Garlic peeling machine

A technology of garlic machine and garlic peeling, which is applied in application, food processing, food science, etc., to achieve the effect of preventing slipping and facilitating disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

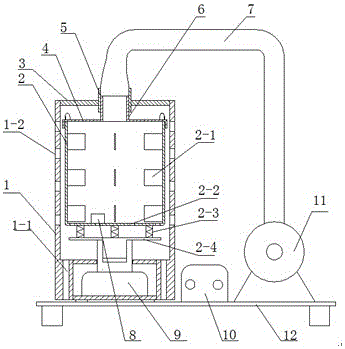

[0024] Further detailed description will now be made in conjunction with the accompanying drawings.

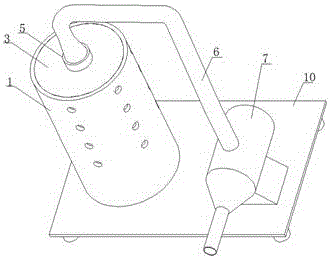

[0025] like figure 1 As shown, the garlic peeling machine includes: a shell 1, a garlic peeling tube 2, a fixed frame 3, a sealing cover 4, a rotary joint 5, an exhaust pipe 6, an induced draft fan 7, a motor 8, a control box 9, a base 10, and the shell 1 Also includes: drainage hole 1-1, ventilation hole 1-2. Garlic peeling tube 2 also includes: flapping sheet 2-1, air inlet hole 2-2, spring tube 2-3, chassis 2-4. The bottom of the casing 1 is provided with two symmetrical drainage holes 1-1 for draining water when cleaning the bottom, and the middle part of the casing 1 is also provided with a plurality of ventilation holes 1-2. The bottom of the peeling garlic tube 2 is provided with a plurality of air inlet holes 2-2. Ventilation hole 1-2 communicates with peeling garlic tube 2 inside by air inlet 2-2, is convenient when starting induced draft fan 7, and exhaust pipe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com