Patents

Literature

44results about How to "Increase picking speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

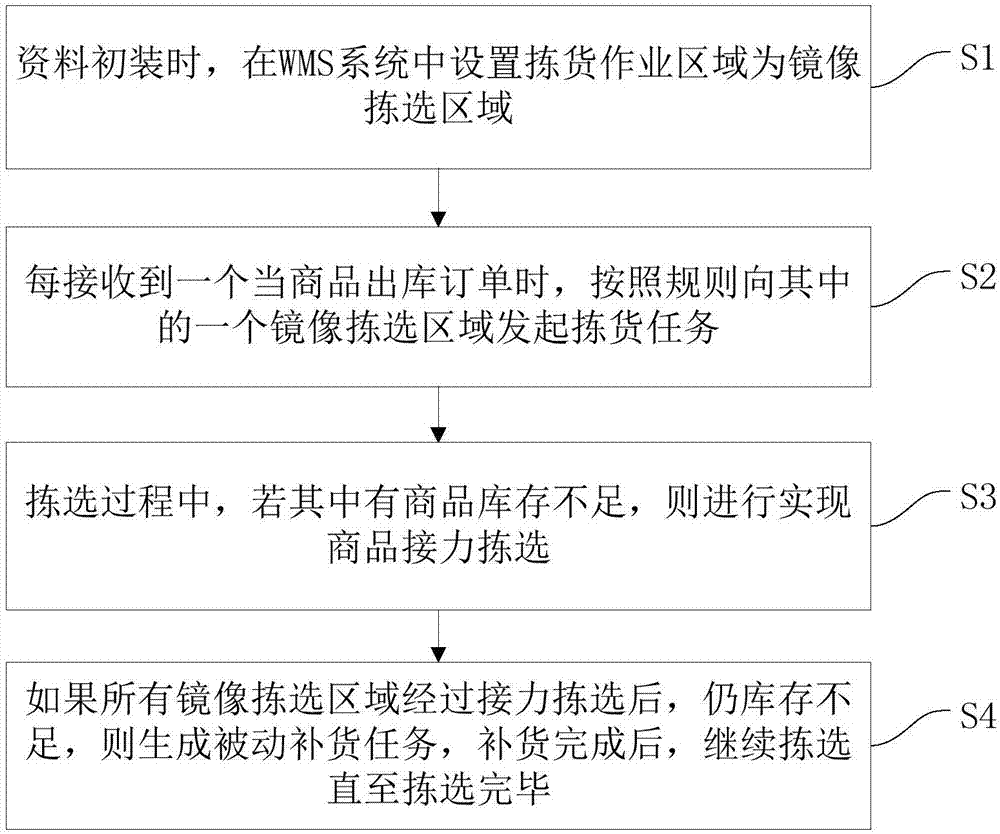

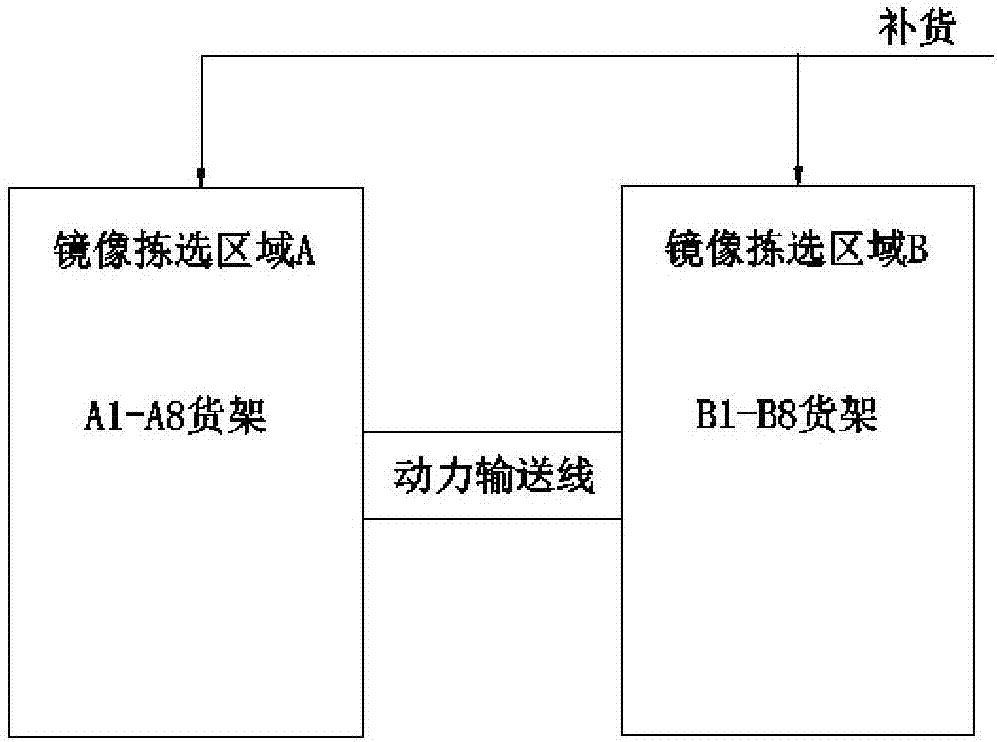

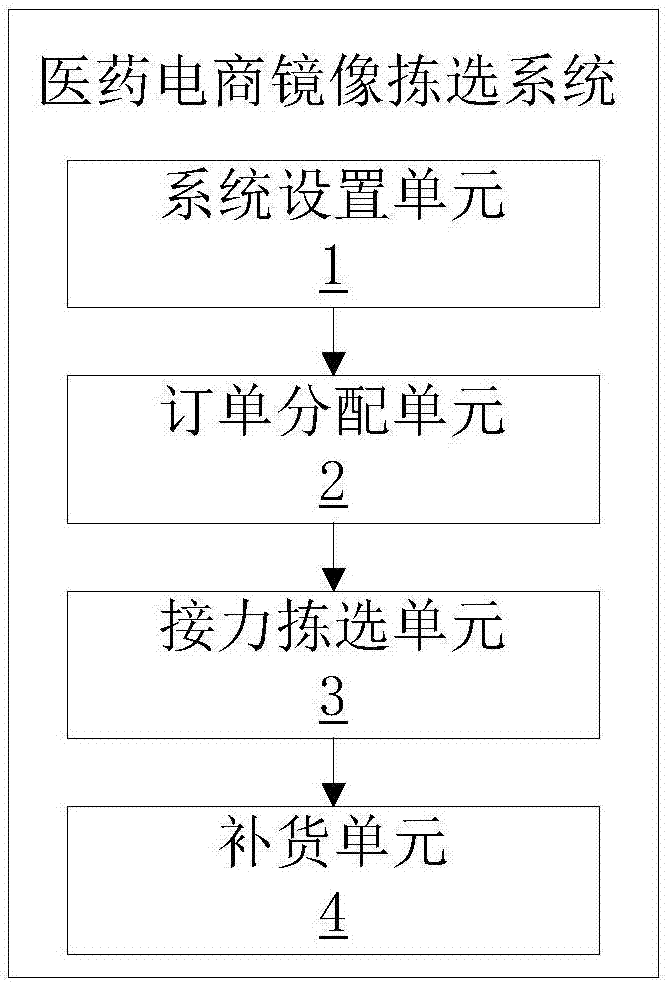

Medicine e-business mirror image selection method and system

ActiveCN106960301ASave walking timeGuaranteed picking efficiencyLogisticsInformation technology support systemLogistics managementWalking time

The invention relates to the medicine logistics field, and provides a medicine e-business mirror image selection method and system; the method comprises the following steps: setting order picking work zones in a WMS system as the mirror image selection zones; receiving a goods warehouse-out order, and starting an order picking task in one of the mirror image selection zone according to rules; carrying out goods relay selection in the selection process if the goods stock is insufficient; forming a passive replenishment task if relay selection is done in all mirror image selection zones and the stock is still insufficient; finishing replenishment, continuously selecting until the selection task is complete. The method arranges the plurality of mirror image selection zones, and selects one proper mirror image section zone to start the selection task according to rule algorithms when the goods warehouse-out order arrives, thus ensuring the selection efficiency as possible, and improving the order picking speed. The method tries to pick goods in one mirror image selection zone as possible, thus reducing order picking personnel walking time; if the stock in the mirror image selection zone is insufficient, the relay selection is carried out in the next mirror image selection zone through a power transmission line, and active and passive replenishment can be carried out when the stock is insufficient.

Owner:HUBEI JOINTOWN TECH

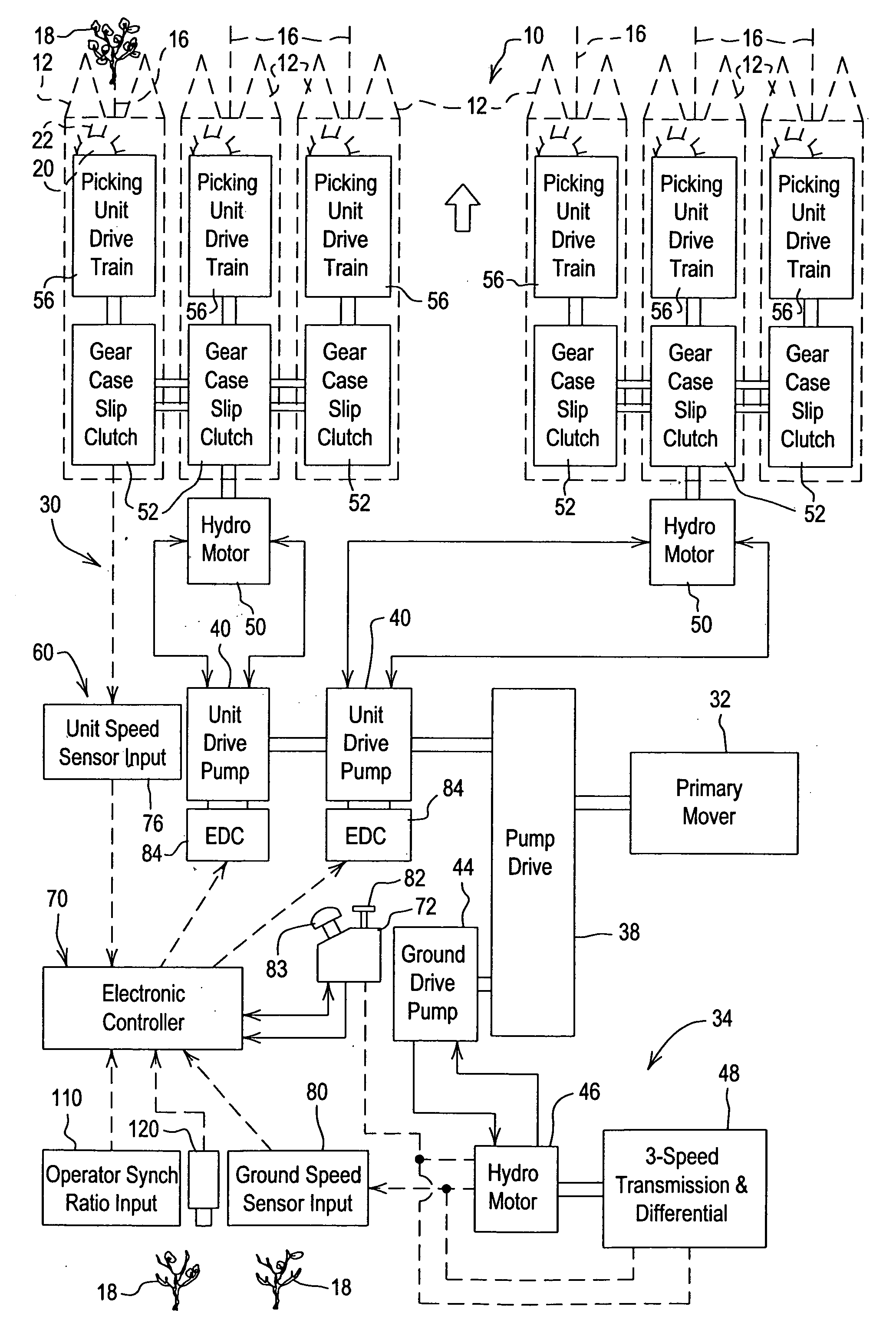

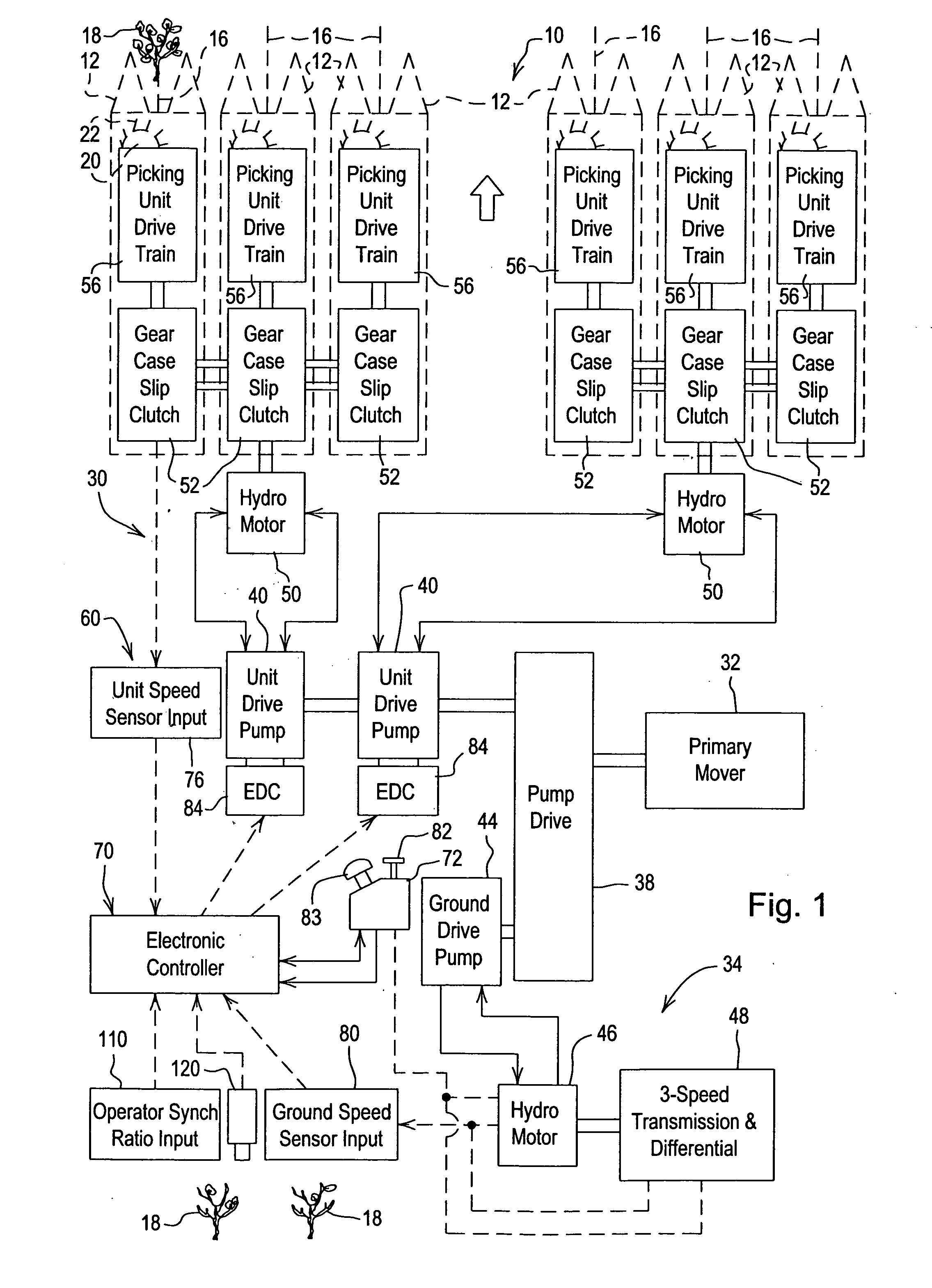

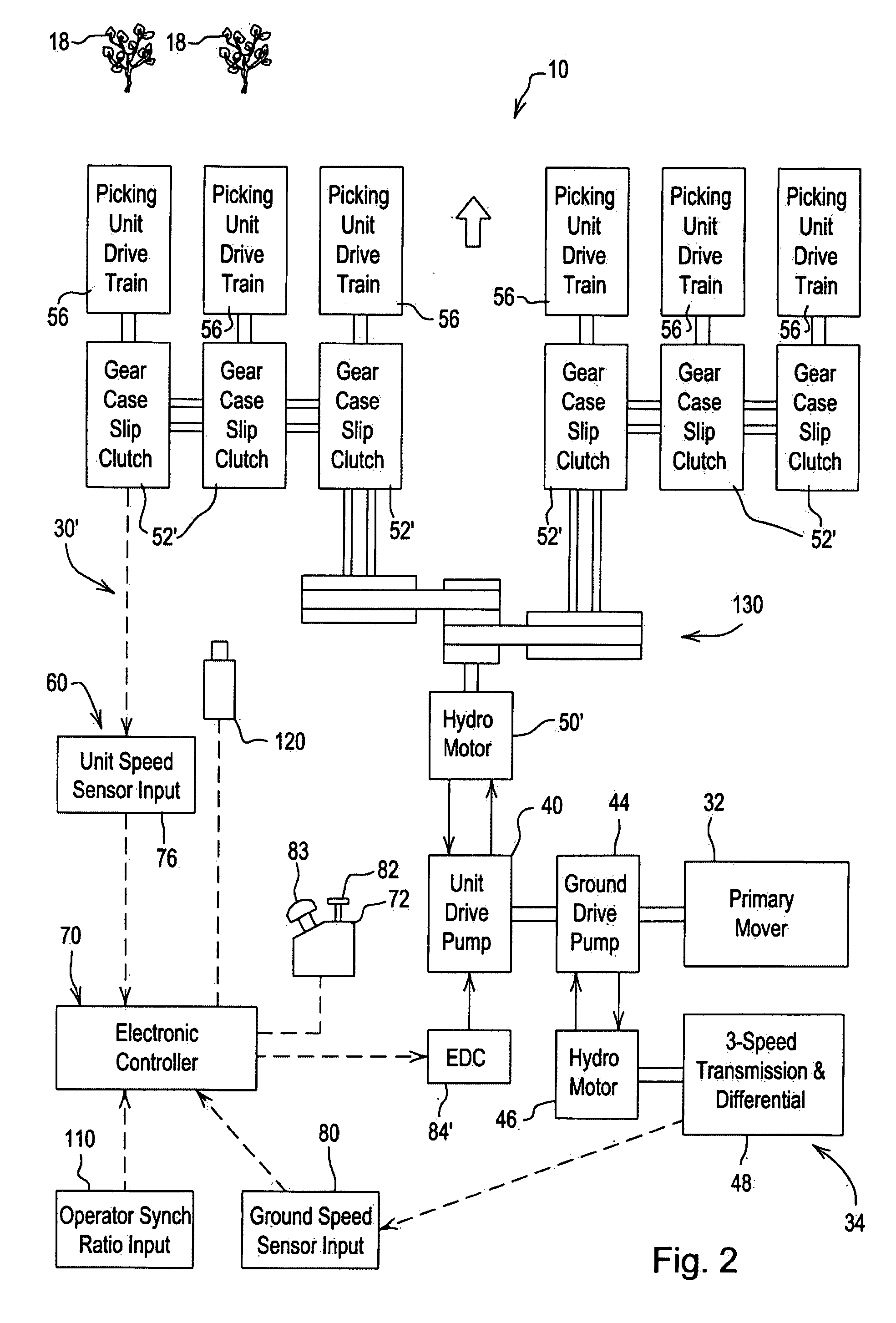

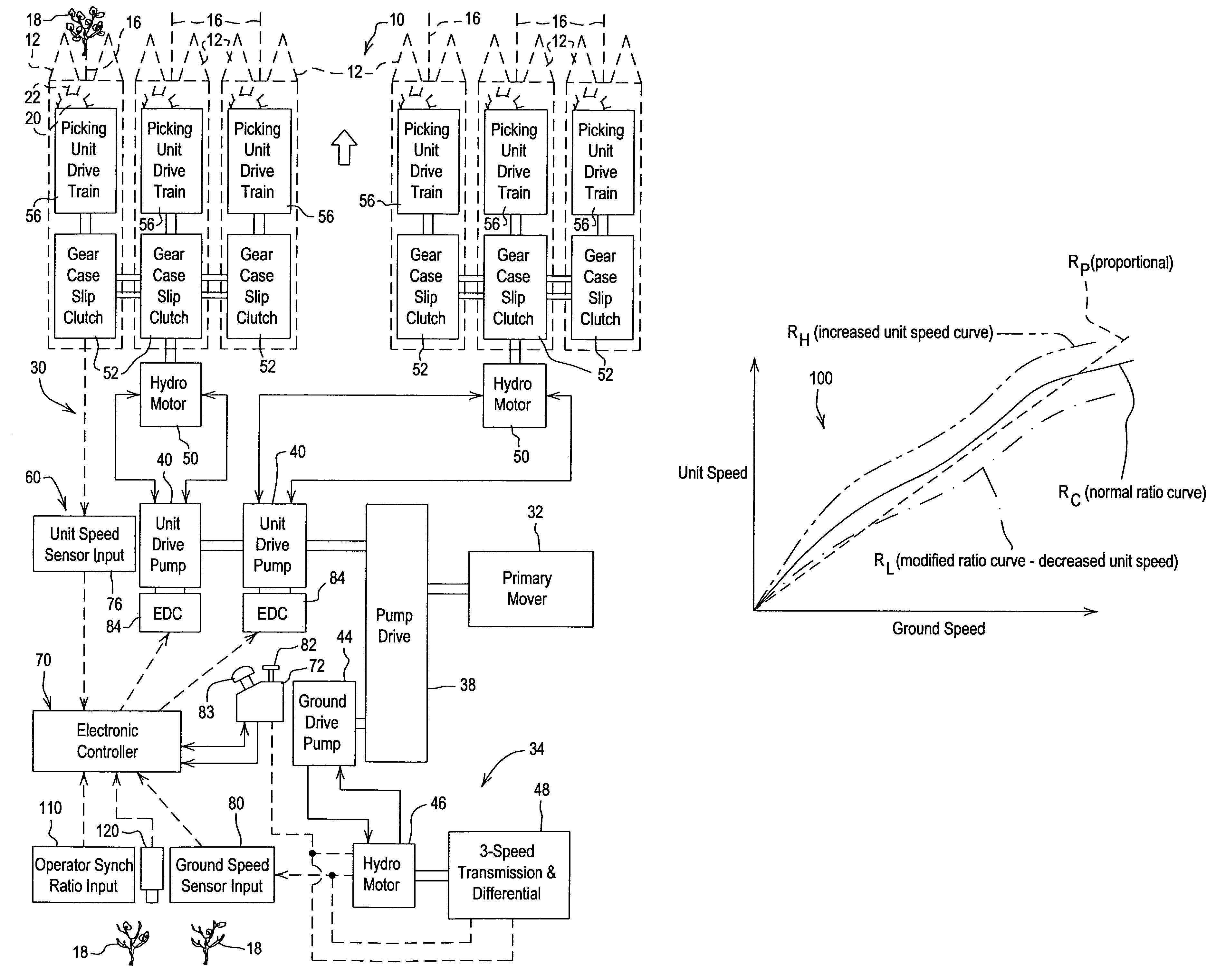

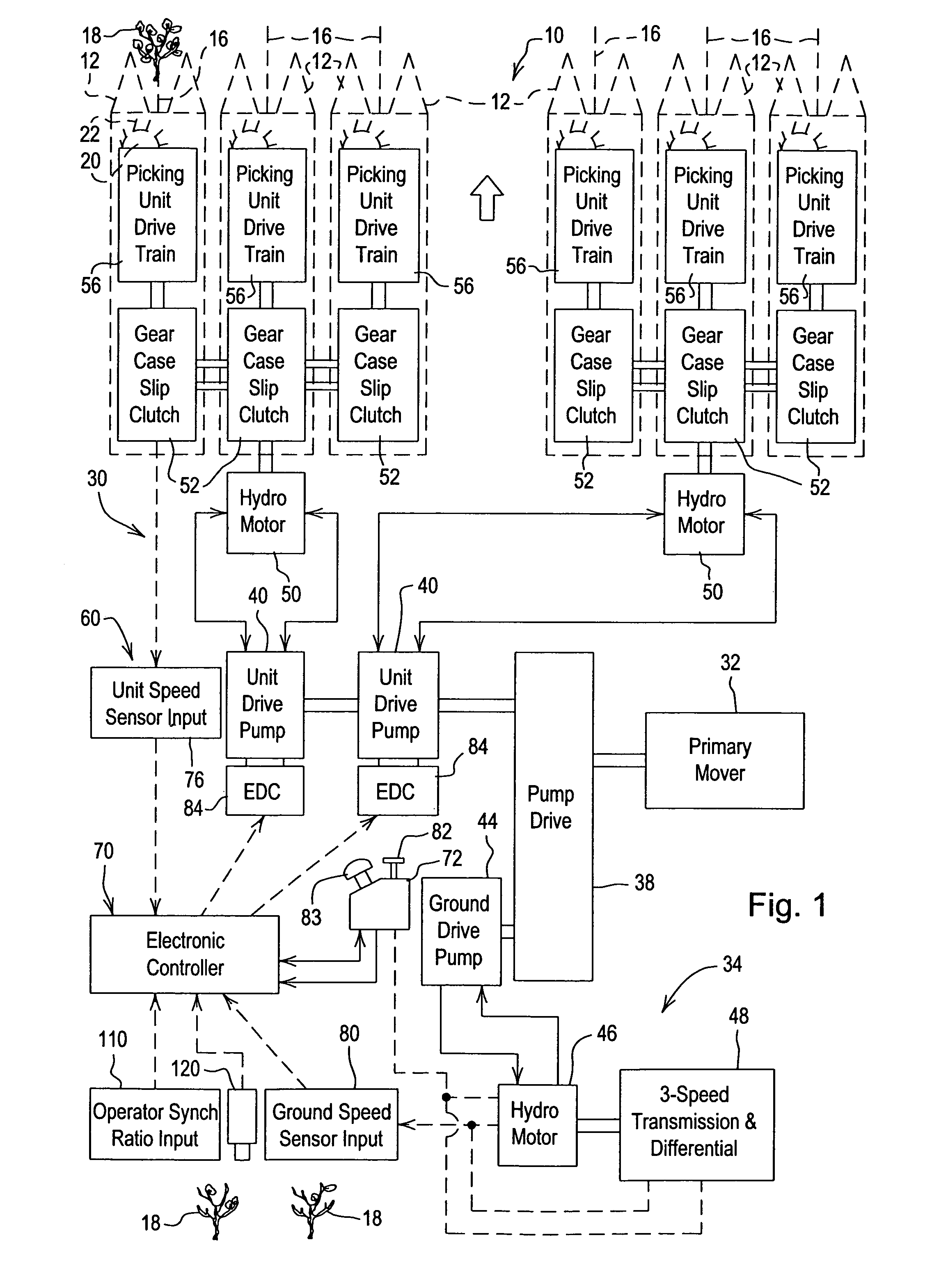

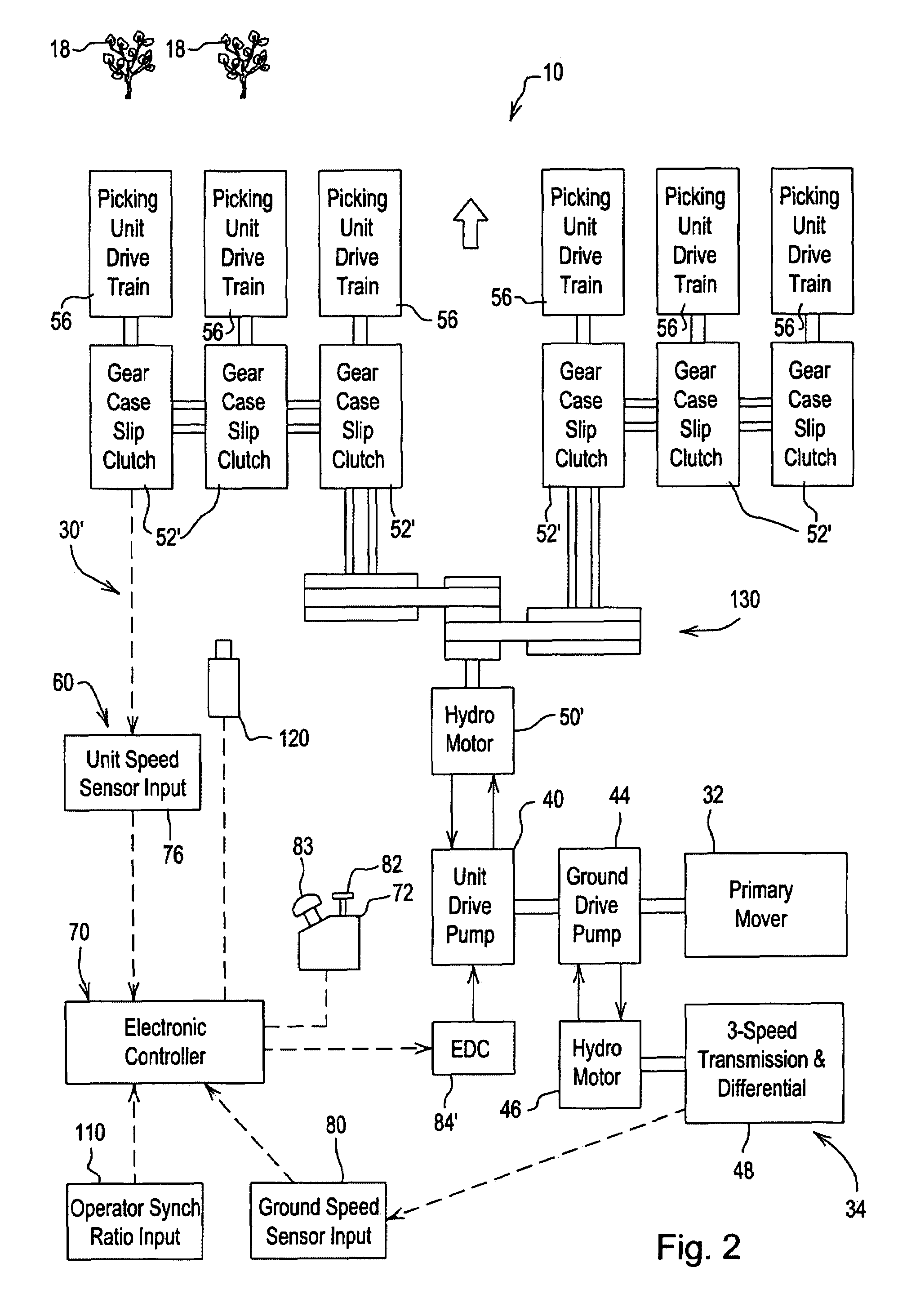

Cotton harvester row unit speed synchronization control

ActiveUS20080046154A1Optimize drive structureOvercome problemsAnalogue computers for trafficMowersProduction rateElectronic controller

An electronic controller with a sensed ground speed input calculates appropriate cotton harvester row unit speed based on harvester ground speed and a preset ground speed versus a unit speed curve. The controller includes an automatic or manual ratio adjustment input. The ratio adjustment input allows the unit speed to be increased or decreased from the preset speed. The controller reads row unit speed via unit speed sensors and sends a signal to the unit speed actuator or electronic drive control (EDC) on a hydro, variable sheave, or other variable drive device to adjust unit speed to the calculated value. A detector or field vision device such as a camera responsive to cotton on the plants provides a signal to the automatic ratio adjustment input to change the ratio for increased productivity and reduced machine wear.

