Cargo-to-human workstation conveying line routing control method based on multilayer material box storage library

A transmission line and control method technology, applied in the direction of storage devices, transportation and packaging, etc., can solve the problems of increasing the work intensity of picking personnel, reducing the work efficiency of the transmission line, and limited storage capacity, so as to shorten the transportation time, speed up the picking speed, The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

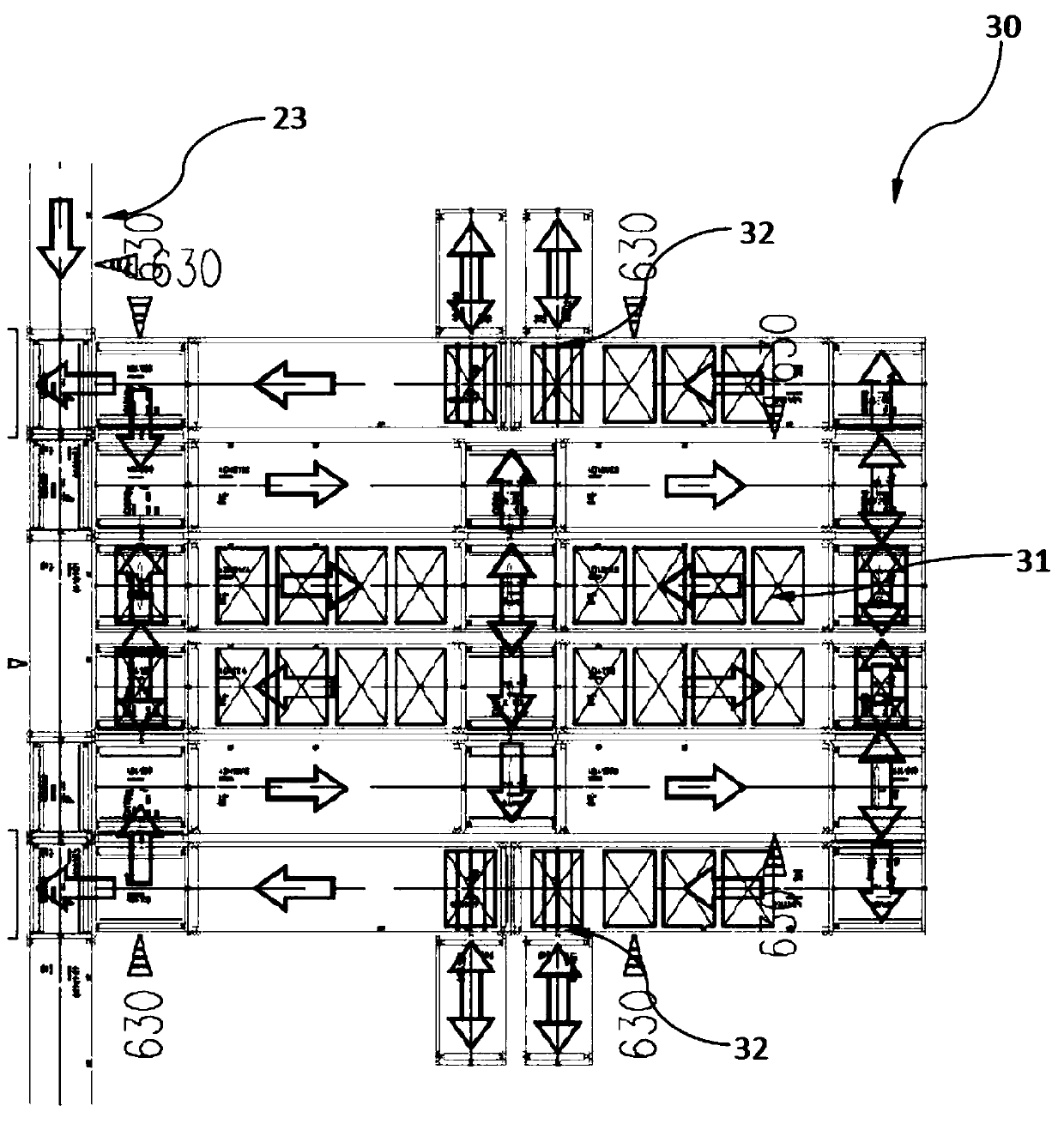

[0022] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the method for controlling the delivery route of goods-to-person workstations based on multi-layer bin storage in the present invention in conjunction with the accompanying drawings.

