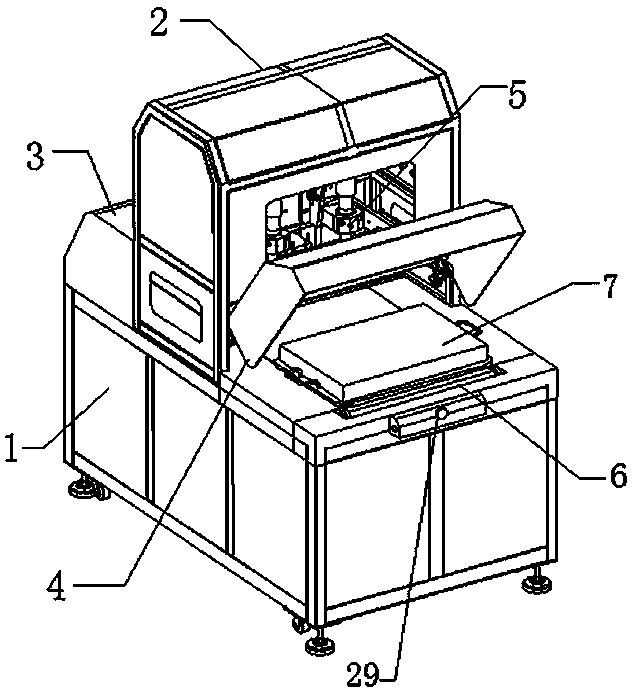

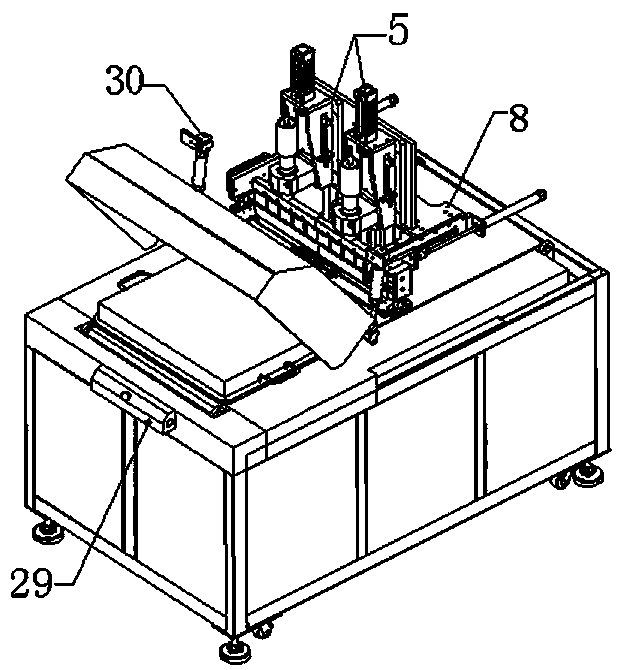

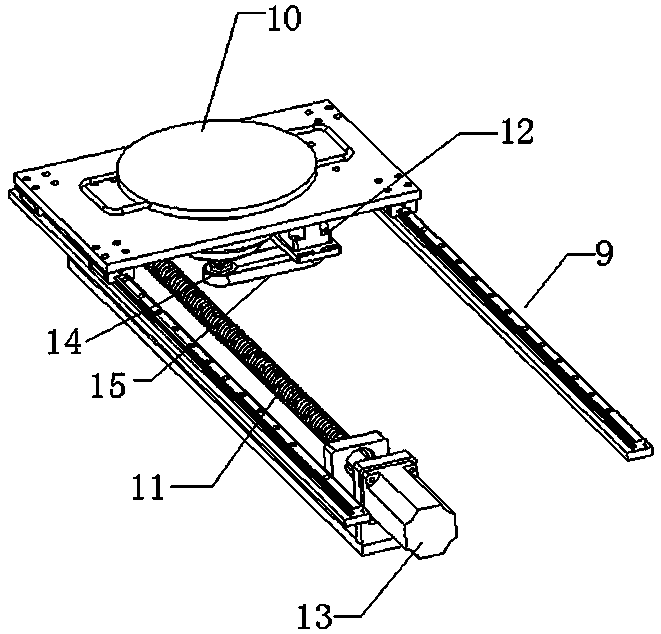

Ultrasonic food cutting machine

ActiveCN106808517ASmall cut filletsPrevent shreddingMetal working apparatusUltrasoundMechanical engineering

The invention discloses an ultrasonic food cutting machine. The machine comprises a stainless steel rack, a cutting shield, a transparent shield, a paper supply shield, an ultrasonic cutter mechanism, a food conveying mechanism, a shield rotating mechanism and a paper piece taking mechanism. Equal-distance forward movement of a tray of the machine can cooperate with the ultrasonic cutter mechanism for cutting of foods in the square specifications, equal-angle rotation of the tray can further cooperate with the ultrasonic cutter mechanism for cutting of foods in the equal-angle circumference specifications, the machine integrates functions of full-automatic taking of paper pieces, full-automatic and accurate placing of the paper pieces, full-automatic adoption of ultrasonic waves for cutting of the foods, full-automatic and accurate positioning of the foods and full-automatic conveying of the foods, equal-distance moving cutting and rotating cutting can be performed on the foods, the foods in different shapes and different sizes and the like can be cut automatically, numbers and distances of transversely cut foods and vertically cut foods are input respectively according to actual conditions of production, positioning and ultrasonic cutting can be completed for the foods automatically, and the automatic operation degree is high.