Owner:DEERE & CO

Cotton harvester row unit speed synchronization control

ActiveUS7386380B2Optimize drive structureOvercome problemsAnalogue computers for trafficMowersProduction rateElectronic controller

An electronic controller with a sensed ground speed input calculates appropriate cotton harvester row unit speed based on harvester ground speed and a preset ground speed versus a unit speed curve. The controller includes an automatic or manual ratio adjustment input. The ratio adjustment input allows the unit speed to be increased or decreased from the preset speed. The controller reads row unit speed via unit speed sensors and sends a signal to the unit speed actuator or electronic drive control (EDC) on a hydro, variable sheave, or other variable drive device to adjust unit speed to the calculated value. A detector or field vision device such as a camera responsive to cotton on the plants provides a signal to the automatic ratio adjustment input to change the ratio for increased productivity and reduced machine wear.

Owner:DEERE & CO

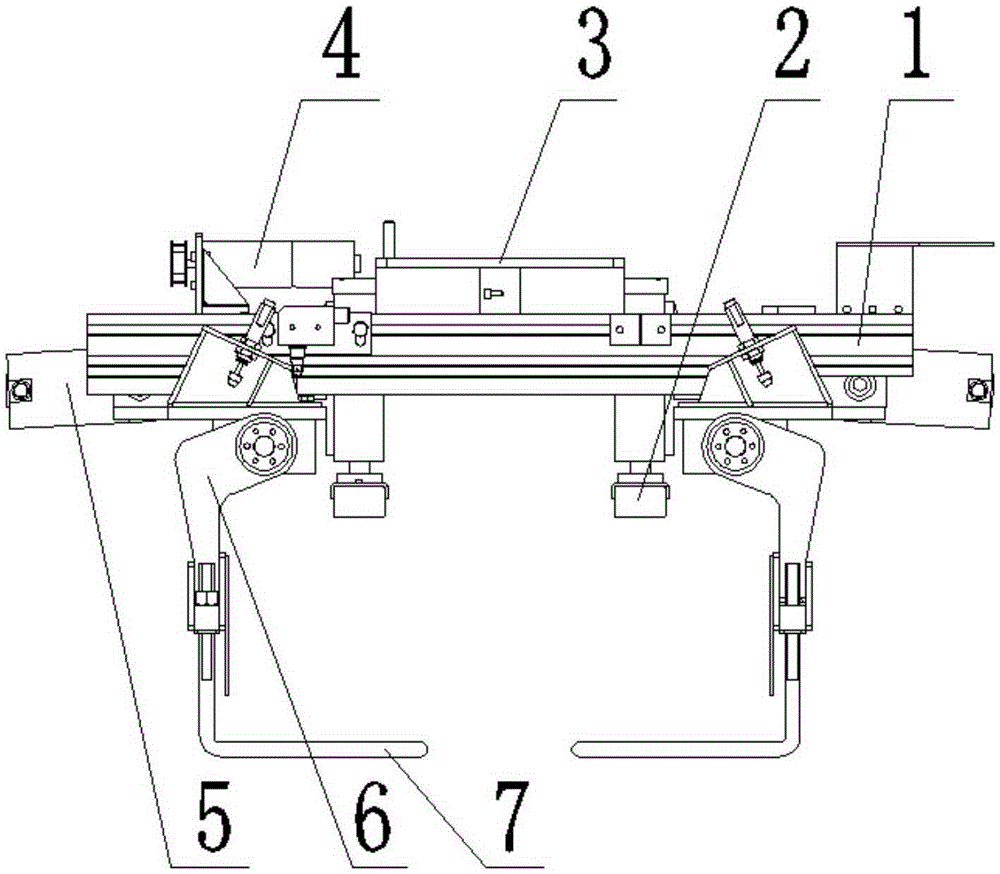

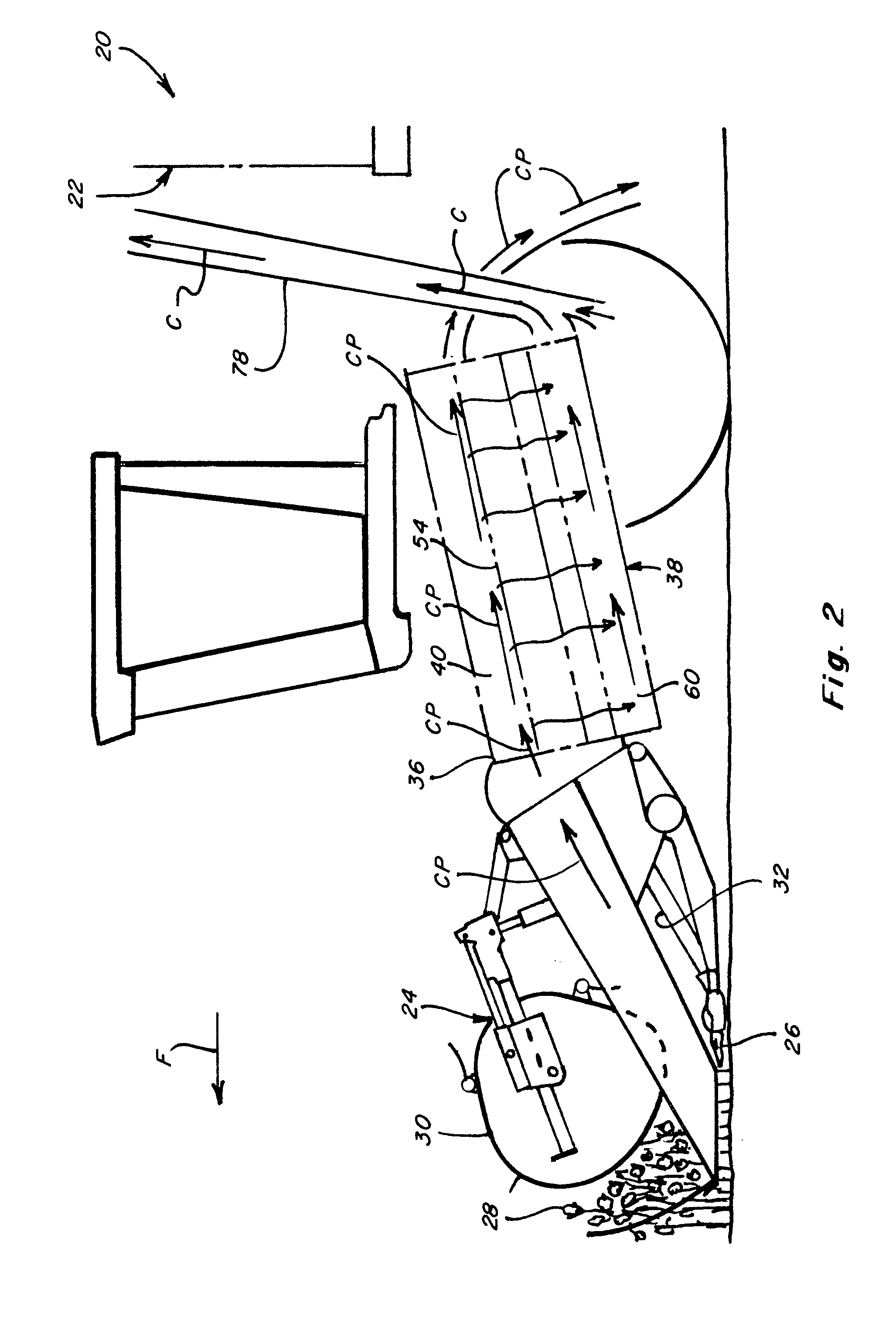

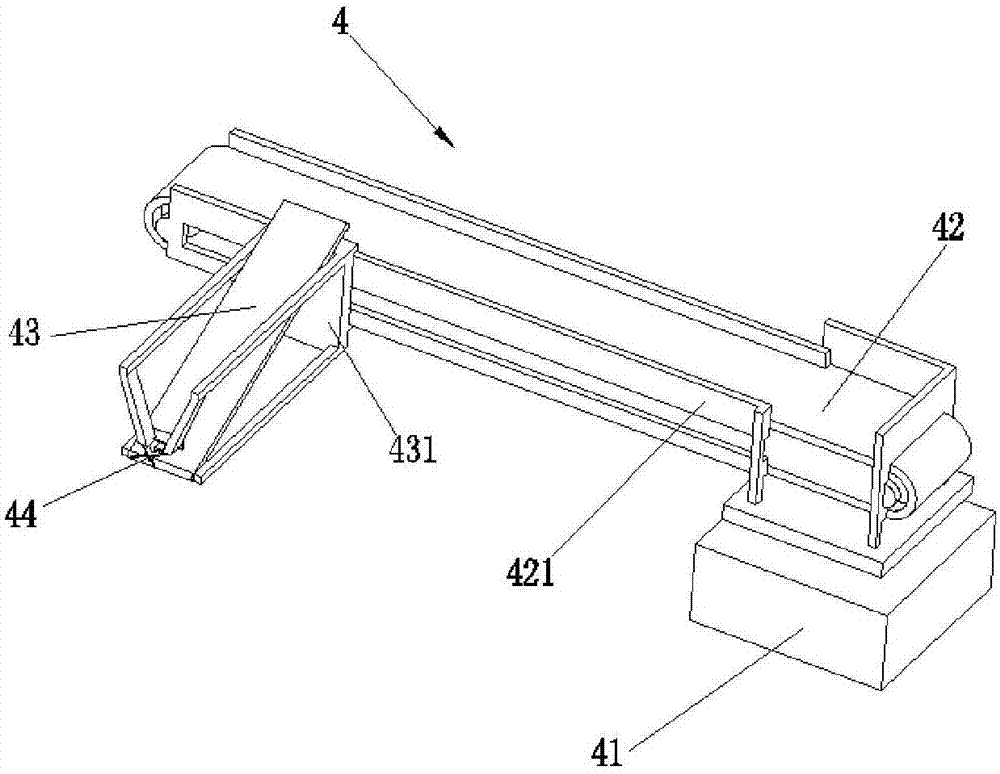

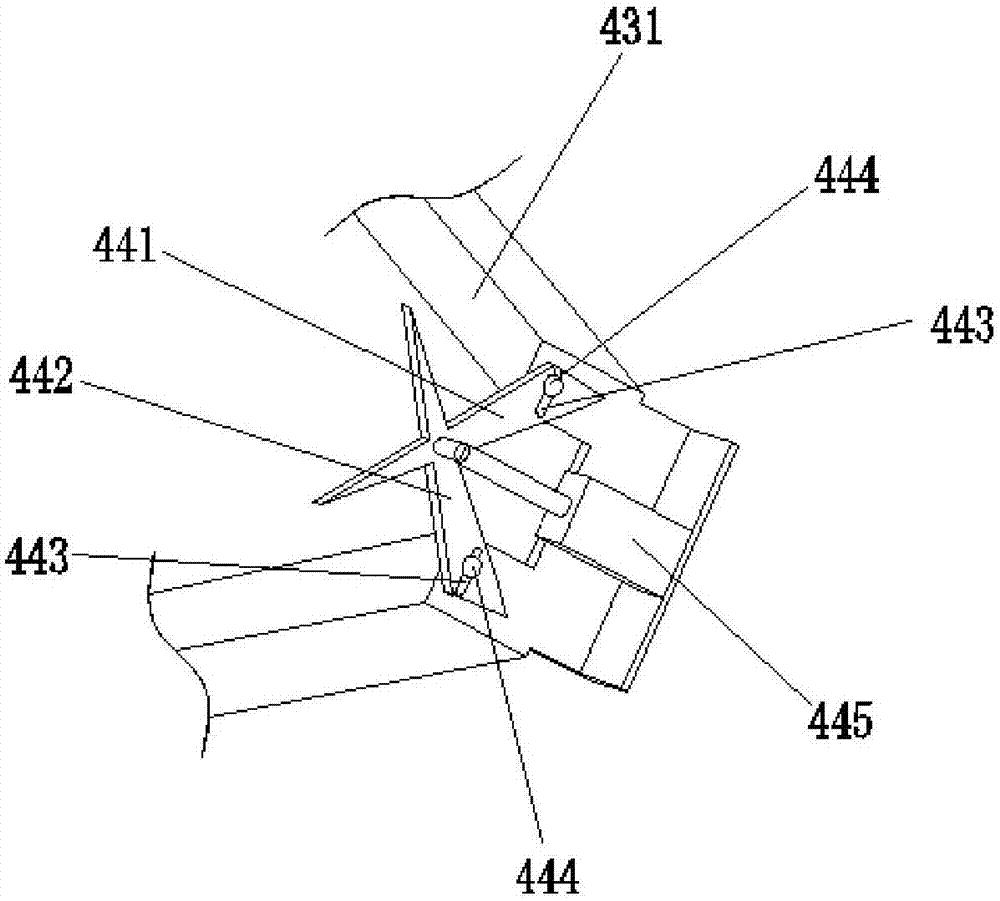

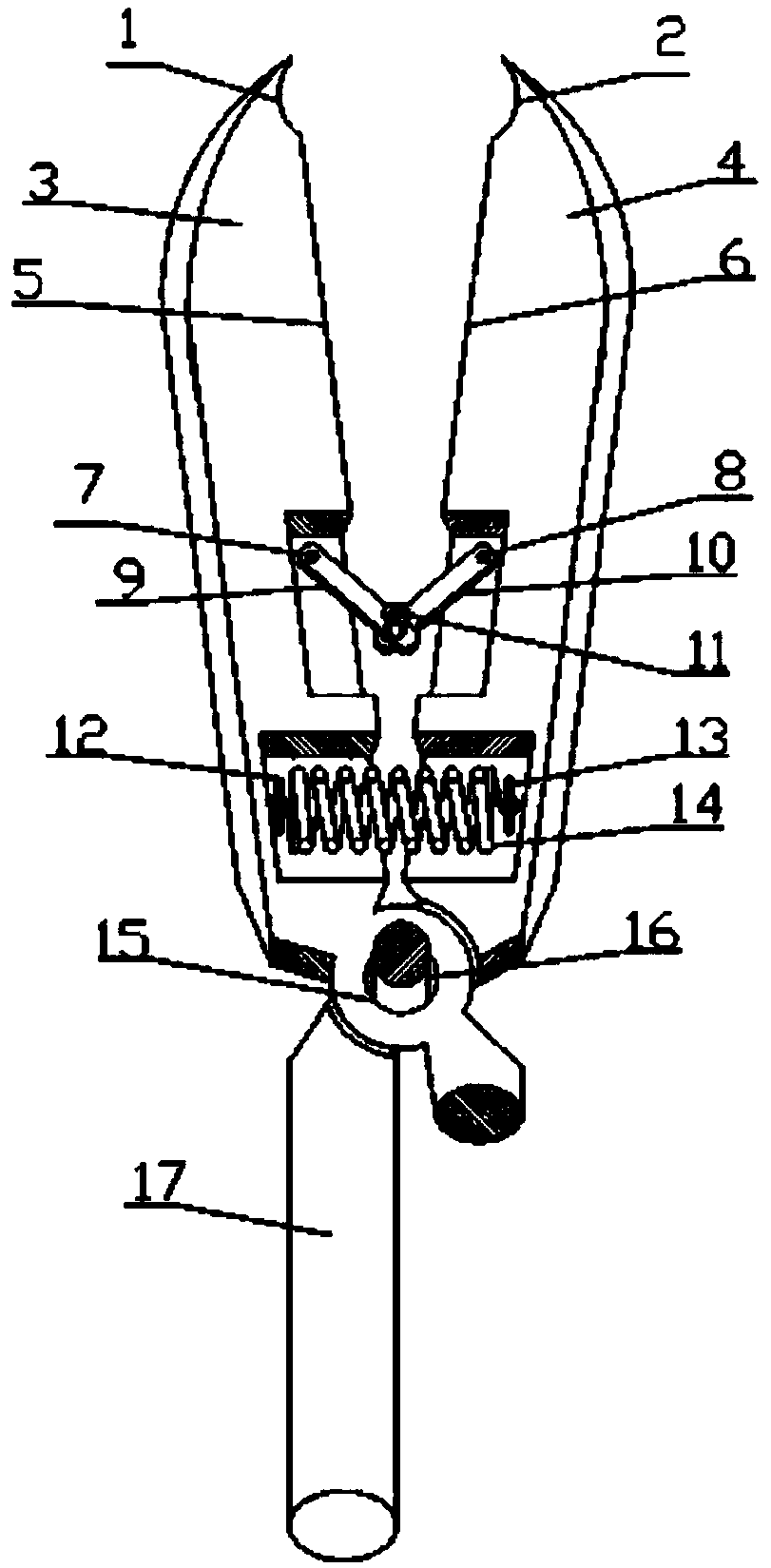

Adjustable grasping arm

InactiveCN105314407AEasy and reliable installationEasy and reliable disassemblyStacking articlesDe-stacking articlesPulp and paper industryFlange

The invention provides an adjustable grasping arm and belongs to the technical field of carriage of paper boxes. The adjustable grasping arm comprises a bracket, wherein a flange connection plate is arranged at the upper part of the bracket; a cylinder is arranged on the bracket; an L-shaped plate is arranged at the lower part of the cylinder; a grasping arm is arranged at the lower part of the L-shaped plate; a box pressing device is arranged at the lower part of the bracket; a width adjusting device is arranged at one end of the cylinder; the width adjusting device is connected to the L-shaped plate; a motor is arranged on the width adjusting device. Through the adjustable grasping arm, the problem of low efficiency of carrying paper boxes manually can be solved; a plywood grasping arm can grasp various specifications of paper boxes different in weight, can grasp cargos with high weight, and is wide in working range; the width adjusting device can automatically adjust the gap between the grasping arms and increase the cargo grasping speed; the grasping arm is convenient and reliable to mount or dismount, convenient to repair, stable in operation and high in working efficiency; the cargos cannot be thrown off.

Owner:HEFEI OBOTE AUTOMATION EQUIP

Portable auxiliary fruit picking apparatus

The invention discloses a portable auxiliary fruit picking apparatus. The apparatus comprises a machine frame, a connecting rod, a shearing mechanism, a sequence mechanism, a labor-saving mechanism and a storage pipe. The machine frame is an outer frame of the apparatus, the shearing mechanism is connected to the machine frame, the sequence mechanism is connected to the lower side of the shearingmechanism, the labor-saving mechanism is connected with the connecting rod, the storage pipe is connected to the sequence mechanism, and the connecting rod is connected with the labor-saving mechanismand the shearing mechanism. When a fruit is picked, the fruit enters into the apparatus, baffle plates of the sequence mechanism are closed, a rope of the labor-saving mechanism is pulled, the connecting rod is driven to make the shearing mechanism shear a fruit pedicle, the connecting rod drives the sequence mechanism to open the baffle plates at the same time, the sheared fruit falls into the storage pipe through the sequence mechanism, the rope is released, and springs of the sequence mechanism make the whole mechanism return to the original position. The mechanical structure of the apparatus aims to assist people in picking fruits, traditional fruit picking demands are ensured, and people operation amounts are also reduced. The apparatus has the advantages of being simple in operationand labor-saving, so that the apparatus is convenient in putting on the market for sales.

