Hydraulic auto-tensioner

A tensioner, hydraulic technology, applied in the field of hydraulic automatic tensioners, can solve problems such as shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

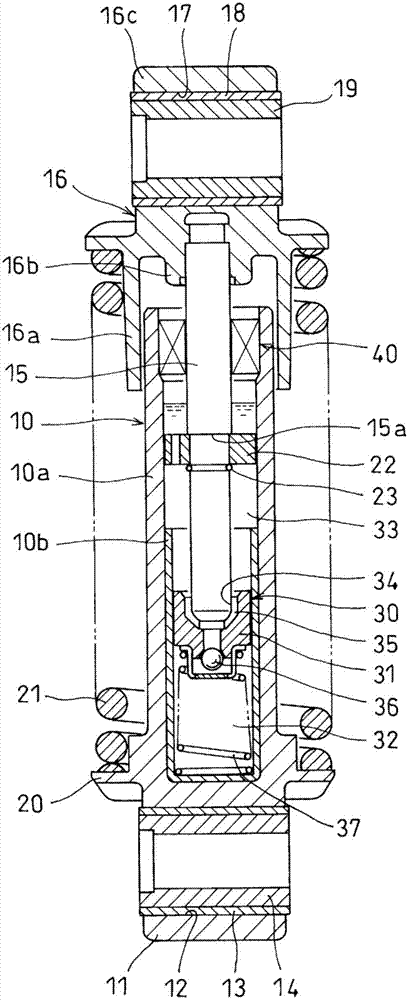

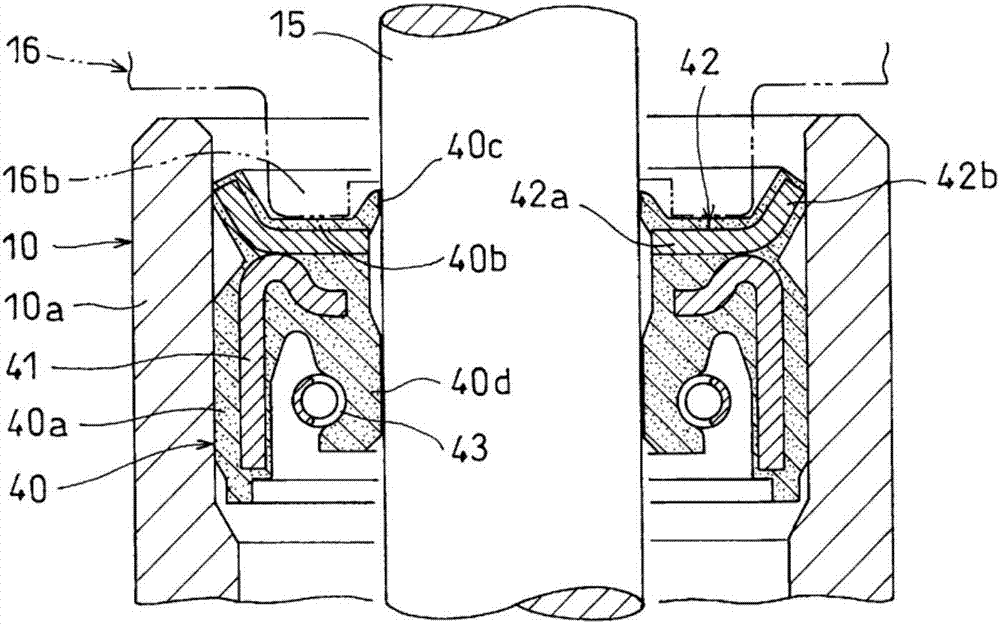

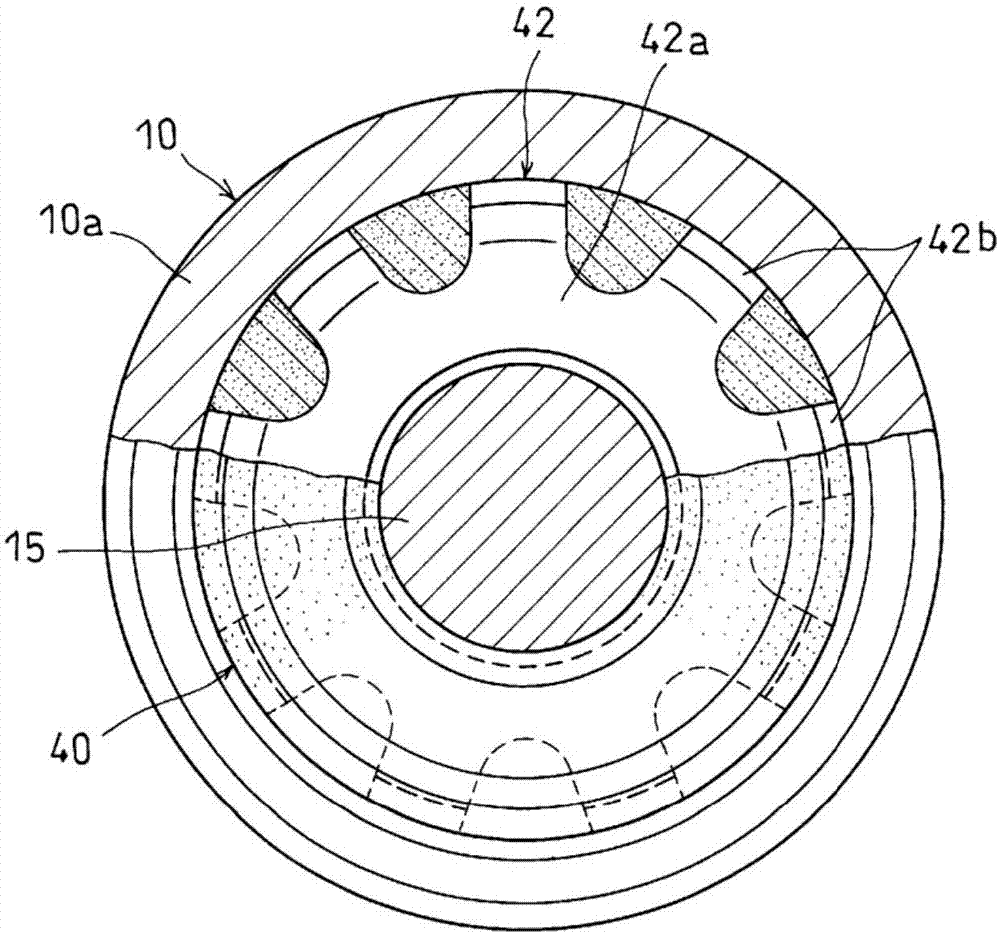

[0023] Embodiments of the present invention will be described below based on the drawings. Such as figure 1 As shown, the cylinder block 10 is composed of an outer cylinder 10a and a bottomed inner cylinder 10b fitted inside the outer cylinder 10a. The outer cylinder 10a is made of aluminum or aluminum alloy and molded by die casting. On the other hand, the inner cylinder 10b is made of hard metal such as stainless steel.

[0024] A connecting piece 11 is provided at the closed end of the outer cylinder 10a. A connecting hole 12 penetrating both side surfaces is formed in the connecting piece 11 , and a sleeve 14 is rotatably incorporated in the connecting hole 12 via a slide bearing 13 .

[0025] Hydraulic oil is filled in the cylinder 10 . In addition, a rod 15 is inserted into the cylinder 10 , and a spring seat 16 is attached to an end of the rod 15 protruding from the open end of the cylinder 10 to the outside. The spring seat 16 is provided with a cylindrical skirt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com