Owner:DONGGUAN BRDASON ULTRASONIC EQUIP CO LTD

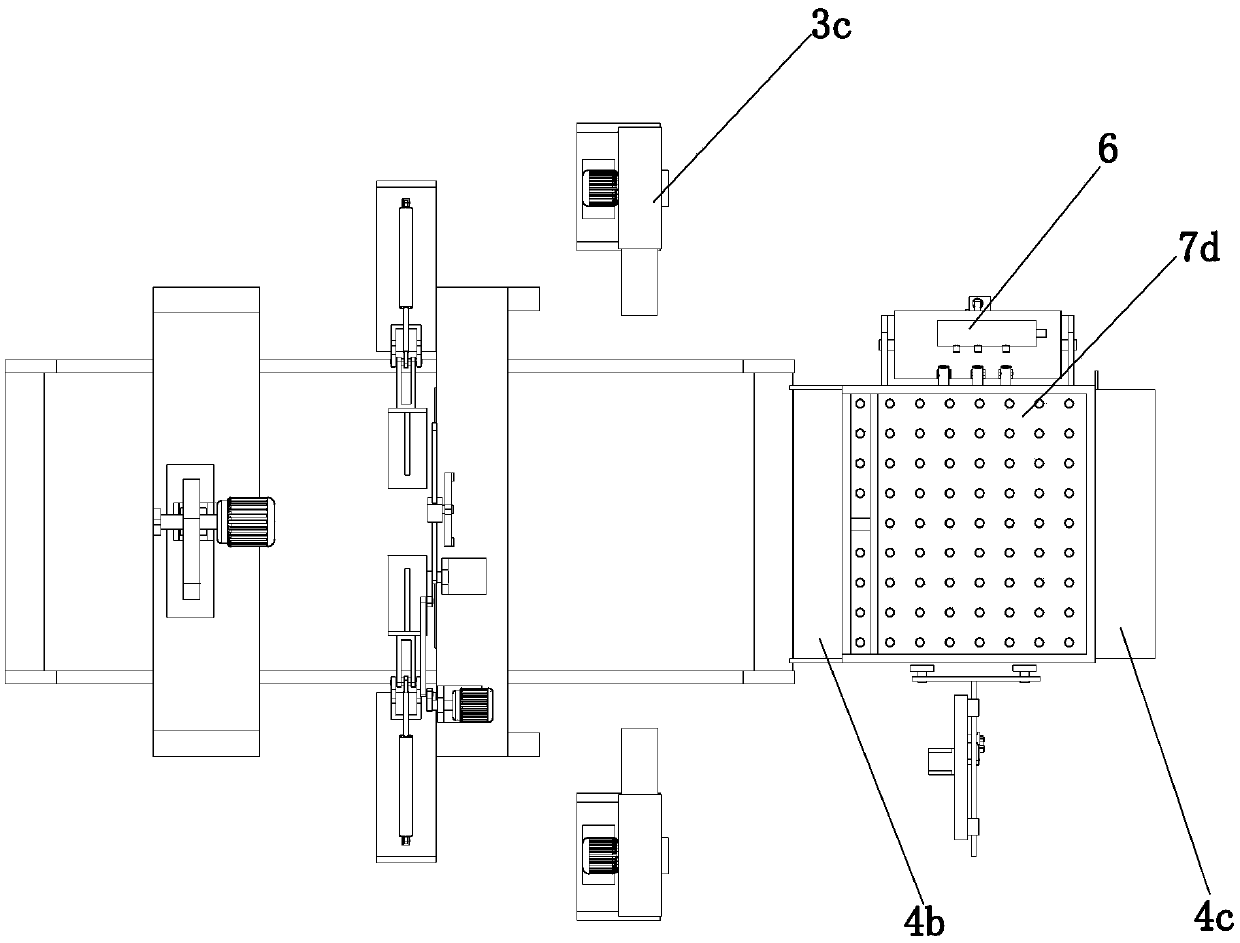

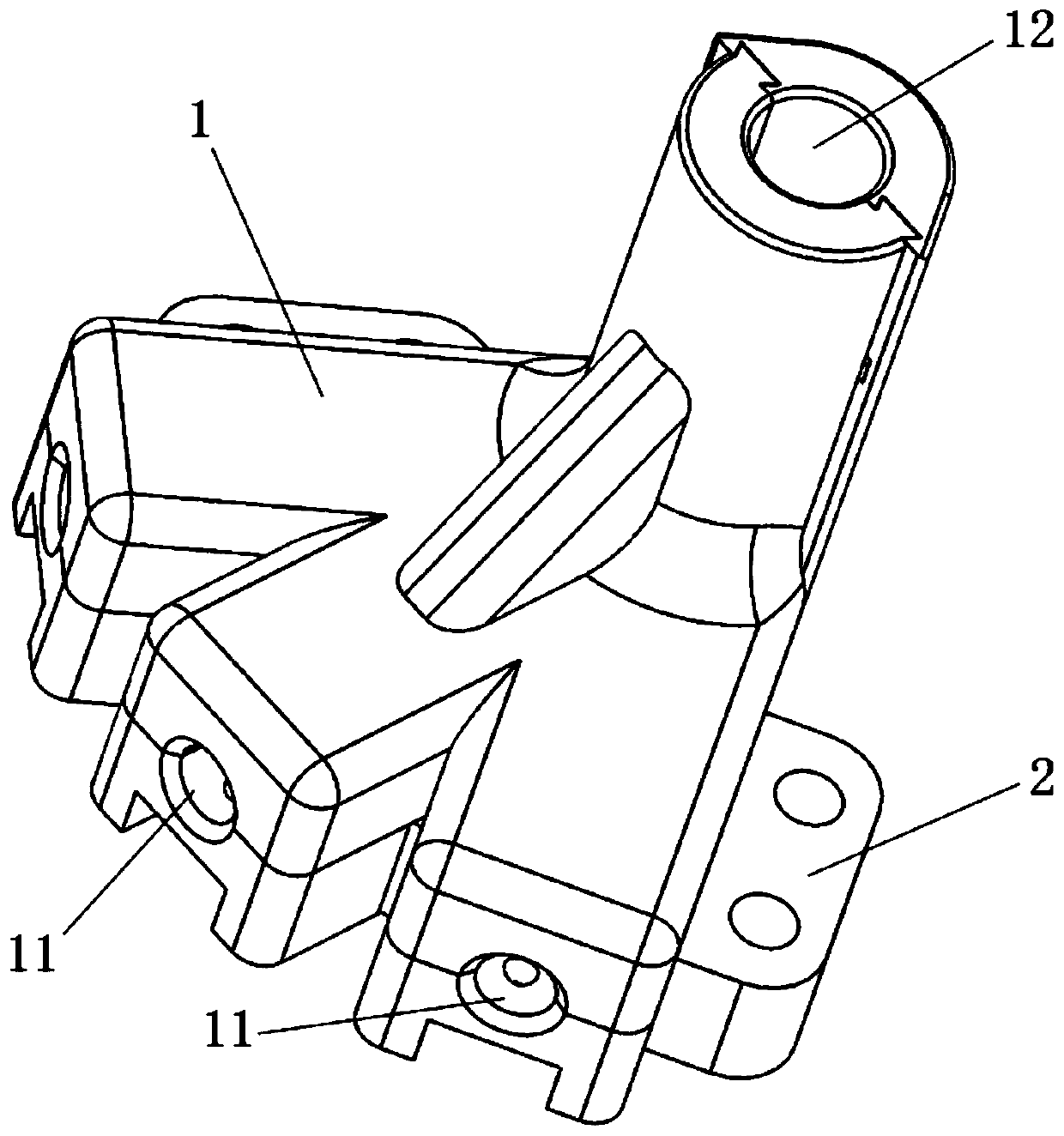

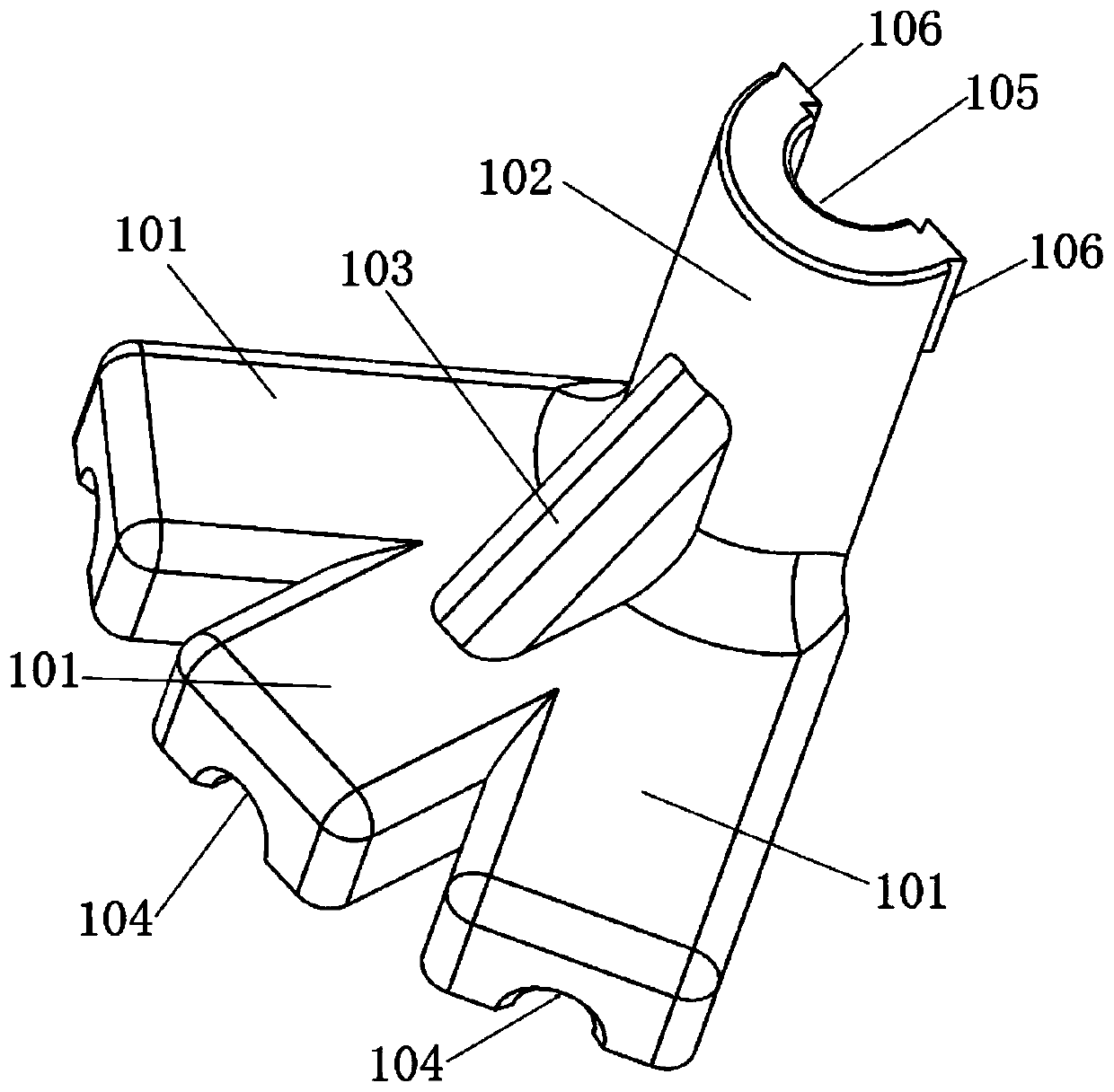

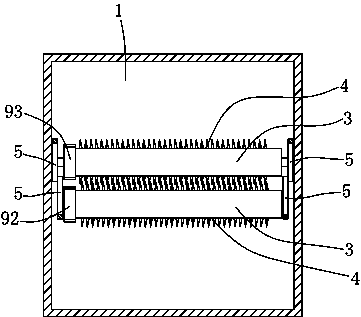

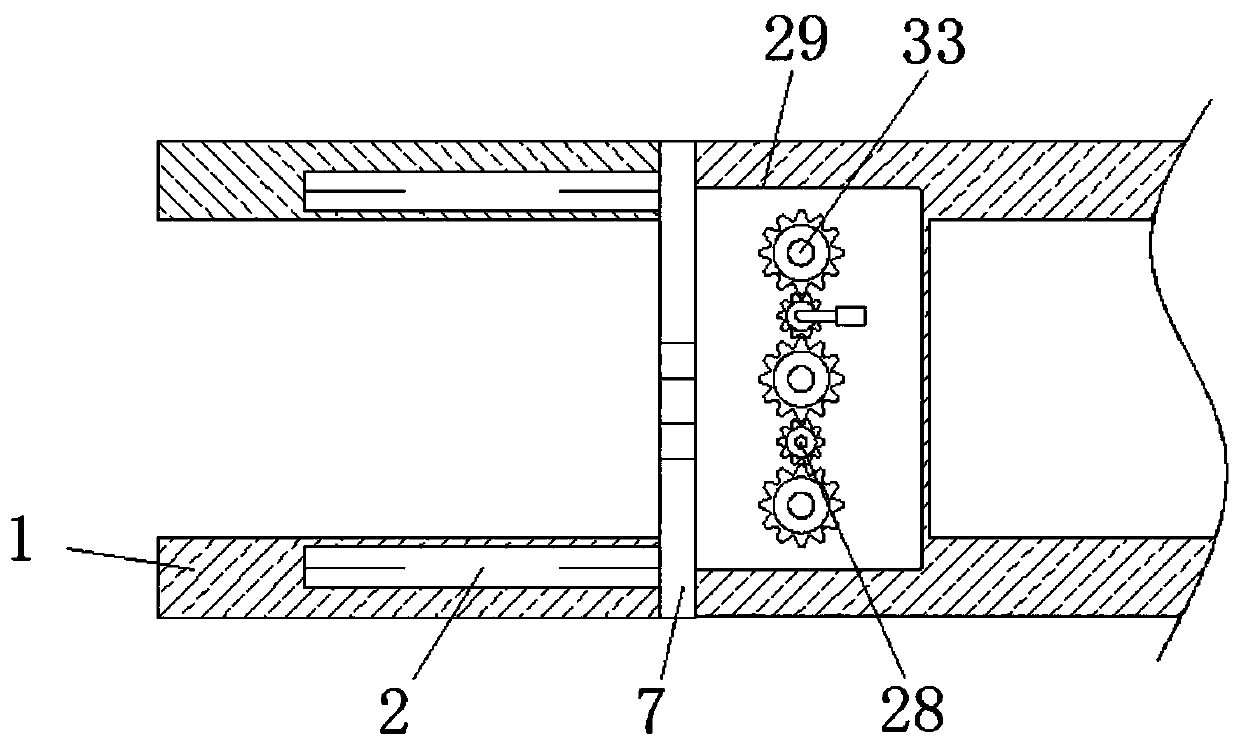

Automatic chicken foot deboning machine

InactiveCN110024838APrevent shreddingFacilitate the separation of flesh and bloodPoultry deboningEngineeringMechanical engineering

The present invention belongs to the technical field of food processing machinery, particularly relates to an automatic chicken foot deboning machine, and aims at problems that in the prior art, automatic deboning devices are not perfect, and no product capable of separating bones and meat and also better preserving meat food appearances exists. A technical scheme is as follows: the automatic chicken foot deboning machine comprises an upper base seat and a lower base seat for clamping chicken feet, three phalanx guiding holes used for extending out one toe of the chicken feet are formed between the upper base seat and the lower base seat, guiding rods are arranged under the lower base seat, the number and extending directions of the guiding rods are the same as those of the phalanx guidingholes, the guiding rods are slidably connected with push blocks, the push blocks are fixedly connected with deboning knives, positions and directions of the deboning knives correspond the opening positions and directions of the phalanx guiding holes, and the push blocks are also connected with driving devices. The automatic chicken foot deboning machine has two advantages of being rapid in deboning of the chicken feet and maintaining complete appearances.

Owner:HENAN INST OF ENG

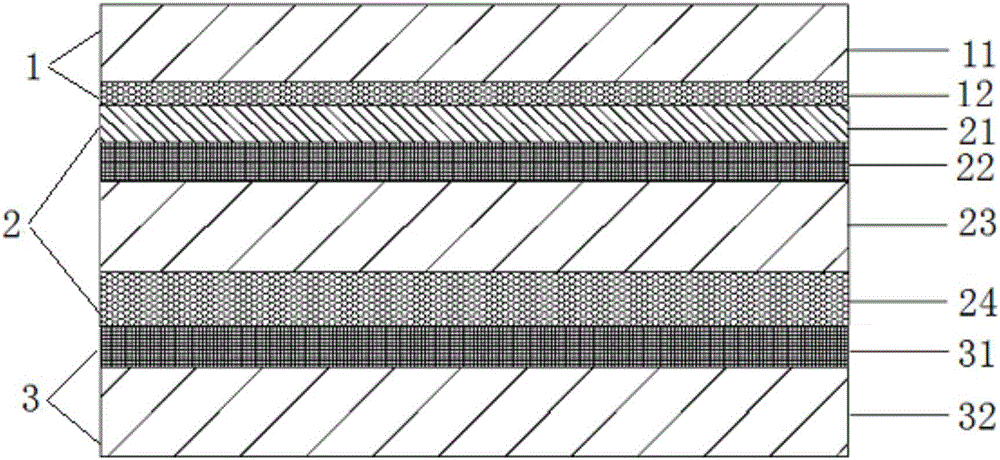

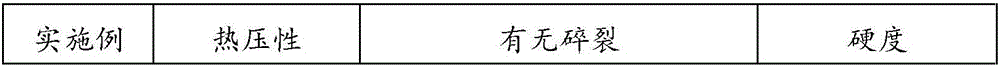

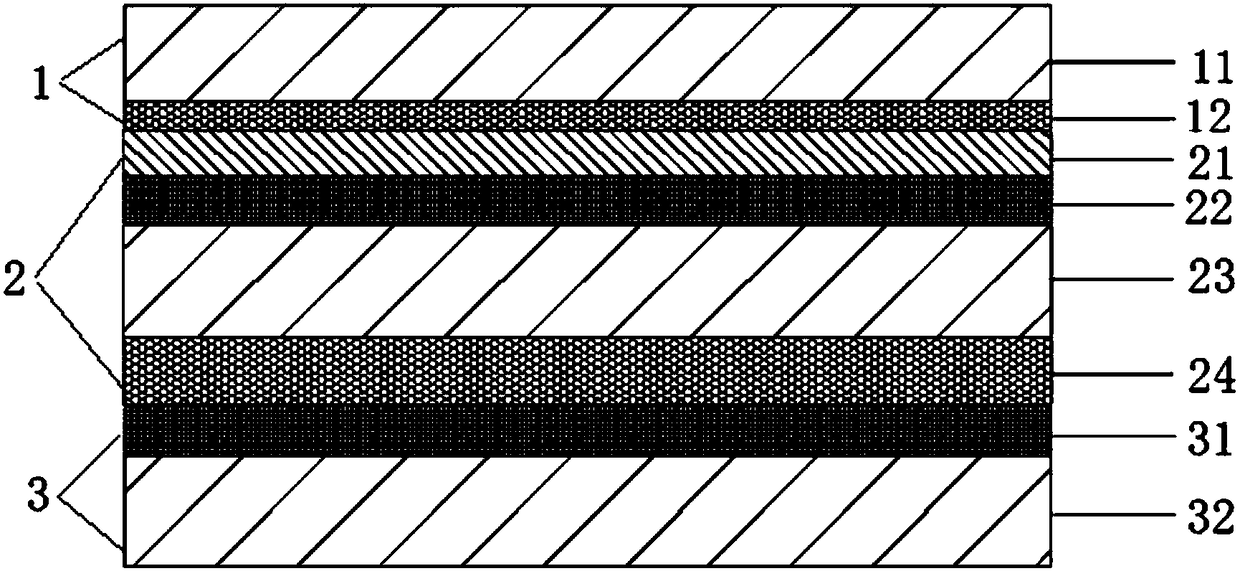

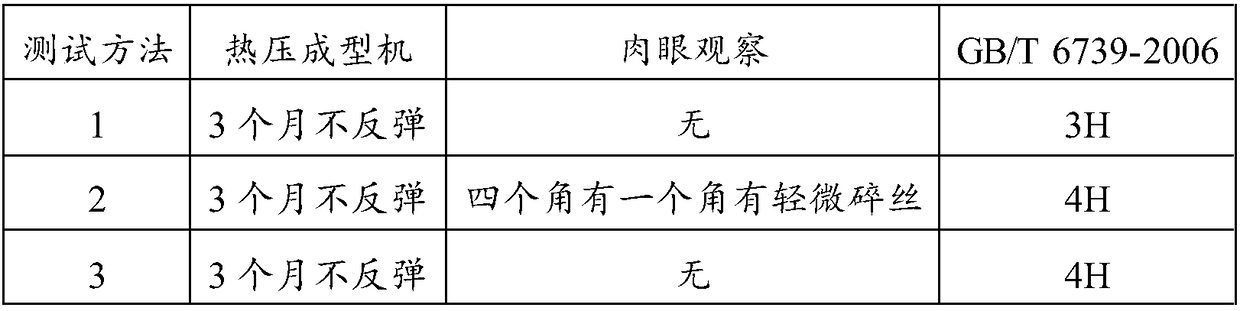

Protective film and preparation method thereof

ActiveCN106183121AImprove the effect of hot pressingReduce hardnessLamination ancillary operationsSynthetic resin layered productsTectorial membranePolymer science

The invention provides a protective film, comprising: a protective film layer; a UV (ultraviolet) hard rubber layer combined to the protective film layer; an application UV soft rubber layer combined to the UV hard rubber layer; an application base layer combined to the application UV soft rubber layer; an application viscose layer combined to the application base layer; a release layer combined to the viscose layer; the hardness of the application UV soft rubber layer is <1H. By coating the bottom of the UV hard rubber layer with one UV soft rubber layer, the hardness of an application layer decreases gradually from top to bottom with overall hardness of the application layer decreased; rebound of the protective film is prevented by using memory function of the viscose layer and UV soft rubber layer that are hot-pressed, and shredding of UV face corners is effectively prevented. Experimental results show that the protective film has good hot-pressing performance and has lasting shape performance after being hot-pressed. The invention also provides a preparation method of the protective film.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Crayfish shelling apparatus with flushing function

ActiveCN109077102AWith washing functionEasy to separate and removeShrimp/lobster processingPrawnSlide plate

The invention discloses a crayfish shelling apparatus with a flushing function, comprising a fixing platform, a shell collection tank, a mixing tank and a meat washing tank. A slide plate is fixedly connected to the surface of the upper end of the fixing platform, a first slider and a second slider are slidably connected inside the transverse plate sequentially from right to left; a support tableis fixedly connected to the right surface of a connection bar; a third gear and a second gear are connected in engaged manner; a threaded bar is passed sequentially through the support table and the third gear from outside to inside; a vertical tool is welded to the right lower end of a cover plate; the cover plate is slidably connected to the right end of the connection bar; rollers are rotationally connected to the surface of a holding plate; a telescopic bar is fixedly connected to the lower end of the first slider. The crayfish shelling apparatus herein allows crayfish head shells and tails to be conveniently separated and removed, helps conveniently collect shells and tails in classified manner, helps conveniently fully mix and wash the tails, and helps provide improved working efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