Owner:SHANGHAI UNIV

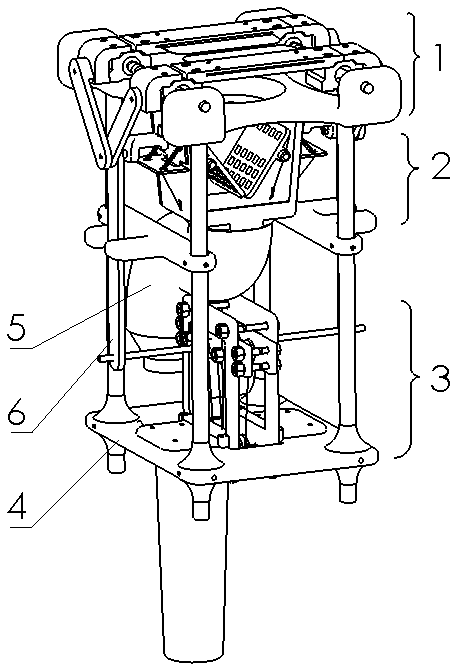

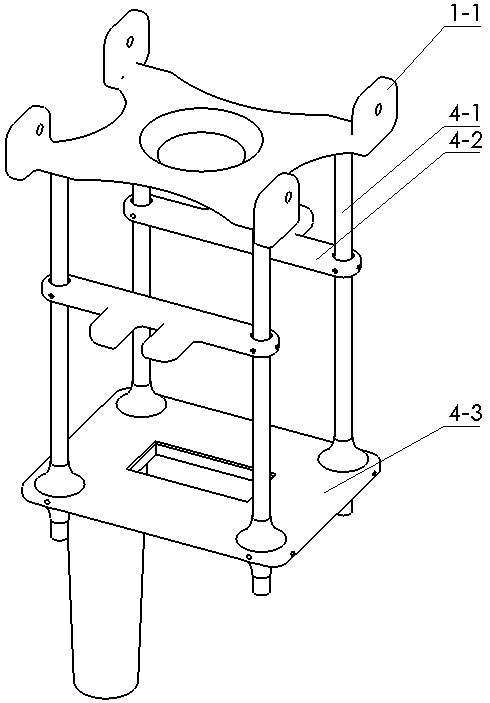

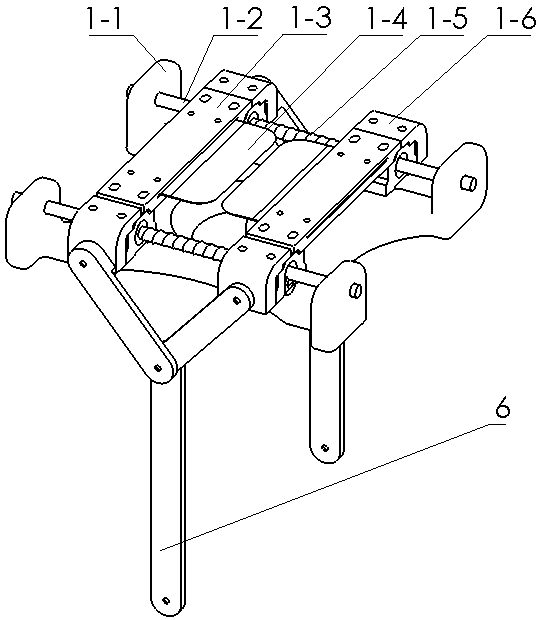

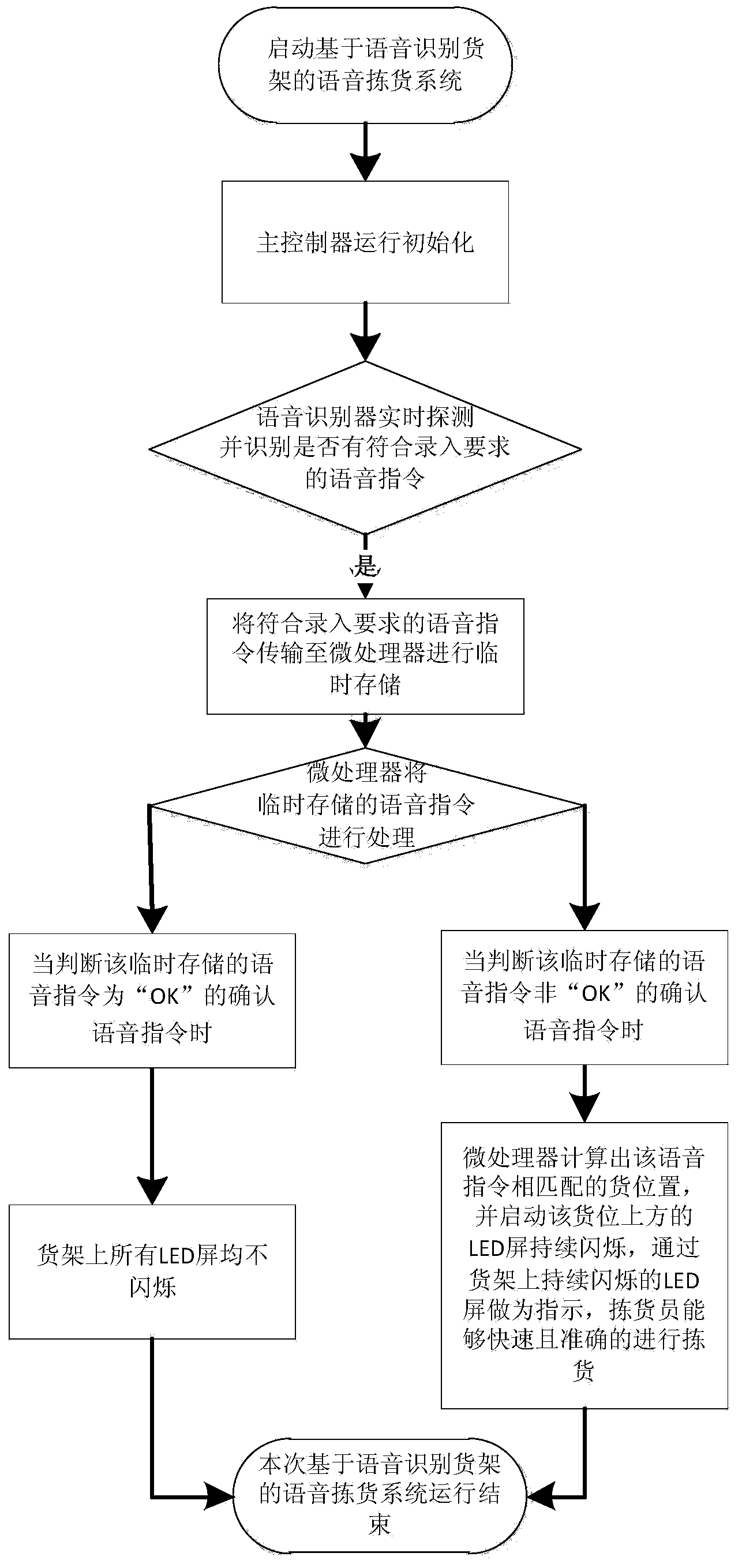

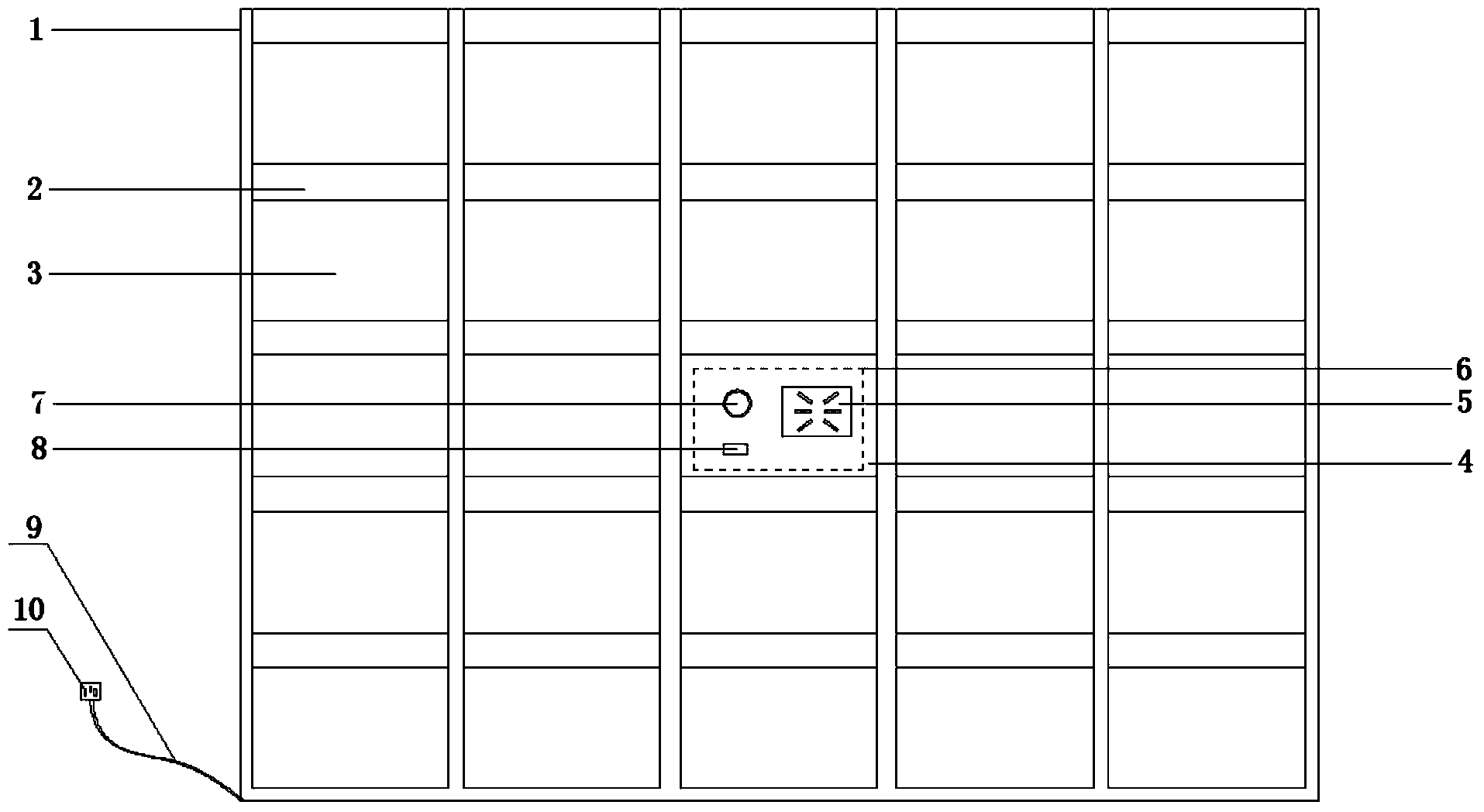

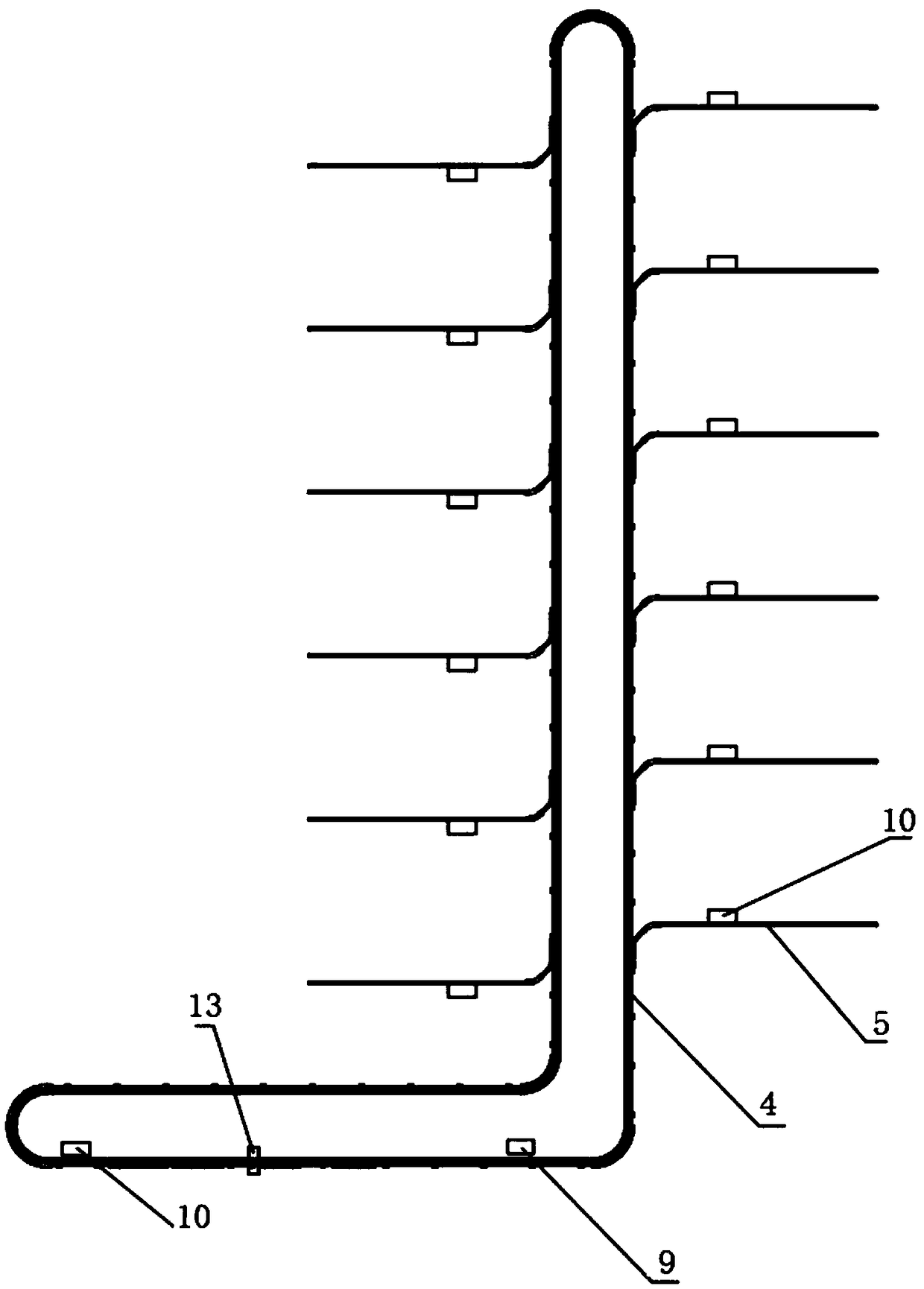

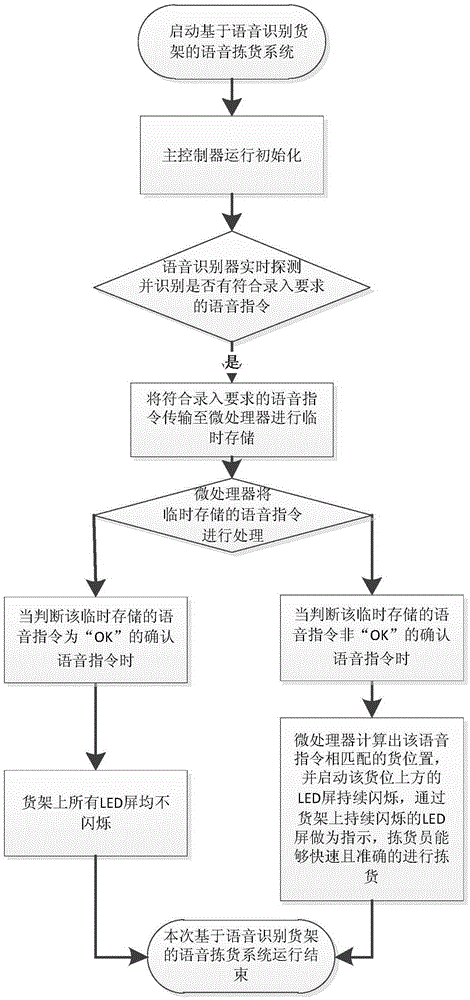

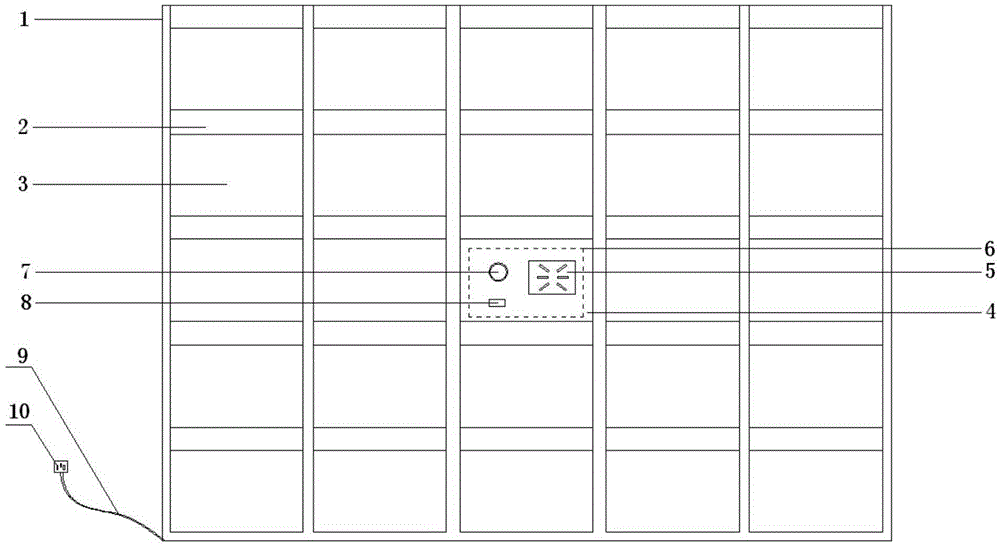

Voice picking system and method based on voice recognition goods shelf

InactiveCN103771072AAccurately complete pickingEasy to complete pickingStorage devicesLogistics managementSpeech identification

The invention relates to a voice picking system and method based on a voice recognition goods shelf. The voice picking system comprises a goods shelf, LED screens and a master controller, wherein a plurality of goods allocations are arranged on the goods shelf, an LED screen is arranged at the upper end of each goods allocation, and the width of each LED screen is consistent with that of the goods shelf; and the master controller is arranged in the goods allocation in the middle of the goods shelf, and comprises a power switch, a USB interface, a voice recognizer and a microprocessor. The voice picking system and method based on the voice recognition goods shelf have the benefits as follows: whether a voice command requiring for picking goods exists is detected and recognized in real time by the voice recognizer, and the voice command is displayed on the goods allocations through the LED screens after processed by the microprocessor, so that goods picker finishes goods picking accurately, conveniently and quickly, manual goods picking errors are reduced, and the logistics picking speed is increased.

Owner:GUANGXI POLYTECHNIC

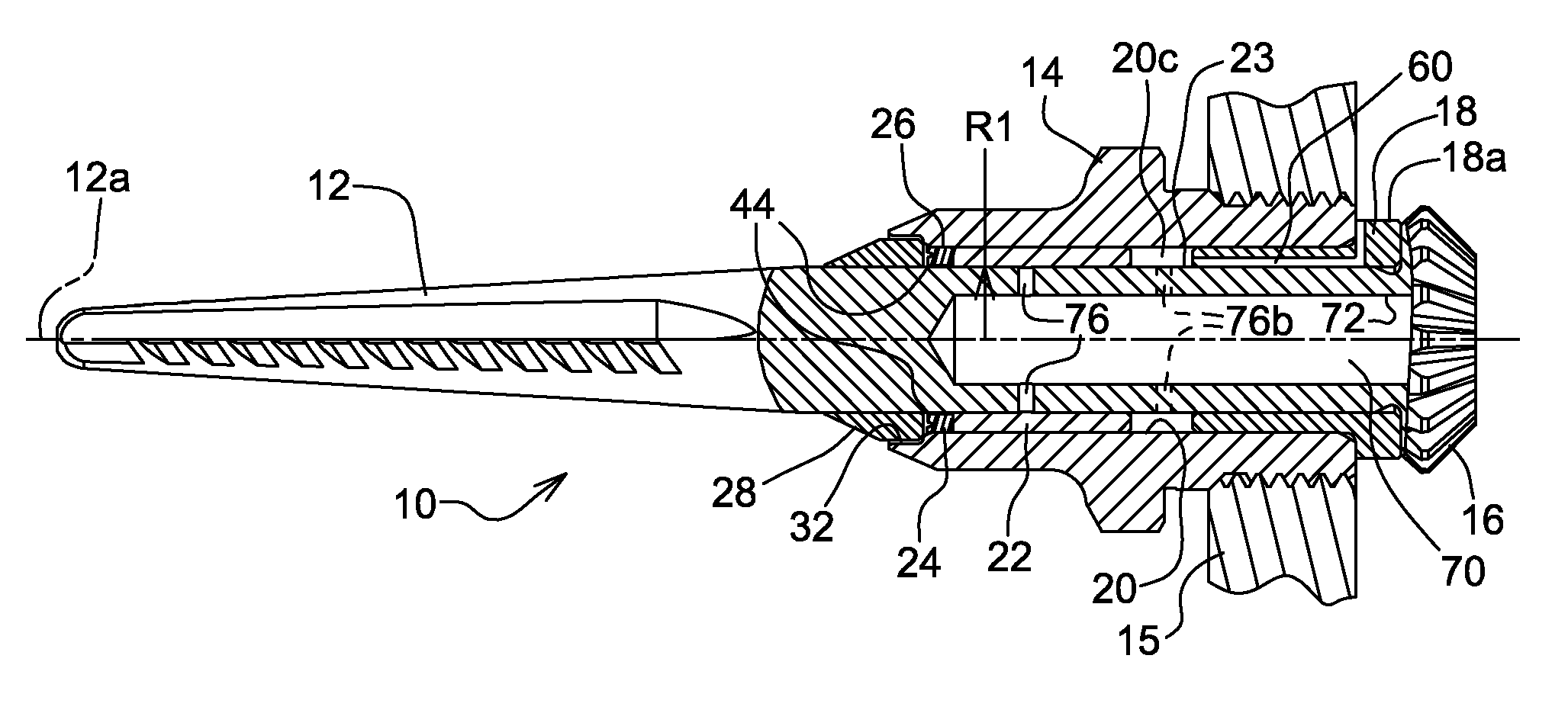

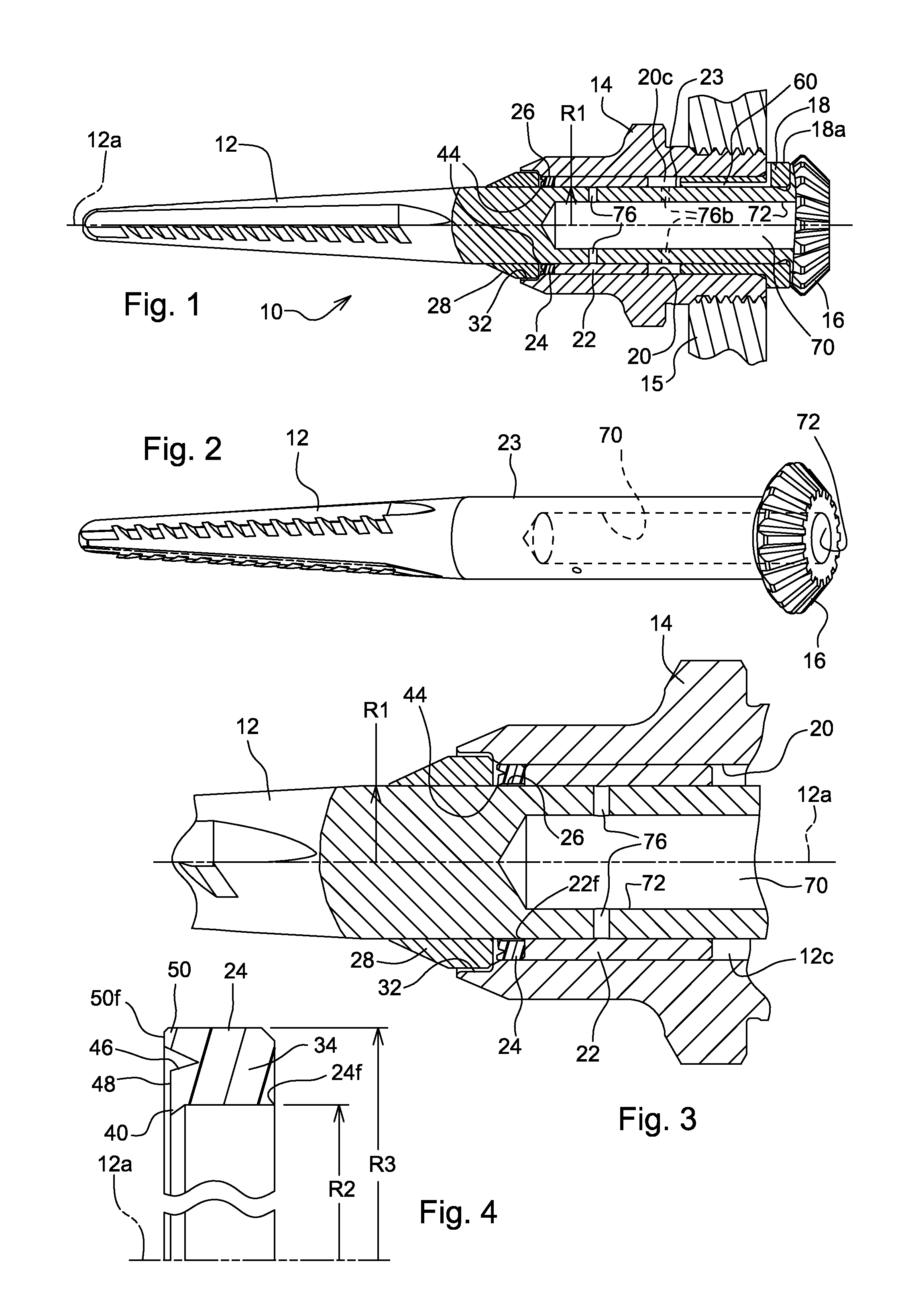

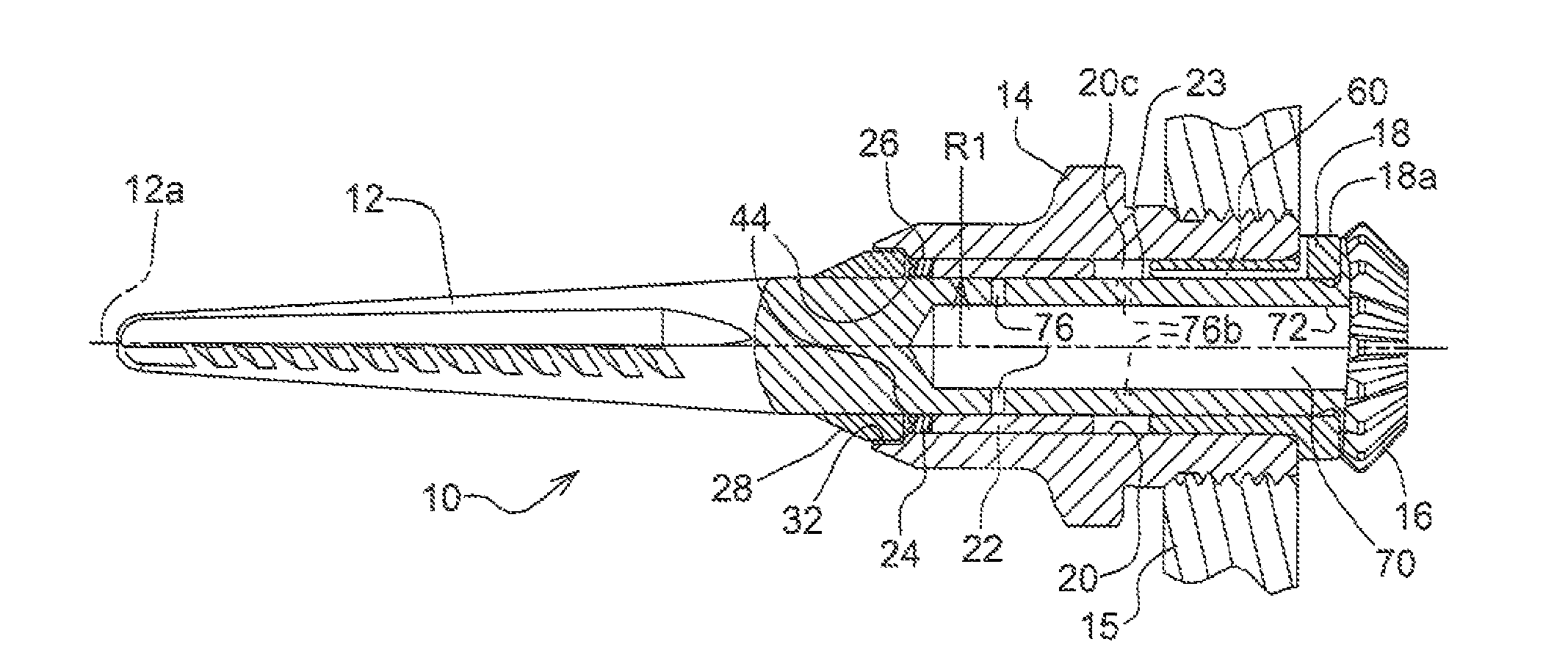

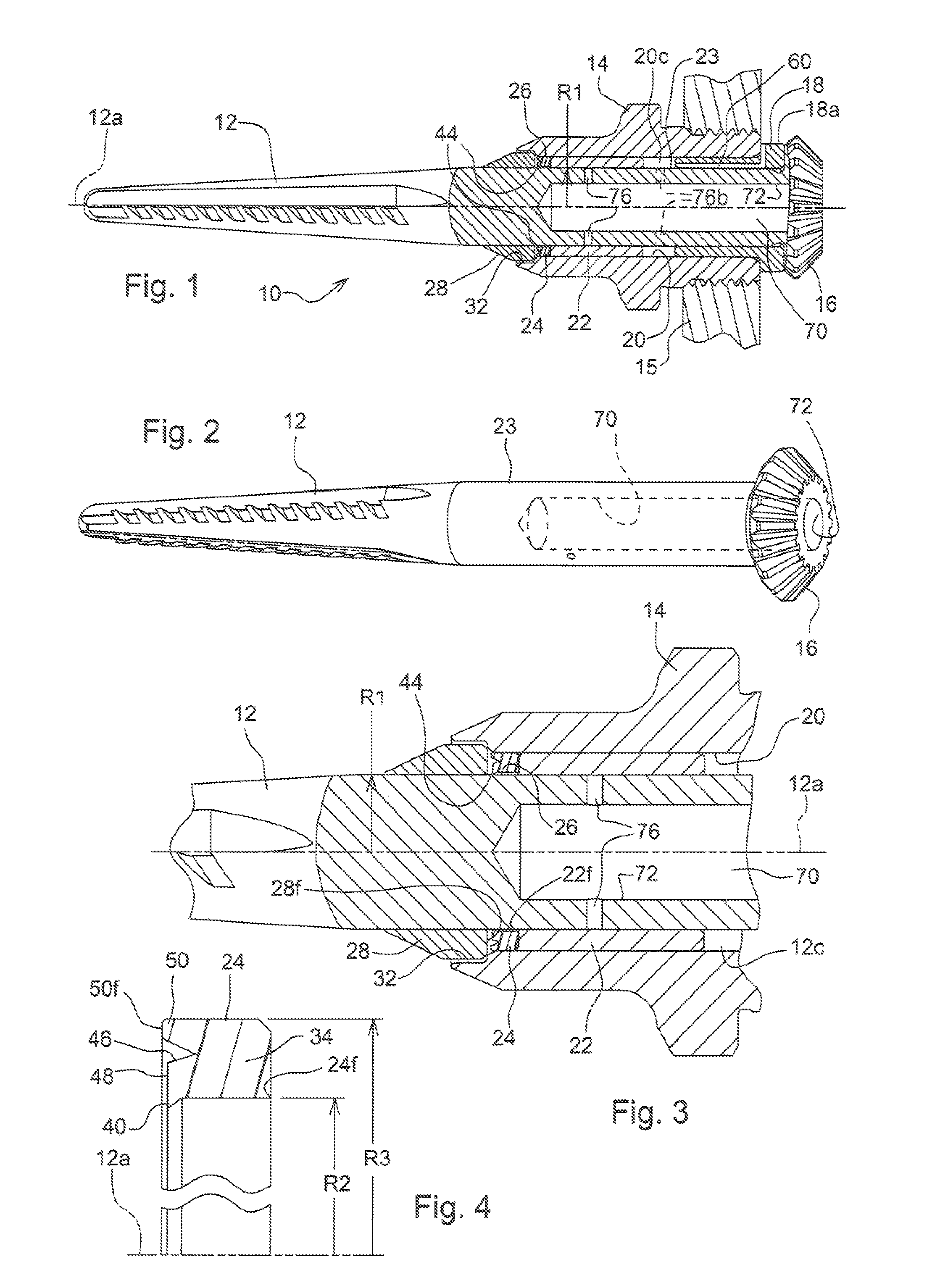

Cotton picker spindle with grease reservoir and a grease and dirt seal

A spindle assembly includes a spindle with a blind bore extending along the spindle axis from the drive gear towards the outer end to reduce spindle weight and provide a lubrication reservoir in the spindle. Cross-formed holes extend from the blind bore through to the bearing surface of the spindle. Lubricant from the spindle bars passes into the bore where it is stored and distributed to the journal areas through the small metering apertures. A very low friction seal between the outer bushing and dust collar is pressed into the spindle nut and seals against the polished chrome spindle surface. The seal allows a slight amount of lubricant passage outwardly from the bushings while limiting inward movement of dust towards the bushings.

