Intelligent picking and transporting robot for orchard and working method thereof

A technology for robots and orchards, applied in the fields of picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as worker injury, fall injury, fruit damage, etc., to improve efficiency and speed, enhance service life, and reduce damage rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

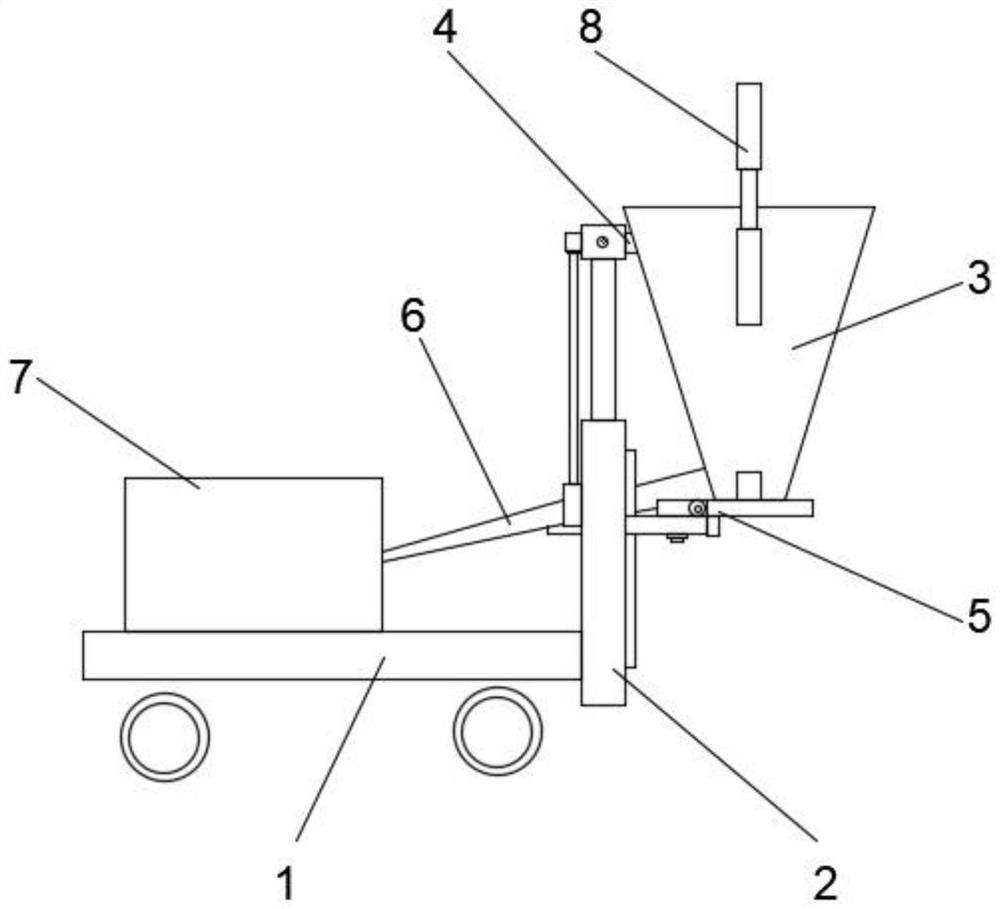

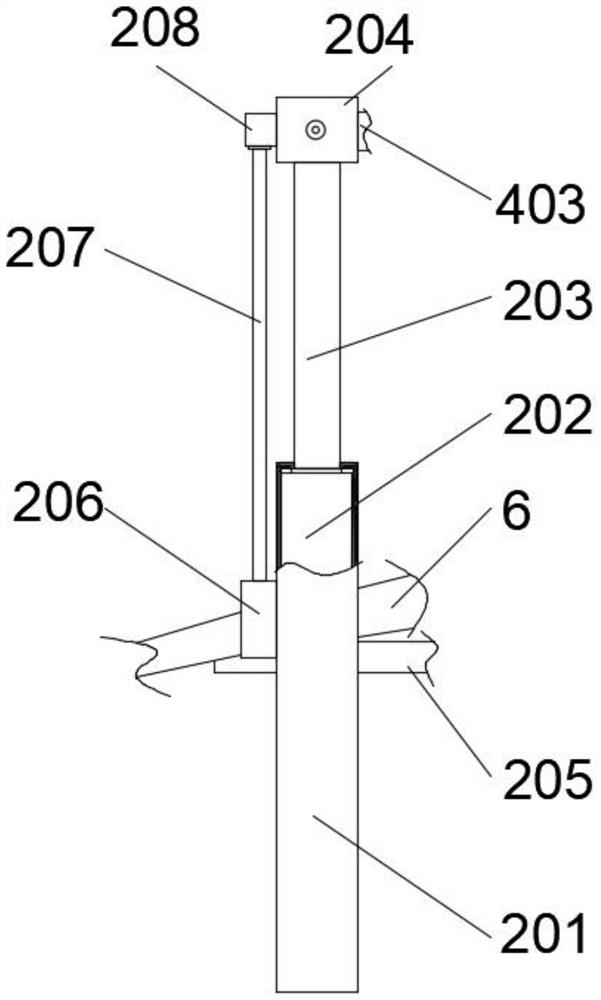

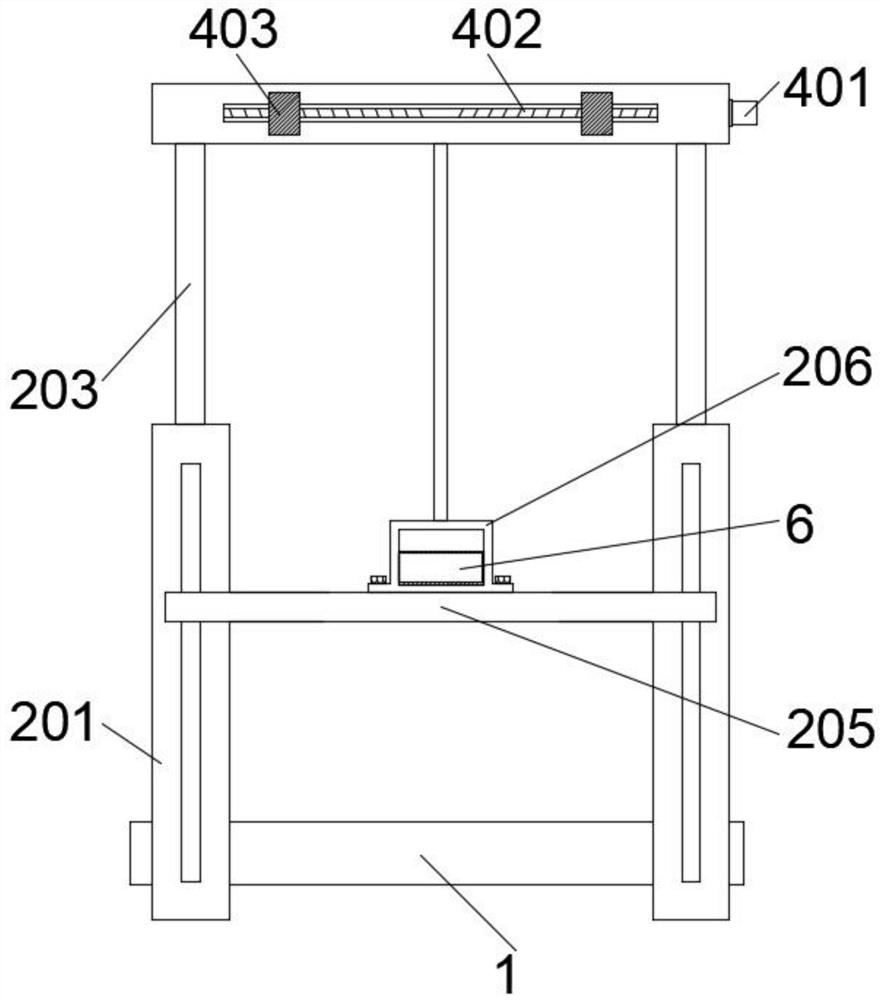

[0048] An orchard intelligent picking and transporting robot, comprising a car body 1, a manipulator 8, a transmission inclined pipe 6, a lifting assembly 2, an anti-falling bucket 3, a driving assembly 4, an auxiliary anti-falling mechanism 5 and a material receiving mechanism 7, and the lifting assembly 2 is vertical It is arranged on one side of the car body 1, and the anti-drop bucket 3 is arranged on the side of the lifting assembly 2. The lifting assembly 2 is used to lift the anti-drop bucket 3 and the auxiliary anti-fall mechanism 5 at the same time. The driving assembly 4 is arranged on the top of the lifting assembly 2, and drives Component 4 is in transmission connection with anti-falling funnel 3, and driving component 4 is used to drive the anti-falling funnel to run. The anti-falling funnel is used to accept the fruit picked by manipulator 8, so that the fruit moves along the inner wall of the anti-falling funnel, so as to protect the fruit, and the auxiliary anti-...

Embodiment 2