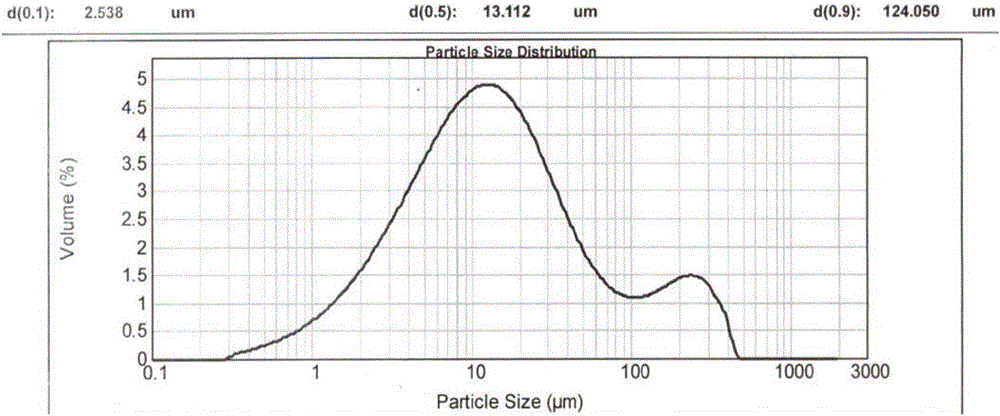

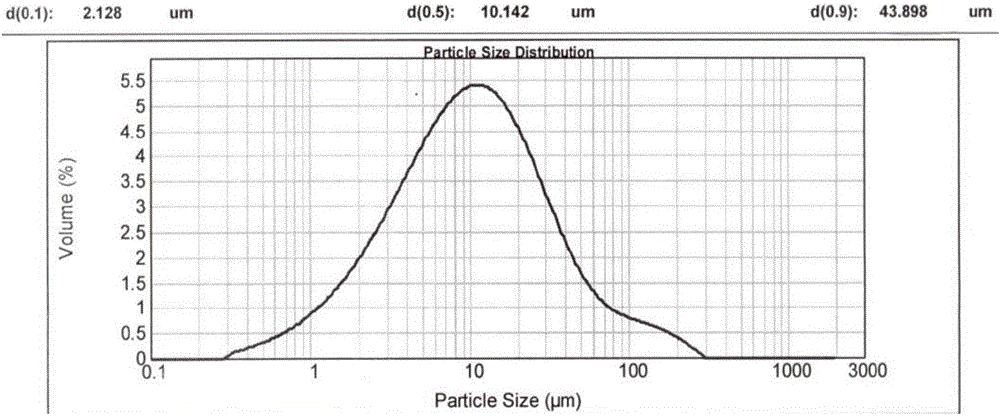

Pharmaceutical composition containing LCZ696 and preparation method of pharmaceutical composition

InactiveCN106389374AFormulation process optimizationImprove performanceOrganic chemistryInorganic non-active ingredientsCrystallizationChemistry

The invention provides an LCZ696 pharmaceutical composition containing special LCZ696 crystal powder. On the basis of special powder characteristics of the adopted LCZ696 crystal powder, preparation technological requirements are satisfied and the prepared pharmaceutical composition conforms to clinical medication requirements, so that the geometric amplification of the pharmaceutical composition is achieved.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

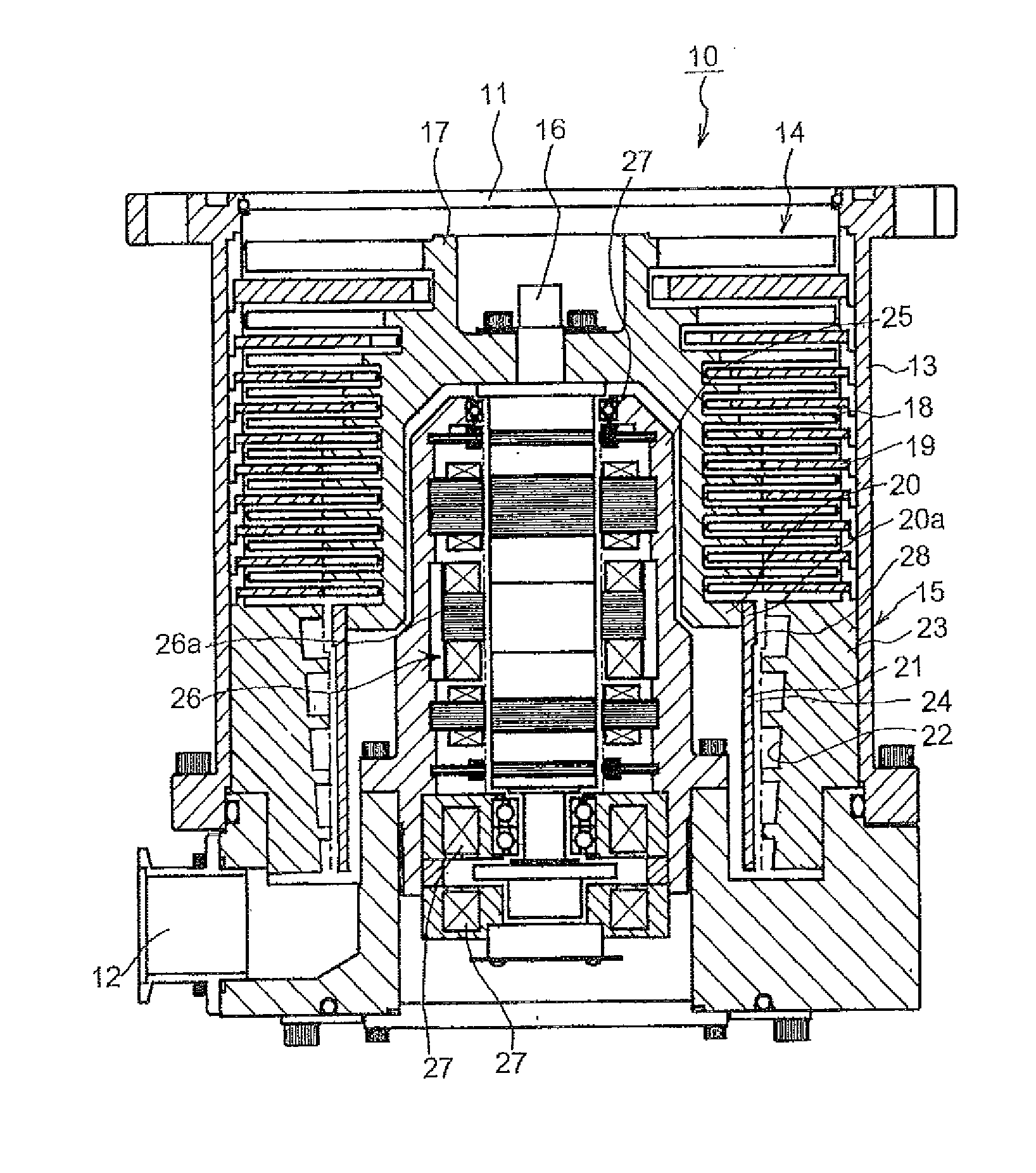

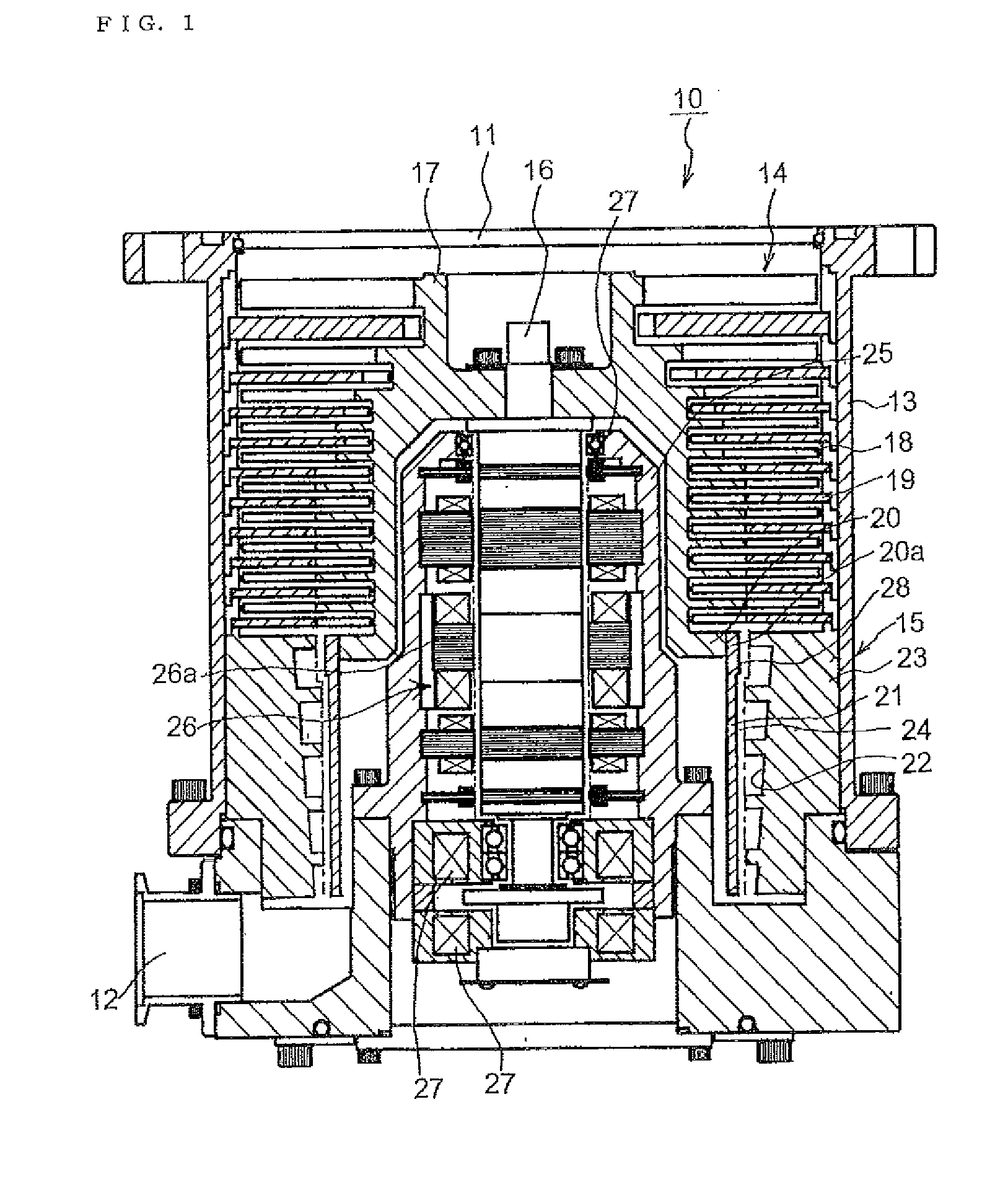

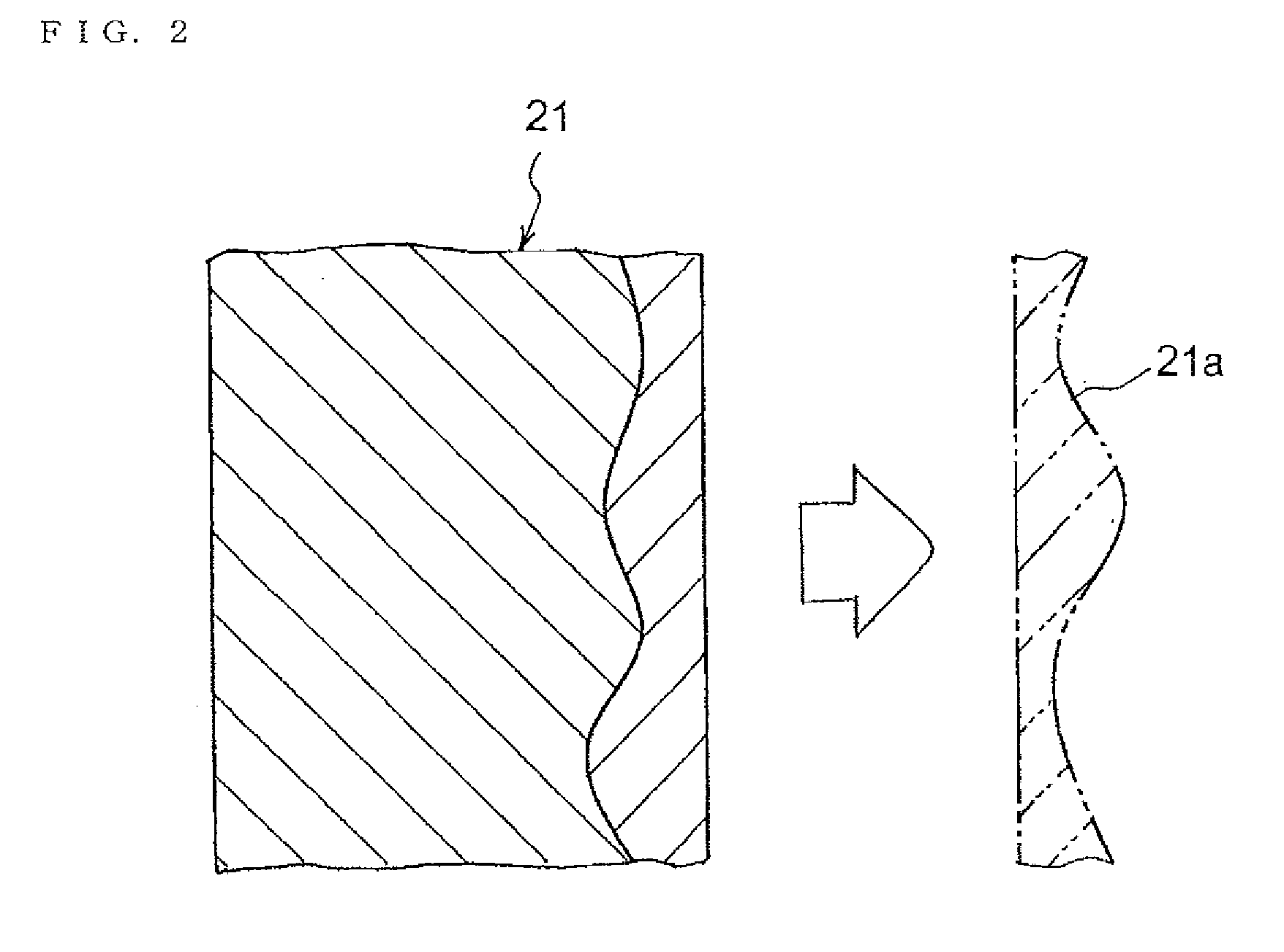

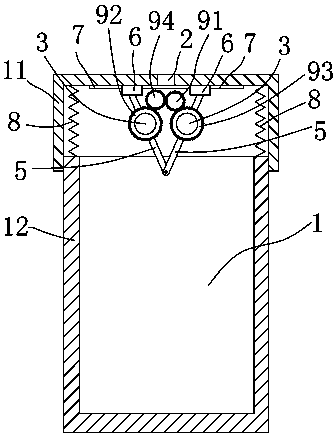

Vacuum pump

ActiveUS20130115094A1Improve marketabilityPreventing partial peeling and damagePump componentsEngine fuctionsFiberPlastic materials

Provided is a vacuum pump in which no finish processing has to be carried out after shaping of a cylindrical rotor even in use of a cylindrical rotor obtained by shaping a fiber-reinforced plastic material into a cylindrical shape. The vacuum pump has a turbo-molecular pump section and a thread groove pump section. The upper end section of a cylindrical rotor, which is obtained by shaping a fiber-reinforced plastic material into a cylindrical shape, of the thread groove pump section, is joined to the lower end section of a rotor of the turbo-molecular pump section. A joining portion of the rotor of the turbo-molecular pump section and the cylindrical rotor of the thread groove pump section is disposed upstream of an exhaust passage. As a result, finish processing does not have to be carried out after shaping of the cylindrical rotor. If finish processing is performed after shaping of the cylindrical rotor a resin may be coated onto a rugged portion of the cylindrical rotor, or fibers may be helically wound at a winding angle not greater than 45 degrees.