Owner:DEERE & CO

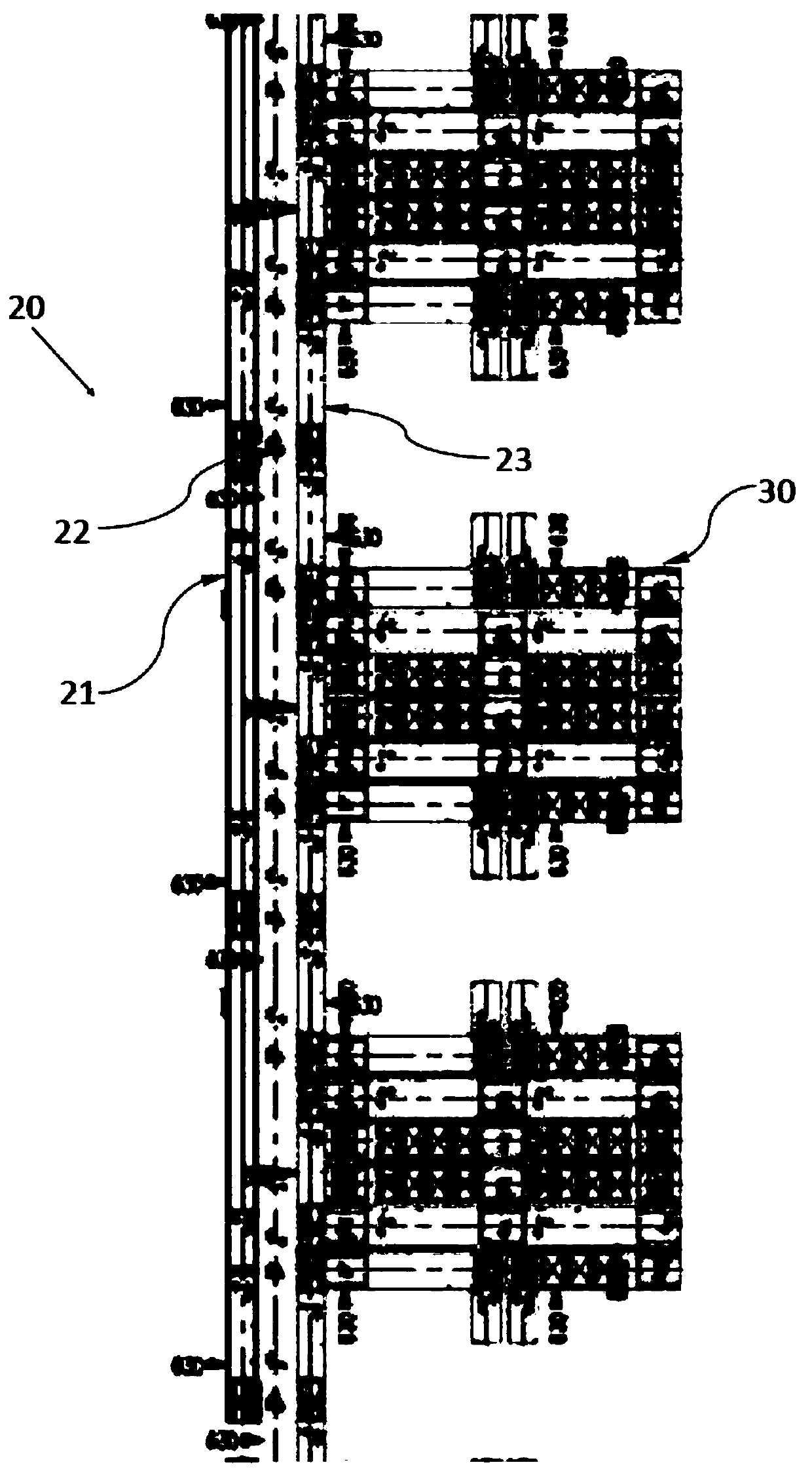

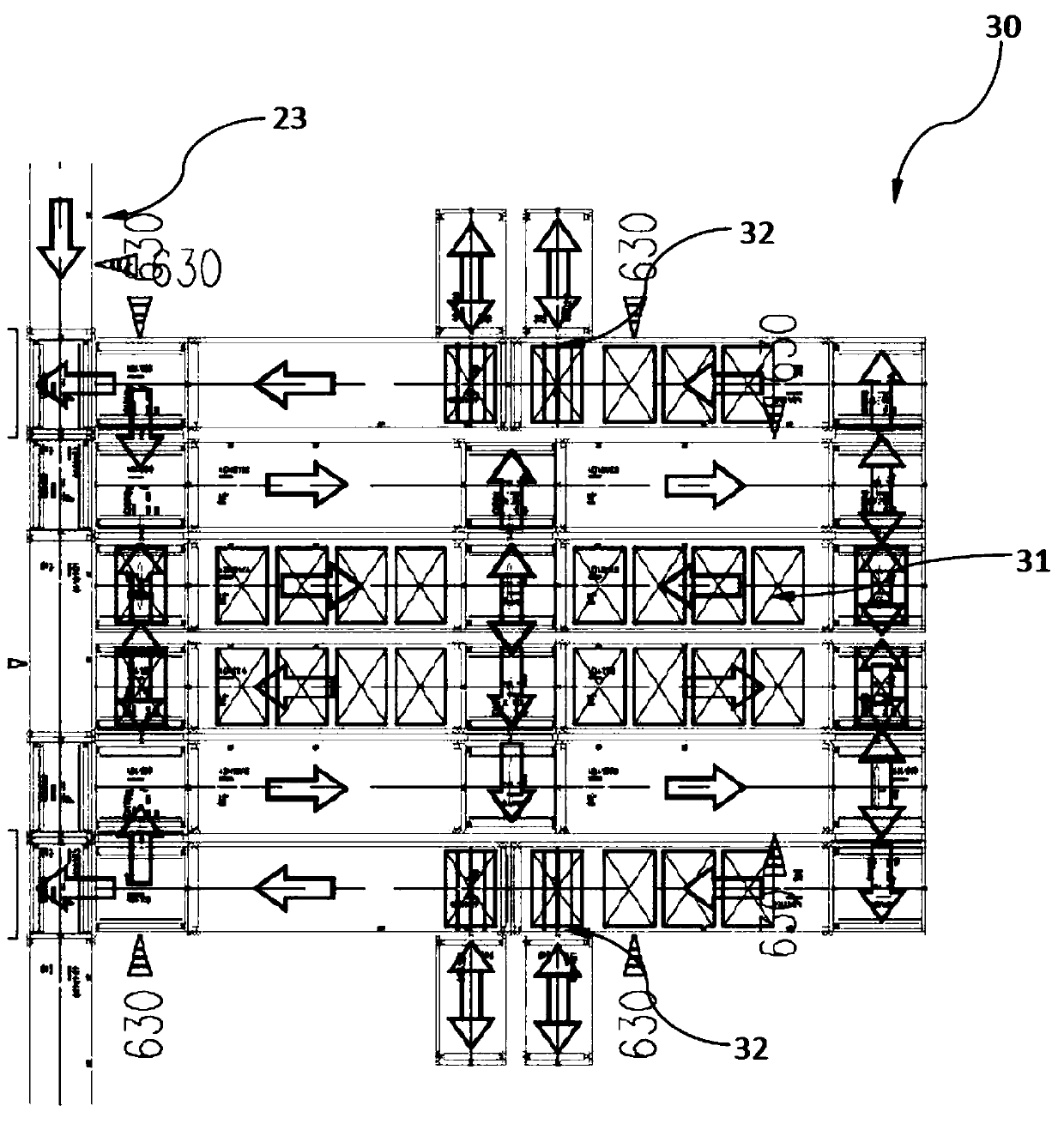

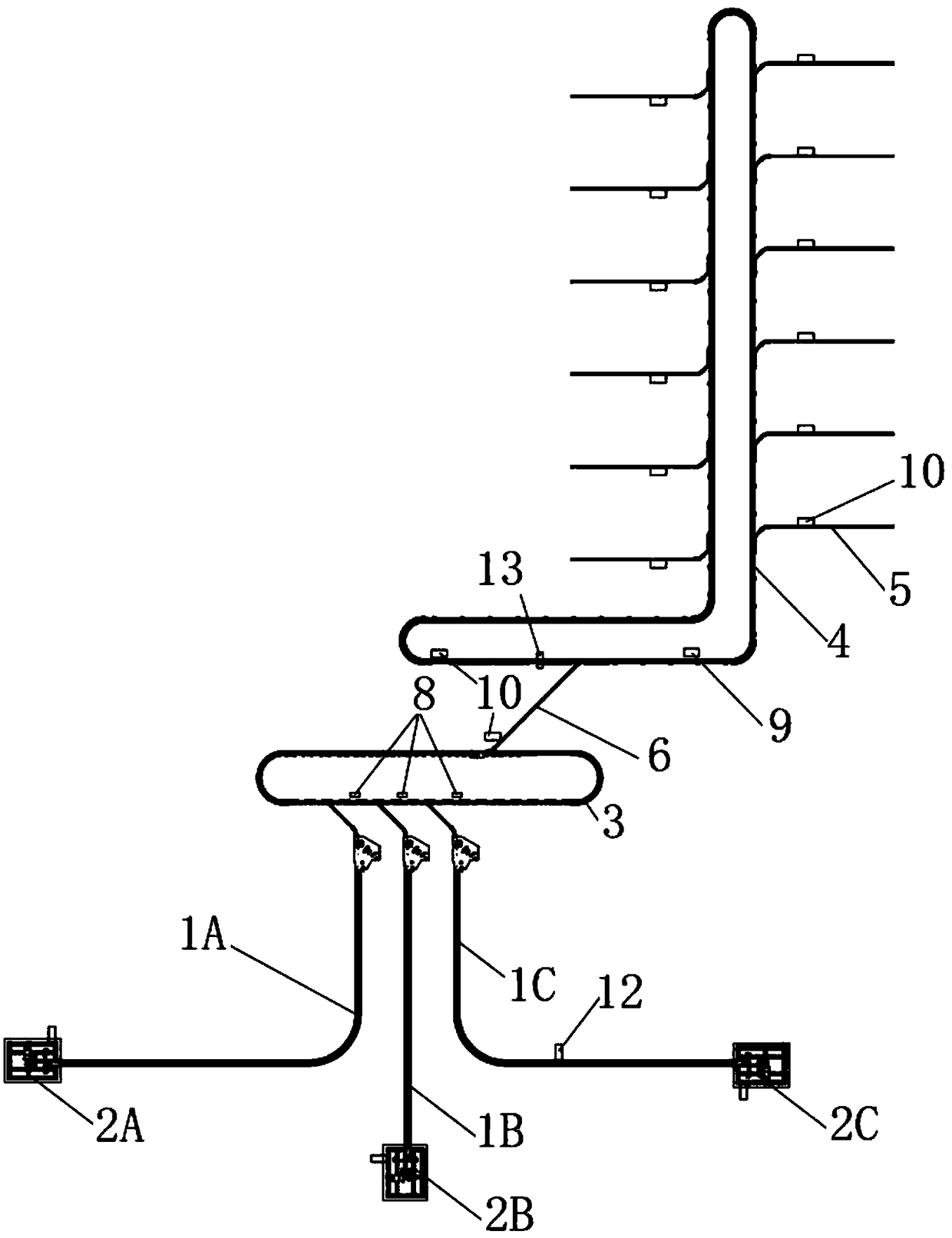

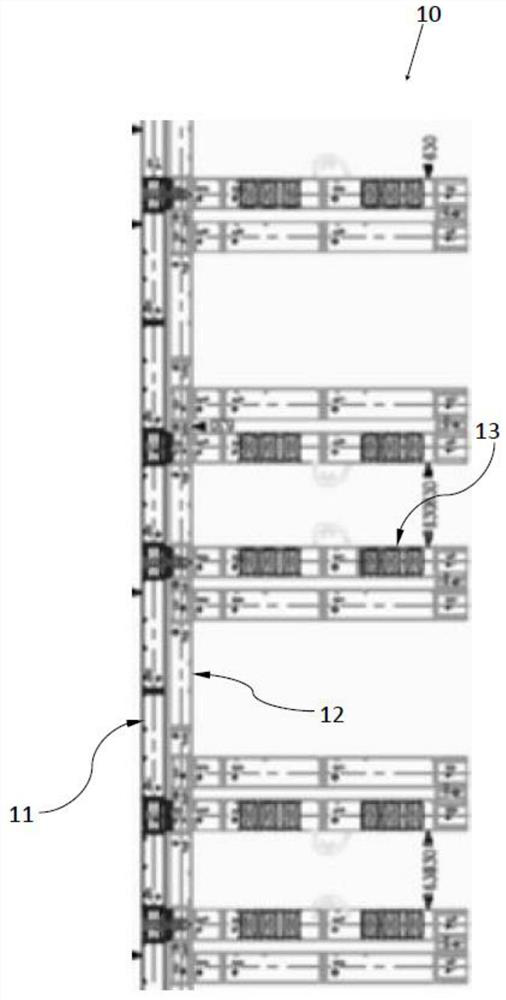

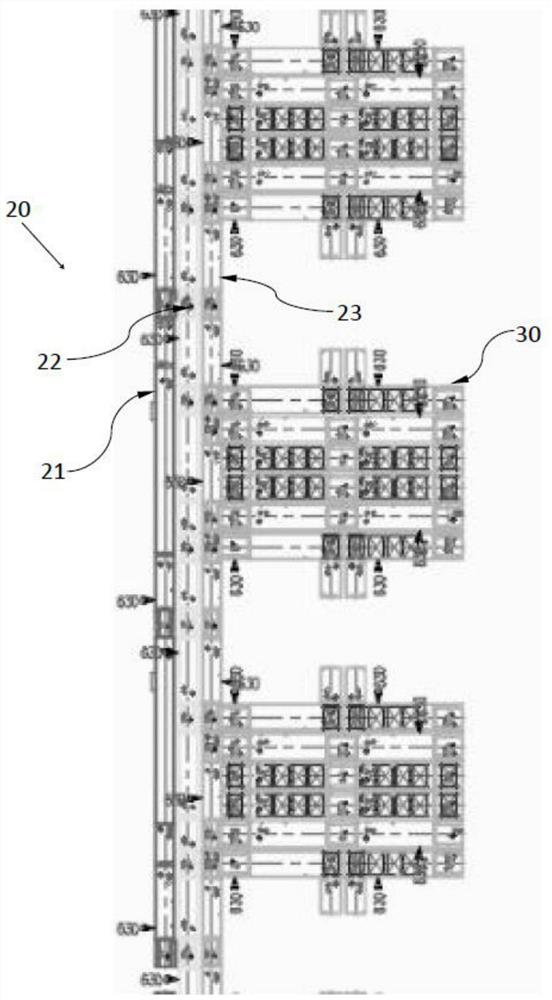

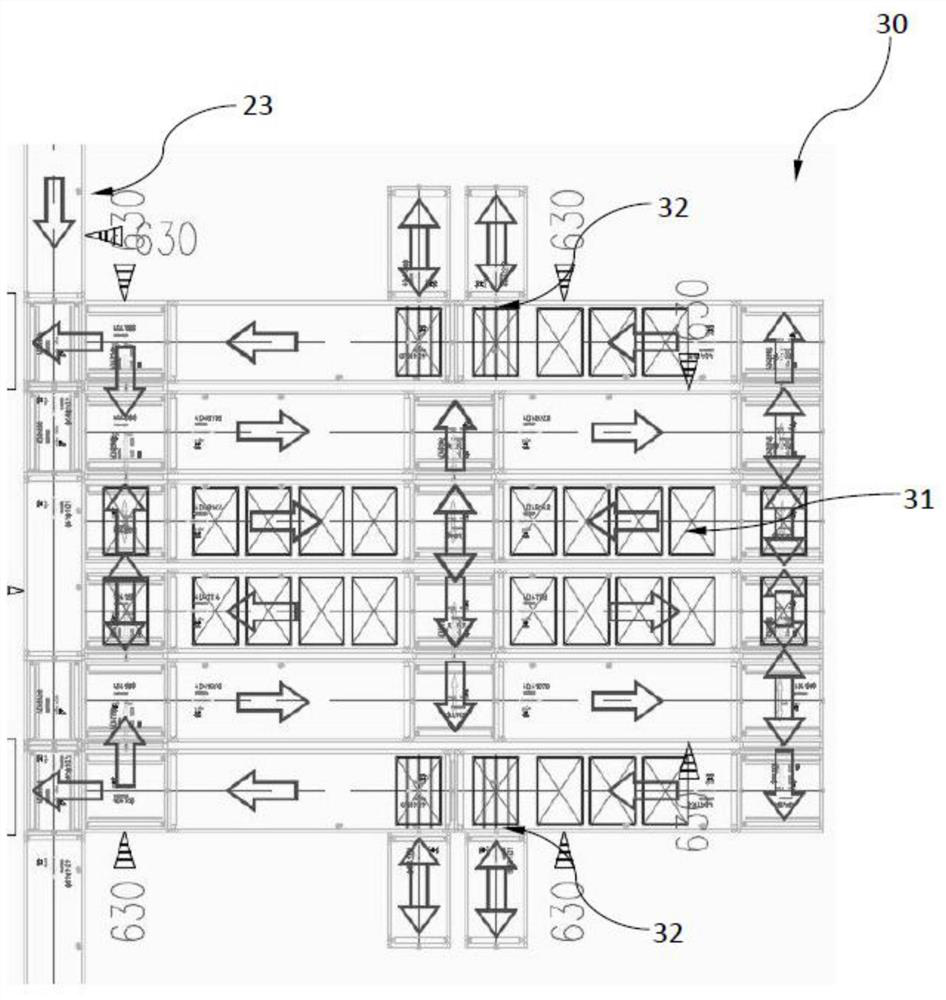

Cargo-to-human workstation conveying line routing control method based on multilayer material box storage library

ActiveCN110963226AIncrease picking speedRealize general pickingStorage devicesOrder controlInformation transmission

The invention provides a cargo-to-human workstation conveying line routing control method based on a multilayer material box storage library. The method is characterized by comprising the following steps: an order control system receives a total order issued by a warehouse management system, binds the total order to a corresponding cargo-to-person workbench according to the material overlap ratioin the total order, and generates corresponding total order binding information; the order control system matches the conveying line with the inventory of the multilayer material box storage library according to the material requirements in the total order, generates or changes a carrying task for the inventory boxes on the conveying line, generates an inventory box off-shelf task for the inventory boxes in the multilayer material box storage library, and further generates order picking task information; the inventory boxes in the multilayer material box storage library and the inventory boxeson the conveying line are received and moved to the corresponding cargo-to-human workbench according to the total order binding information and the cargo picking task information, and information transmission is achieved between the order control system and the inventory boxes through the conveying line control system.

Owner:HUBEI JOINTOWN TECH

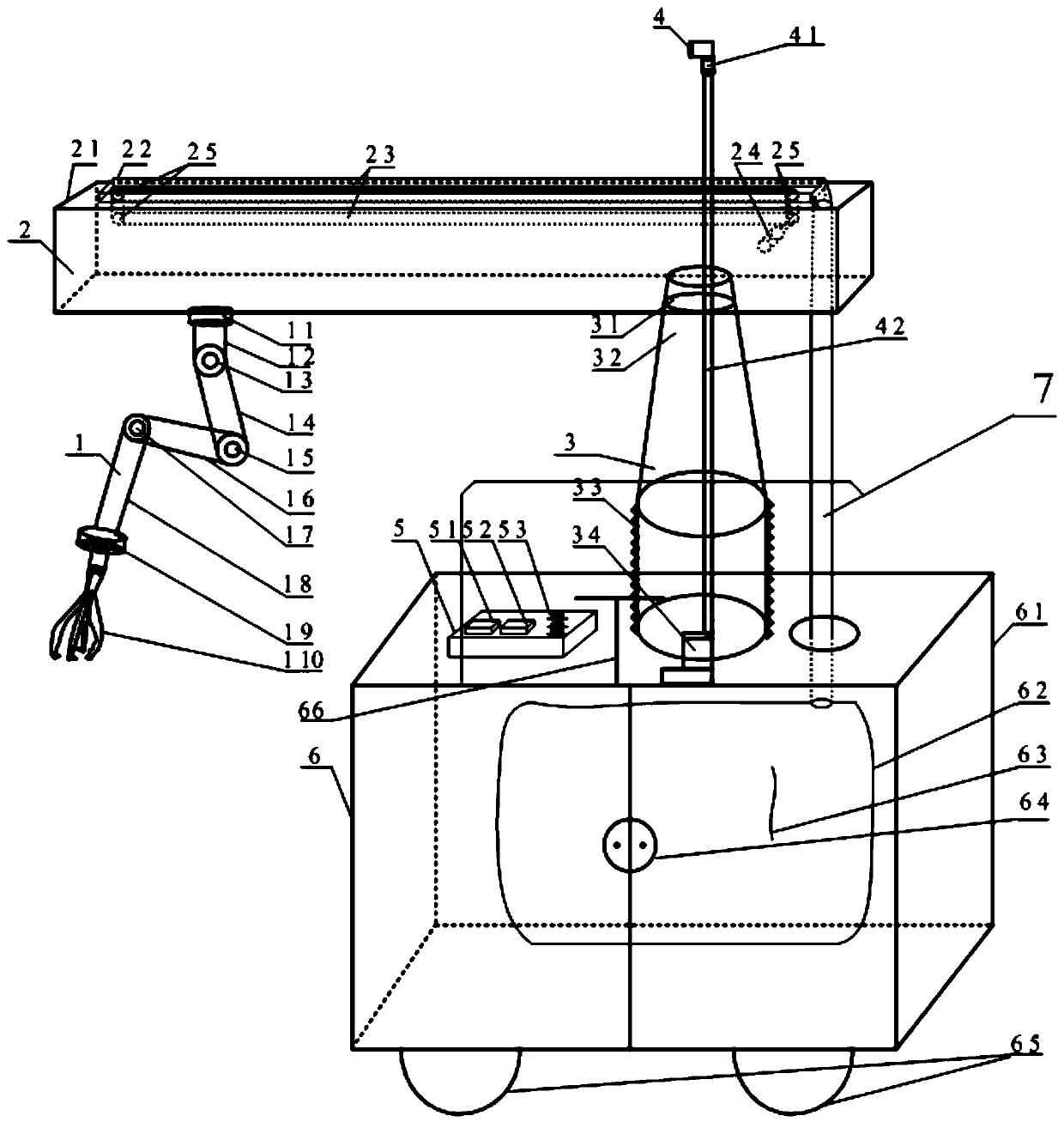

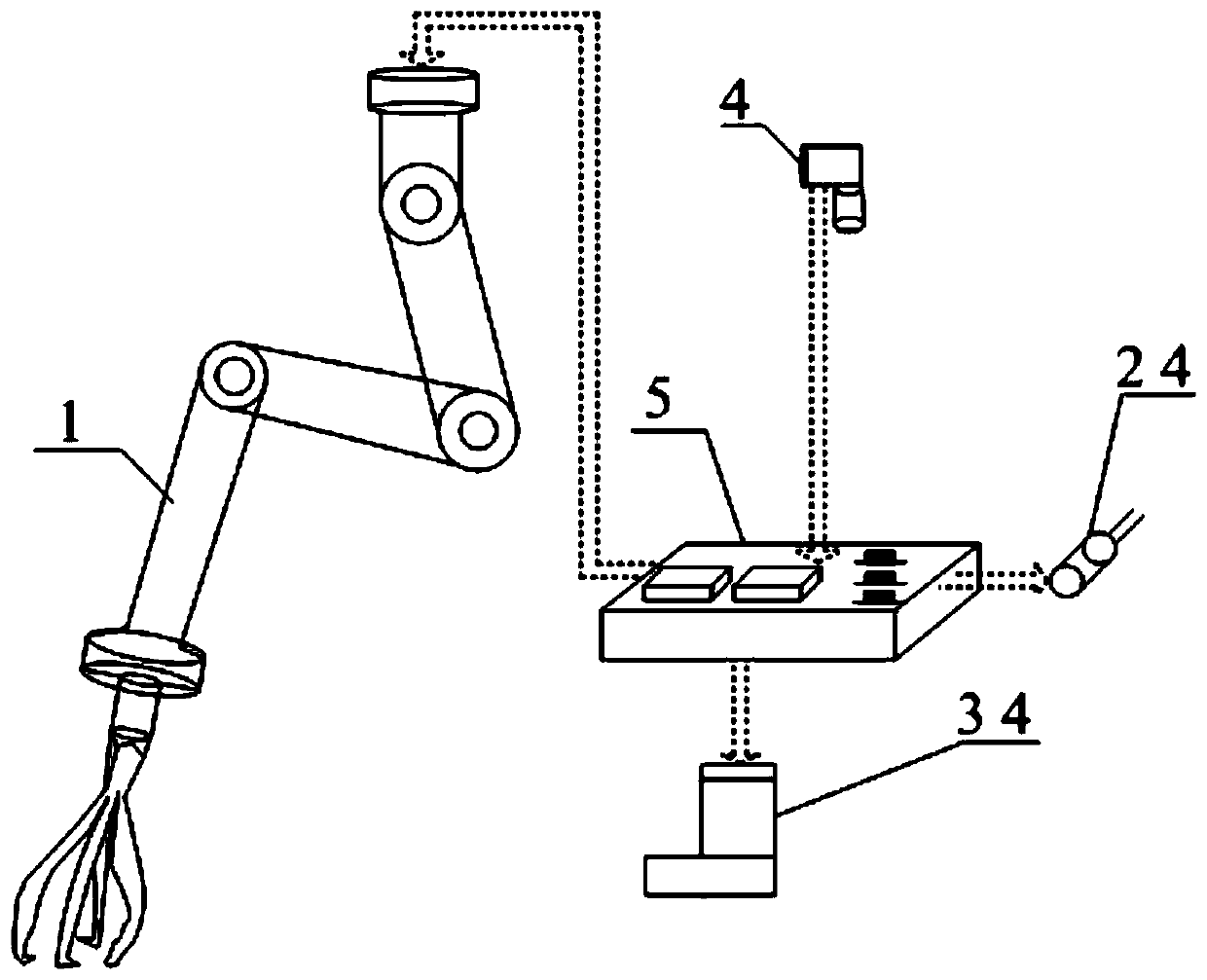

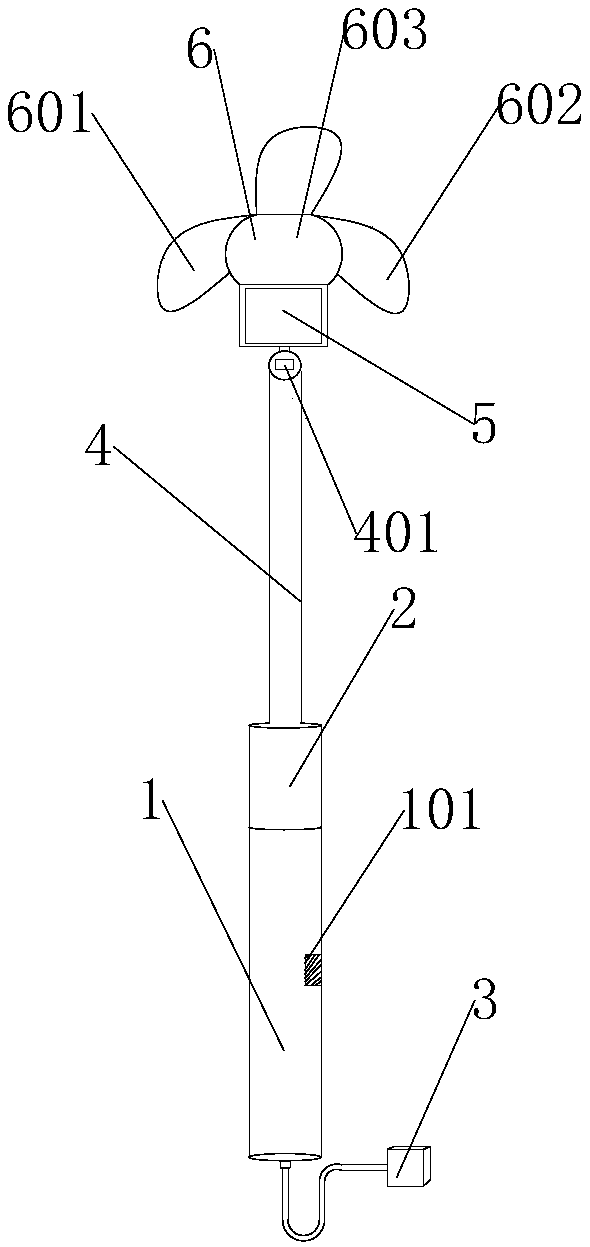

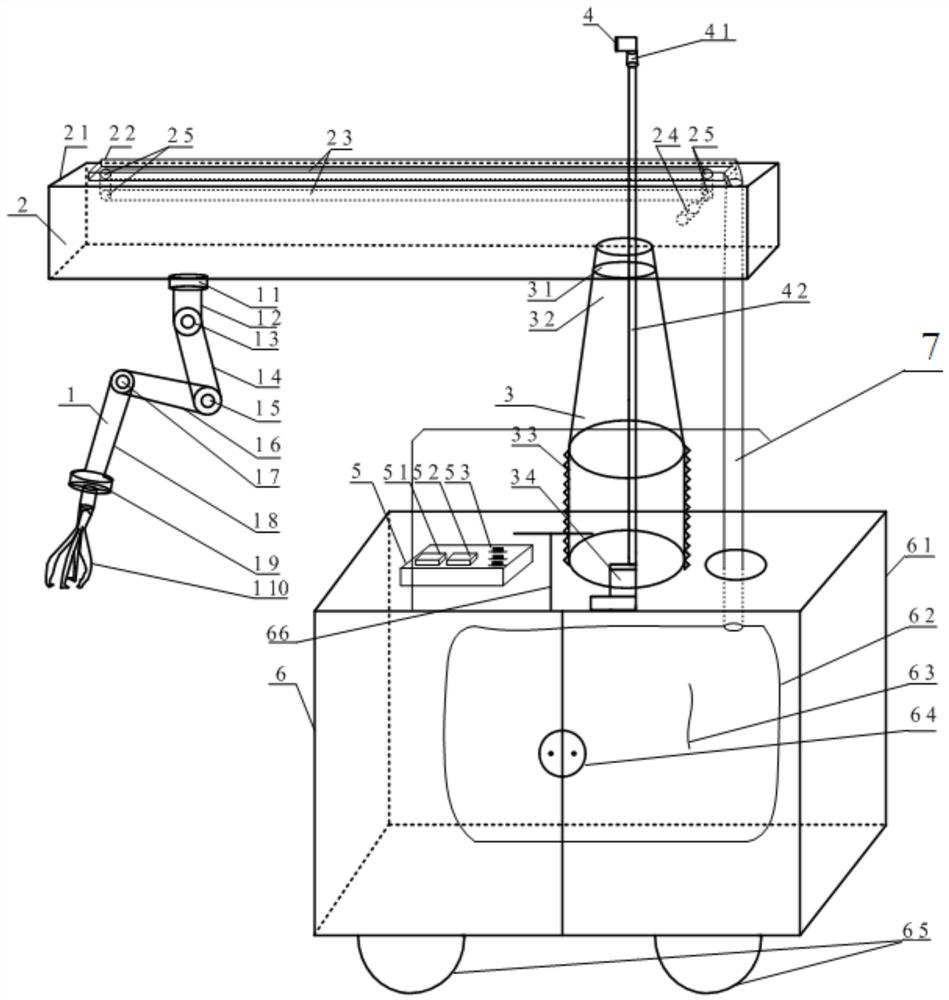

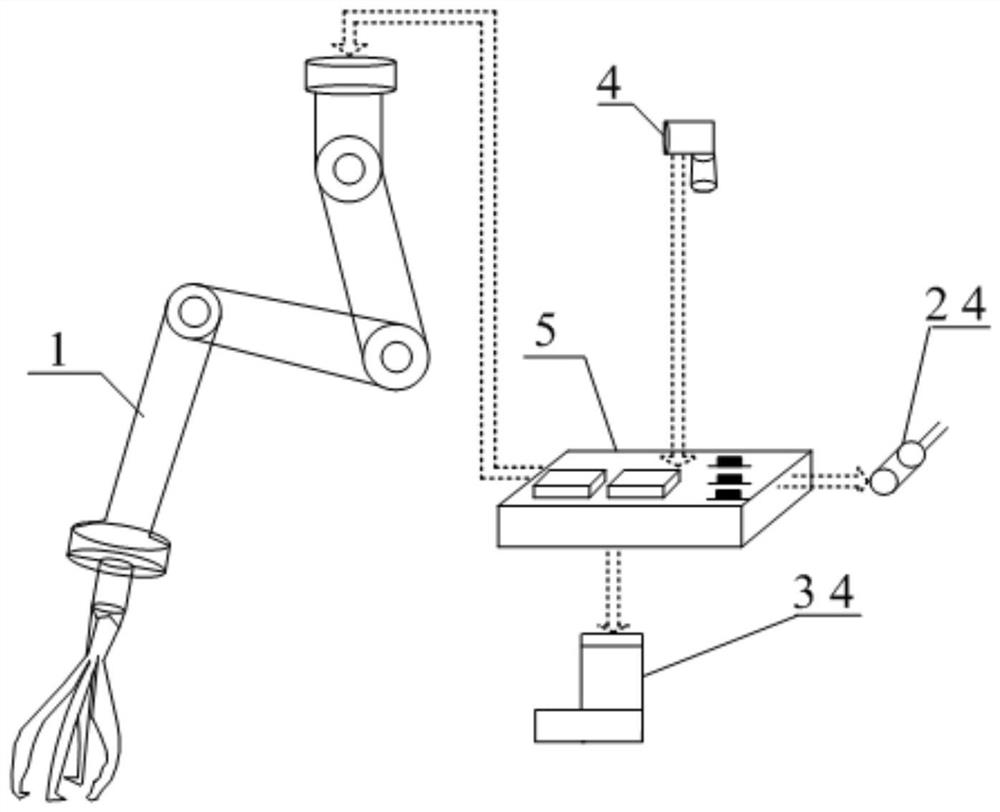

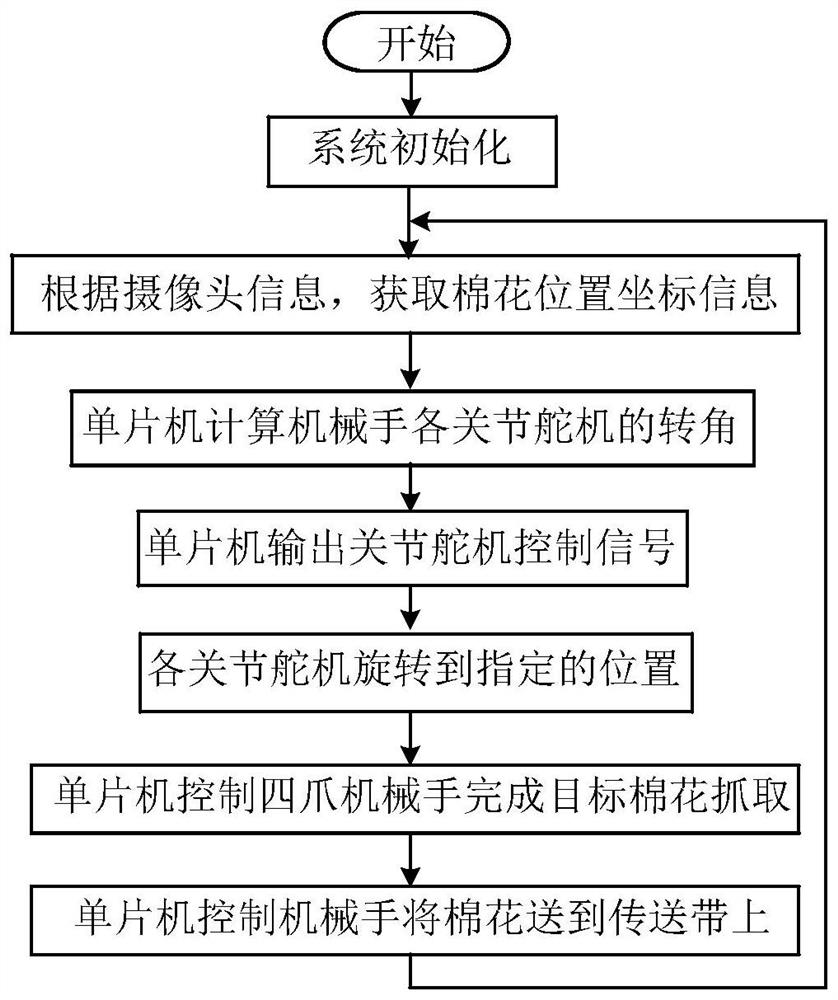

Intelligent cotton picker and control method thereof

The invention discloses an intelligent cotton picker and a control method thereof. The intelligent cotton picker comprises a cotton picking manipulator, a tower arm, a tower pole, a camera shooting component and a cotton receiving component; the tower pole is installed on the top of the cotton receiving component, the tower arm is installed on the top of the tower pole, the cotton picking manipulator is installed at the bottom of the other end of the tower arm, the camera shooting component penetrates through the tower arm to be fixed to the tower pole, a single-chip microcomputer control component is arranged at one end of the top of the cotton receiving component, and a cotton sampling hose is arranged at the other end of the top of the cotton receiving component. The invention further discloses the intelligent cotton picker control method. The whole system is simple in structure and easy to control, the joint number and arm length of the cotton picking manipulator are reduced, the control difficulty is reduced, the complexity of a control program is lowered, the cotton picking speed is increased, and the cotton picking efficiency is improved.

