Autonomous strawberry picking robot based on image recognition

A technology for picking robots and strawberries, which is applied in the field of agricultural machinery, can solve problems such as time-consuming, and achieve the effects of labor saving, injury reduction, and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with accompanying drawings and examples.

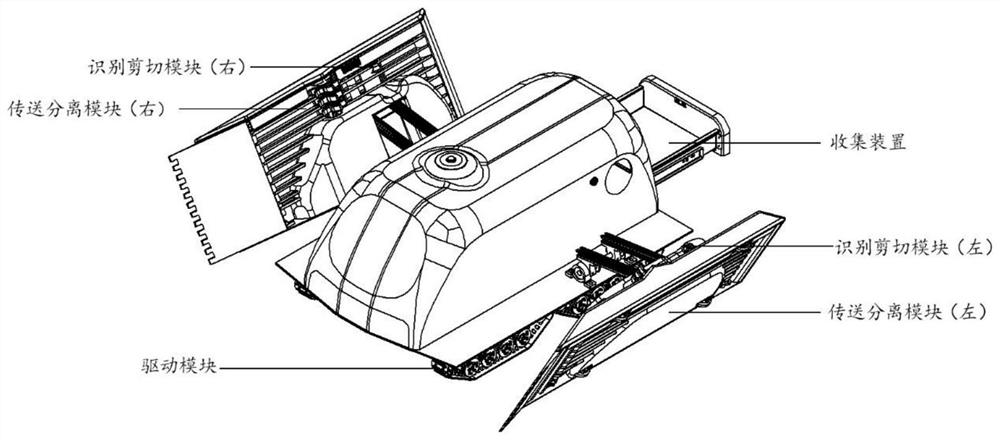

[0034] Such as figure 1As shown, an autonomous strawberry picking robot based on image recognition includes a conveying and separating module, a cutting recognition module, a collecting module and a driving module.

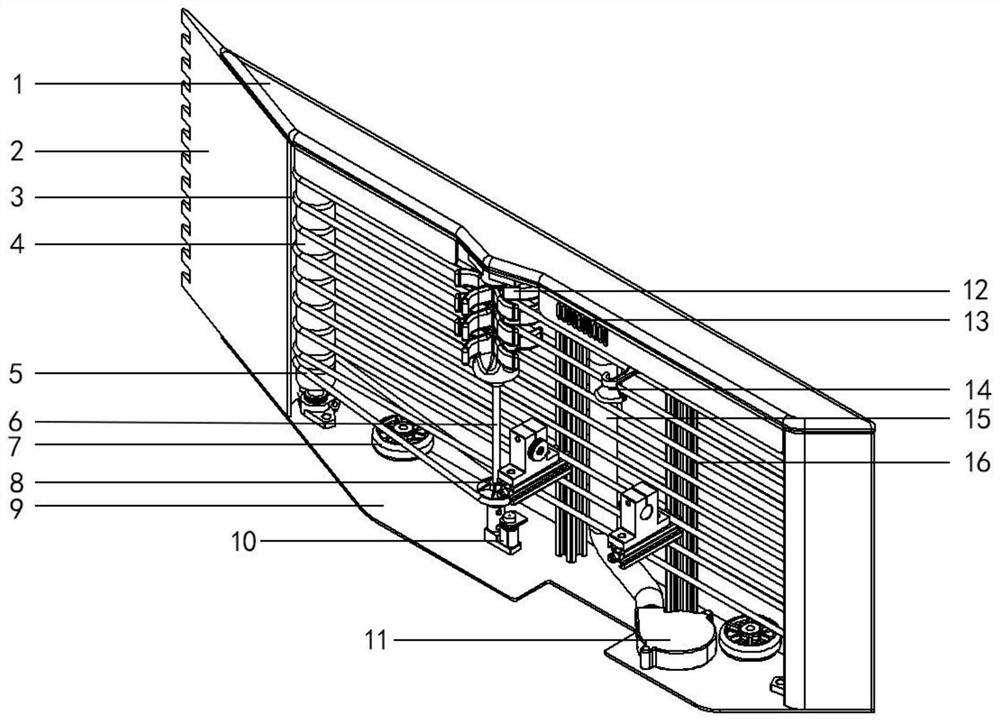

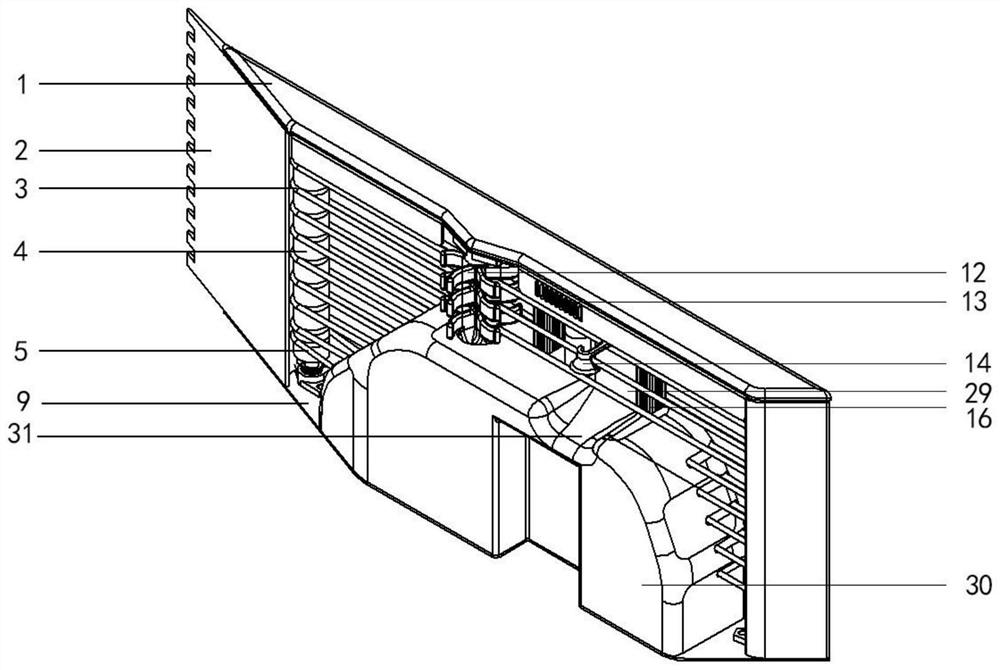

[0035] Such as figure 2 , 3 As shown, the transmission separation module mainly includes a module upper base plate 1, a slope shovel 2, a transmission round belt 13, a round pulley 4, a transmission round belt 5, a dial shaft 6, a wheel 7, a transmission wheel 8, and a module lower base plate 9 , motor 10, blower 11, thumb wheel 12, air outlet 13, crotch 14, ventilation pipe 15, aluminum profile 16, separation module packaging shell 30, slide rail chute 31, gear set 37, connecting rod 38. Wherein two aluminum profiles 30 are located in the middle part, supporting and connecting the upper and lower bottom plates 1, 9, two round belt shafts 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com