Owner:EDWARDS JAPAN

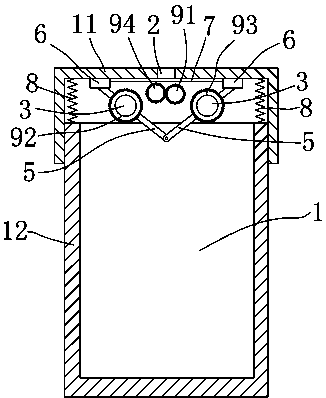

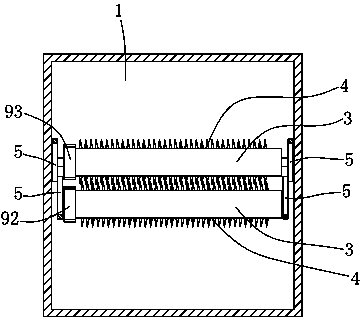

paper shredder

Owner:颍上县永安塑业有限公司

Sampling device for microbial detection of raw meat sample

ActiveCN110542577AAchieve grindingImplement automatic samplingWithdrawing sample devicesPulp and paper industryUltimate tensile strength

The invention discloses a sampling device for microbial detection of a raw meat sample. The device is characterized by comprising a working platform, a raw meat disinfection device and a raw meat grinding device, wherein the raw meat disinfection device comprises a shell and a net barrel; the two ends of the net barrel are rotationally connected to the shell; a first opening is arranged in the netbarrel; a cutter is arranged in the shell; the cutter is matched with the first opening; a cutter rotating shaft and the shell are slidably connected through a first sliding block; the cutter rotating shaft is rotationally connected to the first sliding block; a nozzle is arranged at the lower end of the shell; the raw meat grinding device comprises a bracket, a grinding pestle and a sterile mortar; the upper end of the grinding pestle is slidably connected to the bracket; the lower end of the grinding pestle is matched with the sterile mortar; and the raw meat disinfection device and the rawmeat grinding device realize automatic sampling and grinding of raw meat, the automation degree is high, and the labor intensity is reduced.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

Paper shredder

Owner:颍上县永安塑业有限公司

Textile plant dye extraction device

ActiveCN111825998ANot easy to wasteEasy extractionTextile disintegration and recoveryNatural dyesEngineeringTextile production

The invention belongs to the technical field of textile production, in particular to a textile plant dye extraction device. Directed at the problems that the existing dye extraction device is simple in design structure, cannot extract most of pigments in plants, so that the pigment extraction quality is poor and plants are easily wasted, the invention provides the following scheme that: the devicecomprises a working box, a feeding hole is formed in the outer wall of the top of the working box, a crushing box is inserted into the inner wall of the feeding hole, and a motor is fixed on the outer wall of the top of the crushing box through screws. According to the invention, when cams rotate, under the extrusion action of the cams, bulges and convex particles, juice in plant crushed materials is squeezed out and can fall into a recovery box along filter cloth after being squeezed out, and crushed residues can be left in the filter cloth, so that a good dye extraction effect is achieved,most of pigments in plants can be extracted, the pigment extraction quality is good, and plant waste is not likely to be caused.

Owner:哈尔滨市七彩莲花文化艺术发展有限公司

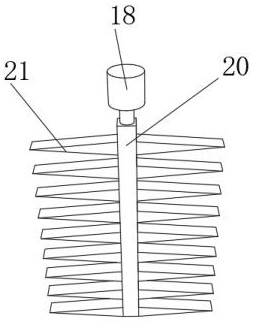

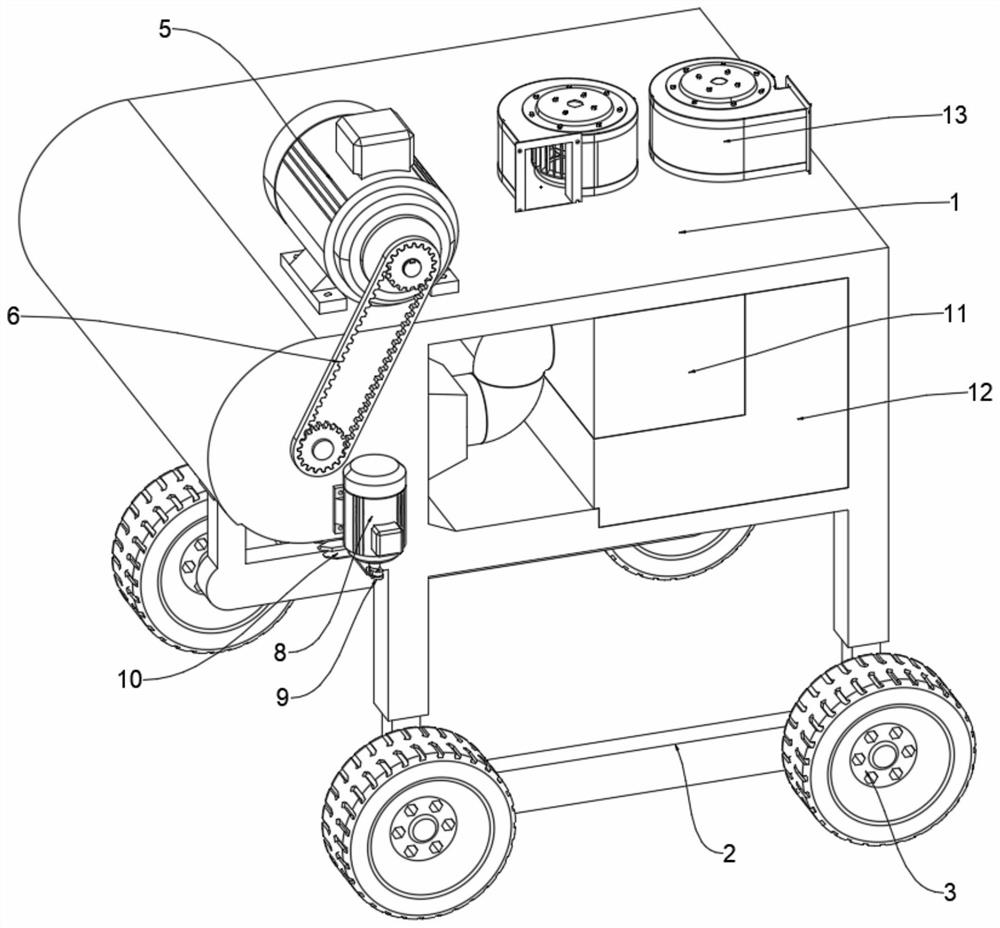

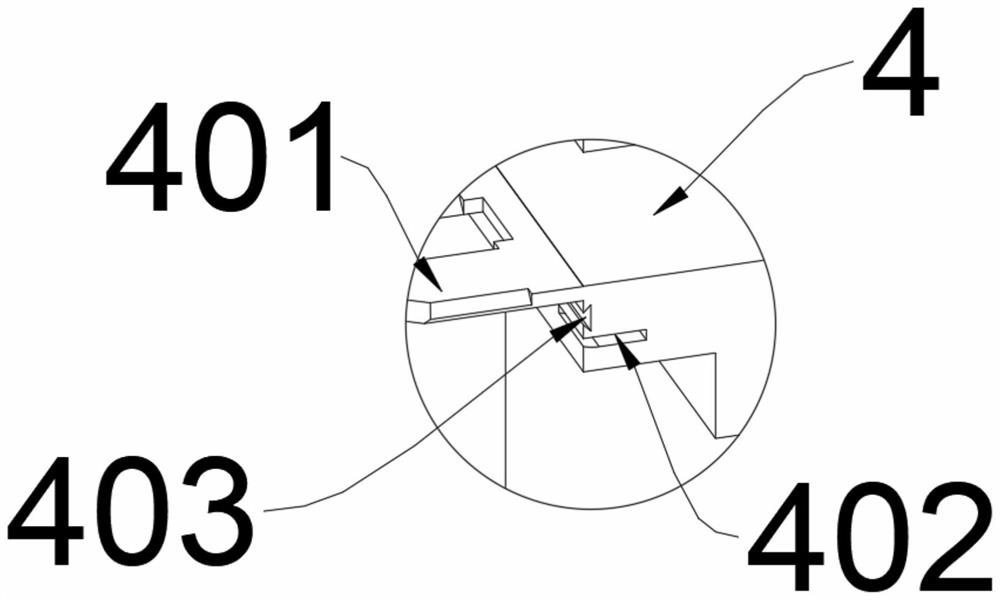

Multi-stage tea leaf picking device for picking tender tea leaves

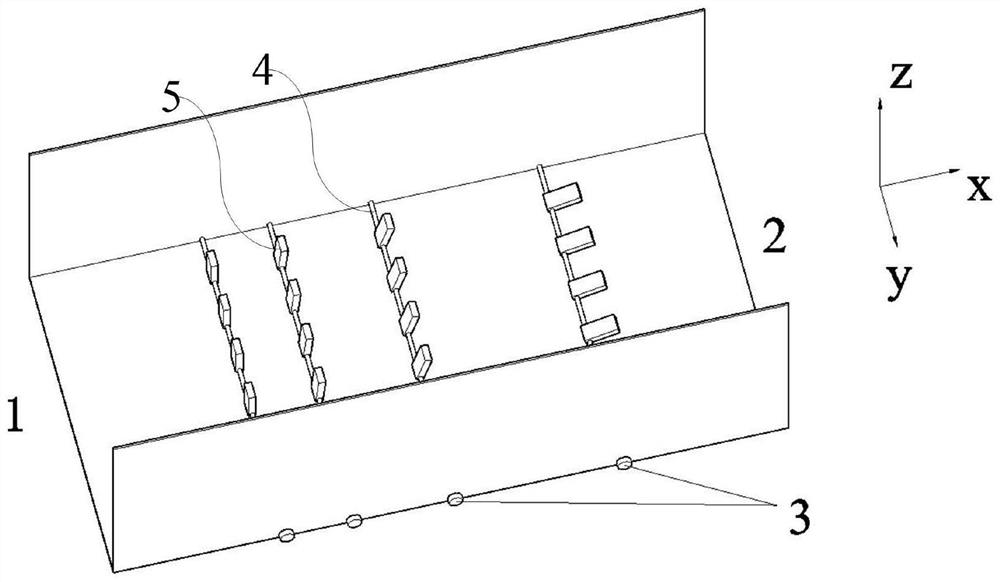

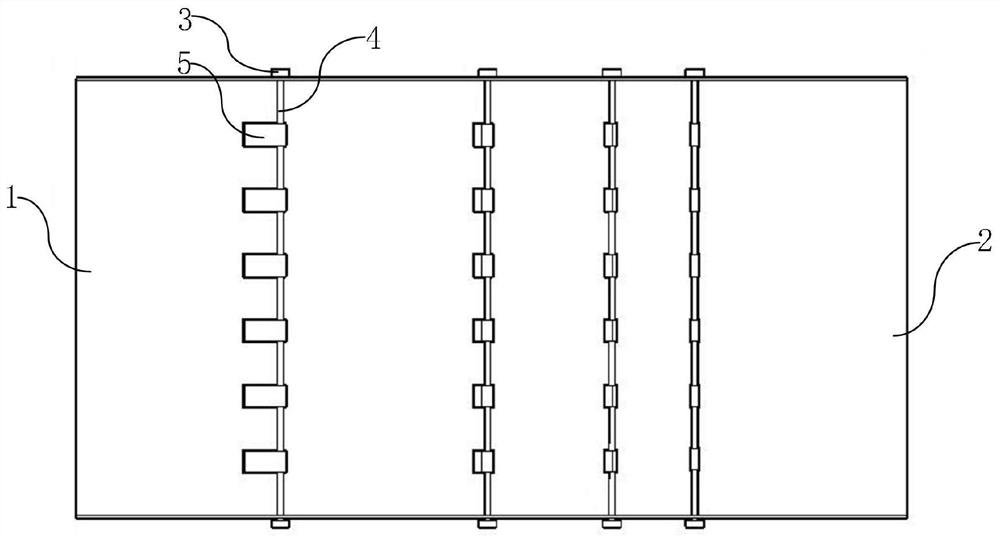

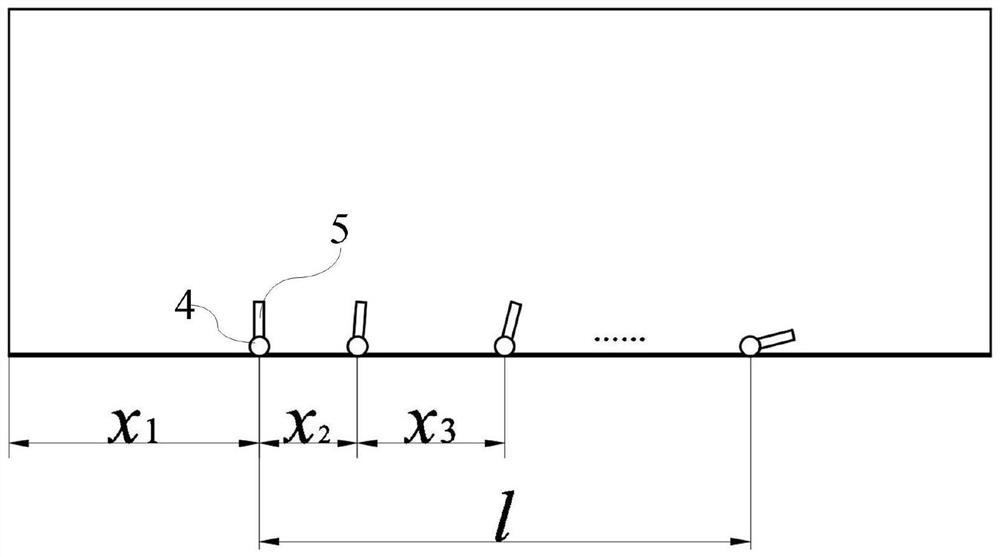

InactiveCN112790003APrevent shreddingEasy to shapeGas current separationPicking devicesAgricultural engineeringCentrifugal fan

The invention provides a multi-stage tea leaf picking device for picking tender tea leaves. The multi-stage tea leaf picking device comprises a rack, wherein the bottom of the rack is connected with an adjustable walking frame; a tender leaf collecting bin and an old leaf collecting bin are arranged at the left end of the rack from top to bottom, the right end of the tender leaf collecting bin communicates with a tender leaf storage bin through two tea suction tubes, and the right end of the old leaf collecting bin communicates with an old leaf storage bin; a swing motor is installed on the front end face of the left side of the rack and connected with a leaf cutting rack through a swing rod; and two centrifugal fans are arranged at the top of the right end of the top of the rack. According to the multi-stage tea leaf picking device, tender tea tree leaves collected in the tender leaf collecting bin enter the tender leaf storage bin through the tea suction tubes under the action of the centrifugal fans, old tea tree leaves collected in the old leaf collecting bin enter the old leaf storage bin through a collection pipeline under the action of the centrifugal fans, classified storage of the collected tea leaves is achieved, and therefore, the pressure of subsequent staff on tea classification is reduced.