Owner:YANCHENG ZHENGBANG ENVIRONMENTAL PROTECTION TECH +1

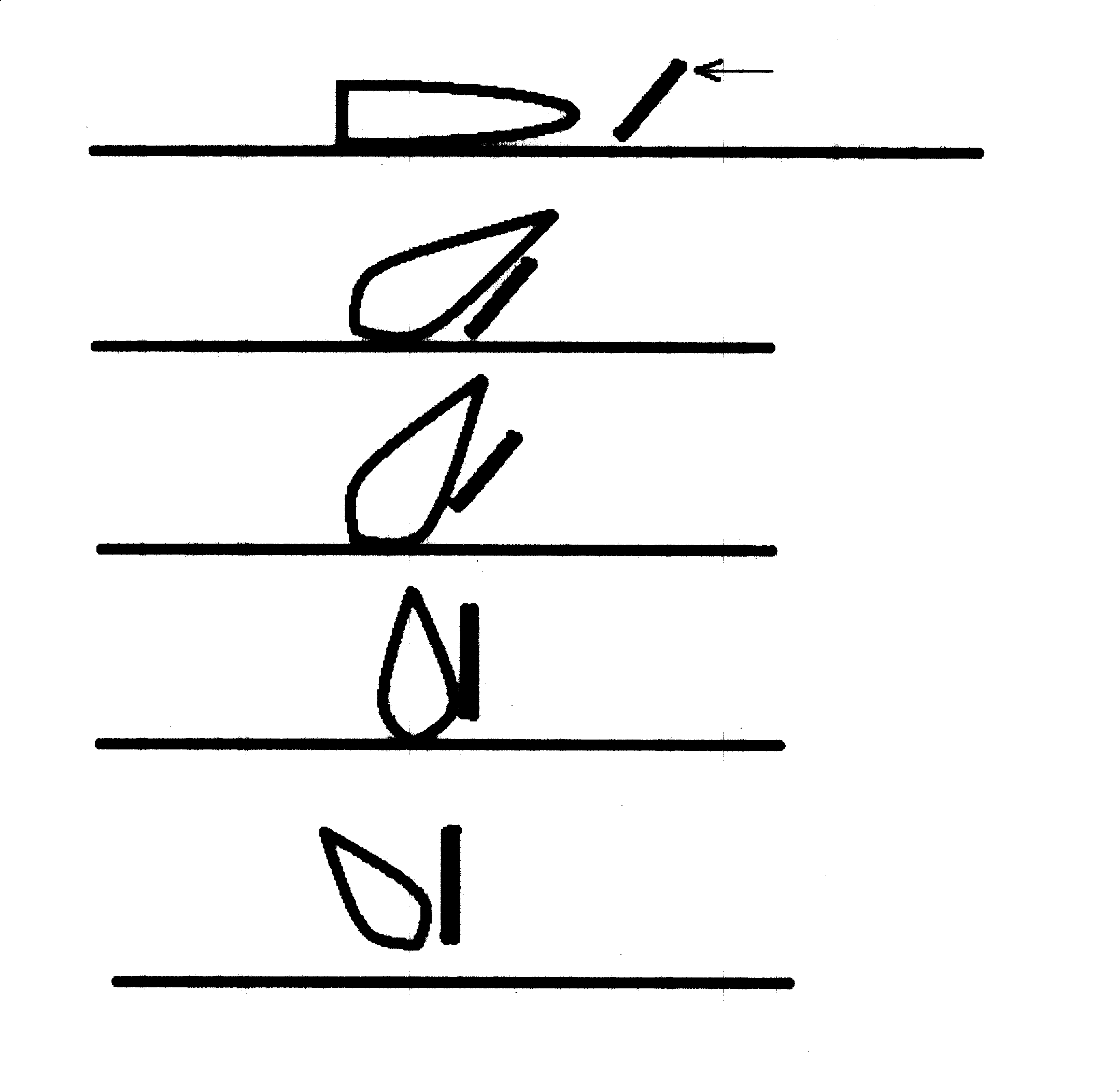

Corn retrograde motion ear-picking principle and device

The invention relates to a maize picker principle and a device arranged on a cropper, and is an agricultural machine. Compared with the current stripping by means of squeezing and rubbing forcibly with a principle of roll rotating and rubbing, the invention is characterized in that when the tip part of a maize plant turns towards a stripper intercept rod and operates reversely from the rod, the corn ear can be toggled from the tip downwardly and steered by the stripper intercept rod, leading the ear to be separated from the plant in the natural direction. The invention has the advantages that the ear can not be impacted and any position of the ear can not be rubbed to cause an injury in the picking process; the picking efficiency can be greatly improved; the energy consumption is lowered in a large scale.

Owner:于政道

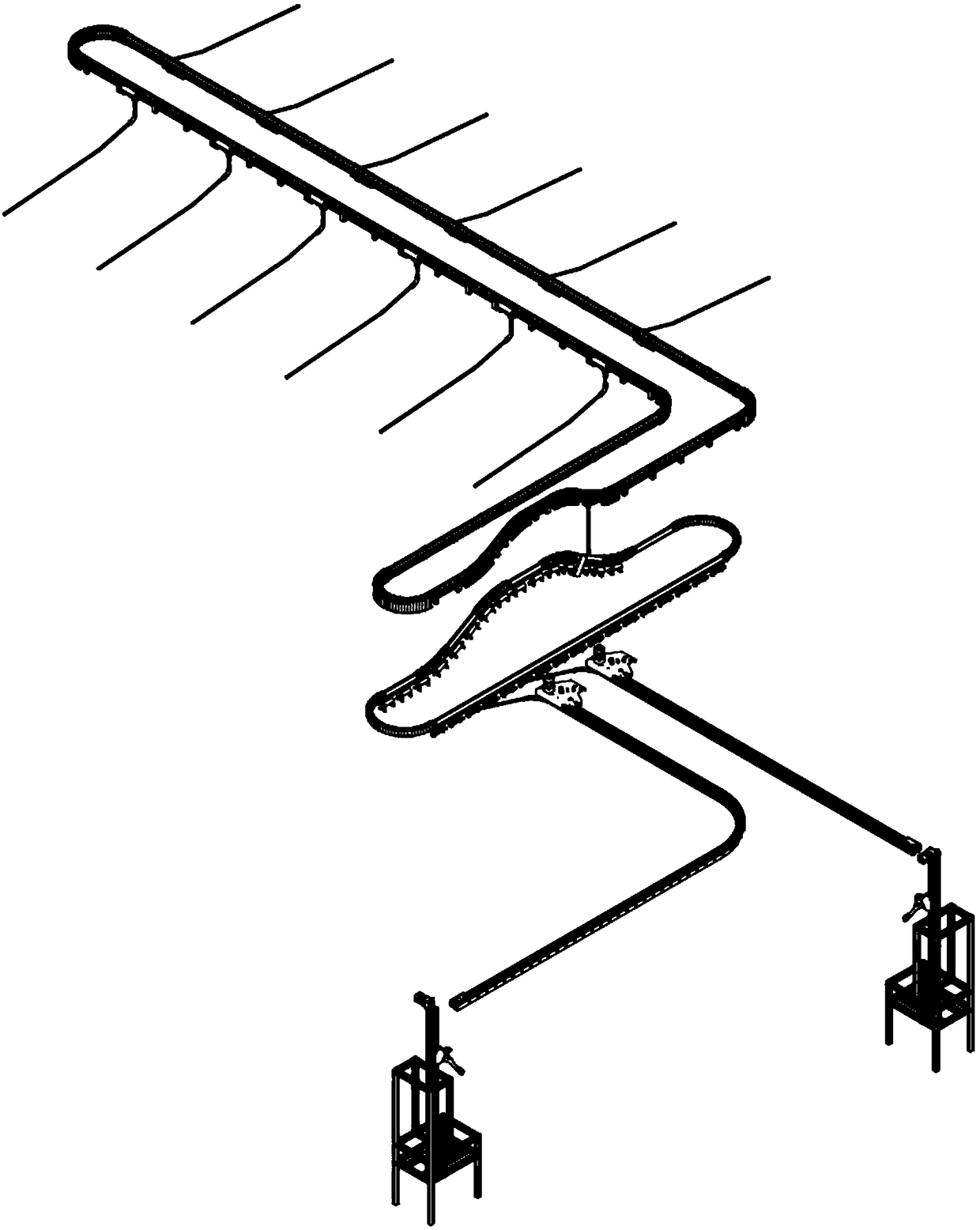

Sorting system and sorting method

PendingCN108993905AReduce labor intensityImprove picking speedSortingSystem controllerIndustrial engineering

The invention provides a sorting system and a sorting method, and belongs to the technical field of transportation. The system comprises at least one transport line, wherein the inlet of the transportline is provided with a hoist. The system also comprises a cargo collecting line, a sorting line and a system controller, wherein the outlet of the transport line can be communicated with or separated from the cargo collecting line; the outlet of the cargo collecting line is provided with a connecting rail; the outlet of the connecting rail can be communicated with or separated from the sorting line; the sorting line is a closed circulation transport line and is provided with a corresponding sorting position for sorting cargoes; and the system controller controls the actions of the hoist, thetransport line, the cargo collecting line and the sorting line. According to the sorting system provided by the invention, the hoist, the transport line, the cargo collecting line and the sorting line are integrated, so that sorters can complete respective order picking work in different regions, and the cargoes are centralized to a branch line sorting position by the sorting system provided by the invention, so that the picking speed is improved, and the labor intensity of employees is reduced.

Owner:ZHEJIANG RESISTING INTELLIGENT TECH CO LTD +1

Strawberry picking apparatus

The invention discloses strawberry picking apparatus. The apparatus comprises a rod body and a height adjuster; and the lower part of the rod body is connected with a direct current electrical machine, a power source button is installed above the direct current electrical machine, the upper part of the power source button is connected with the height adjuster, the top of the height adjuster is connected with a telescopic rod, the top end of the telescopic rod is fixedly connected with a fixing member, a fruit receiving box is installed on the fixing member, the top of the fruit receiving box is connected with a shearing device, a rotating disc is fixed in the middle of the shearing device, the right side of the rotating disc is connected with a second shearing component, and a first shearing component is installed at the left side of the second shearing component. According to the invention, the strawberry picking apparatus is provided with two pulleys, the pulleys are arranged in parallel and distributed at symmetrical positions around the center of the rod body, the two pulleys are respectively connected with a first pulling member and a second pulling member, and when a currentreaches the pulleys, the pulleys rotate at a high speed, so that the picking speed is accelerated, and the working efficiency is improved.

Owner:镇江市丹徒区明兰瓜果种植家庭农场

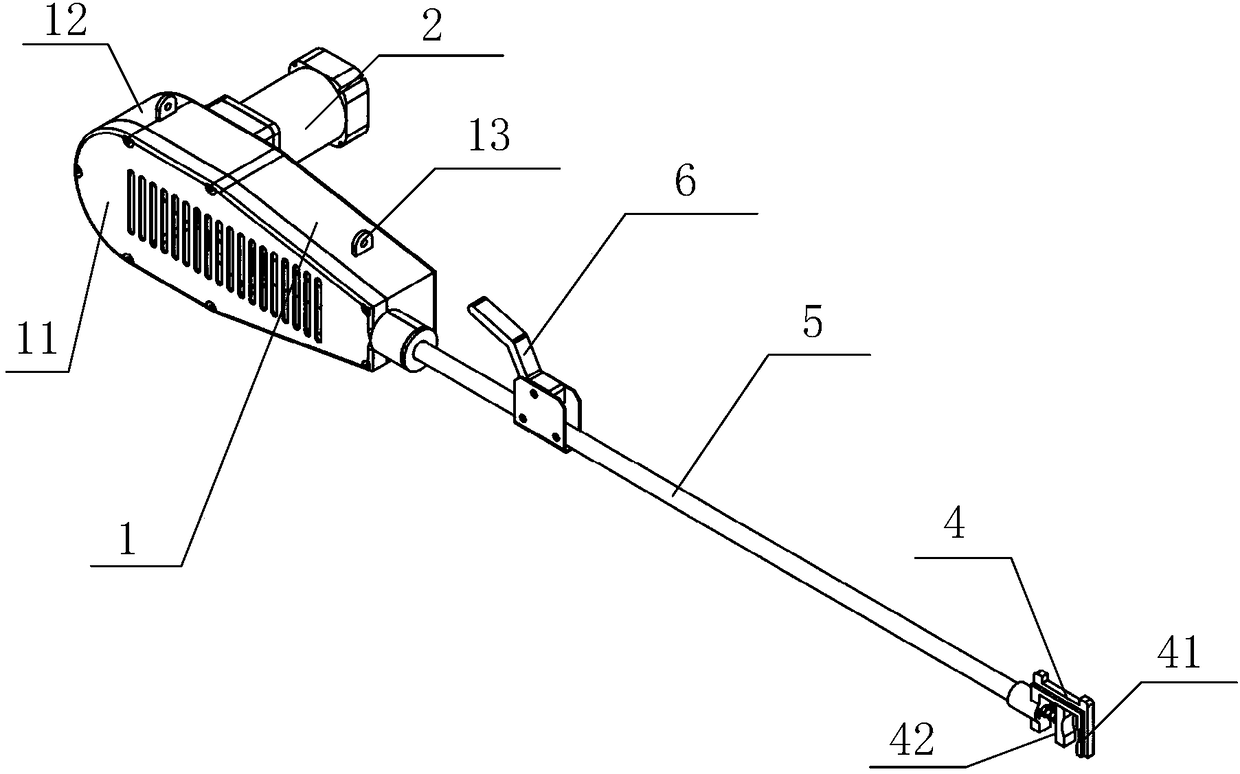

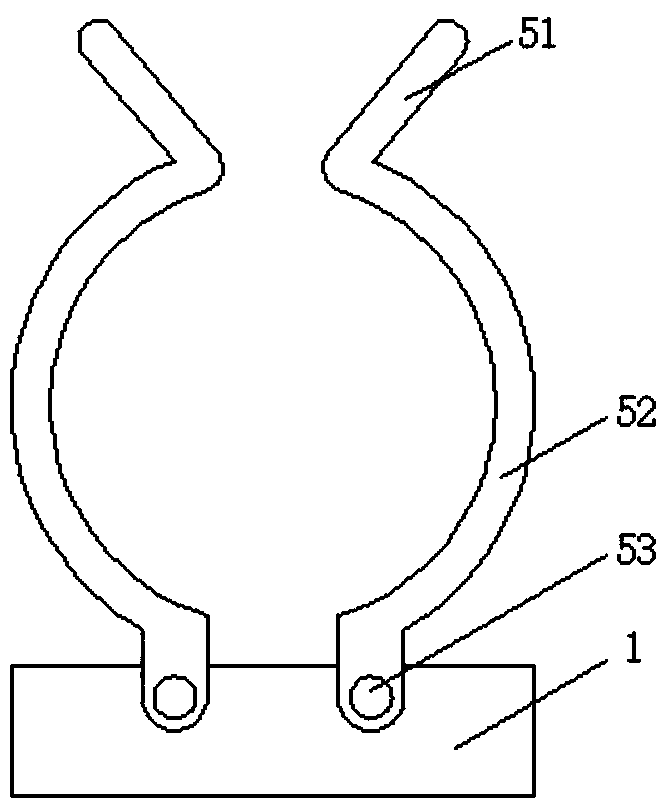

Intelligent variable-speed picking machine

The invention provides an intelligent variable-speed picking machine. The picking machine includes a shell, a power device, a transmission device and a clamping device, wherein the power device is fixed to the shell, and an output shaft of the power device is connected with the transmission device for inputting power to the transmission device; the transmission device is installed in the shell andconnected with the clamping device through a support rod to drive the clamping device to reciprocate in the axis direction of the support rod; the clamping device is used for being clamped on a trunk; the power device comprises an electric motor, a control module and a storage battery, wherein the storage battery is used for supplying electric power to the electric motor and the control module; the power device is installed in an outer casing of the power device, and the outer casing of the power device is mounted on the shell; the control module is connected to the electric motor and used for automatically adjusting the rotating speed of the electric motor. The intelligent variable-speed picking machine is small in size, light in weight, compact in structure, great in force performance and convenient to move and can be operated by one person.

