Reciprocating type cauliflower dicer suitable for different sizes

A reciprocating and dicing machine technology, applied in metal processing and other directions, can solve the problems of not easy cooking, affecting the cooking speed, and consuming processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

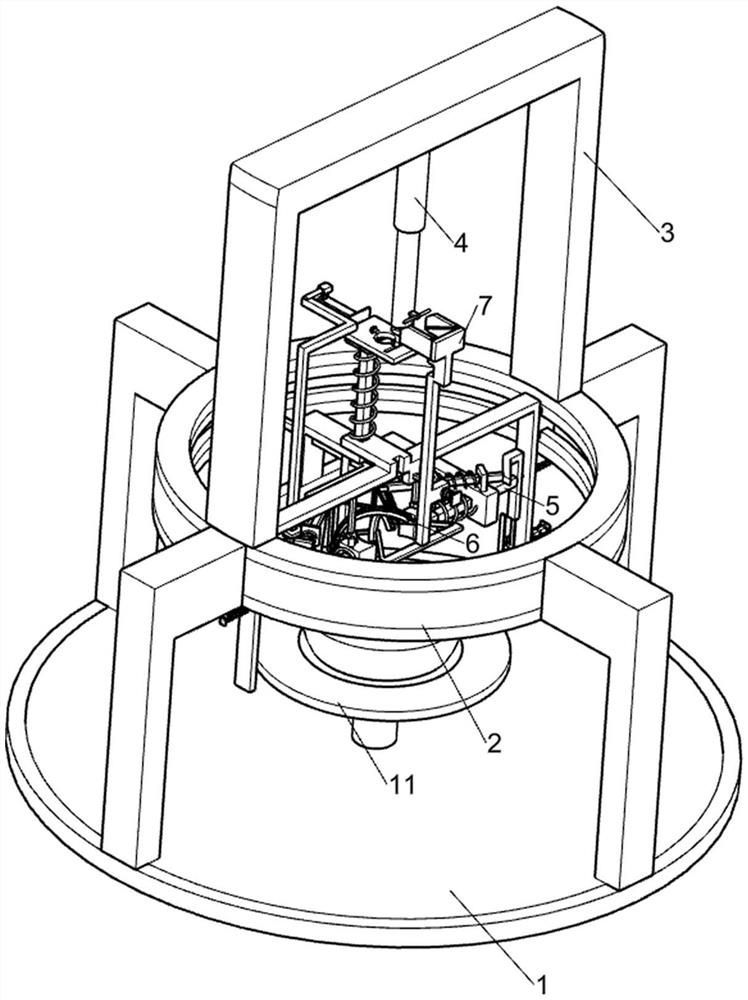

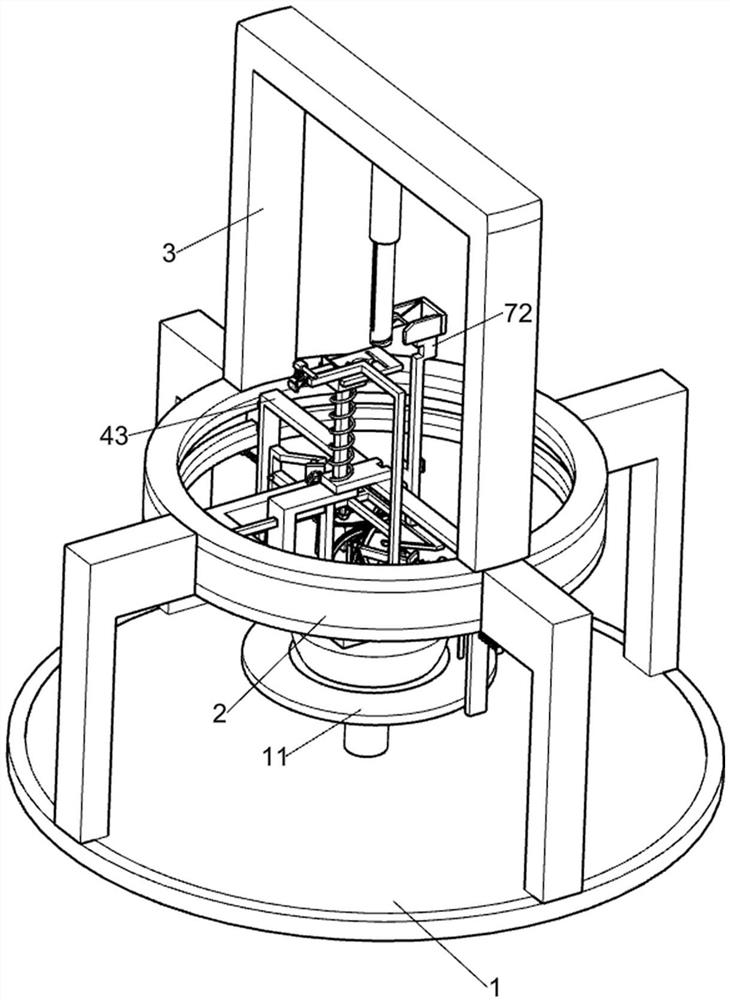

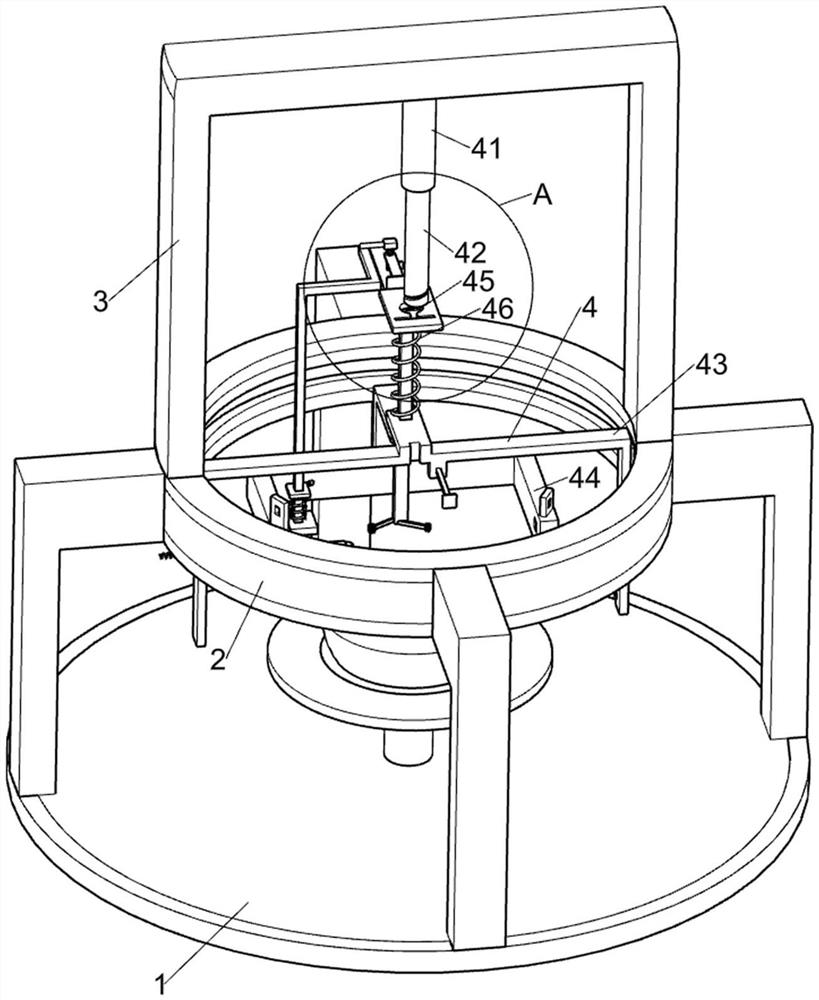

[0024] Embodiment: A kind of reciprocating cauliflower cutting machine applicable to different sizes, such as Figure 1-9 As shown, it includes a support base 1, a placement table 11, a slide rail ring 2, a first support frame 3, a pushing and rotating assembly 4, a clamping assembly 5, an ejection assembly 6 and a reset assembly 7, and the center of the top surface of the support base 1 is affixed There is a placing platform 11 for placing cauliflower, a slide rail ring 2 is fixedly connected to the support seat 1, a first support frame 3 is fixedly connected to the top surface of the slide rail ring 2, and a push rotation assembly 4 is slidably connected to the slide rail ring 2, The clamping assembly 5 for clamping the cauliflower is slidably connected to the pushing and rotating assembly 4, the ejecting assembly 6 for cutting the cauliflower is also slidably connected to the pushing and rotating assembly 4, and the reset assembly 7 is arranged on the pushing and rotating as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com