Owner:董串连

A kind of protective film and preparation method thereof

ActiveCN106183121BImprove the effect of hot pressingReduce hardnessLamination ancillary operationsSynthetic resin layered productsTectorial membranePolymer science

Owner:NALI OPTICAL MATERIAL DONGGUAN

LCZ696 crystallized powder and a preparing method thereof

InactiveCN106397248AFormulation process optimizationImprove performanceOrganic compound preparationOrganic chemistry methodsFiltrationMoisture absorption

LCZ696 crystallized powder directly prepared through preparation is provided for the first time by the invention. The crystallized powder has specific powder properties, and has characteristics of suction filtration convenience, moisture absorption avoiding, and the like in a synthetic process. A prepared product is nearly free of agglomeration, and can avoid a crushing step in a preparation preparing process, thus facilitating achievement of optimized properties of preparations.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

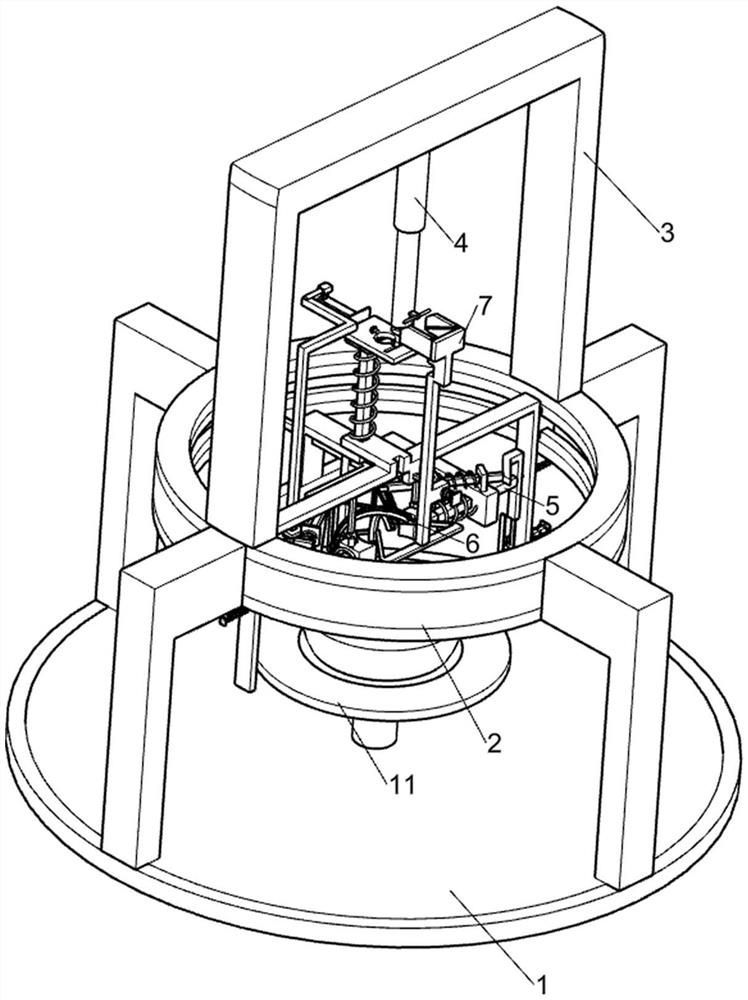

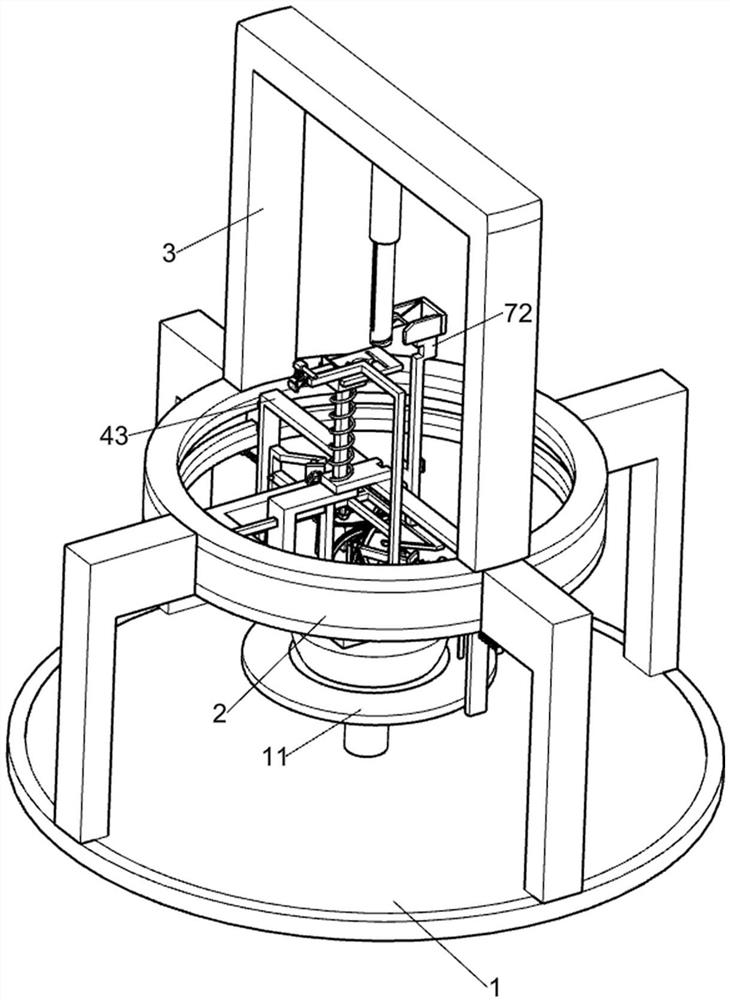

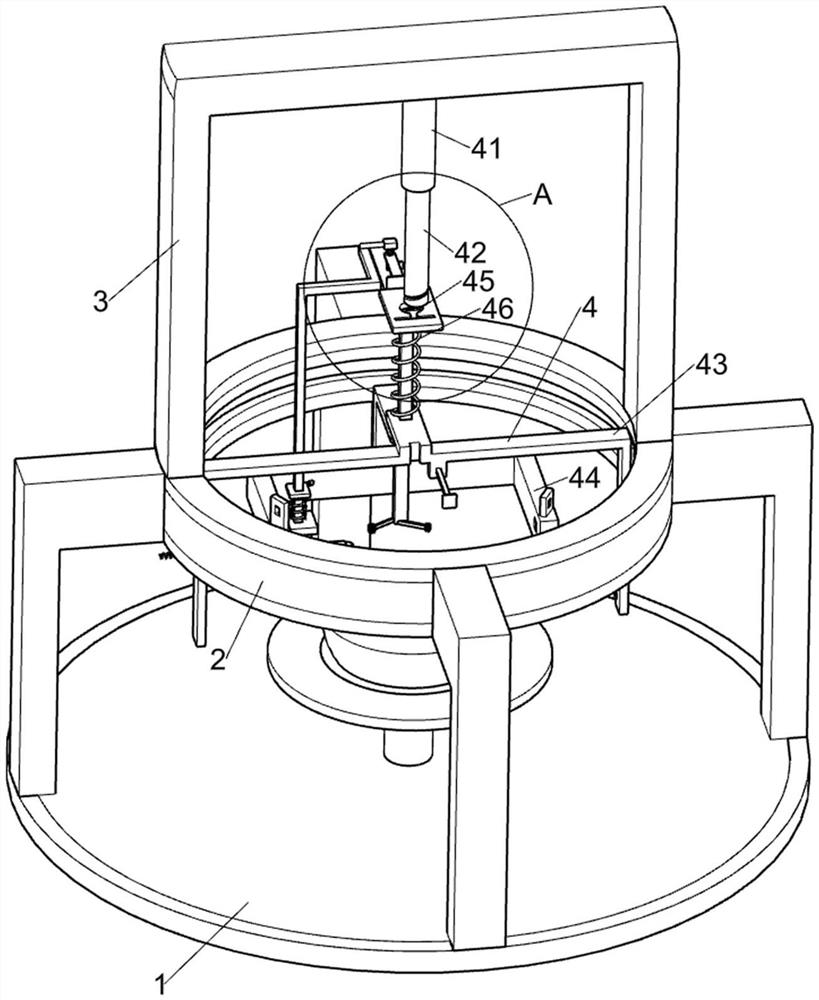

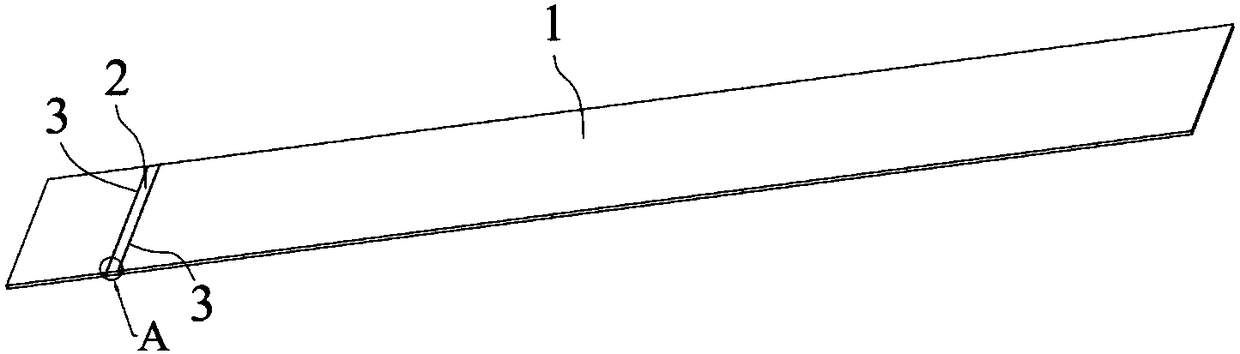

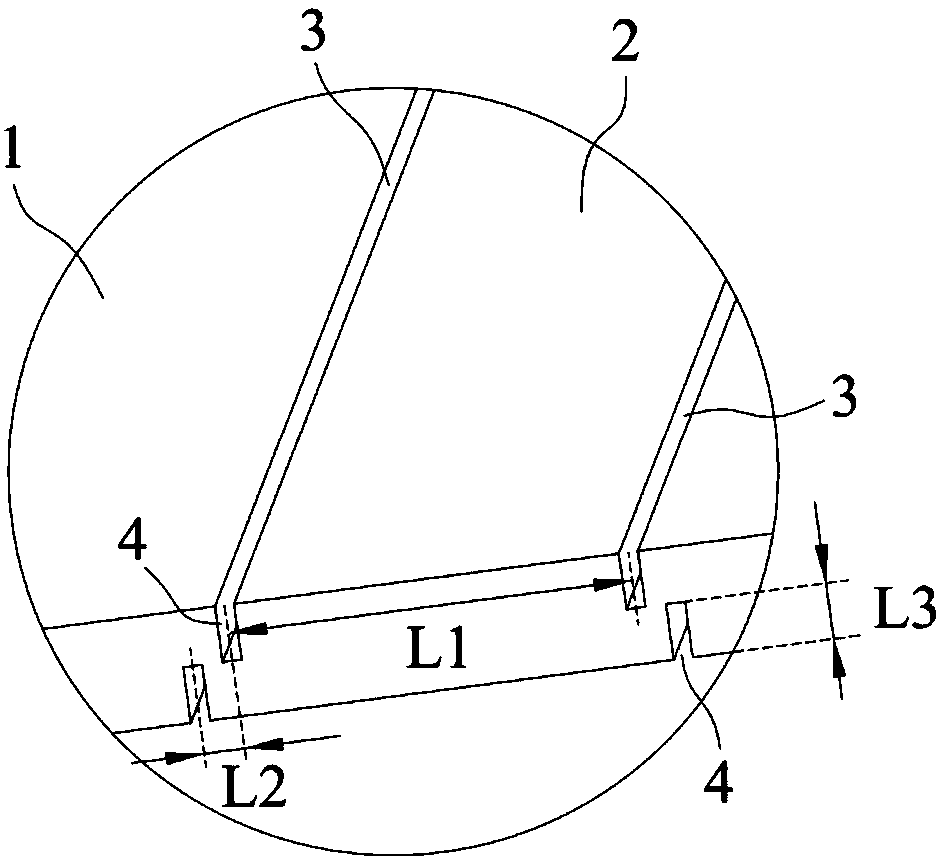

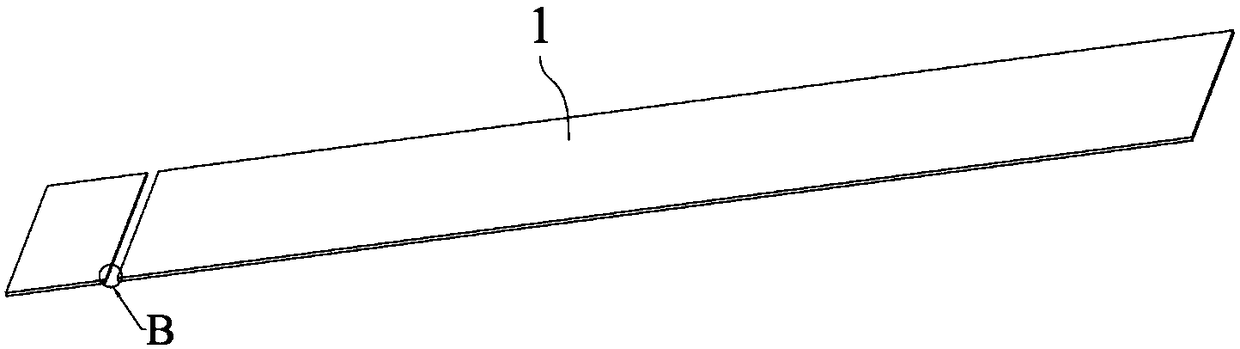

Reciprocating type cauliflower dicer suitable for different sizes

PendingCN113103311APrevent shreddingEasy to cutMetal working apparatusClassical mechanicsControl theory

The invention relates to a reciprocating type cauliflower dicer, in particular to a reciprocating type cauliflower dicer suitable for different sizes. The reciprocating type cauliflower dicer comprises a support seat, a placing table, a slide rail ring, a first support frame, a push rotating component and the like, wherein the placing table is fixedly connected to the center of the top face of the support seat, the slide rail ring is fixedly connected to the support seat, the first support frame is fixedly connected to the top face of the slide rail ring, and a push rotating component is slidably connected to the slide rail ring. Through the push rotating component, a clamping column on a sliding opening frame is clamped into a groove of a grooving push rod, the grooving push rod moves downwards, the sliding opening frame drives a first supporting plate and a device on the first supporting plate to rotate by a circle under the action of the groove of the grooving push rod, a first cutter or a second cutter rotates by a circle around a cauliflower, and the first cutter or the second cutter surrounds the root of the cauliflower to cut the cauliflower, so that the first cutter or the second cutter completely cuts the small piece of the cauliflower, and the cauliflower flower cluster is prevented from being cut up.