Owner:常州有恒智能装备科技有限公司

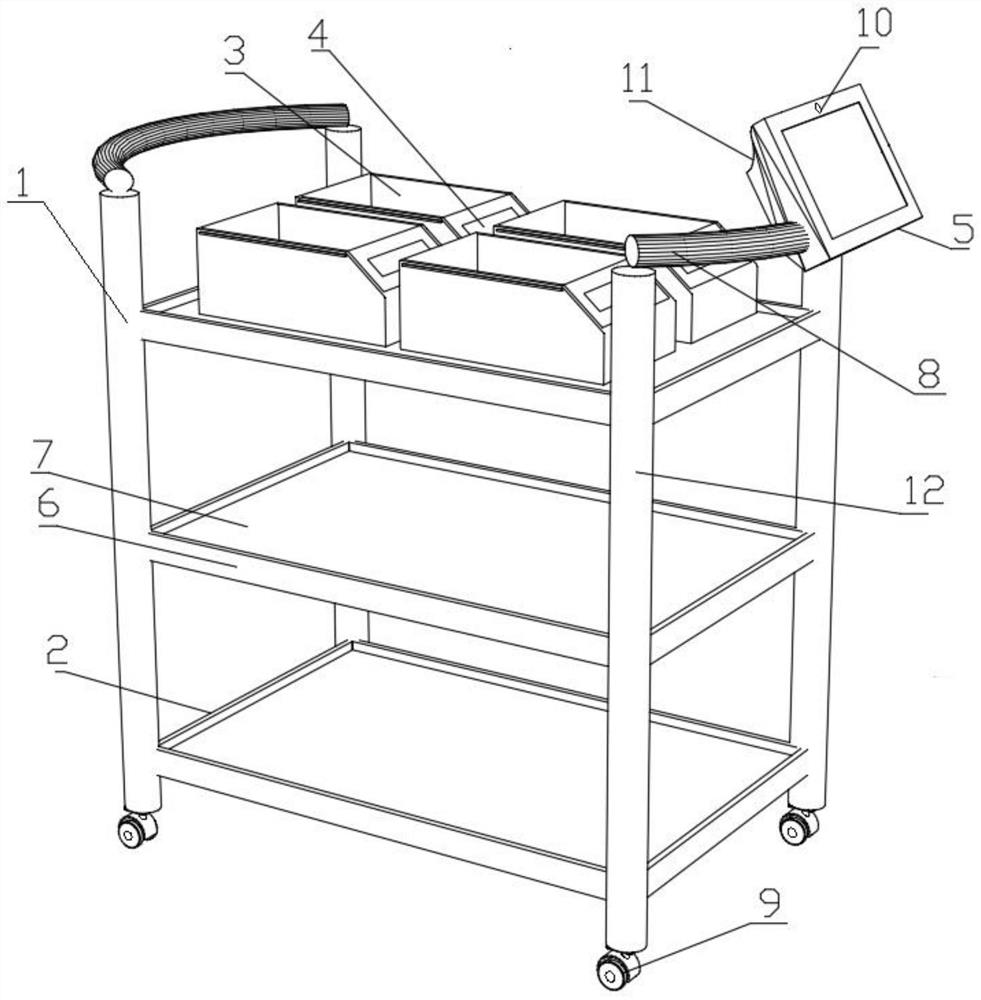

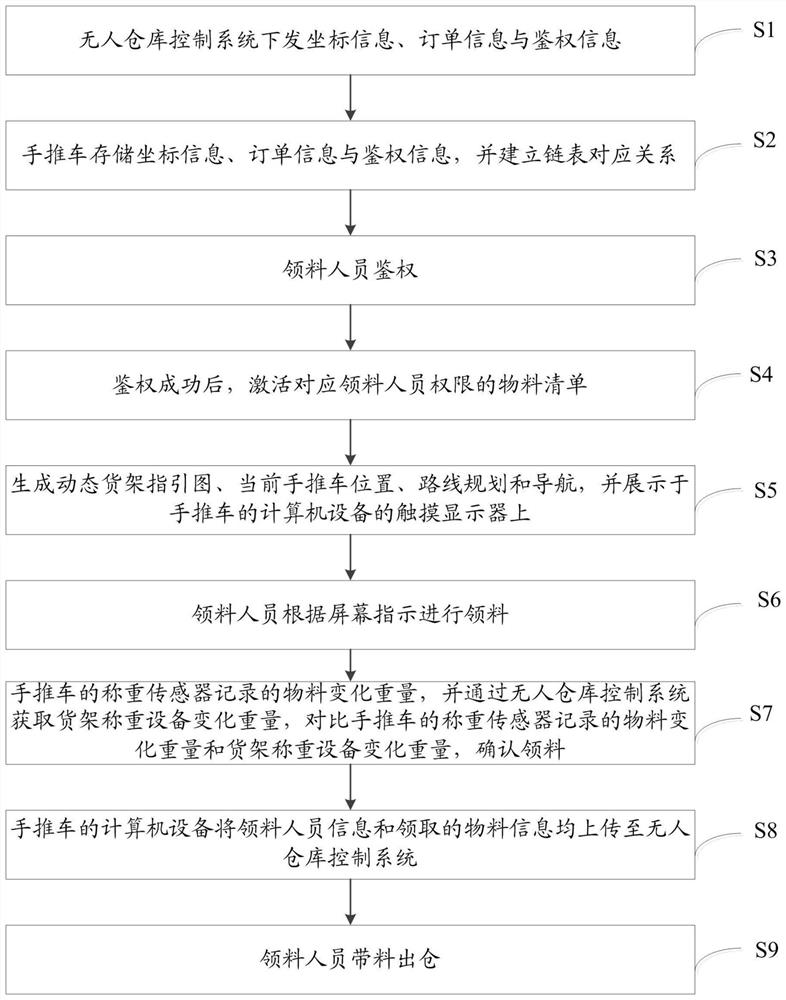

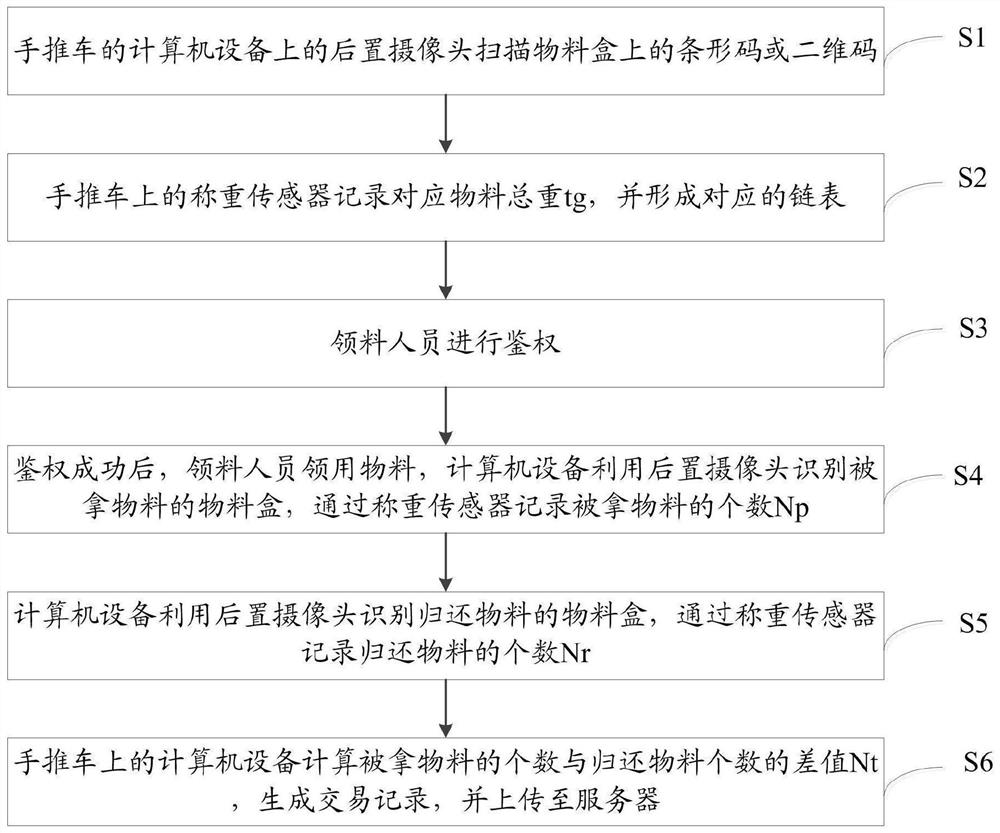

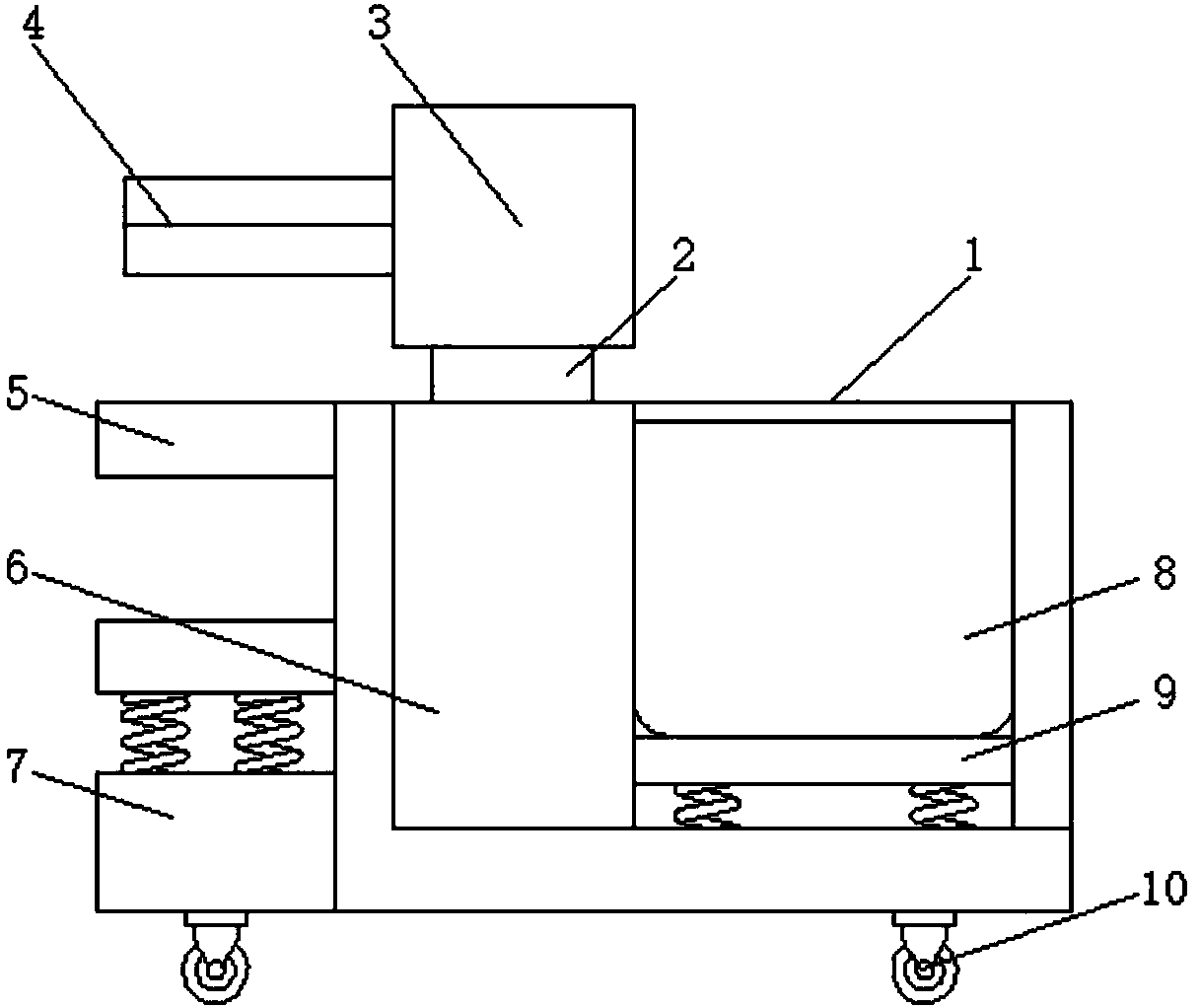

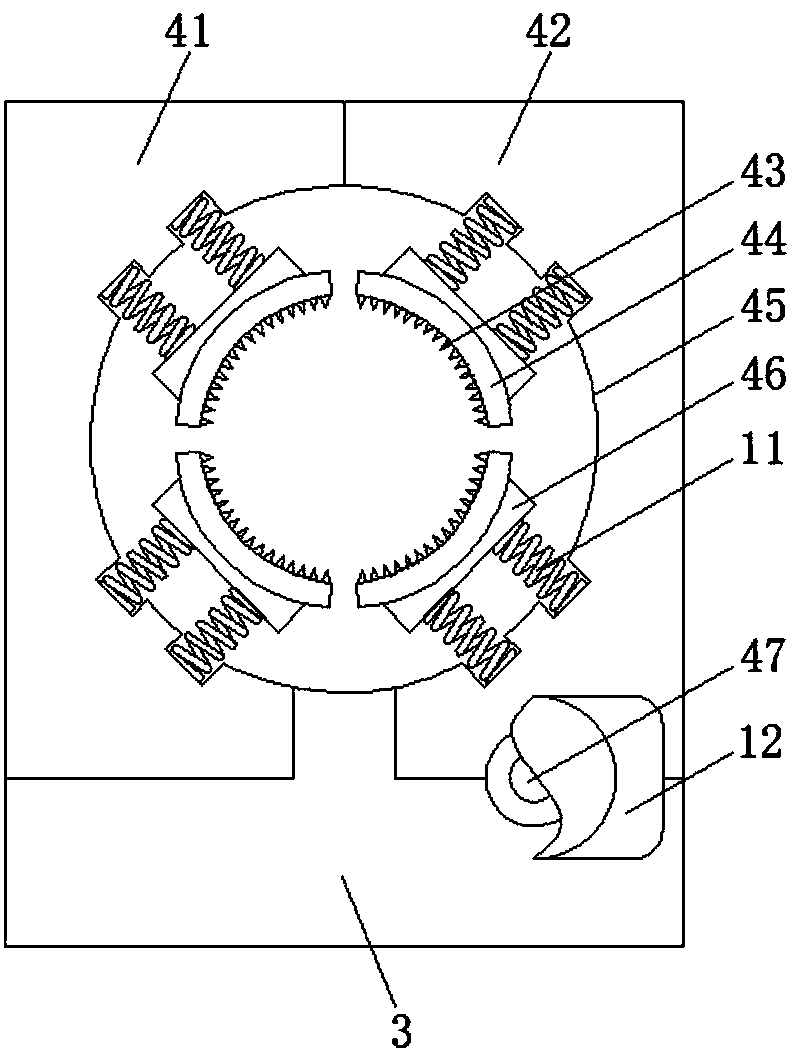

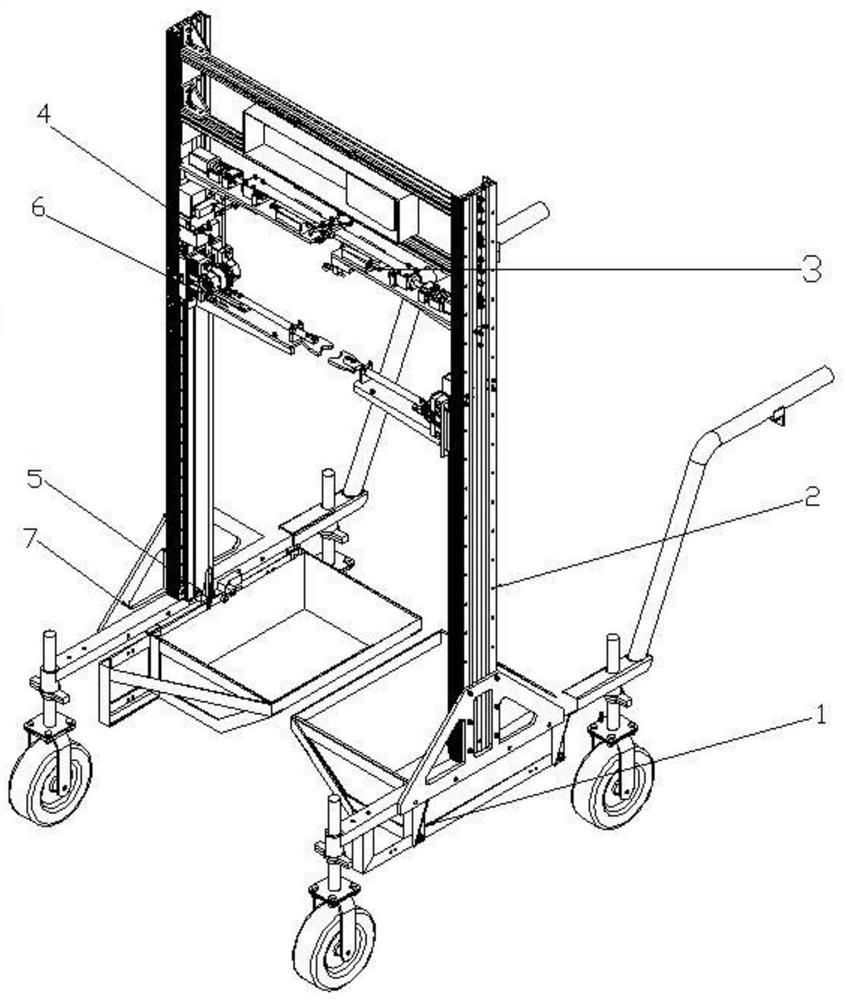

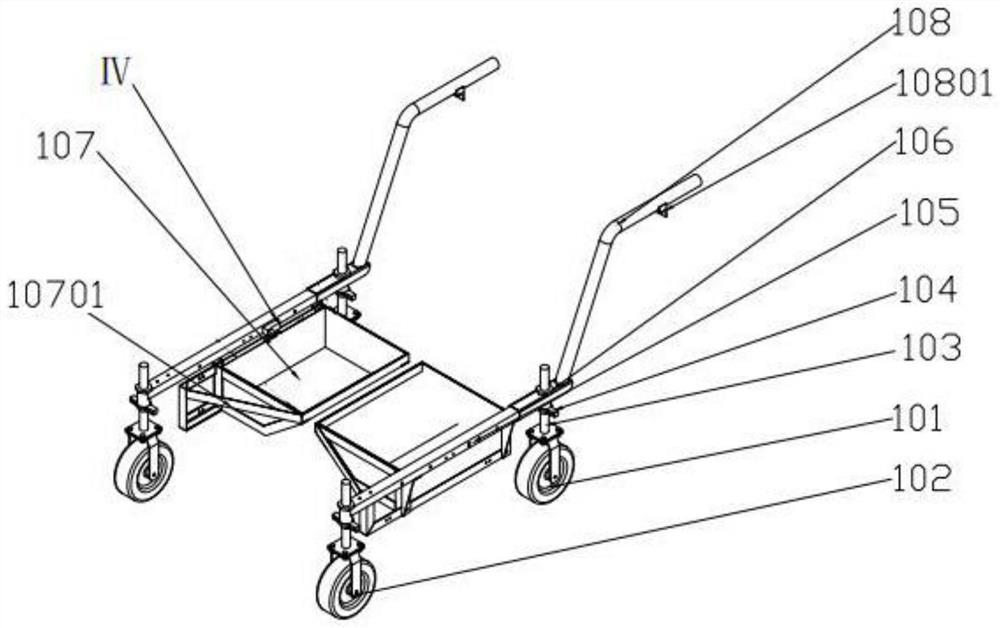

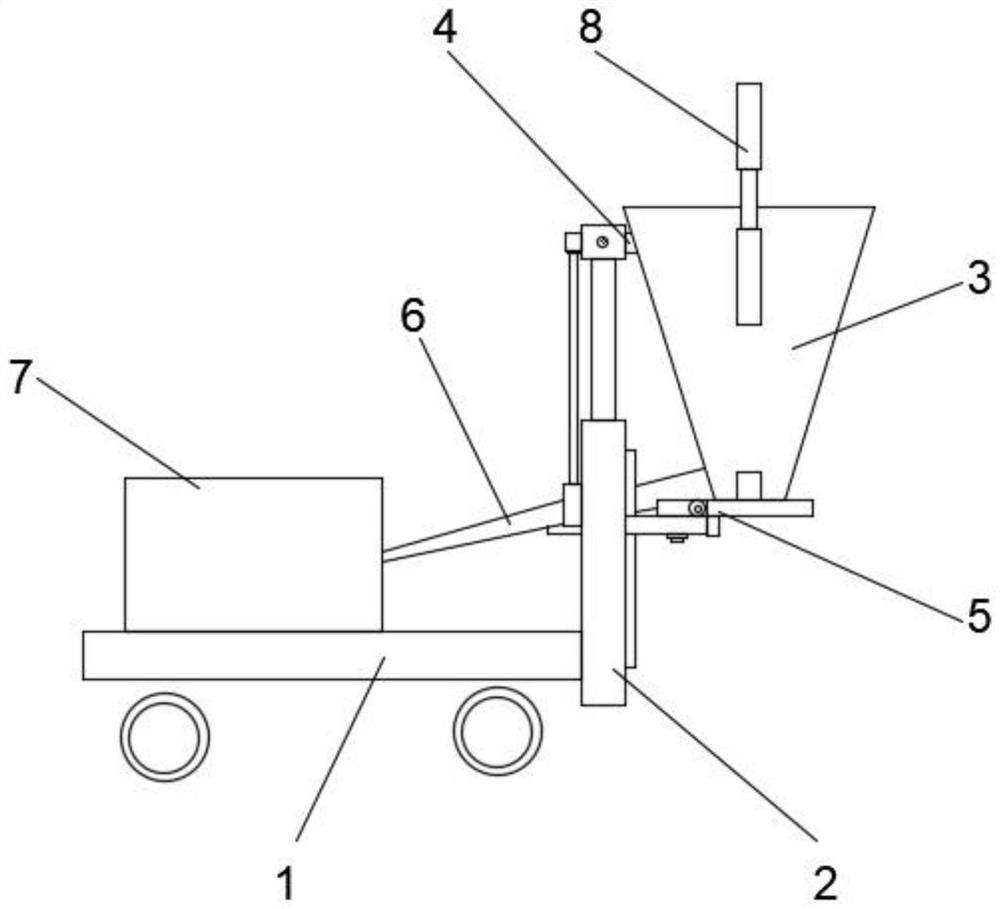

Trolley and method for applying trolley to unmanned warehouse and line-side material receiving

ActiveCN112092876AIncrease picking speedUnderstand the work statusForecastingLogisticsDisplay devicePortable power

The invention relates to a trolley and a method for applying the trolley to an unmanned warehouse and line-side material receiving. The intelligent trolley comprises a trolley body, the trolley body is provided with one or more layers of bearing plates, steady sensors are arranged in the bearing plates, computer equipment is fixed to the top of the trolley body, and a portable power source is fixed to the trolley body; the portable power source is connected with the computer equipment, the steady sensors are connected with the computer equipment, and a front camera, a rear camera, a touch display, an acceleration sensor, a card swiping module, a loudspeaker and a wireless module are arranged on the computer equipment; and the front camera is used for collecting face information, and the rear camera is used for collecting information of materials on the bearing plates. The difficulties of warehouse keeper canceling, accurate settlement, simultaneous material receiving by multiple persons and the like are overcome, the management cost is reduced, the production efficiency is improved, and the trolley has good market application value.

Owner:深圳市坤同智能仓储科技有限公司

Planting and picking apparatus for edible mushroom Flammulina velutipes

ActiveCN108377857AIncrease picking speedEasy to fixWeighing apparatus for materials with special property/formCultivating equipmentsEdible mushroomEngineering

The invention discloses a planting and picking apparatus for edible mushroom Flammulina velutipes, comprising a main box; a support pillar is mounted in the main box; a rotating seat is mounted at thetop end of the support pillar, the top end of the rotating block is connected with a rotating block through a bearing, a picker is mounted on one side of the rotating block and comprises a first picking plate and a second picking plate, a fixing device is mounted at the top end of one side of the main box and includes a fixing plate, a holding seat is mounted at the bottom end of one side of themain box and includes a bottom plate, the surface of the bottom plate is provided with spring channels, a pressure sensor is mounted in each spring channel, a spring is mounted on each pressure sensor, a top plate is mounted at the top ends of the springs, the surface of the top plate is provided with a holding cavity, and universal wheels are mounted at the bottom of the holding seat and the mainbox. The planting and picking apparatus for the edible mushroom Flammulina velutipes allows a Flammulina velutipes culture bag to be fixed conveniently and is more convenient to use.

Owner:滁州市百年食品股份有限公司

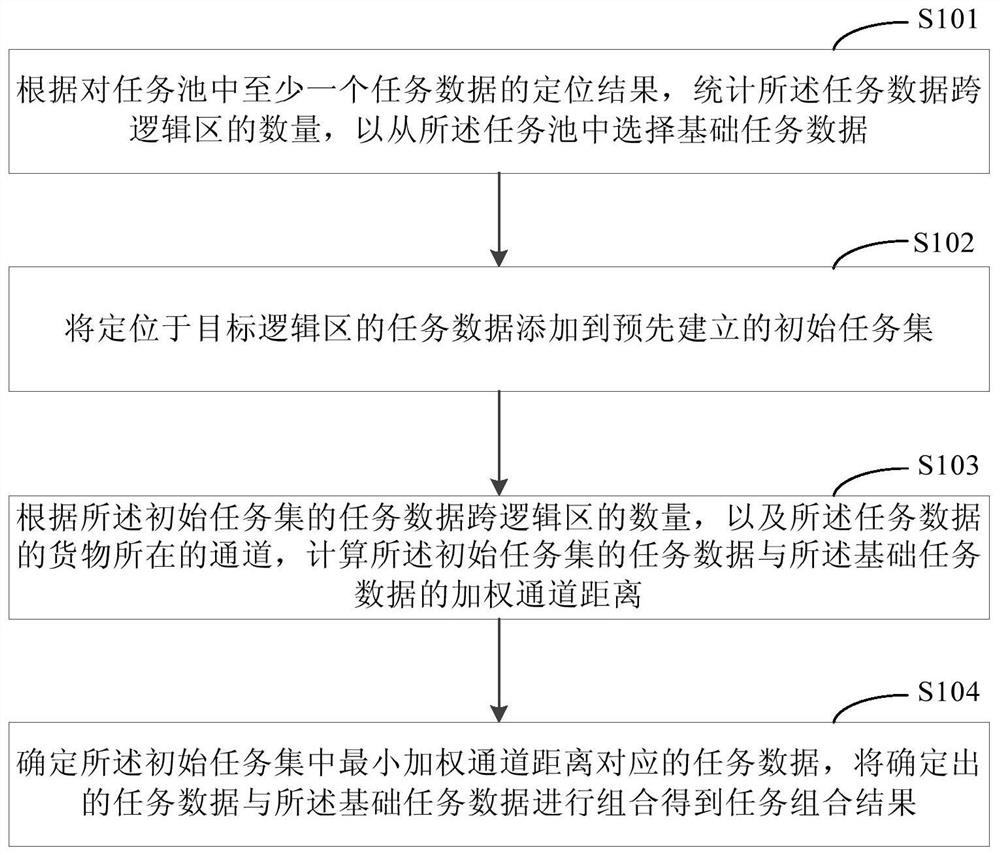

Task combination method and device

PendingCN111754059AIncrease picking speedReduce the difficulty of pickingResourcesLogisticsLogistics managementAlgorithm

The invention discloses a task combination method and device, and relates to the technical field of logistics storage. A specific embodiment of the method comprises the steps of counting the number oftask data cross-logic regions to select basic task data from a task pool; adding the task data positioned in the target logic area into a pre-established initial task set; calculating a weighted channel distance between the task data of the initial task set and the basic task data according to the number of the task data cross-logic regions of the initial task set and the channel where the goodsof the task data are located; and determining task data corresponding to the minimum weighted channel distance in the initial task set, and combining the determined task data with the basic task datato obtain a task combination result. According to the method, the distance between the task data is calculated in combination with the number of the task data cross-logic regions and the distance between the channels where the goods of the task data are located, and then the task data are combined according to the distance, so that the picking difficulty is reduced, and the subsequent confluence pressure can be reduced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

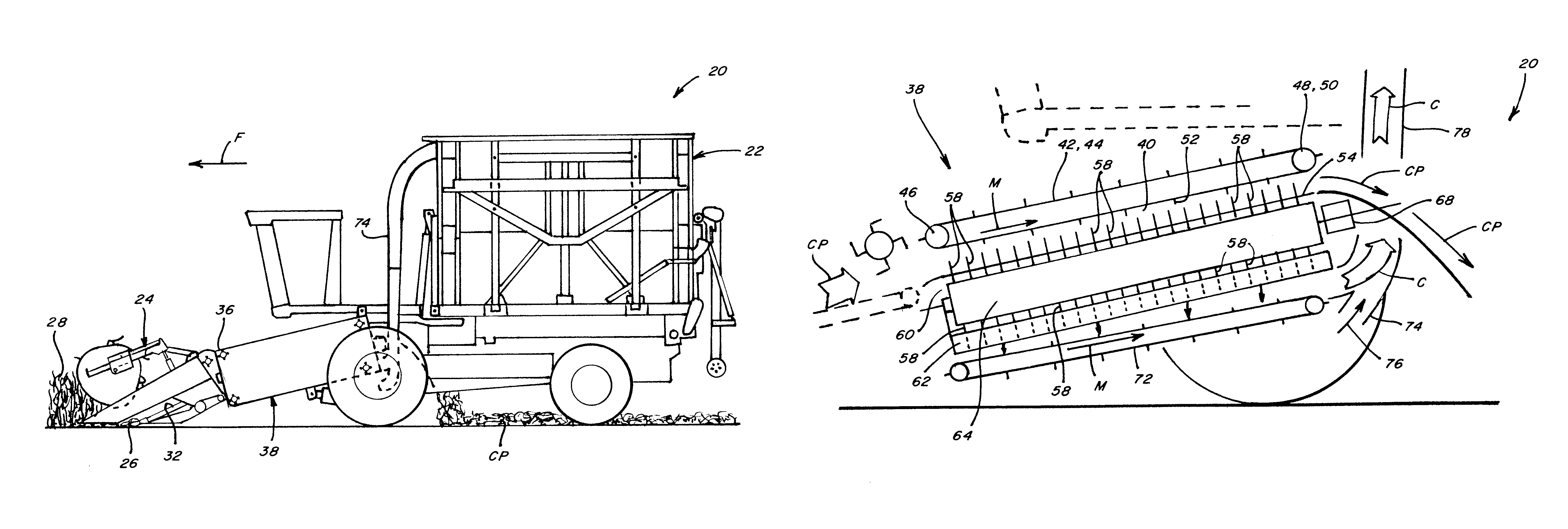

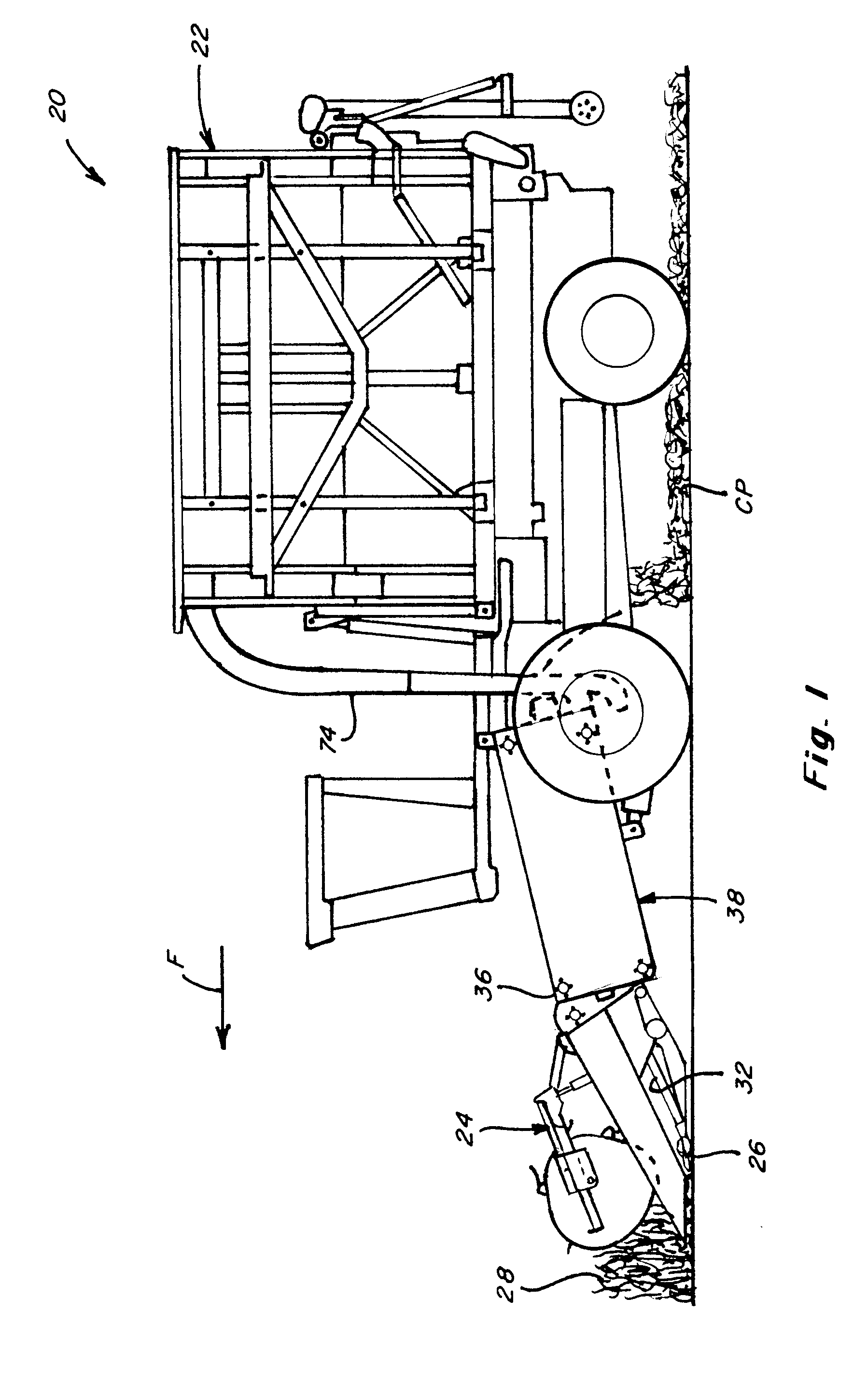

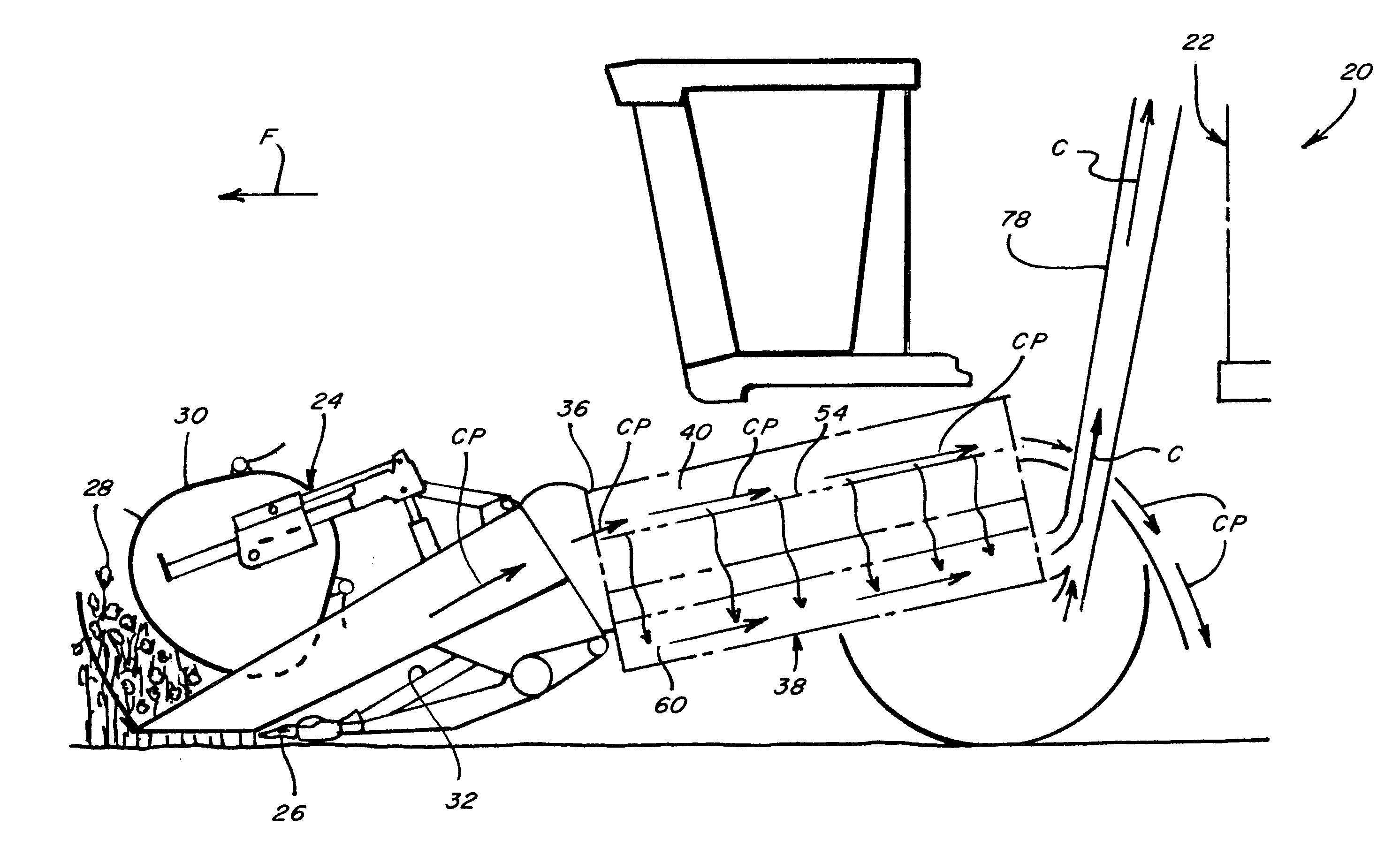

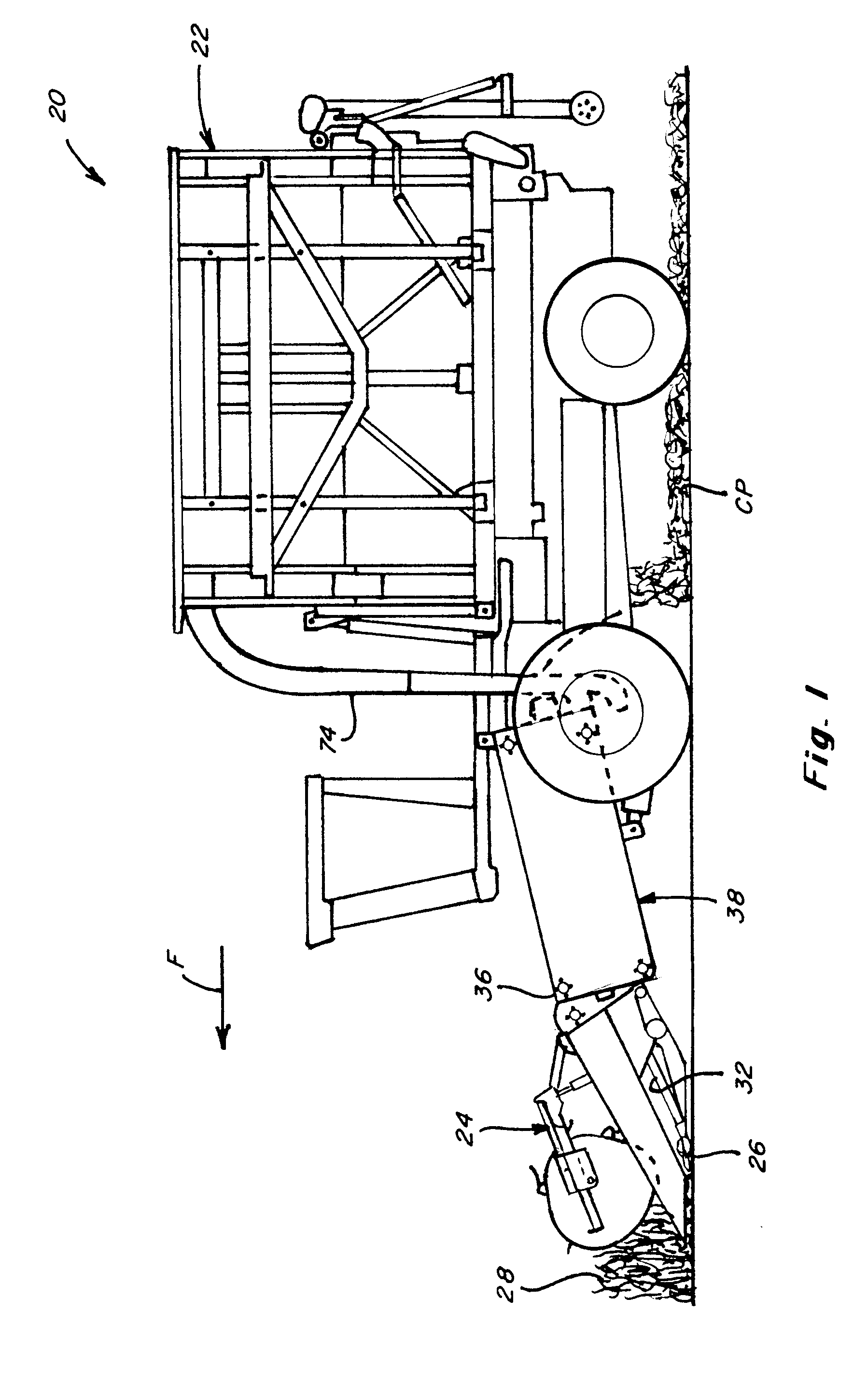

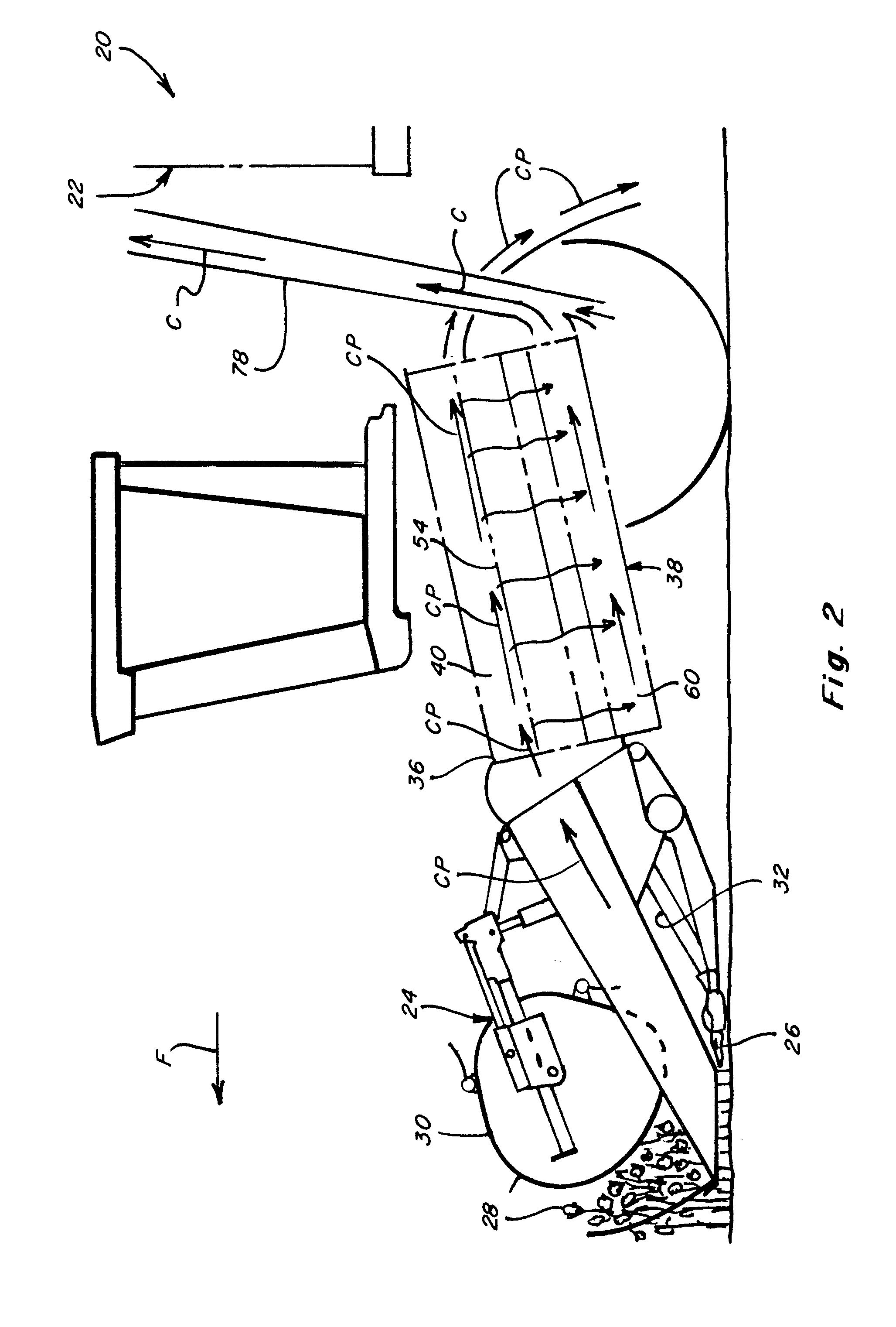

Cotton harvester

A cotton harvester includes plant cutting apparatus to sever cotton plants from a ground surface, plant conveyor apparatus to convey the severed plants into and through a picking chamber, and cotton picking apparatus including picker spindles that move upwardly into the picking chamber through a floor of the chamber to pick cotton filaments from bolls of the plants conveyed as a flattened mat therethrough and carry the cotton downwardly through the floor to doffers that remove the cotton from the spindles. Cotton conveyor apparatus also below the floor conveys the cotton to a receiver, while the plant residue passes from the chamber.

