Protective film and preparation method thereof

A protective film, protective film technology, applied in chemical instruments and methods, other household appliances, lamination and other directions, can solve the problems of arc edge rebound, unable to lasting stereotype, unable to protect the screen and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

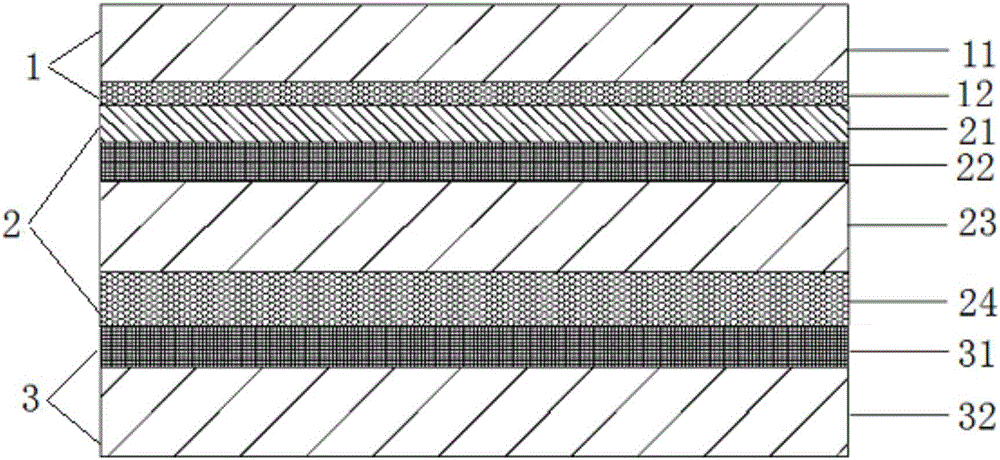

[0049] The present invention also provides a kind of preparation method of protective film, comprises the following steps:

[0050] A) Coating the UV soft glue solution on one side of the substrate to be used, and curing by ultraviolet light to obtain the substrate to be compounded with the UV soft glue layer; the hardness of the UV soft glue layer is <1H;

[0051] B) coating the UV hard glue on the UV soft glue layer, and curing by ultraviolet light to obtain the UV hard glue layer;

[0052] C) coating the viscose glue solution on the other side of the base material for use, and obtaining the viscose glue layer after drying;

[0053] D) Compounding a release layer on the surface of the adhesive layer used, and compounding a protective film layer on the surface of the UV hard adhesive layer to obtain a protective film.

[0054] In the present invention, the UV soft glue is first coated on one side of the base material, and after being cured by ultraviolet light, the base mate...

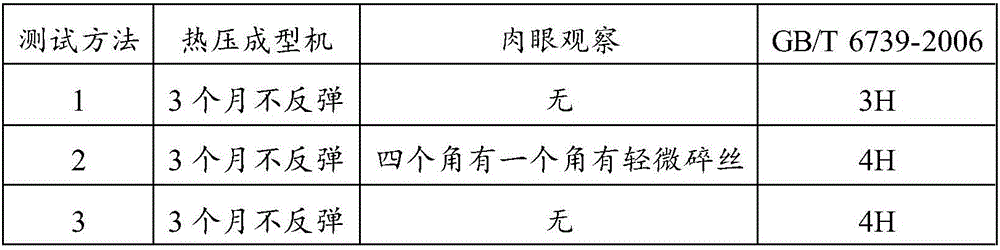

Embodiment 1

[0067] Coat the UV soft glue on the 50μm optical grade PET substrate through a micro concave roller, then dry the solvent in a 100°C oven for 60s, and then pass the UV lamp, at 500mJ / cm 2 Under irradiate for 3s to make it fully cured to obtain a UV soft rubber coating with a thickness of 2 μm.

[0068] Then apply UV hard glue on the surface of the UV soft glue coating through a micro concave roller, dry the solvent in an oven at 100°C for 60s, and then pass the UV lamp, at 500mJ / cm 2 Irradiate for 3s to make it fully cured to obtain a UV hard glue coating with a thickness of 3μm

[0069] The silicone pressure-sensitive adhesive was coated on the back of the substrate with a doctor blade, and dried in an oven at 150° C. for 120 seconds to obtain an adhesive layer with a thickness of 50 μm. At this point, the used layer is obtained.

[0070] Take another PET base material with a thickness of 50 μm, apply UV soft glue on the PET base material through a micro concave roller, hea...

Embodiment 2

[0073] Coat the UV soft glue on the 100μm optical-grade PET substrate through a micro concave roller, then dry the solvent in an oven at 80°C for 50s, and then pass the UV lamp at 400mJ / cm 2 Under irradiate for 5s to make it fully cured to obtain a UV soft rubber coating with a thickness of 3 μm.

[0074] Then apply UV hard glue on the surface of the UV soft glue coating through a micro concave roller, dry the solvent in a 100°C oven for 80s, and then pass the UV lamp, at 600mJ / cm 2 Under irradiate for 2s to make it fully cured to obtain a UV hard glue coating with a thickness of 5 μm

[0075] The silicone pressure-sensitive adhesive was coated on the back of the substrate by a doctor blade, and dried in an oven at 130° C. for 150 seconds to obtain an adhesive layer with a thickness of 50 μm. At this point, the used layer is obtained.

[0076]Take another PET base material with a thickness of 50 μm, apply UV soft glue on the PET base material through a micro concave roller, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com