Owner:郭婷

Packaging structure and manufacturing process of packaging structure

PendingCN108482789ABeautiful appearanceEliminate potential safety hazardsRigid containersEngineering

Owner:DONGGUAN MYS ENVIRONMENTAL PROTECTION TECH

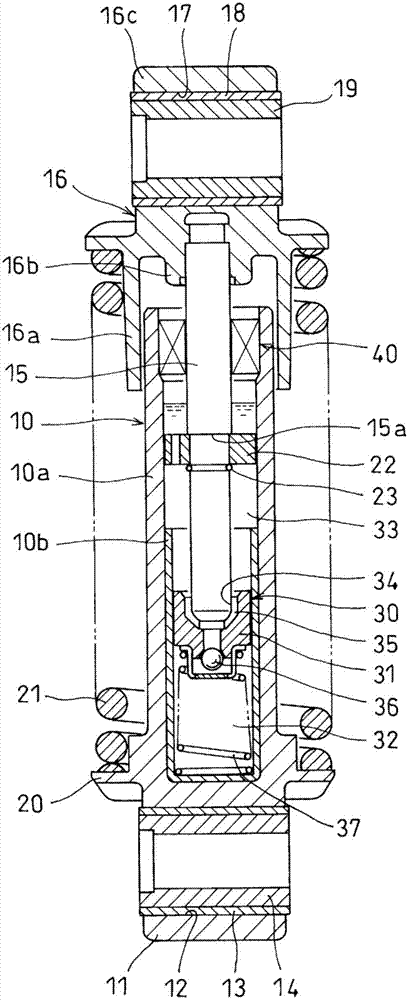

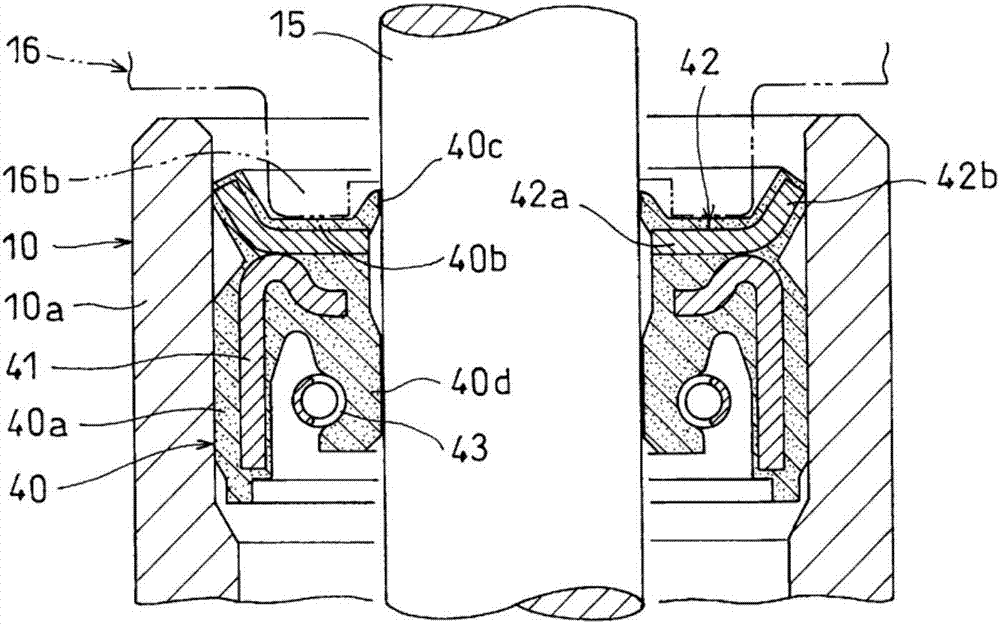

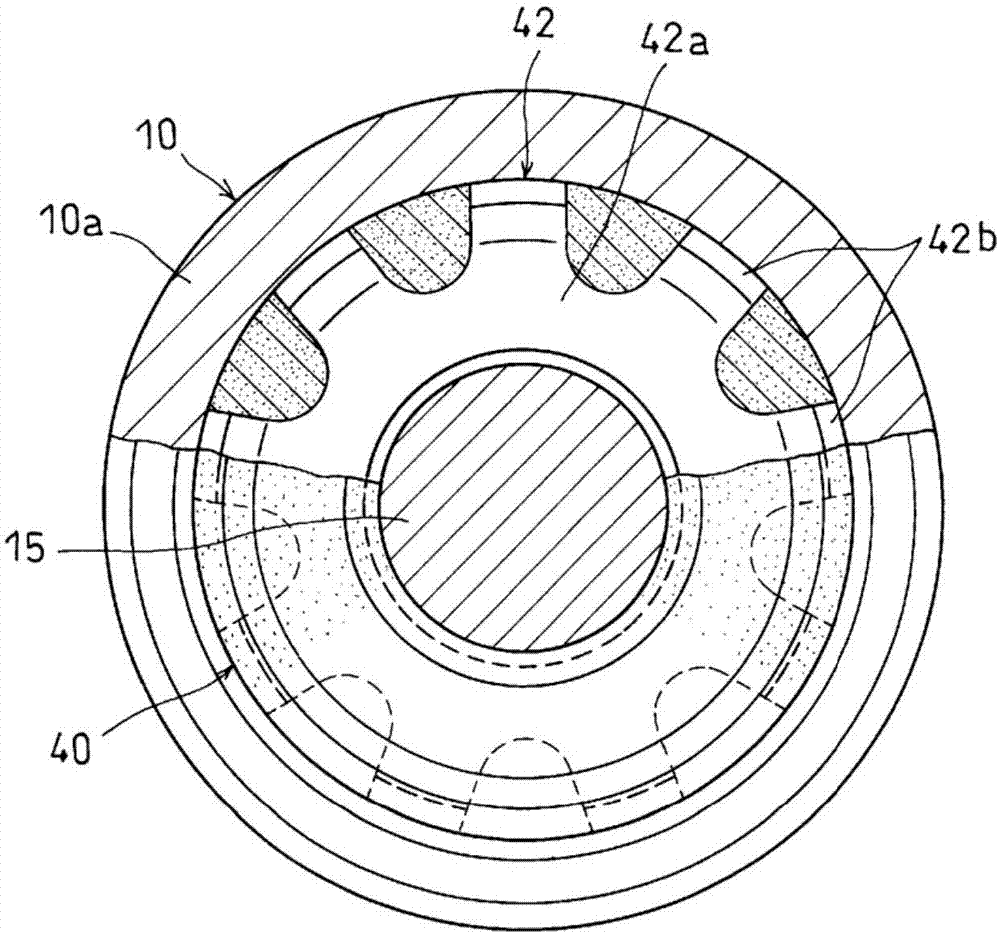

Hydraulic auto-tensioner

In the present invention a rod (15) is inserted into a bottomed cylinder (10) filled with operating oil, and a hydraulic damper (30) that absorbs pressing force in the direction causing the cylinder (10) and the rod (15) to retract relative to one another is provided in the cylinder (10). A cogwheel-shaped retaining ring (42) is formed integrally with an oil seal (40) sealing the end opening of the cylinder (10), thereby preventing a dust lip (40c) provided at the inner circumference of the oil seal (40) from being pulled into a center hole of the cogwheel-shaped retaining ring (42) by relative axial movement or relative tilting of the rod (15) and the cylinder (10).

Owner:NTN CORP

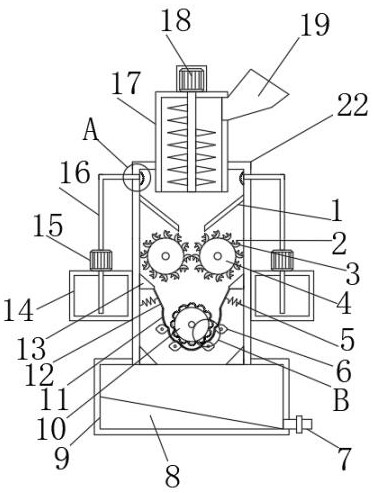

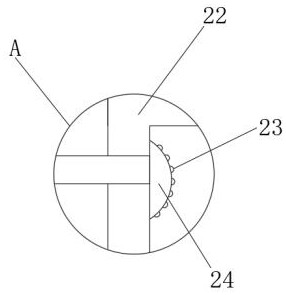

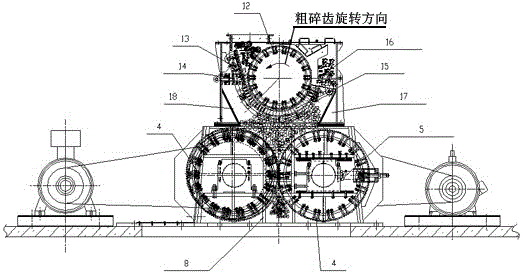

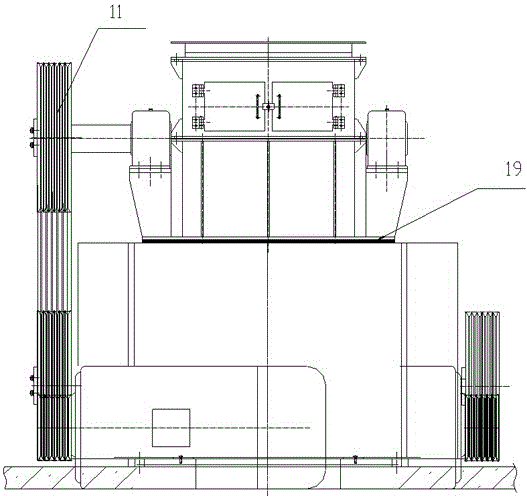

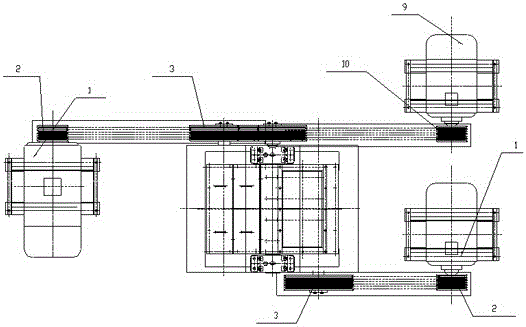

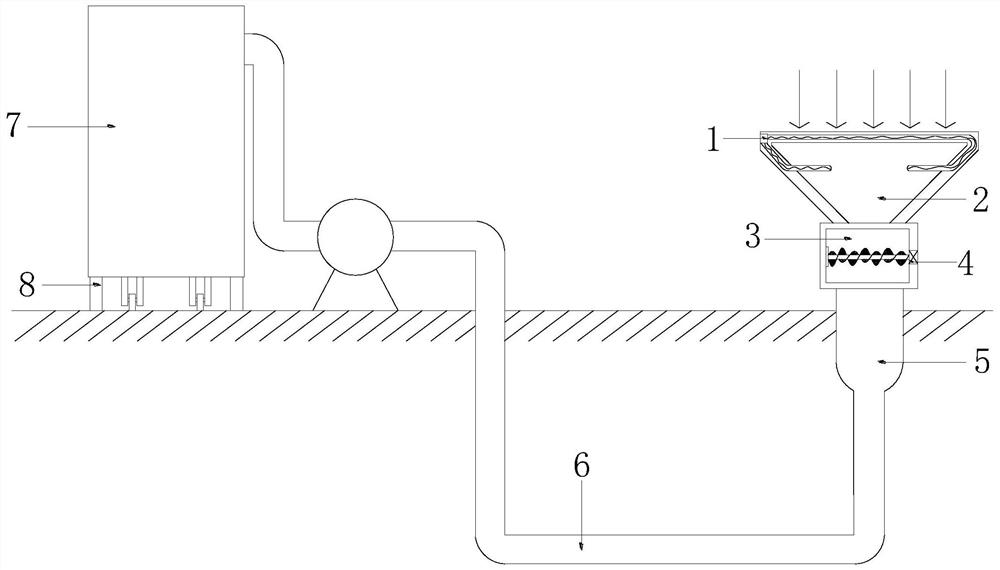

A kind of impurity sorting comprehensive crusher for fluidized bed boiler fuel

ActiveCN104826689BIncrease the gapImprove combustion efficiencyFluidized bed combustionGrain treatmentsFluidized bedEngineering

The invention discloses an impurity sorting comprehensive crusher for a fluidized bed boiler fuel, belongs to the crusher in the material crushing technical field, and provides the impurity sorting comprehensive crusher for the fluidized bed boiler fuel, wherein the crusher can be used for processing a crushed material containing more hard stones, iron blocks, wood blocks and other impurities, allows the crushed material after crushing treatment to have less impurities, has relatively high commodity degree and is provided with a yielding protecting device. The crusher comprises a coarse crushing operation zone and a fine crushing operation zone; the coarse crushing operation zone comprises an upper coarse crushing zone machine body which is internally provided with a coarse crushing toothed roller, a coarse crushing discharging sieve plate is arranged below the coarse crushing toothed roller, the inner wall of the upper coarse crushing zone machine body is hinged with a coarse crushing toothed plate, the coarse crushing toothed plate is relatively engaged with the coarse crushing toothed roller, and one side of the coarse crushing toothed plate is provided with the yielding protecting device; a part, at a discharging side of the coarse crushing discharging sieve plate, of the inner wall of the upper coarse crushing zone machine body is provided with an impurity storage cavity. The crusher is suitable for producing the circulating fluidized bed boiler fuel.

Owner:四川秦岭金属铸造有限公司

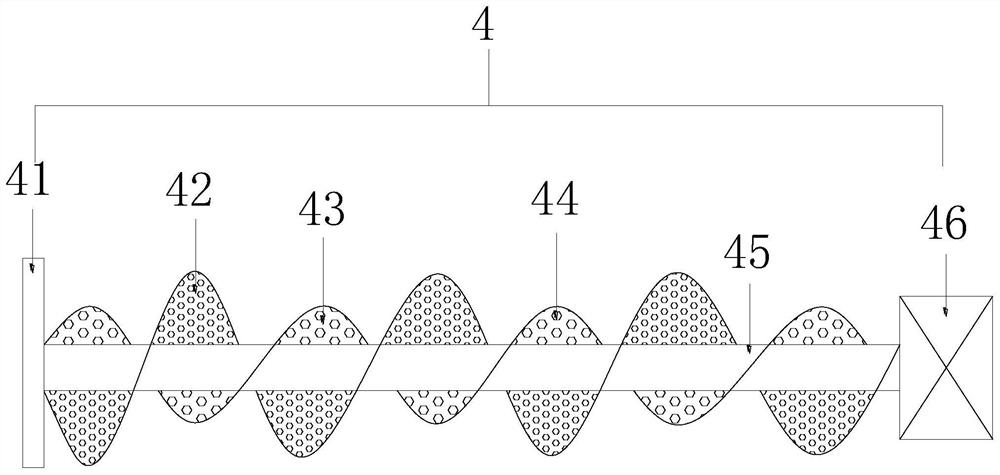

A sewage treatment device that accelerates hair degradation

ActiveCN109205912BEasy to handleLow viscosityTreatment involving filtrationMultistage water/sewage treatmentSewageSewage treatment

The invention discloses a sewage treatment device for accelerating hair degradation, which relates to the field of sewage treatment, and its structure includes a heating assembly, a water inlet bucket, a working chamber, a chopping mechanism, a water storage chamber, a water pipe, a sewage processor, and a water outlet pipe. The present invention utilizes the heating assembly provided to increase the temperature of the sewage, so that the hair will deteriorate at high temperature, which is beneficial to its degradation, and the chemical composition in the shampoo, silicone oil, has a reduced viscosity at high temperature and is not easy to stick to the hair. Agglomeration can prevent the problem of clogging the sewage treatment device for a long time, which is beneficial to the circulation of sewage and subsequent sewage treatment operations, while the No. 1 spiral slice, the No. 2 spiral slice, the exhaust hole, the electric heating plate, the cylinder and the precision filter The mutual cooperation between the nets makes the hair completely chopped, and the hair area is minimized, which is very beneficial to the degradation of the hair.