Owner:BLUE LEAF I P INC

Automatic vegetable picking device

InactiveCN107980354AIncrease picking speedIncrease labor intensityPicking devicesGreenhouseEngineering

The invention relates to the field of cultivation equipment, in particular to an automatic vegetable picking device which comprises a movable base. The movable seat is provided with a driving device,a seat, a frame and a picking and conveying mechanism, the seat is used for riding, the frame is used for placing vegetables, the driving device drives the movable base to move in a soilless culture greenhouse, the picking and conveying mechanism comprises a connecting seat, a first conveying belt, a second conveying belt and a shearing mechanism, the shearing mechanism is arranged at a feeding end of the second conveying belt, a discharging end of the second conveying belt is connected to the first conveying belt, the conveying belt is connected with the connecting seat, the connecting seat is mounted on the movable base, and the vegetables are sheared by the shearing mechanism and falls into the second conveying belt. Compared with the prior art, the automatic vegetable picking device can relieve labor intensity of the workers, and picking of the vegetables is accelerated.

Owner:佛山市田森温室科技有限公司

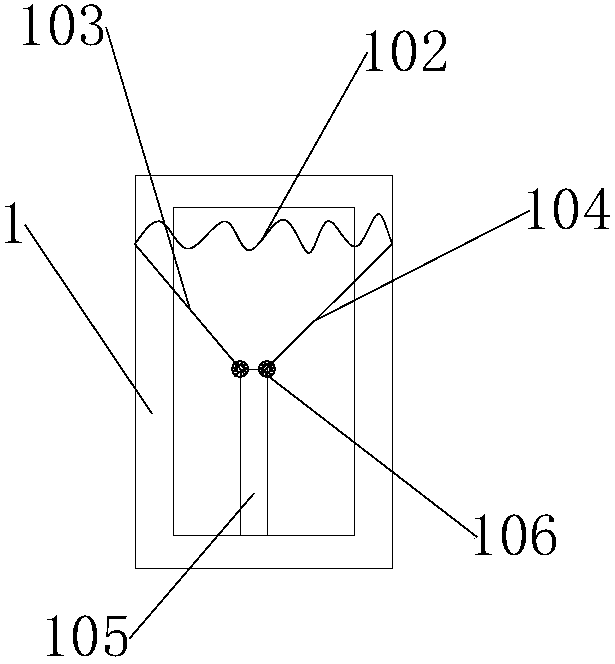

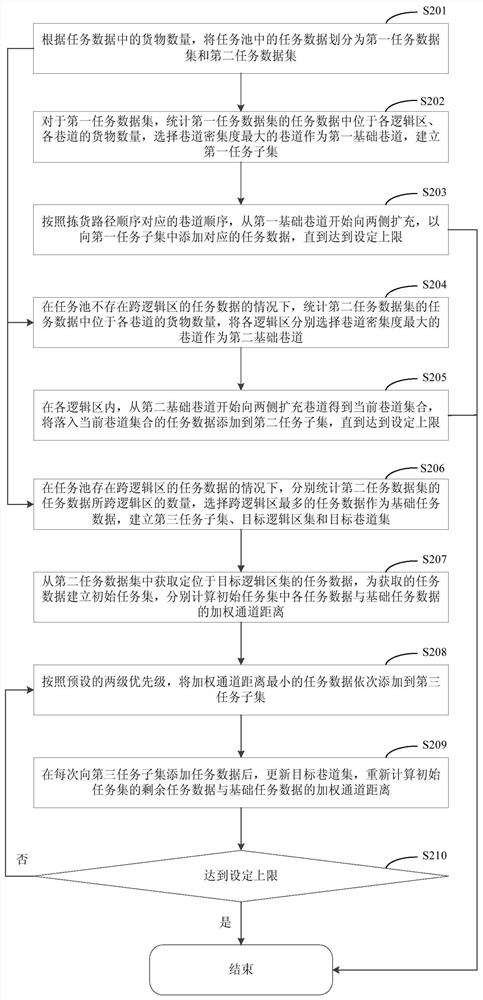

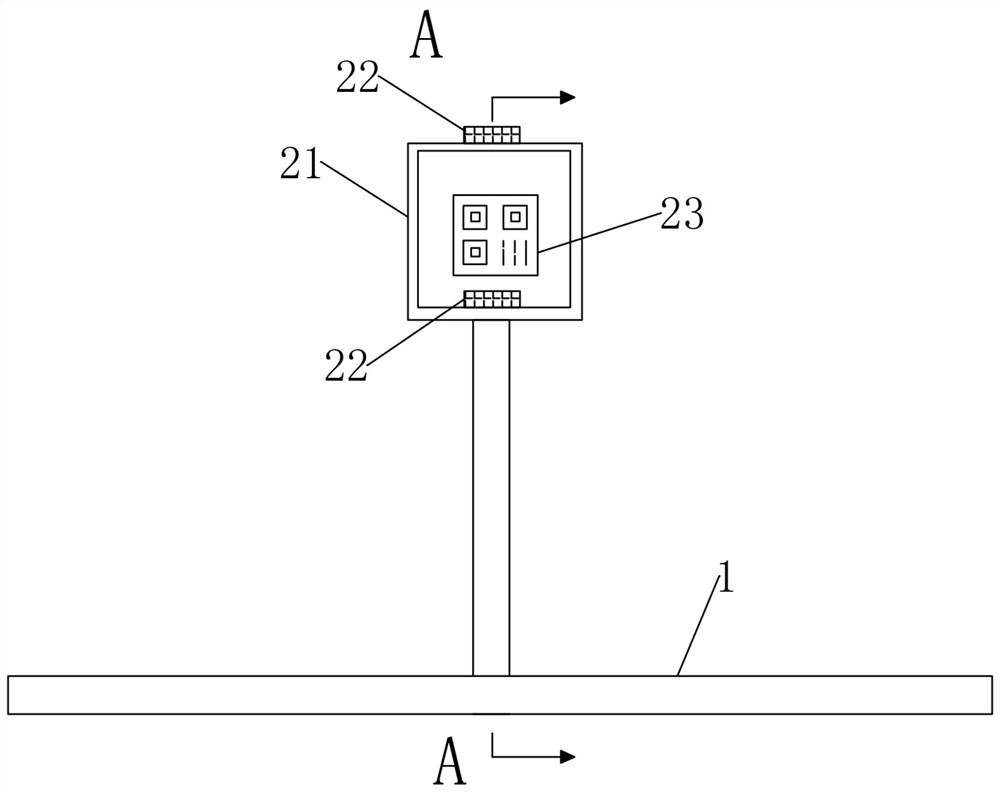

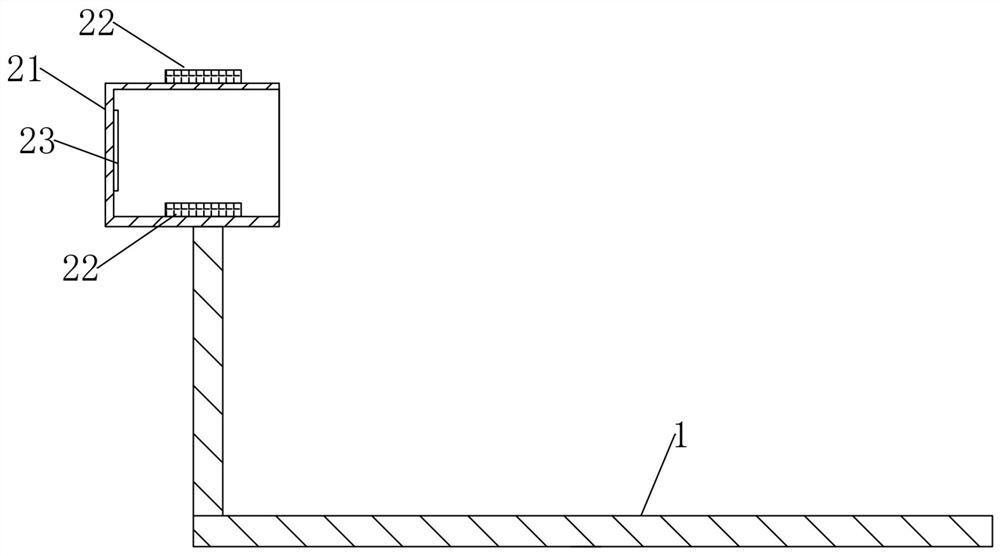

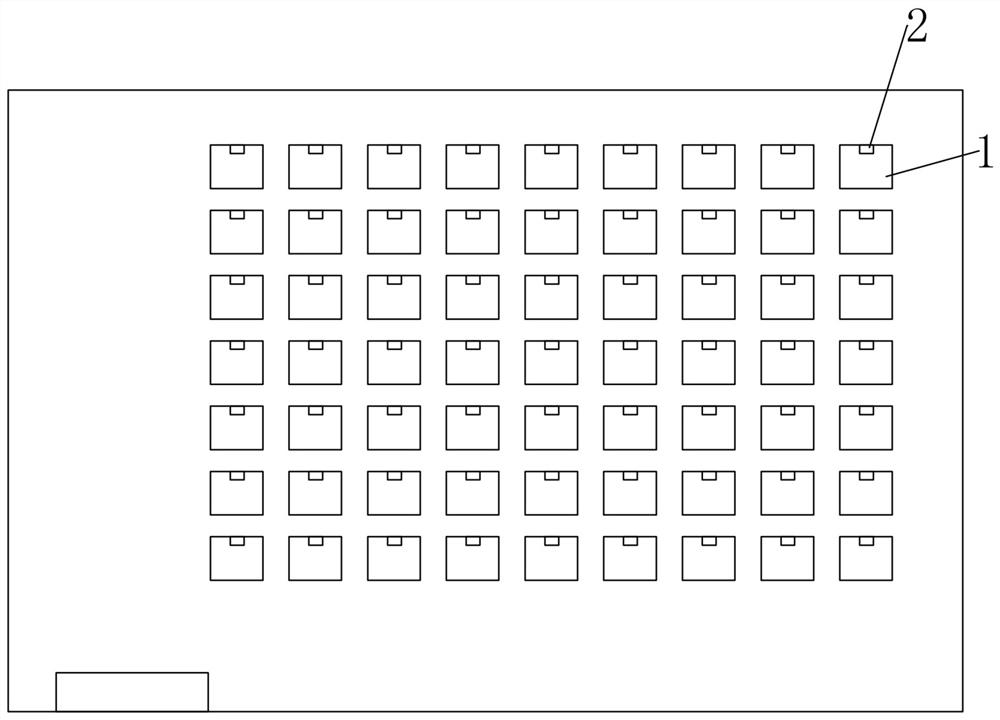

Low-cost intelligent shipping space positioning system based on a warehouse

PendingCN113962345AImprove overall utilizationReduce wrong entryCo-operative working arrangementsResourcesLighting systemStorage garage

A low-cost intelligent shipping space positioning system based on a warehouse comprises a controller, a plurality of shipping spaces and goods with goods two-dimensional codes, and each shipping space is provided with an indicator lamp with a shipping space two-dimensional code; the indicating lamps indicate the corresponding storage spaces of the goods; the system further comprises a read-write device. The controller is used for carrying out information interaction with the read-write device, respectively carrying out storage and data processing on the warehouse information and the commodity information, and controlling the on / off of the indicating lamp through the controller. The warehouse two-dimensional code is visible when the indicating lamp is turned on and is invisible when the indicating lamp is turned off, and low-cost improvement is carried out on an existing warehouse lighting system through the execution methods of the system from the first to the third, so that the comprehensive utilization rate of automatic information is improved, and warehouse entry and exit visual guidance can be quickly and accurately provided.

Owner:广东龙眼数字科技有限公司

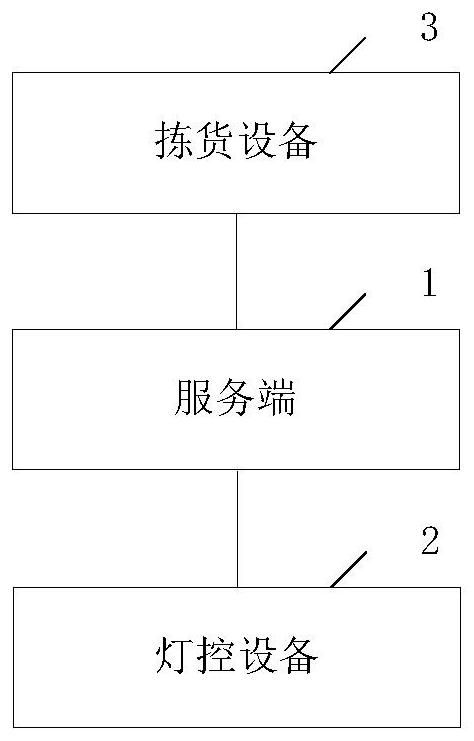

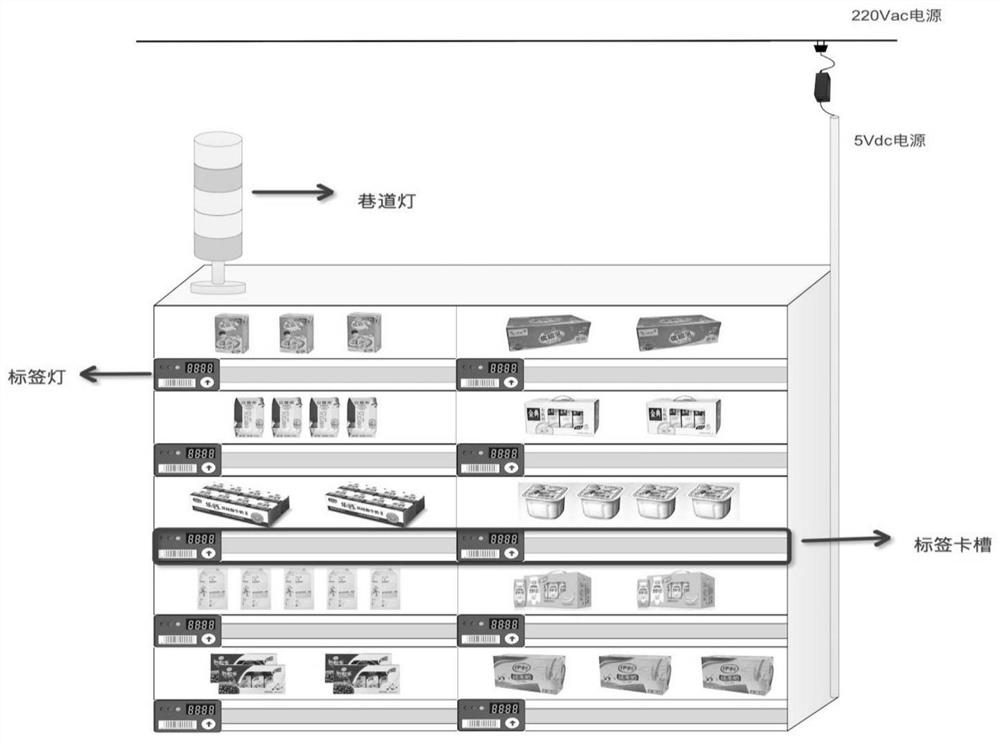

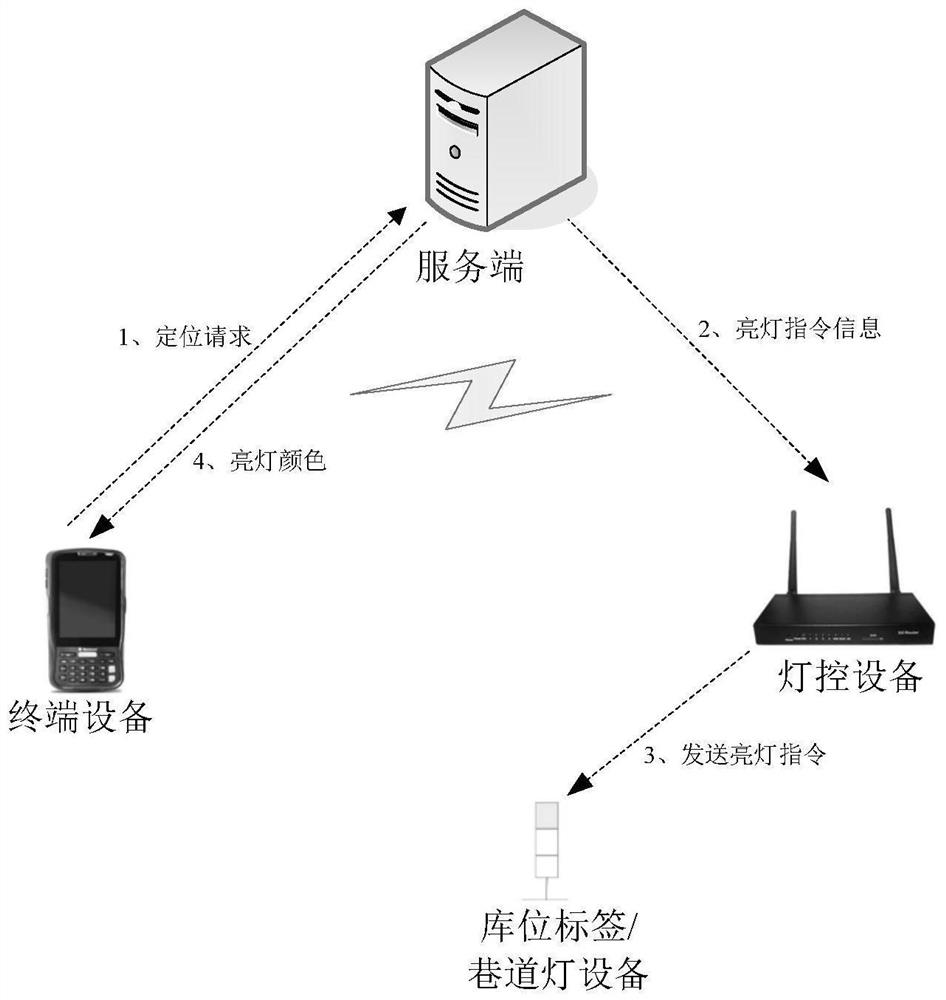

Goods picking system, related method, device and equipment

PendingCN113219453ALow costFast positioningElectrical apparatusEnergy saving control techniquesEmbedded systemIndustrial engineering

The invention discloses a goods picking system, a related method, a device and equipment. The goods picking system sends a positioning request for a target business object to a server through goods picking equipment; the server determines an identifier of a target roadway lamp and an identifier of a target storage location label, wherein the target roadway lamp and the target storage location label are corresponding to the target business object; lamp lighting instruction information aiming at the target roadway lamp and the target storage location label is sent to lamp control equipment; and the lamp control equipment turns on the target roadway lamp and the target storage location label lamp according to the instruction information. By adopting the processing mode, when a picking person needs to search for commodities in a physical store warehouse, the picking person can submit a commodity positioning request to the server, and the goods shelf storage location and the roadway where the corresponding commodities are located can be turned on; therefore, the commodity positioning speed can be effectively improved, the picking speed is improved, and an order is ensured to be performed on time.

Owner:HEMA (CHINA) CO LTD

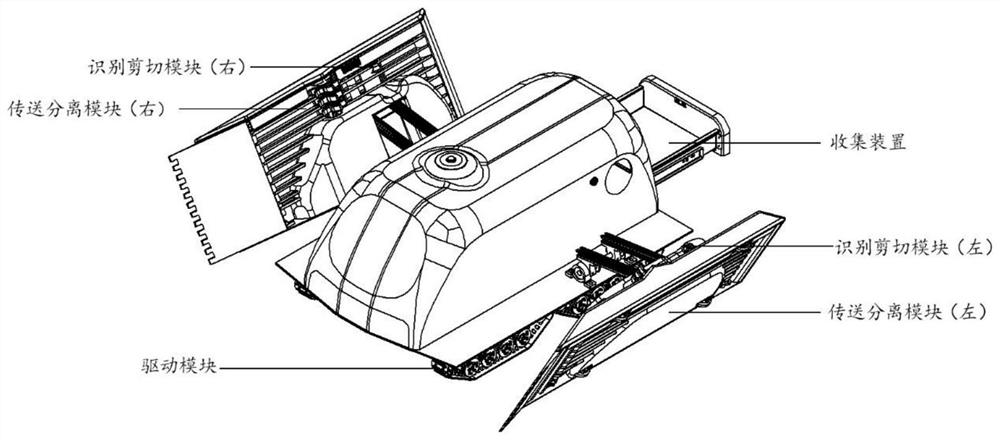

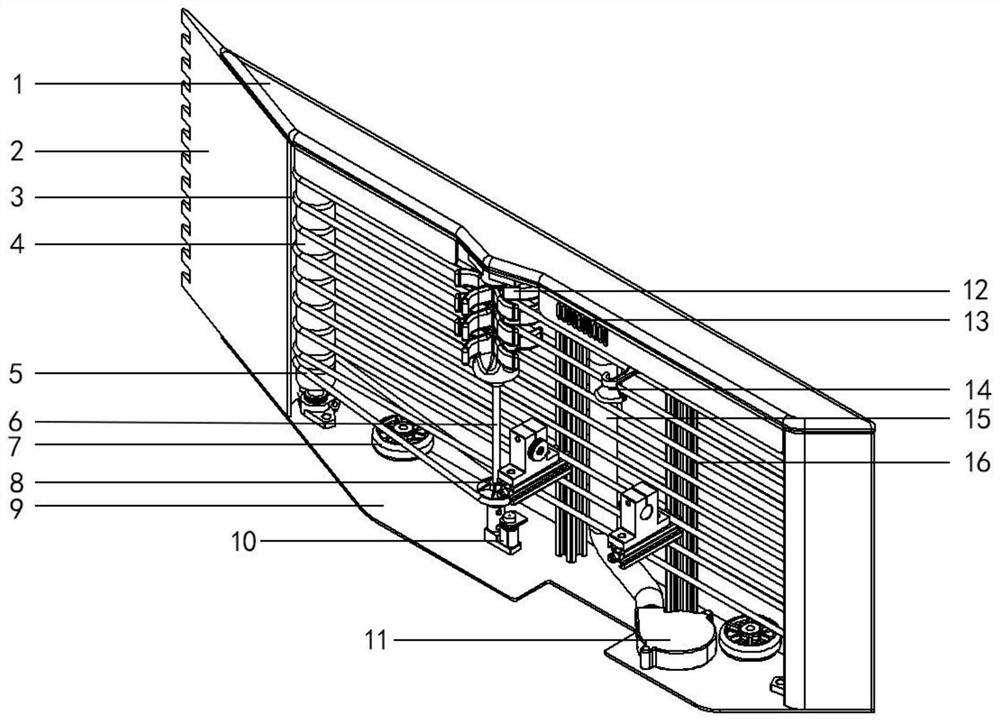

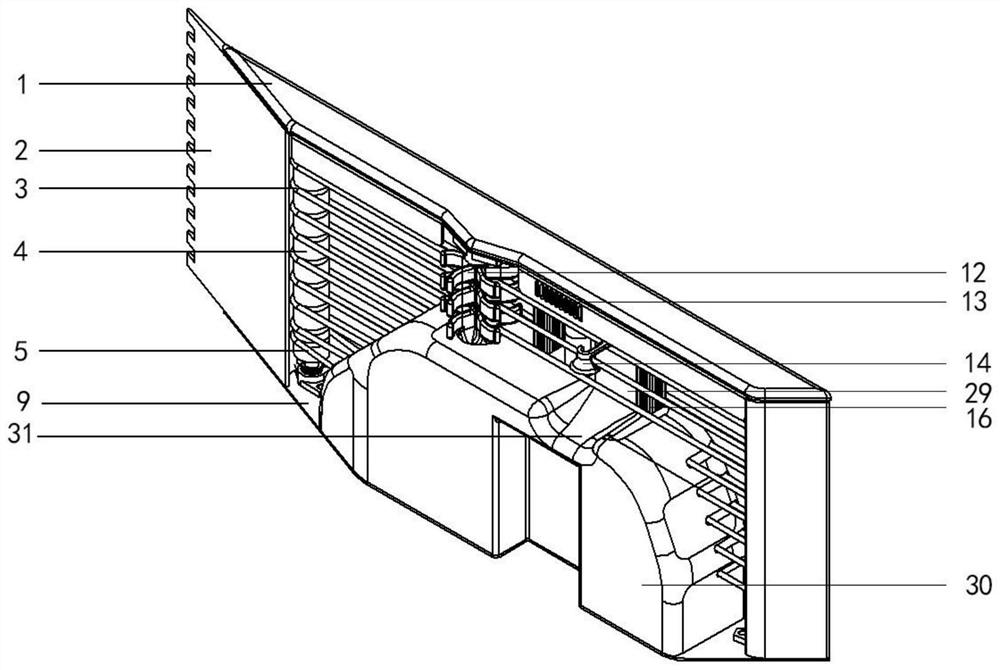

Autonomous strawberry picking robot based on image recognition

InactiveCN111727739AIncrease picking speedImprove picking efficiencyEndless track vehiclesPicking devicesFragariaMachine

The present invention provides an autonomous strawberry picking robot based on image recognition. The picking robot is mainly composed of a conveying separation module, a cutting recognition module, acollection module and a driving module. The conveying separation module is two conveyor belt systems located on both sides of a machine body for conveying and arranging strawberries to be identified;the cutting recognition module is arranged in the conveying separation module and on both sides of a main body outer shell for identifying and cutting the ripen strawberries; the collection module ismainly a pull-out drawer located in middle and lower parts of the machine body for collecting the cut strawberries; and the driving device is a four-group crawler system arranged at a bottom part ofthe machine body to drive the body forward. The strawberry picking robot does not require human assistance during a picking process, can realize coordinated progress of machine body travel and pickingoperation while ensuring safety of fruits, improves picking efficiency and reduces picking labor costs.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Cotton harvester

A cotton harvester includes plant cutting apparatus to sever cotton plants from a ground surface, plant conveyor apparatus to convey the severed plants into and through a picking chamber, and cotton picking apparatus including picker spindles that move upwardly into the picking chamber through a floor of the chamber to pick cotton filaments from bolls of the plants conveyed as a flattened mat therethrough and carry the cotton downwardly through the floor to doffers that remove the cotton from the spindles. Cotton conveyor apparatus also below the floor conveys the cotton to a receiver, while the plant residue passes from the chamber.

Owner:BLUE LEAF I P INC

Cotton picker spindle with grease reservoir and a grease and dirt seal

A spindle assembly includes a spindle with a blind bore extending along the spindle axis from the drive gear towards the outer end to reduce spindle weight and provide a lubrication reservoir in the spindle. Cross-formed holes extend from the blind bore through to the bearing surface of the spindle. Lubricant from the spindle bars passes into the bore where it is stored and distributed to the journal areas through the small metering apertures. A very low friction seal between the outer bushing and dust collar is pressed into the spindle nut and seals against the polished chrome spindle surface. The seal allows a slight amount of lubricant passage outwardly from the bushings while limiting inward movement of dust towards the bushings.

Owner:DEERE & CO

Walnut picker

The invention relates to a walnut picker and belongs to the technical field of fruit picking. The walnut picker comprises a knife handle I and a knife handle II; the bottom end of the knife handle I is provided with a hole, and the knife handle I is connected to a convex block of the knife handle II through the hole; the top end of a knife edge I is provided with a concave knife edge I, and the top end of a knife edge II is provided with a concave knife edge II; a blade I is arranged at the lower end of the knife edge I, and a blade II is arranged at the lower end of the knife edge II; one endof the blade I is connected with one end of the blade II through a connector III; and a spring is arranged below the blades. The walnut picker helps greatly increase picking speed and picking efficiency in the walnut picking process and reduce damage to walnut trees in the picking process, and is simple to set and convenient to use.