[0061] In Embodiment 1, the present invention fits the appearance of the trunk by means of the half-arc spring washer 505 abutting against the trunk, but the diameter of the trunk is not uniform and the outer surface of the trunk is uneven. When relying on the properties of the material of the half-arc spring washer 505 itself When abutting against the tree trunk and conforming to its shape, the semi-arc spring washer 505 is prone to deformation and wrinkles after long-term use, which reduces the service life of the half-arc spring washer 505;

[0062] Both the half-arc spring pad 505 and the half-arc bracket 504 are hollow inside, and the half-arc spring pad 505 is provided with a first sliding bar 506 and a fitting spring 507, and the fitting spring 507 is slidingly sleeved on the first sliding bar 506 outer ends, one end of the first slide bar 506 runs through the inner wall of the semi-arc spring washer 505 and the outer wall of the semi-arc bracket 504 successively and ext...

Embodiment 3

[0066] The receiving mechanism 7 of embodiment 1 collects the fruit through the receiving box 701, but when the fruit enters the receiving box 701 from the fruit inlet, due to the height difference between the bottom of the receiving box 701 and the fruit inlet, when the fruit When the fruit falls into the bottom of the receiving box 701, it is easy to cause falling damage;

[0067] The receiving mechanism 7 also includes a receiving plate 716 that is slidably arranged in the receiving box 701. The receiving plate 716 is slidably arranged in the receiving box 701, and the outer end of the receiving plate 716 abuts against the inner wall of the receiving box 701, and the receiving box 701 A third servomotor 703 is fixed inside, and the output shaft of the third servomotor 703 is fixedly connected with a third bidirectional screw mandrel 704, and the third bidirectional screw mandrel 704 is rotated and arranged in the receiving box 701. The third bidirectional screw mandrel 704 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com