Owner:苏州昌泽环保工程科技有限公司

High-stability LCZ696 crystallized powder and a preparing method thereof

InactiveCN106397249AFormulation process optimizationImprove performanceOrganic compound preparationOrganic chemistry methodsHydrolysisImpurity

High-stability LCZ696 crystallized powder and a preparing method thereof are provided. According to the LCZ696 crystallized powder, through controlling the using amount and the concentration of sodium hydroxide, contents of hydrolysis impurities in the prepared LCZ696 crystallized powder are controlled to a relatively low range. The LCZ696 crystallized powder has higher stability.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

A crayfish peeling device with flushing function

ActiveCN109077102BWith washing functionEasy to separate and removeShrimp/lobster processingSlide plateCrayfish

Owner:HUNAN UNIV OF ARTS & SCI

A flocculation tank for enhancing bottom flocculation effect and flocculation method thereof

ActiveCN113200590BImprove flocculation efficiencyAdapt to needsWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationThermodynamics

The invention discloses a flocculation tank for strengthening the flocculation effect at the bottom and a flocculation method thereof. The bottom of the flocculation tank is provided with a plurality of baffle spoiler components arranged in sequence along the water flow direction. Each baffle spoiler assembly includes one or a plurality of baffles arranged side by side. Along the water flow direction, the included angle between the baffle plates in each baffle plate spoiler assembly and the water flow direction gradually decreases. Compared with the traditional flocculation method, the invention adds a method of generating a vortex at the bottom to strengthen the flocculation effect, so that the flocculation efficiency is higher. In the present invention, in the direction from the water inlet to the water outlet, the spacing of different rows of baffles is in a trend from small to large, and the angle between the partitions and the bottom of the flocculation tank is in a trend from large to small, so that the flocculation tank produces a flow of water along the water flow direction. The large to small vortex not only increases the flocculation speed in the initial flocculation stage, but also avoids the large vortex to chop the flocs in the end stage of flocculation.

