Efficient powder mixing equipment

A mixing equipment and powder technology, applied in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problems of increasing production costs, increasing production costs, and large motors, saving production costs and increasing mixing. The effect of area and material mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

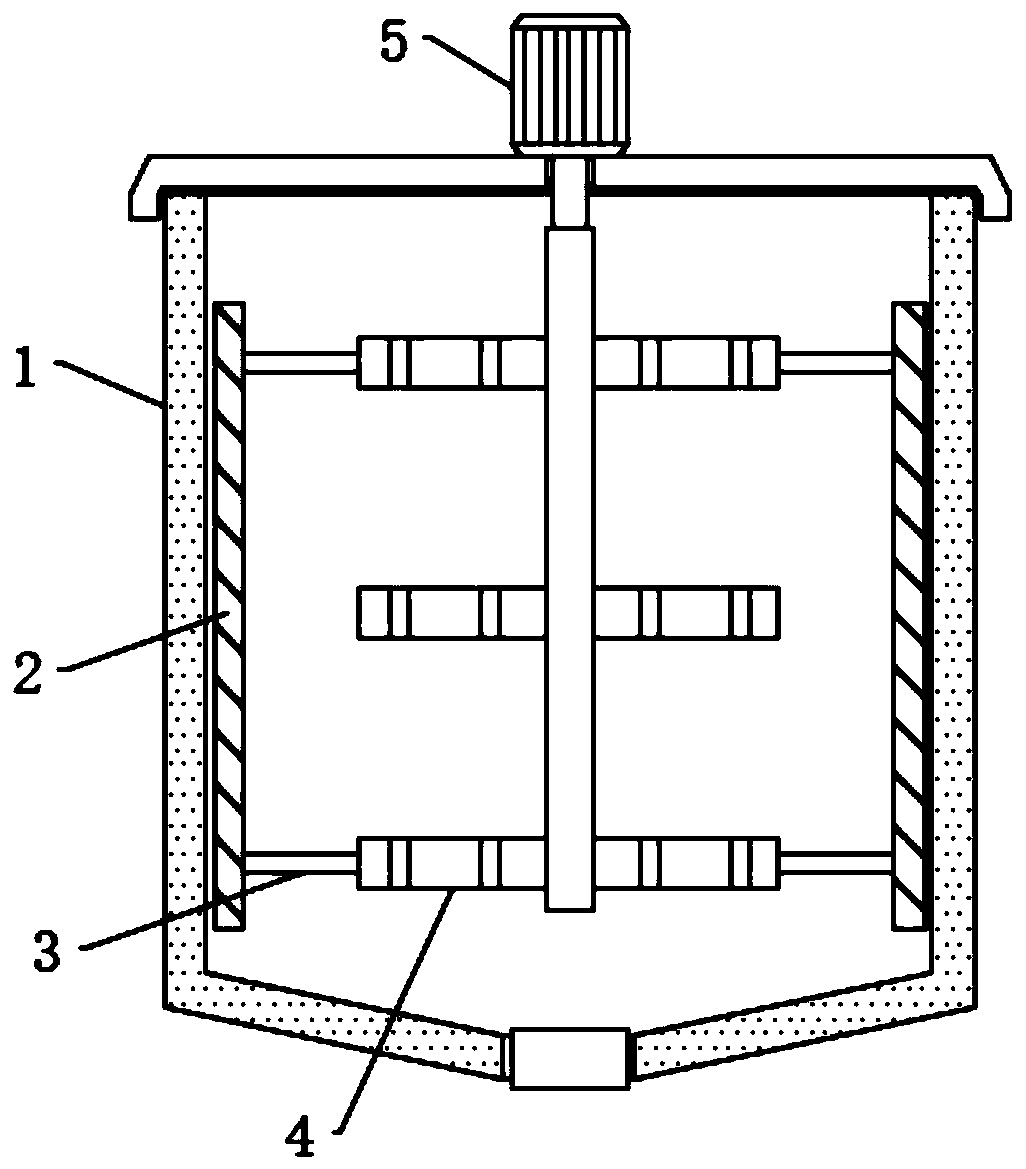

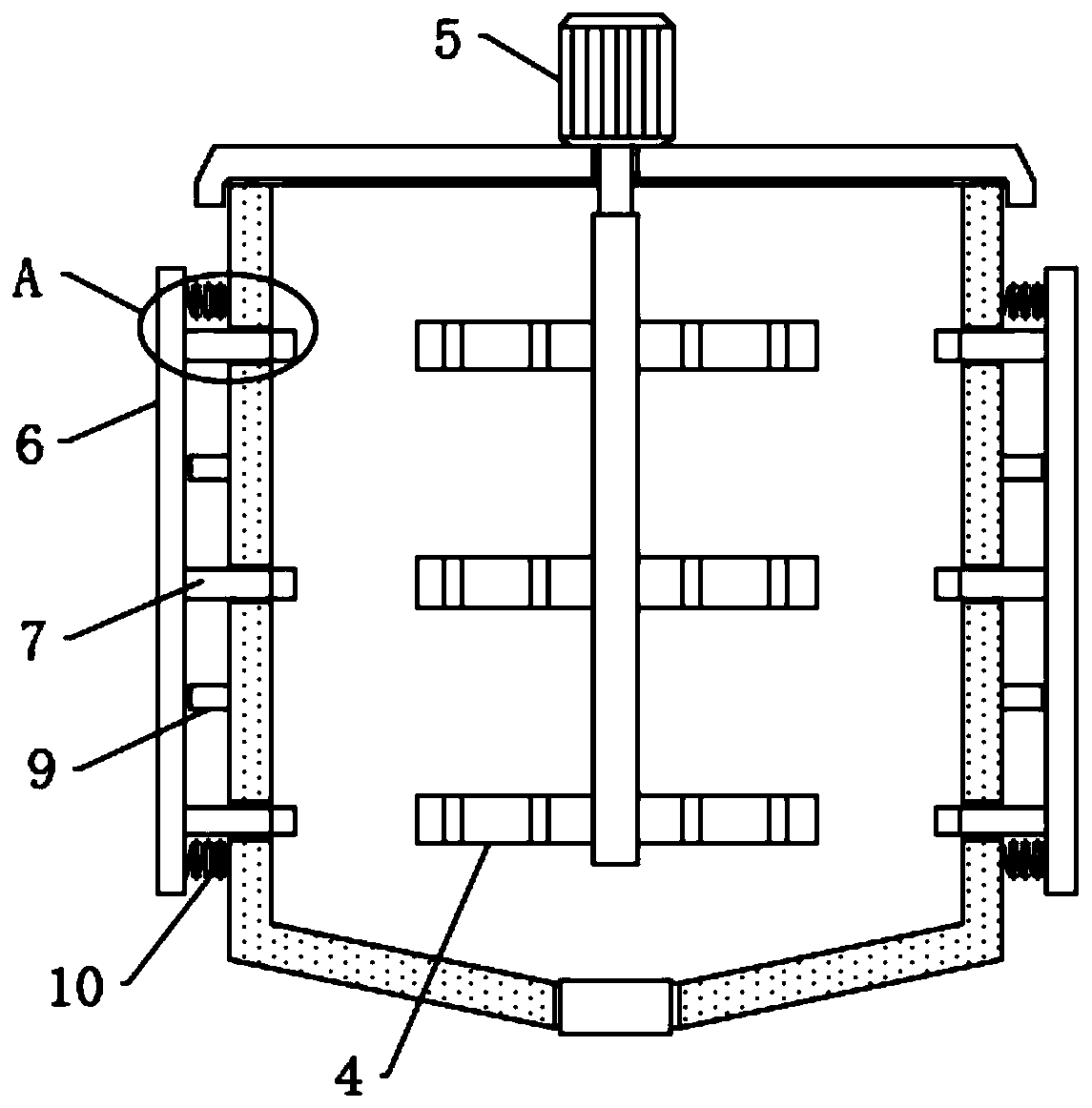

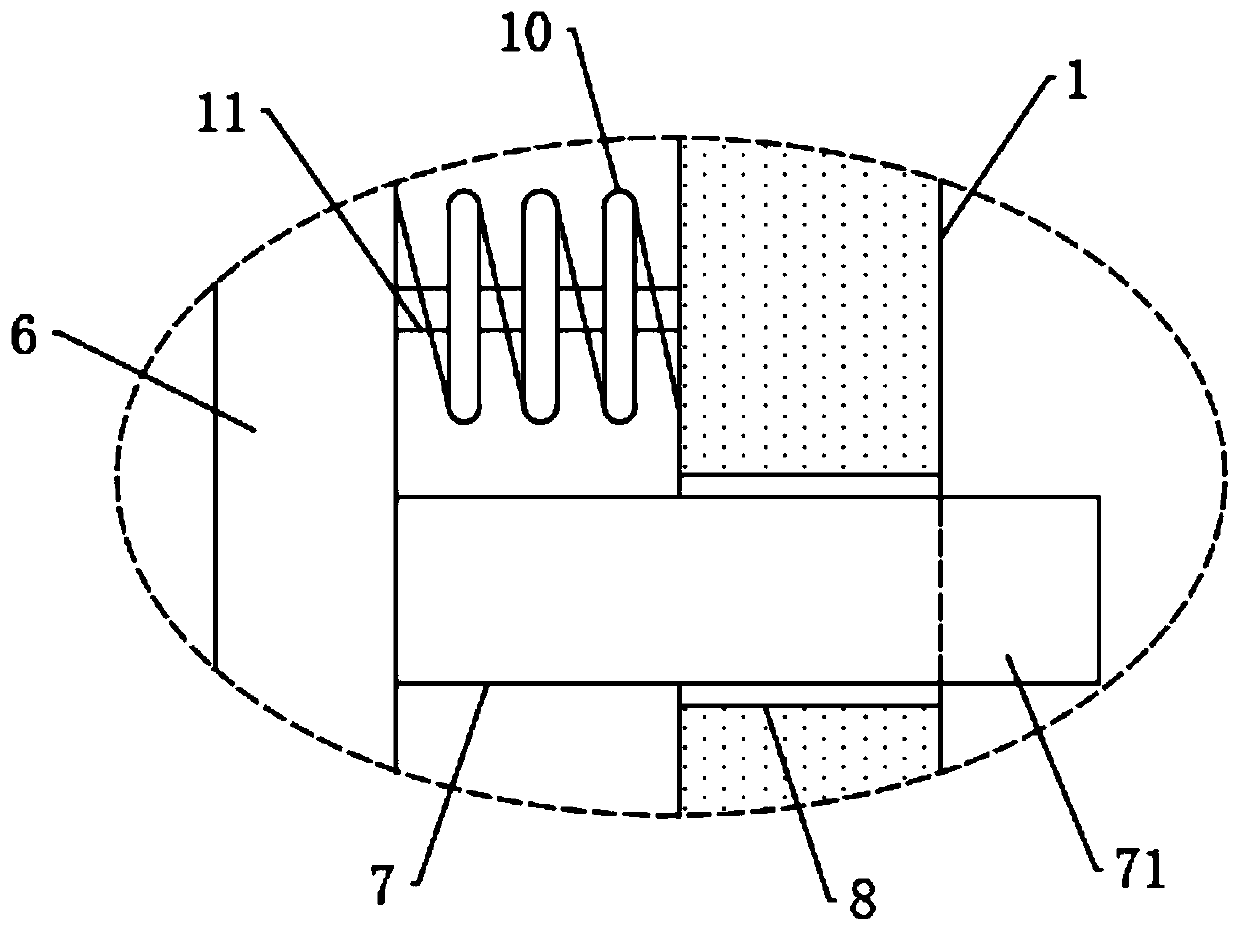

[0043] see figure 1 , a high-efficiency powder mixing equipment, including a mixing equipment body 1 with an upper cover, the mixing equipment body 1 is provided with a stirring structure for uniform mixing of materials, and the mixing equipment body 1 is also provided with at least one The scraper is used to make the inner wall of the mixing device body 1 not easy to adhere to the material. The scraper is connected with the stirring structure. There are several sets of vibrating parts outside the mixing device body 1. The scraper is inside the mixing device body 1. The circumferential motion of the vibrating element drives the vibrating element to vibrate on the main body 1 of the mixing equipment.

[0044] The stirring structure includes a rotating motor 5, which is fixedly connected with the upper cover of the mixing device body 1, the output end of the rotating motor 5 penetrates the upper cover and extends into the mixing device body 1, and the rotating motor 5 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com