Owner:杨楠

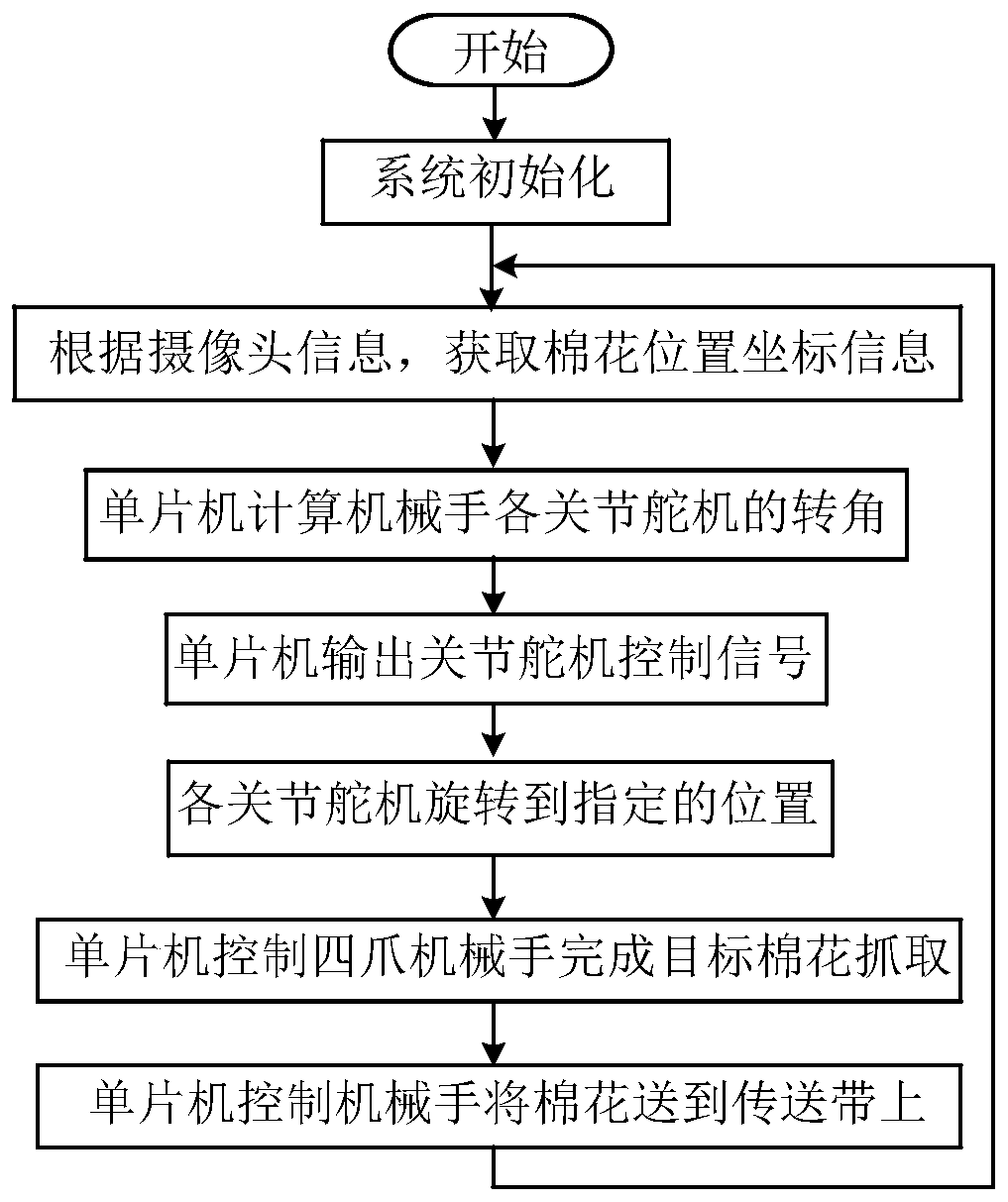

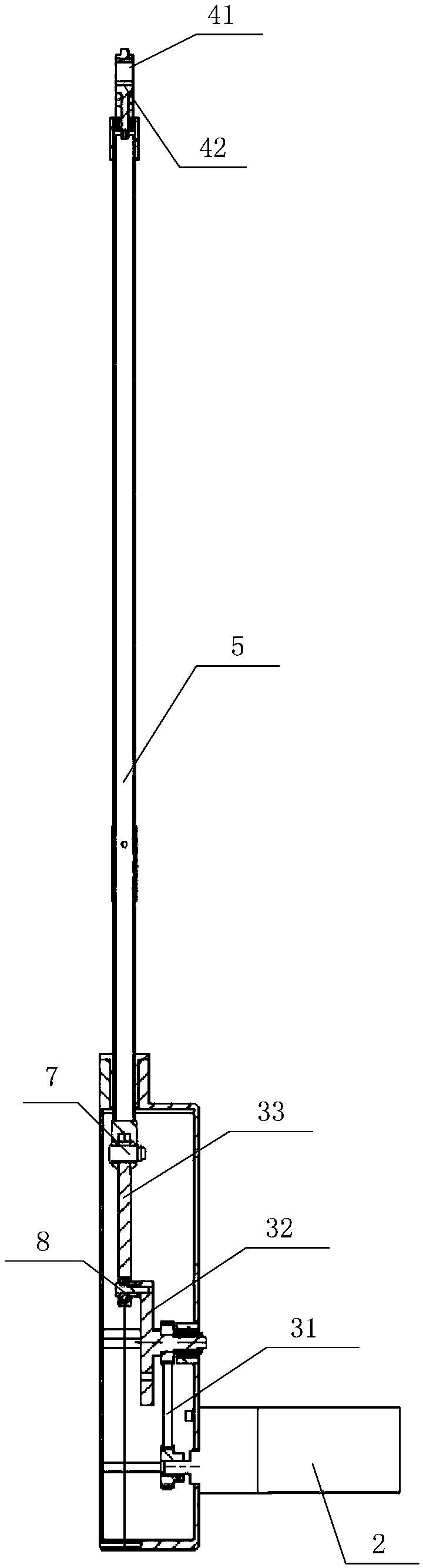

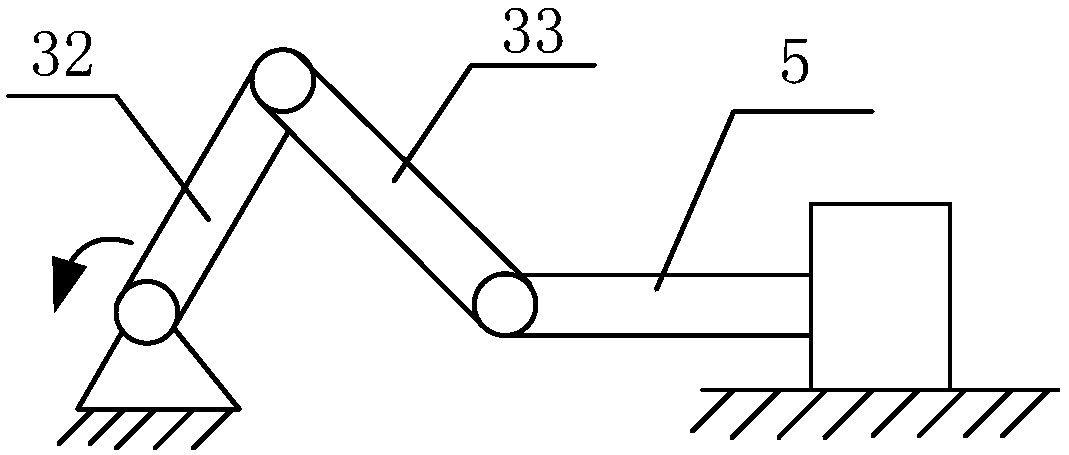

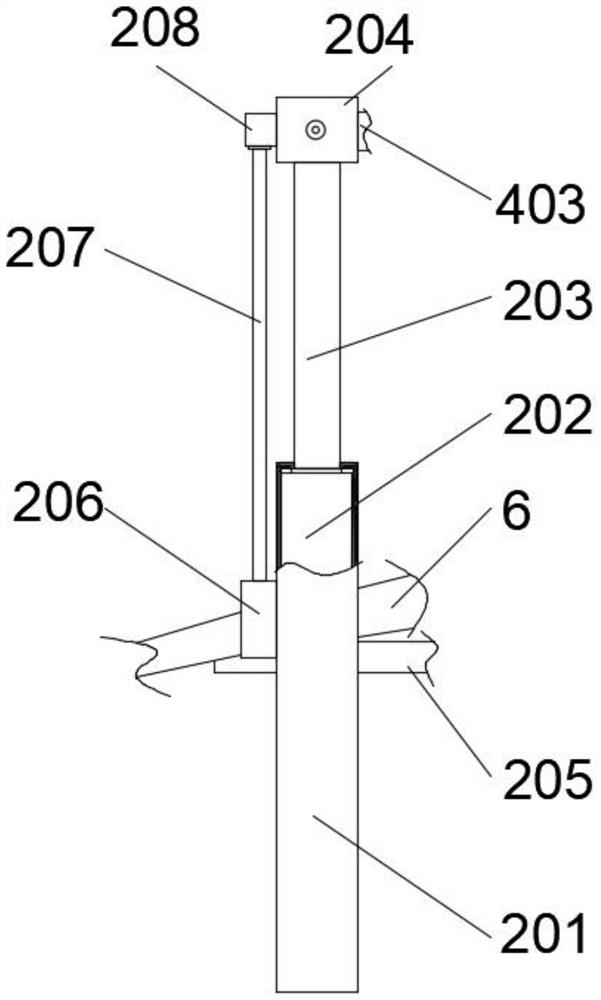

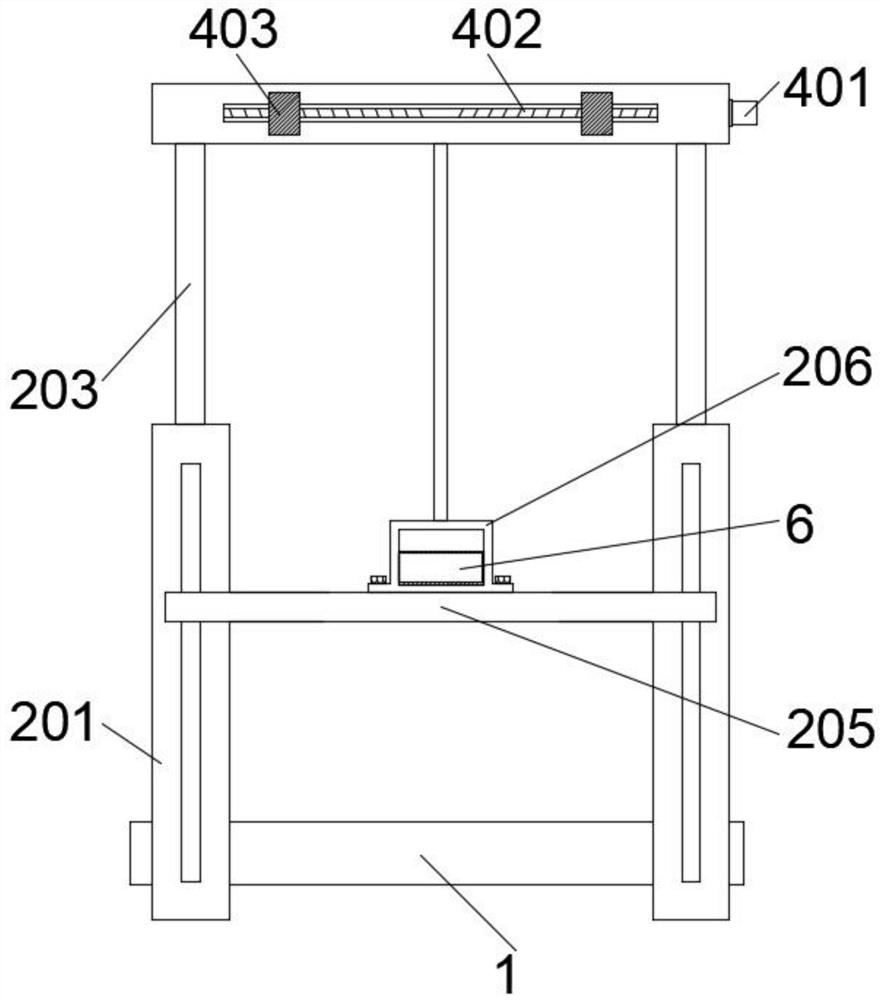

An intelligent cotton picker and its control method

ActiveCN110402683BEasy to controlSimple structurePicking devicesMicrocontrollerAgricultural engineering

The invention discloses an intelligent cotton picker and its control method, comprising a cotton picking manipulator, a tower arm, a tower rod, a camera part and a cotton storage part, the tower rod is installed at the top of the cotton storage part, the The tower arm is installed on the top of the tower rod, and the cotton picking manipulator is installed on the bottom of the other end of the tower arm. One end is provided with a cotton picking hose, and the invention also discloses a control method for an intelligent cotton picking machine; the whole system has a simple structure and simple control, reduces the number of joints and arm length of the cotton picking manipulator, reduces the difficulty of control, and reduces the The complexity of the control program is reduced, and the speed and efficiency of cotton picking are improved.

Owner:YANCHENG ZHENGBANG ENVIRONMENTAL PROTECTION TECH +1

A voice picking system and method based on voice recognition shelf

The invention relates to a voice picking system and method based on a voice recognition goods shelf. The voice picking system comprises a goods shelf, LED screens and a master controller, wherein a plurality of goods allocations are arranged on the goods shelf, an LED screen is arranged at the upper end of each goods allocation, and the width of each LED screen is consistent with that of the goods shelf; and the master controller is arranged in the goods allocation in the middle of the goods shelf, and comprises a power switch, a USB interface, a voice recognizer and a microprocessor. The voice picking system and method based on the voice recognition goods shelf have the benefits as follows: whether a voice command requiring for picking goods exists is detected and recognized in real time by the voice recognizer, and the voice command is displayed on the goods allocations through the LED screens after processed by the microprocessor, so that goods picker finishes goods picking accurately, conveniently and quickly, manual goods picking errors are reduced, and the logistics picking speed is increased.

Owner:GUANGXI POLYTECHNIC

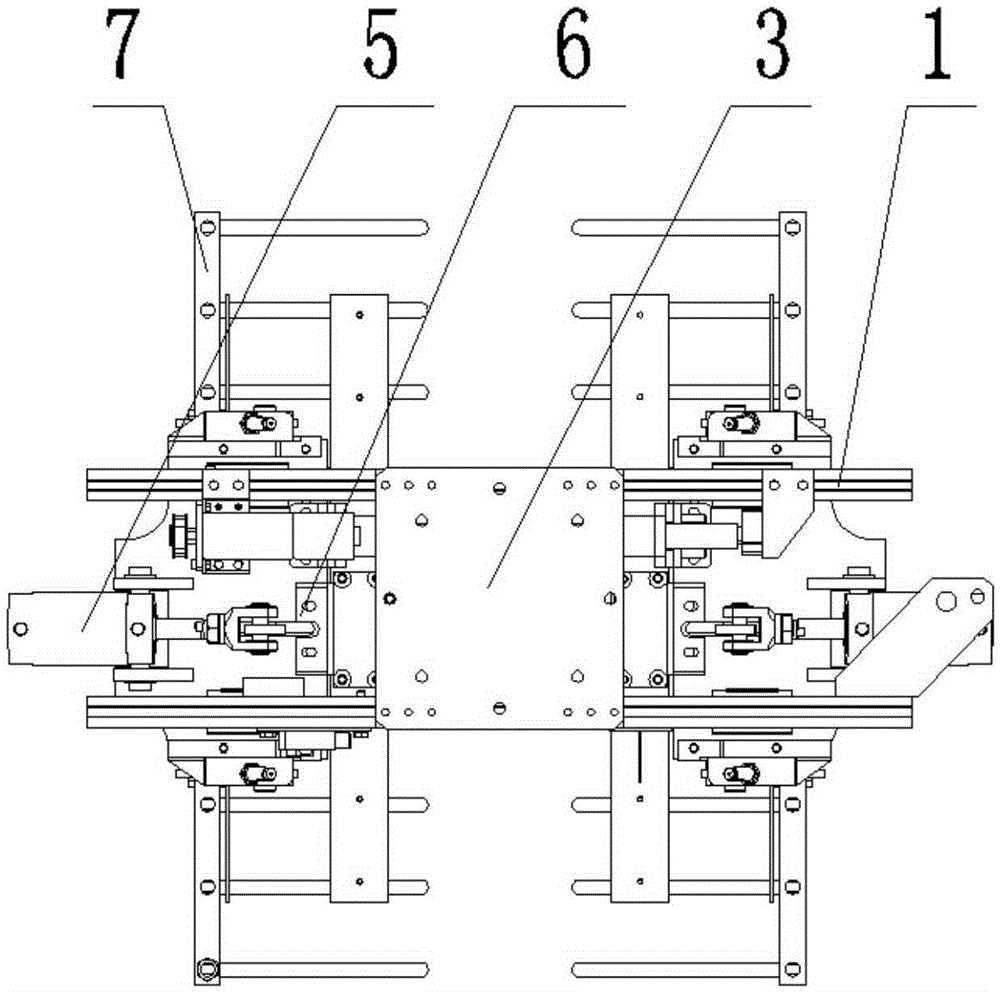

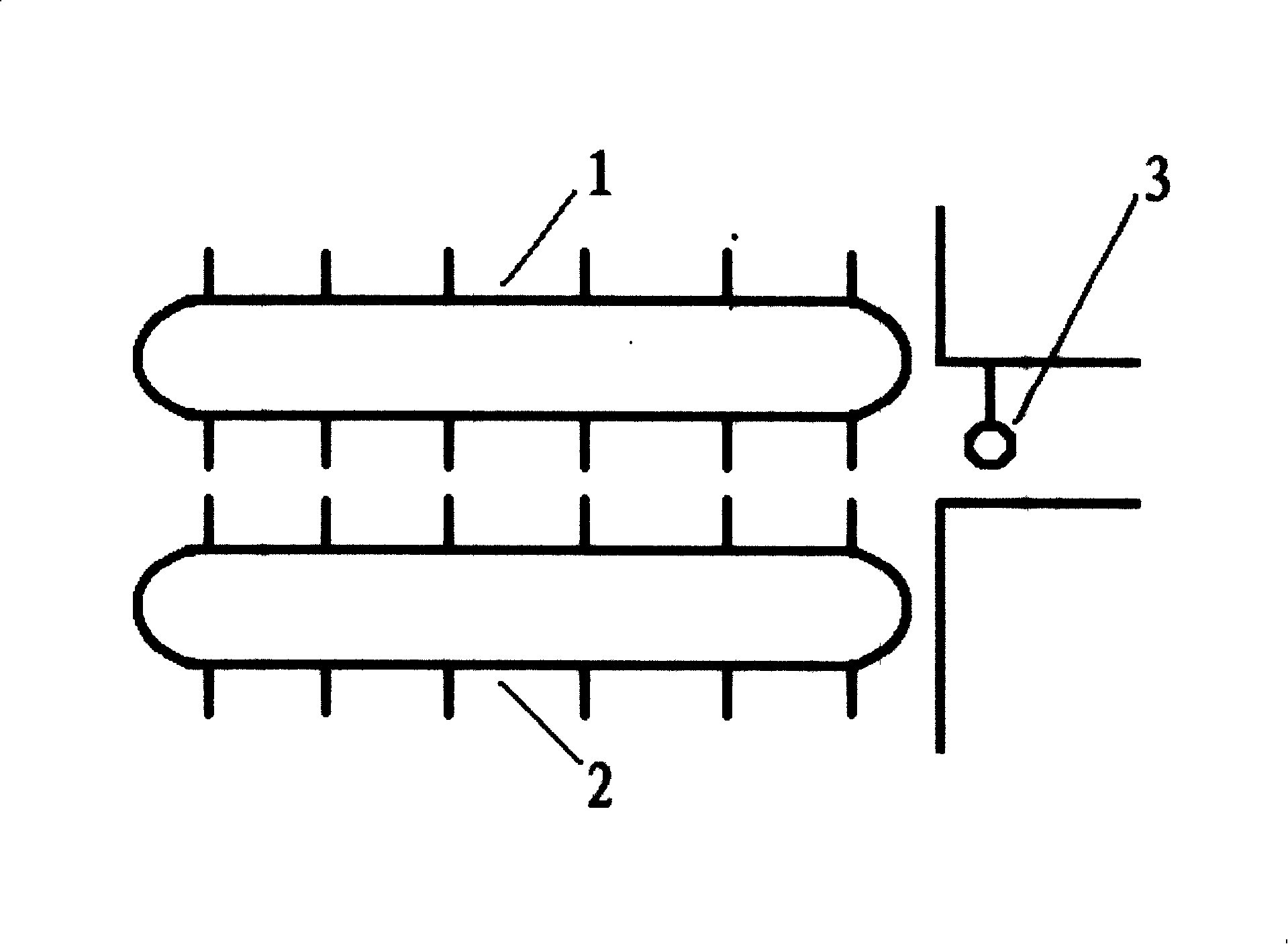

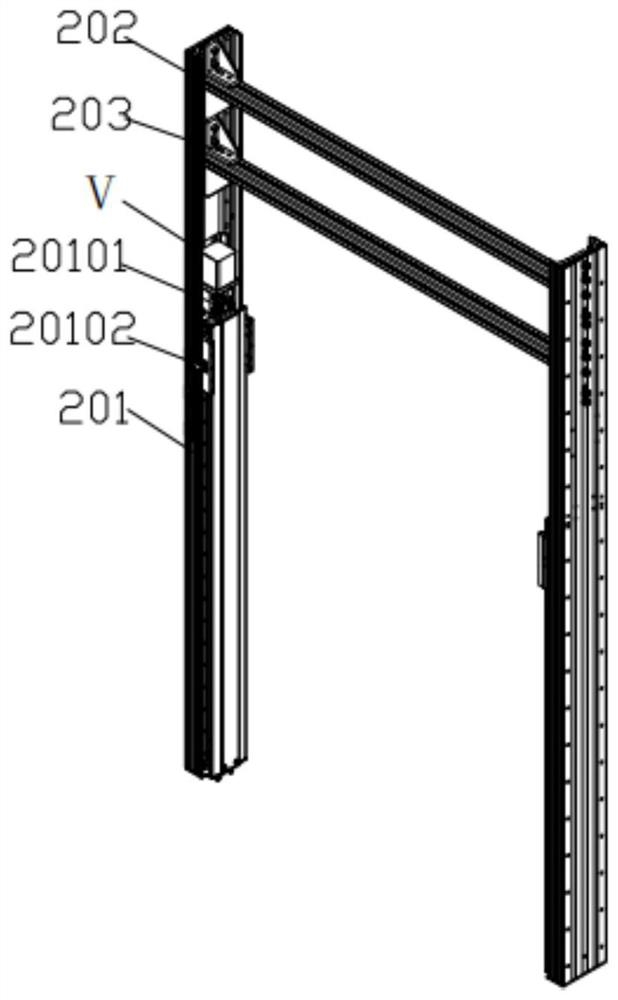

Semi-automatic mulberry leaf picking machine

PendingCN111602511AReduce labor intensityFlexible operationPicking devicesAgricultural engineeringSemi automation

The invention discloses a semi-automatic mulberry leaf picking machine. The machine comprises an electric control system, a walking device, a gantry mechanism, a mulberry twig holding device, an upperlimit push rod assembly, a lower limit push rod assembly and a mulberry leaf picking device. By assembly of the walking device and the gantry mechanism, walking across mulberry trees in mulberry plantations can be achieved; induction travel switches are arranged at different positions of the electric control system to control connection and disconnection of a circuit in sections, so that a mulberry twig holding servo motor and a driver of the mulberry twig holding servo motor are prompted to drive the mulberry twig holding device to be opened and closed, a mulberry leaf picking servo motor and a driver of the mulberry leaf picking servo motor are prompted to drive the mulberry leaf picking device to achieve closing and downward movement and opening and upward movement between the upper limit push rod assembly and the lower limit push rod assembly, and finally, mulberry holding and picking are achieved by sequential cyclic action of mulberry leaf picking. Labor intensity of mulberry farmers is further reduced, the farmers are helped to be liberated from heavy work, human-machine combination is achieved, the machine runs flexibly, and the picking speed and picking rate of mulberry leaves are increased.

Owner:GUANGXI NORMAL UNIV

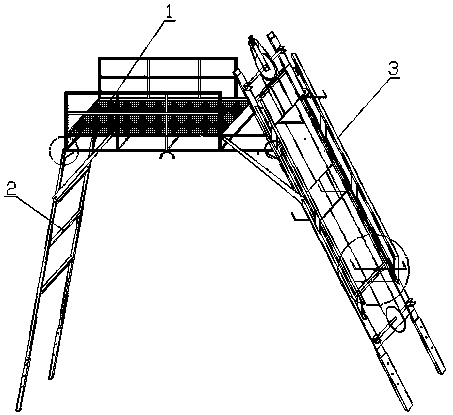

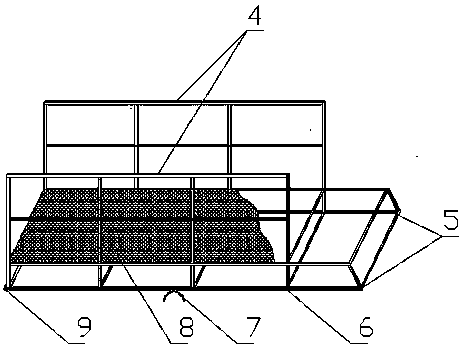

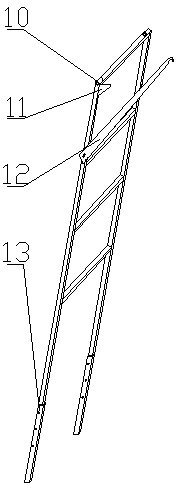

Multifunctional fruit picking ladder

The invention discloses a multifunctional fruit picking ladder. The multifunctional fruit picking ladder has fruit picking, basket loading, reciprocating slow dropping and pulling transportation functions according to the principle of eccentric wheel tight pressing and slow dropping. The multifunctional fruit picking ladder comprises a climbing ladder, a picking platform and a slow dropping sliding rail. In picking, through adjusting the length of the climbing ladder and a slow dropping conveying device according to the height of a fruit tree, the platform lifting and dropping are realized. After picking, the multifunctional fruit picking ladder can be fast dismounted and combined so that the climbing ladder is changed into a trolley for pulling conveying, the platform is changed into a carriage and the slow dropping conveying device is placed at the lower part of the platform and thus a pulling conveying function is realized. The picking ladder is suitable for picking of fruits of various fruit trees, can be operated through a single person and realizes picking, conveying and pulling conveying.

Owner:EASTERN GANSU UNIVERSITY

Routing control method of goods-to-person workstation conveyor line based on multi-layer bin storage

ActiveCN110963226BIncrease picking speedRealize general pickingStorage devicesOrder controlInformation transmission

The present invention provides a method for controlling the delivery route of goods-to-person workstations based on multi-storey bin storage, which has such features, including the following steps: the order control system receives the general bill of lading issued by the warehouse management system, and according to the delivery According to the coincidence degree of materials in the general bill of lading, the general bill of lading is bound to the corresponding goods-to-person workbench and the corresponding binding information of the general bill of lading is generated; the order control system, according to the material requirements in the general bill of lading, Match the inventory of the multi-layer material box storage warehouse, and generate or change the handling tasks for the inventory boxes on the conveyor line, generate inventory box removal tasks for the inventory boxes in the multi-layer material box storage warehouse, and then generate picking task information; The inventory boxes in the layer box storage warehouse and the inventory boxes on the conveyor line are received and moved to the corresponding goods-to-person workbench according to the binding information of the general bill of lading and the picking task information. Among them, the order control system and the inventory box Information transmission is realized through the conveyor line control system.

Owner:HUBEI JOINTOWN TECH

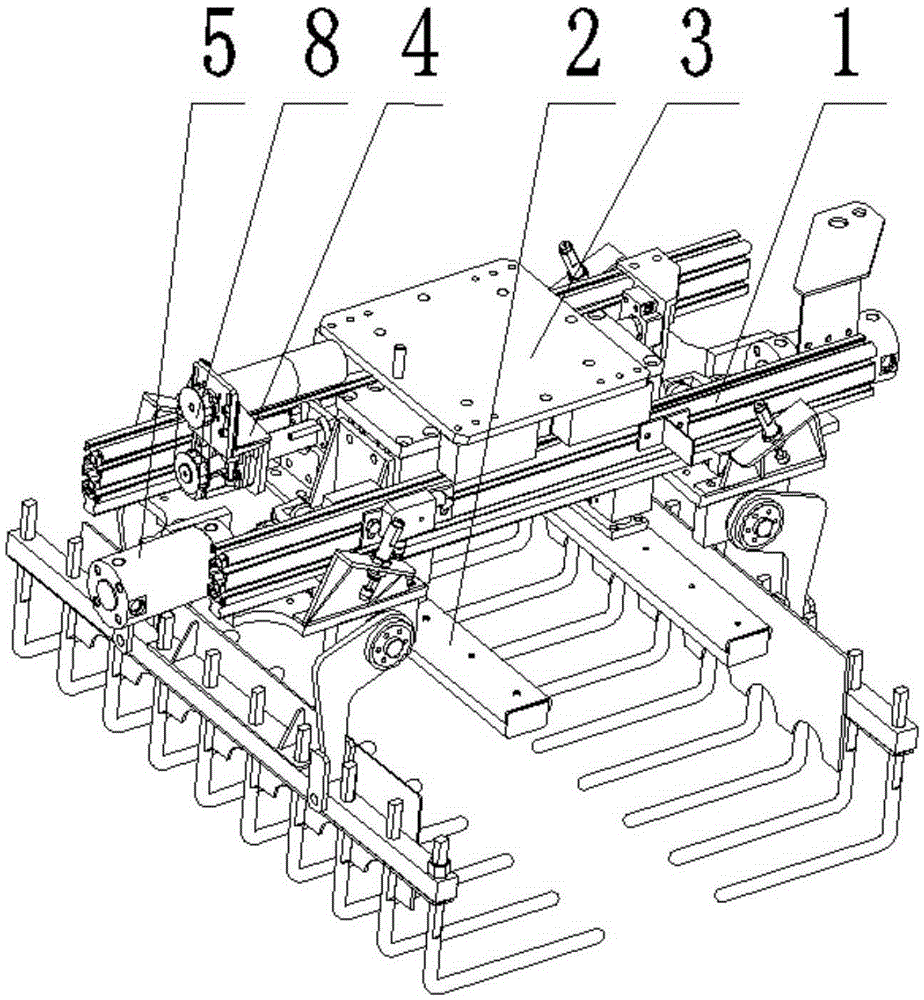

Intelligent picking and transporting robot for orchard and working method thereof

ActiveCN113303095AImprove picking efficiencyIncrease picking speedPicking devicesAgricultural engineeringFruit tree

The invention discloses an intelligent picking and transporting robot for an orchard and a working method thereof, and relates to the technical field of fruit robot picking. A vehicle body is provided with a conveying inclined pipe, a lifting assembly, an anti-falling hopper, a driving assembly, an auxiliary anti-falling mechanism and a material collecting mechanism; and the anti-falling hopper comprises two arc-shaped anti-leakage frames and two arc-shaped anti-leakage pieces. According to the intelligent picking and transporting robot, by arranging multiple manipulators, the conveying inclined pipe, the lifting assembly, the anti-falling hopper, the driving assembly, the auxiliary anti-falling mechanism and the material collecting mechanism, fruits are subjected to anti-falling treatment and collecting treatment, the multiple manipulators can jointly pick the fruits from fruit trees from the ring sides of the fruit trees and work at the same time, and therefore the picking efficiency and speed are improved, and the damage rate of products is reduced; and by arranging the arc-shaped anti-leakage frames, the arc-shaped anti-leakage pieces, semi-arc-shaped supports and semi-arc-shaped elastic pads, the fruits are subjected to anti-falling treatment, the purpose of laterally wrapping trunks is achieved so as to adapt to fruit trees of different diameters and fruit trees with uneven surfaces, and the better picking anti-falling purpose is achieved.

Owner:南通柏睿机器人技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com