Owner:HANGZHOU DIANZI UNIV

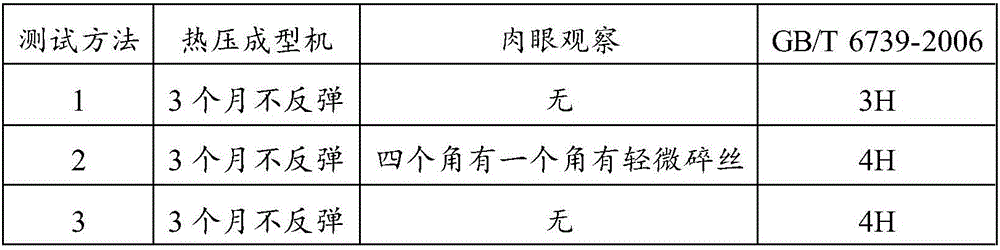

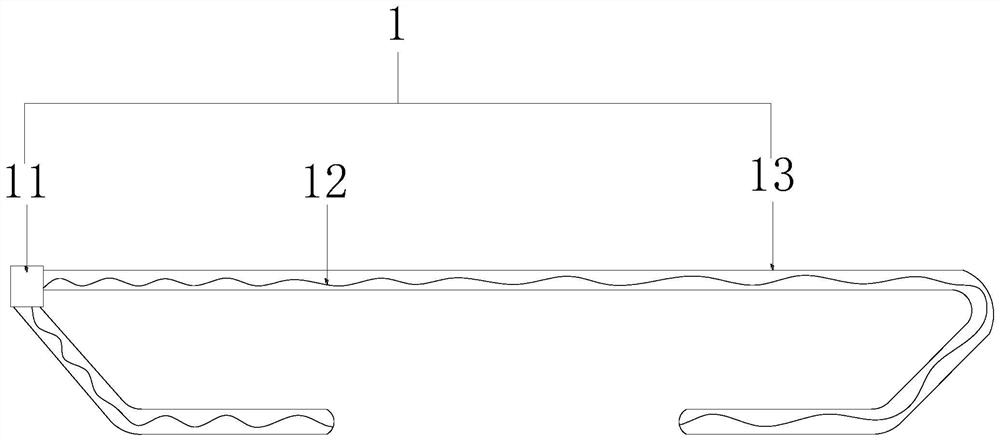

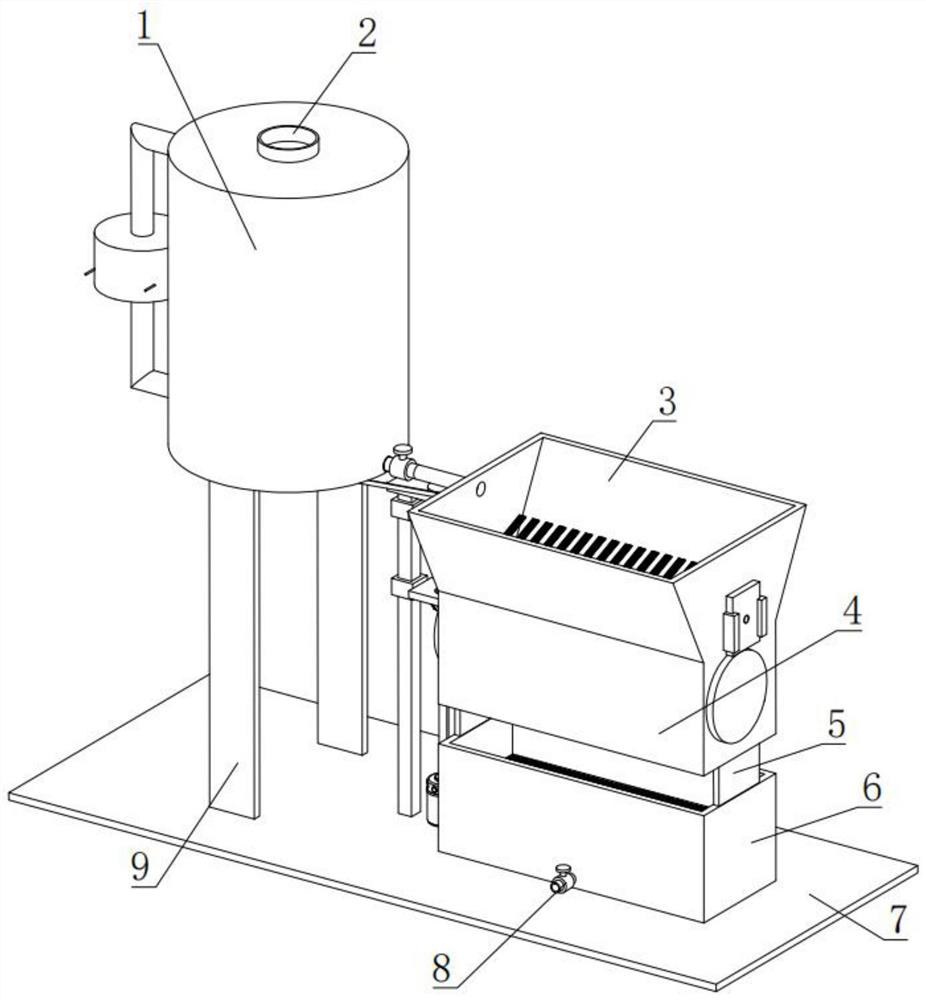

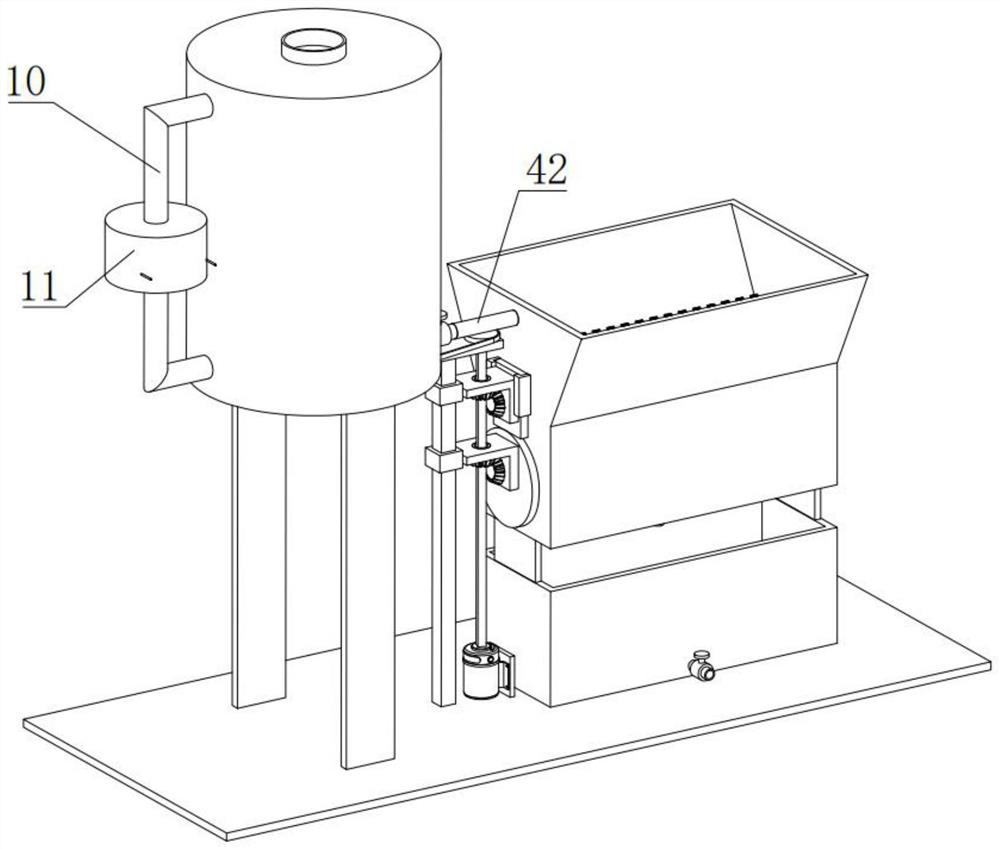

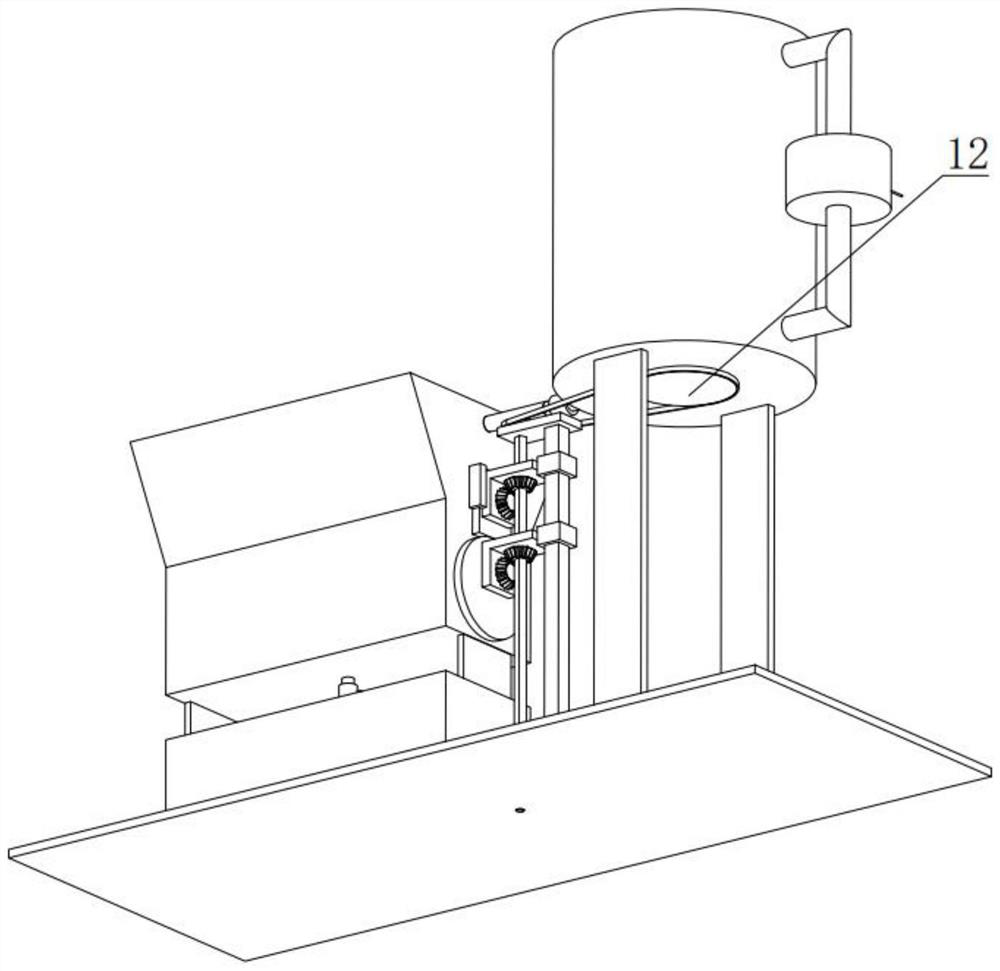

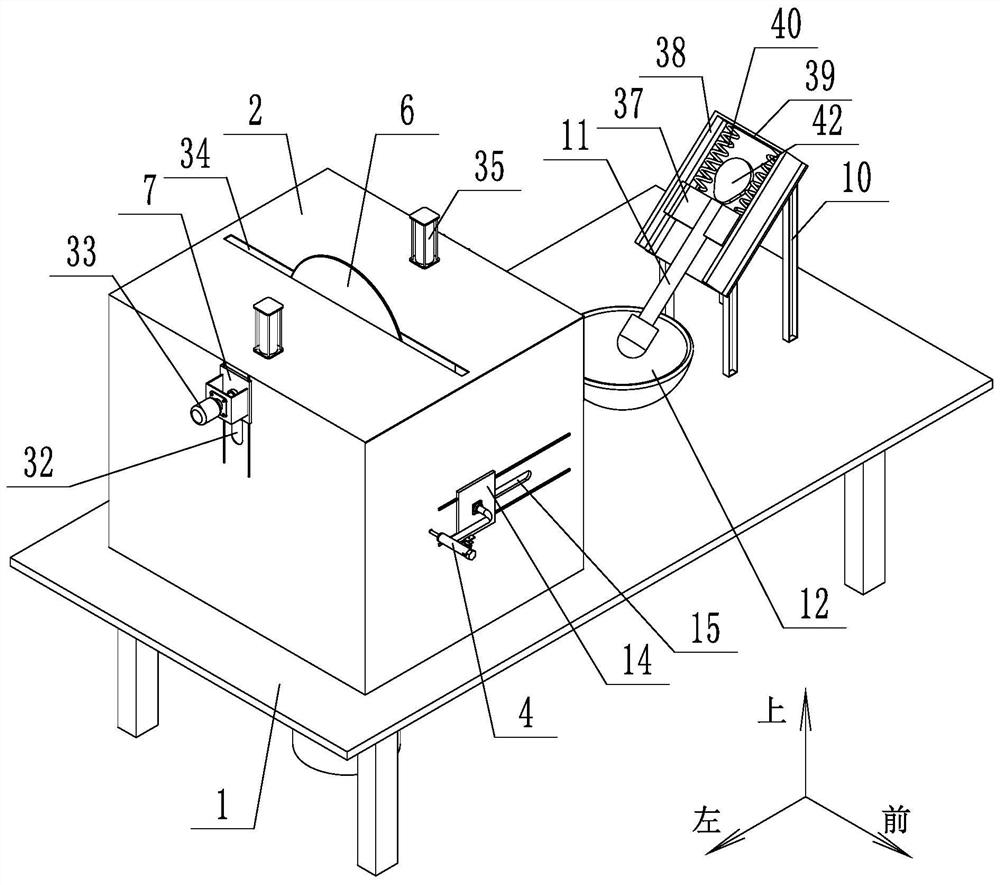

Preparation equipment of jujube fruit wine

The invention discloses preparation equipment of jujube fruit wine. The preparation equipment comprises a bottom plate and is characterized in that one end of the upper side of the bottom plate is fixedly connected with the lower ends of symmetrical supporting plates, the upper side of the bottom plate is fixedly connected with the lower ends of guide rods, the upper side of the bottom plate is fixedly connected with the lower side of a mounting seat, and the other end of the upper side of the bottom plate is fixedly connected with the lower side of a box body; and the upper ends of the two supporting plates are fixedly connected with one end of the lower side of a leaching cylinder correspondingly, and the upper side of the leaching cylinder fixedly communicates with the lower end of a feeding pipe. The invention relates to the field of wine brewing equipment, in particular to the preparation equipment for the jujube fruit wine. According to the preparation equipment, the purpose thatwhen red jujubes are leached in the leaching cylinder, a waterproof motor cooperates with fan blades to suck water into a lower L-shaped pipe, the water flows into the leaching cylinder from an upperL-shaped pipe through a heating tank, the two L-shaped pipes perform water circulation in the leaching cylinder, and the leaching process can be accelerated through cooperation of rotation of a set of stirring rods and beating by the stirring rods on the red jujubes. The red jujubes are uniform to heat.

Owner:LUOYANG NORMAL UNIV

A sampling device for microbial detection of raw meat samples

ActiveCN110542577BAchieve grindingImplement automatic samplingWithdrawing sample devicesBiotechnologyMicroorganism

A sampling device for microbial detection of raw meat samples disclosed by the present invention is characterized in that it includes a working platform, a raw meat disinfection device and a raw meat grinding device. The net barrel is provided with a first opening, and a cutter is arranged in the casing, and the cutter is matched with the first opening. The blocks are rotationally connected, the lower end of the shell is provided with a nozzle, the raw meat grinding device includes a bracket, a grinding pestle and a sterile mortar, the upper end of the grinding pestle is connected to the bracket by sliding, the lower end of the grinding pestle is matched with the sterile mortar, The raw meat disinfection device and the raw meat grinding device realize the automatic sampling and grinding of raw meat, with a high degree of automation and reduced labor intensity.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

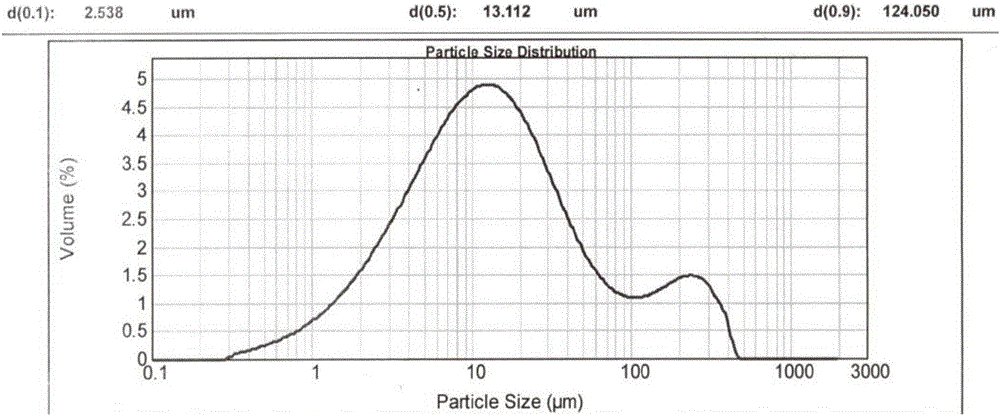

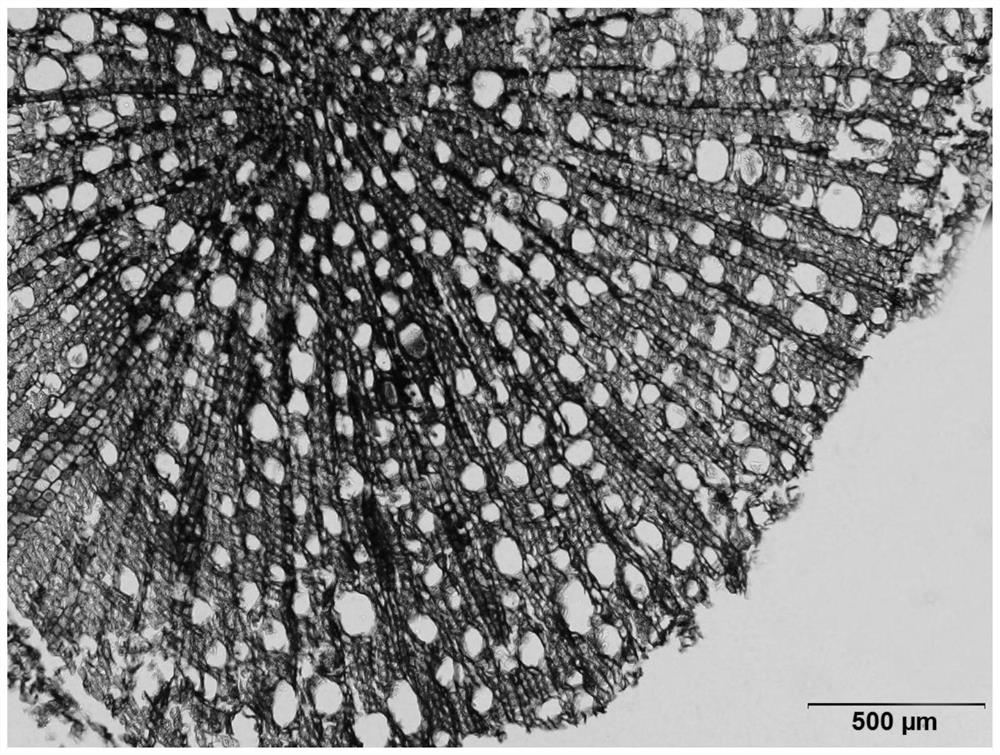

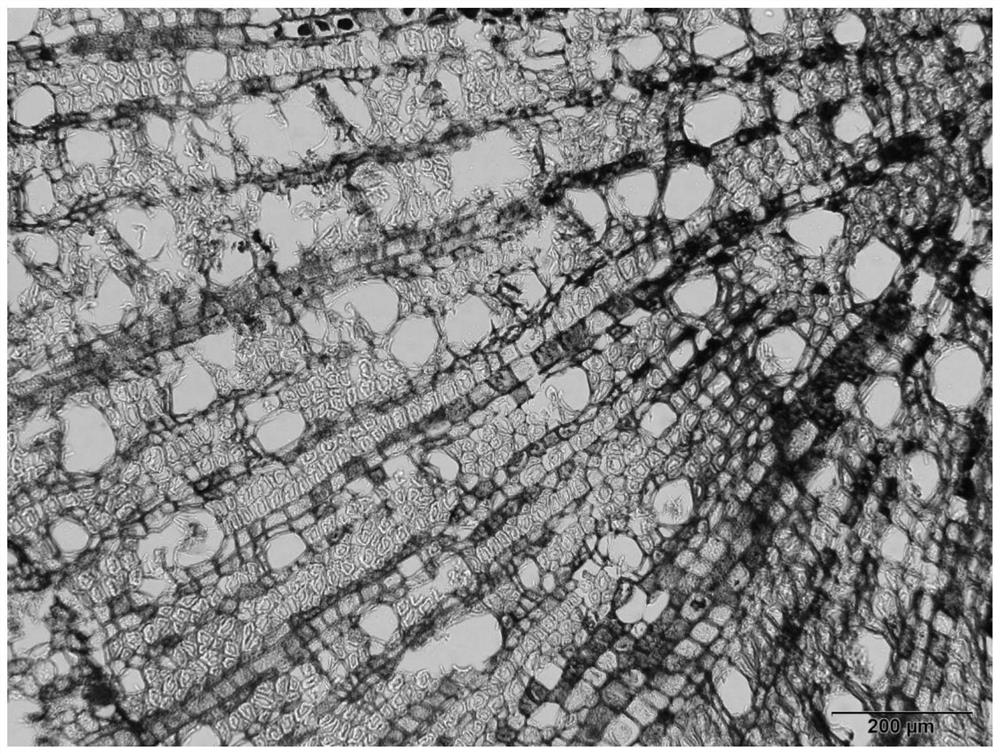

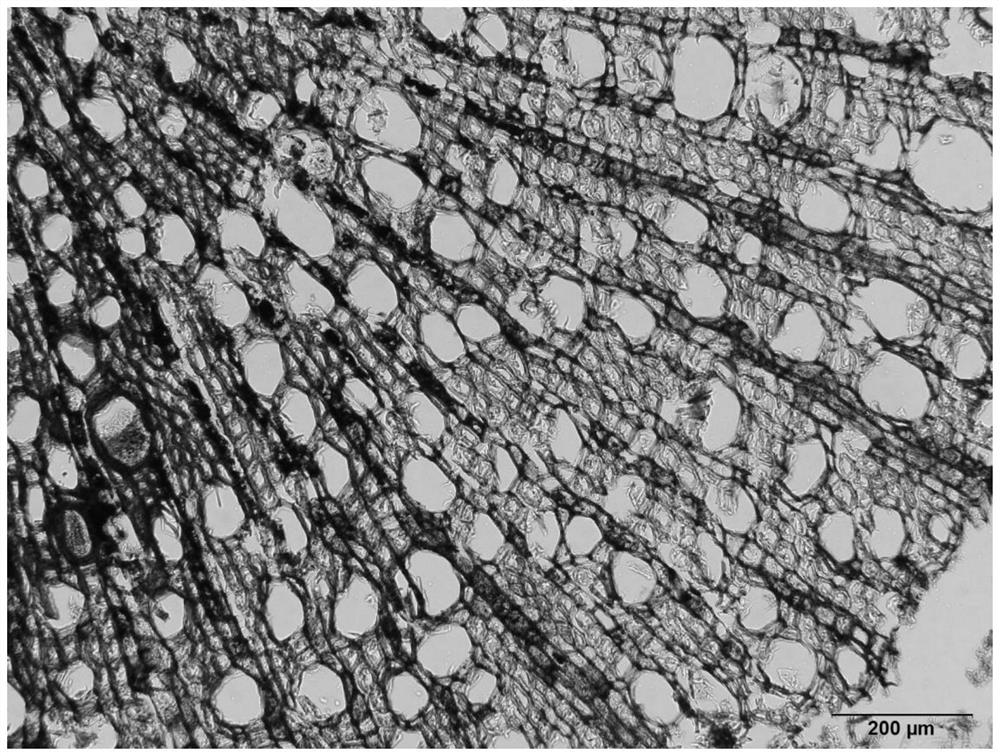

Method for preparing slices of black tiger root

ActiveCN110006721BShorten softening treatment timeConvenient sourcePreparing sample for investigationPhysical chemistryPotassium hydroxide

The invention discloses a method for preparing black tiger root slices, which uses the black tiger root as a raw material, soaks in a softener and adopts ultrasonic treatment to obtain the slices of the black tiger root. Wherein, the softening agent includes the following raw materials in parts by weight: 5 parts of potassium hydroxide or sodium hydroxide solution with a concentration of 50%, 3 parts of glycerol with a volume fraction of 30%, and 2 parts of ultrapure water. The softener prepared from strong alkali, glycerin and water can not only quickly and effectively soften the roots of the black tiger, but also has simple raw materials, convenient sources, and low toxicity. Combined with ultrasonic heating technology, the softening process is more effective. Sufficient, making the prepared slices better.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

An ultrasonic food cutting machine

ActiveCN106808517BSmall cut filletsPrevent shreddingMetal working apparatusAutomatic testingPaper sheet

The invention discloses an ultrasonic food cutting machine. The machine comprises a stainless steel rack, a cutting shield, a transparent shield, a paper supply shield, an ultrasonic cutter mechanism, a food conveying mechanism, a shield rotating mechanism and a paper piece taking mechanism. Equal-distance forward movement of a tray of the machine can cooperate with the ultrasonic cutter mechanism for cutting of foods in the square specifications, equal-angle rotation of the tray can further cooperate with the ultrasonic cutter mechanism for cutting of foods in the equal-angle circumference specifications, the machine integrates functions of full-automatic taking of paper pieces, full-automatic and accurate placing of the paper pieces, full-automatic adoption of ultrasonic waves for cutting of the foods, full-automatic and accurate positioning of the foods and full-automatic conveying of the foods, equal-distance moving cutting and rotating cutting can be performed on the foods, the foods in different shapes and different sizes and the like can be cut automatically, numbers and distances of transversely cut foods and vertically cut foods are input respectively according to actual conditions of production, positioning and ultrasonic cutting can be completed for the foods automatically, and the automatic operation degree is high.

Owner:DONGGUAN BRDASON ULTRASONIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com