Textile plant dye extraction device

An extraction device and a technology for plant dyes, applied in the field of plant dye extraction devices for textiles, can solve problems such as plant waste, pigment extraction, and inability to meet people's needs for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

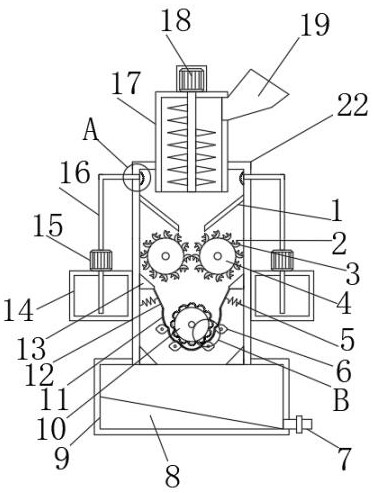

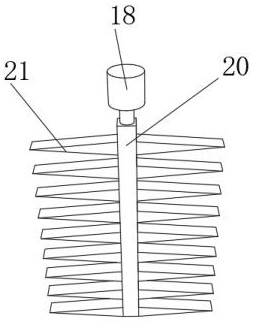

[0029] refer to Figure 1-5 , a plant dye extraction device for textiles, comprising a working box 22, the top outer wall of the working box 22 is provided with a feeding port, and the inner wall of the feeding port is inserted with a crushing box 17, and the top outer wall of the crushing box 17 is fixed by screws. Motor 18, and the output shaft of motor 18 is connected with rotating rod 20 by shaft coupling, and the outer wall of rotating rod 20 is fixed with the pulverizer 21 of equidistant distribution by screw, and one side outer wall of working box 22 is fixed with rotary motor by screw, and The output shaft of the rotating motor is connected with a crushing roller 4 through a coupling, and the outer wall of the crushing roller 4 is fixed with crescent-shaped crushing knives 3 distributed in an equidistant ring by screws, and the outer wall of the crescent-shaped pulverizing knife 3 is welded with crushing teeth 2. The inner walls of both sides of the box 22 are fixed wi...

Embodiment 2

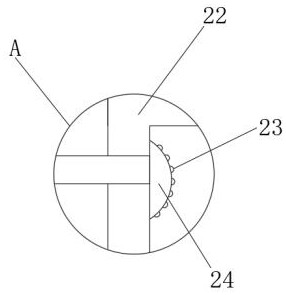

[0038] refer to figure 1 , a plant dye extraction device for textiles. Compared with Embodiment 1, this embodiment also includes that the outer walls of both sides of the working box 22 are fixed with water tanks 14 by screws, and the top outer walls of the water tank 14 are fixed with water pumps 15 by screws. The output end of the water pump 15 is socketed with a water pipe 16, and the end of the water pipe 16 away from the water pump 15 is socketed with a spray block 24. The outer wall of the spray block 24 is provided with spray holes distributed equidistantly, and the inner wall of the spray hole is inserted with an atomizer. Nozzle 23.

[0039] The water pump 15 can pump water from the water tank 14 and enter the working box 22 through the atomizing nozzle 23. On the one hand, the clean water can wash away the slag bonded to the crushing roller 4, and on the other hand, it can soak the slag in the filter cloth 11. , which can make it easier for the plant pigment to be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com