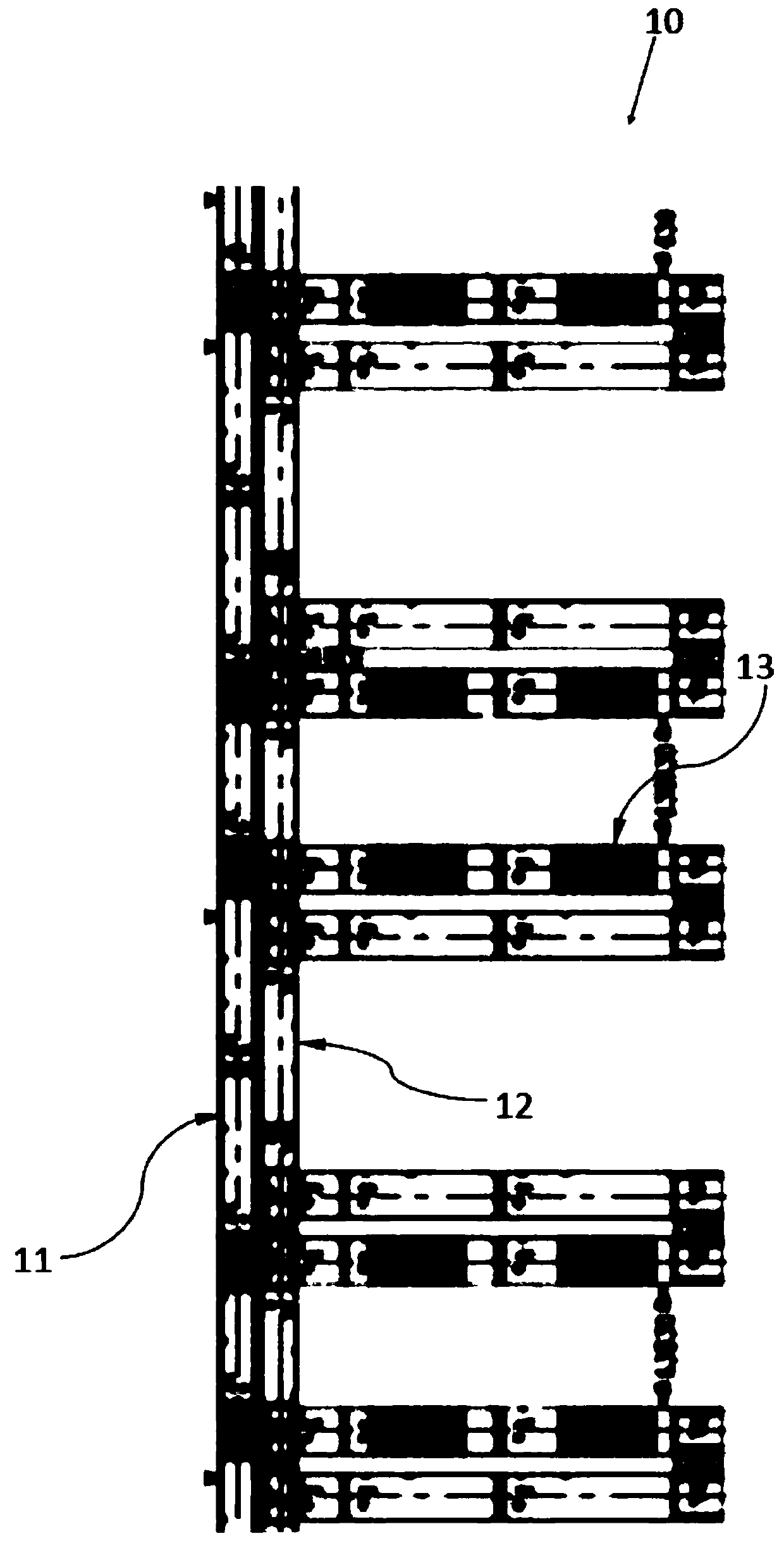

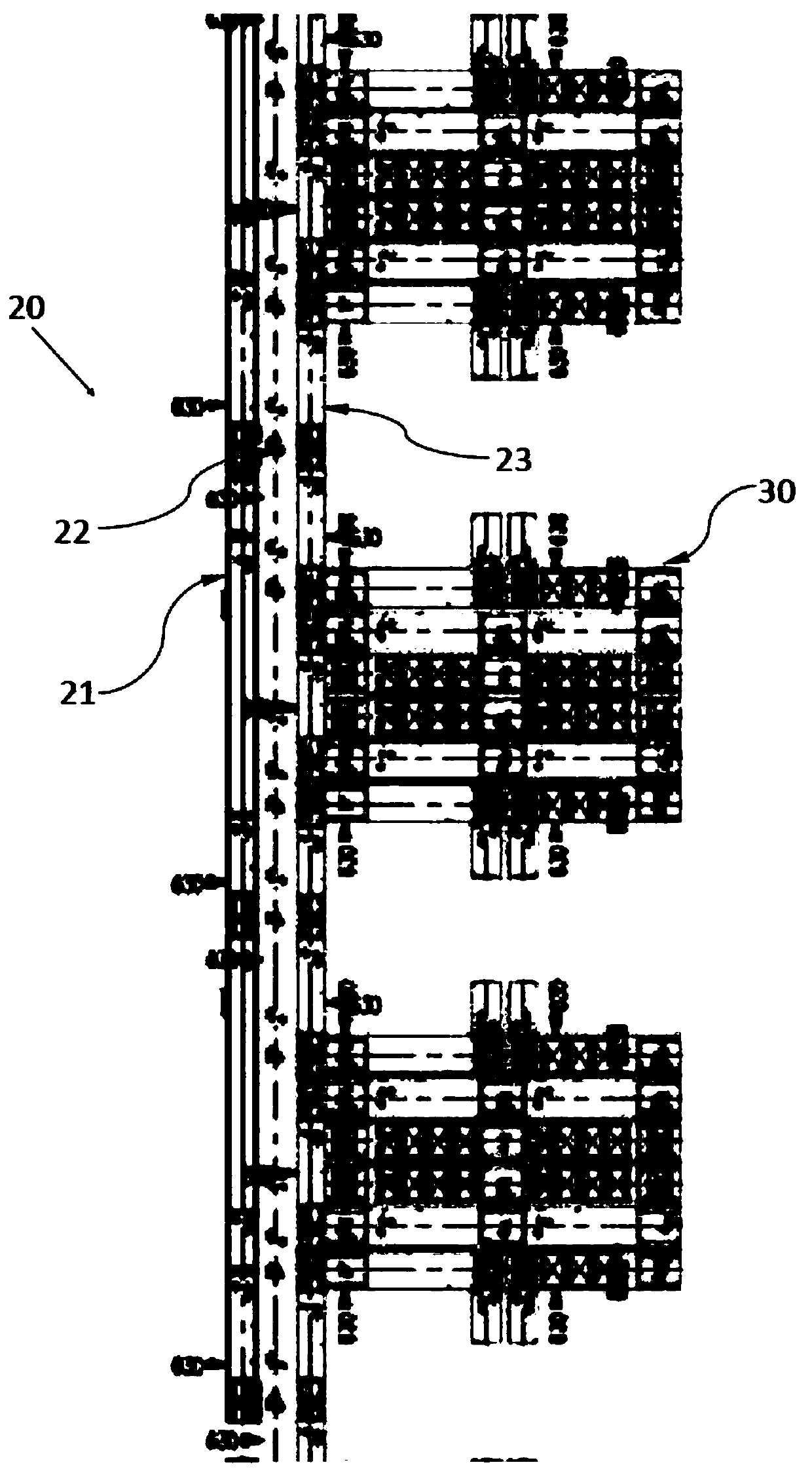

[0023] This embodiment provides a delivery line for goods-to-person workstations, which includes a multi-storey container storehouse, a delivery line, multiple goods-to-person workstations, an order control system, and a delivery line control system.

[0024] A plurality of inventory boxes are stored within the multi-level bin storage, and the plurality of inventory boxes are stored on respective levels of the multi-level bin storage. Multiple items are contained in the inventory box, and preferably, the multiple items contained in the inventory box are the same type of item. A barcode is also provided on the invento...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com