Rebar discharging method

A technology for steel bars and blanking, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

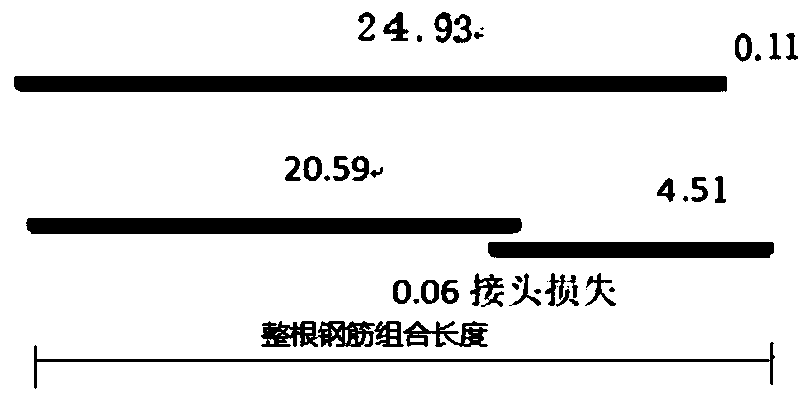

[0088] The steel bar blanking method provided by the embodiment of the present invention considers multiple problems such as the length of the remaining raw material two steel bars after cutting, the waste rate of the steel bar, and the middle span of the beam, and can maximize the use of the entire steel bar, reduce the waste rate of the steel bar, and significantly reduce Cutting times and welding times reduce material and labor costs.

[0089] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

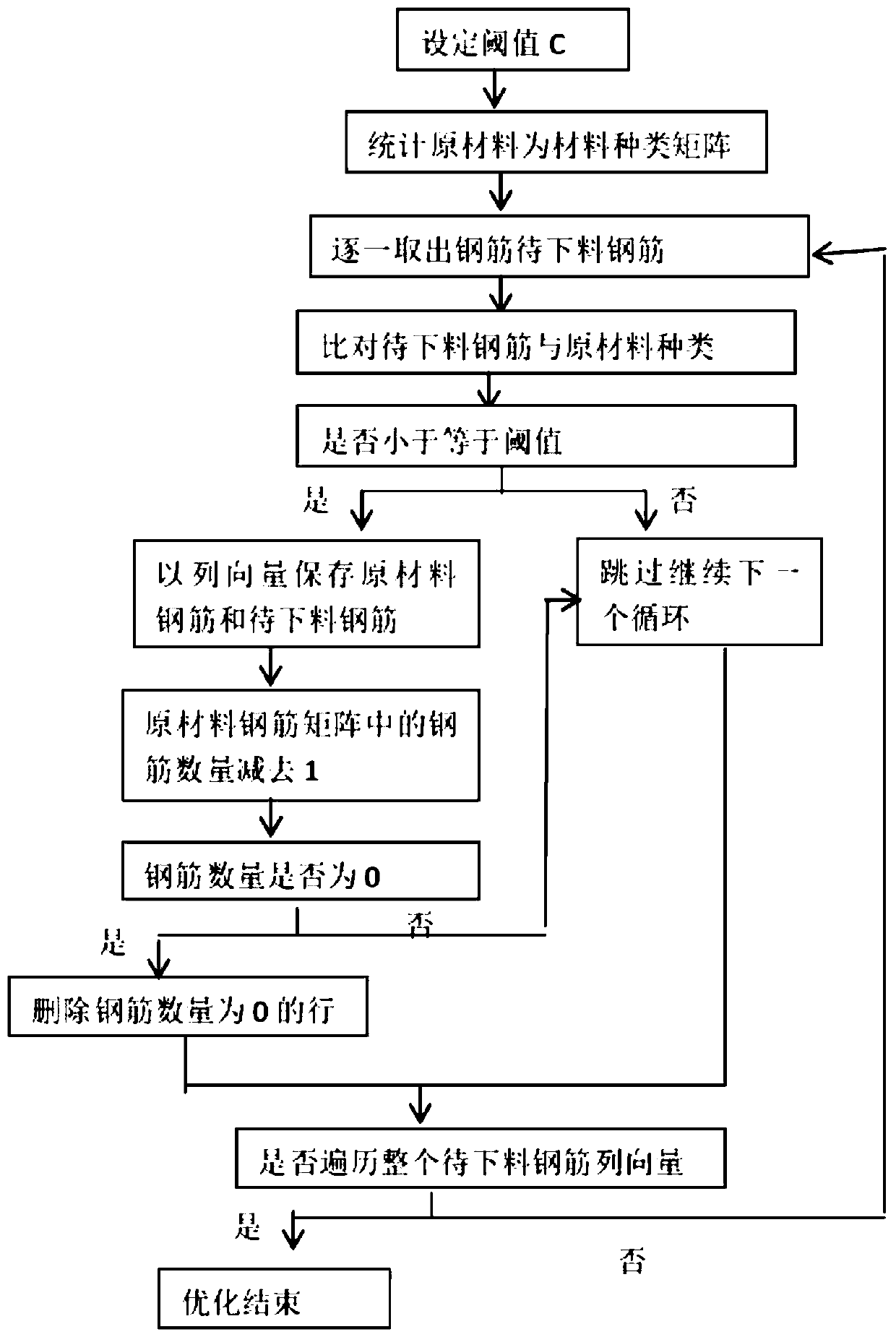

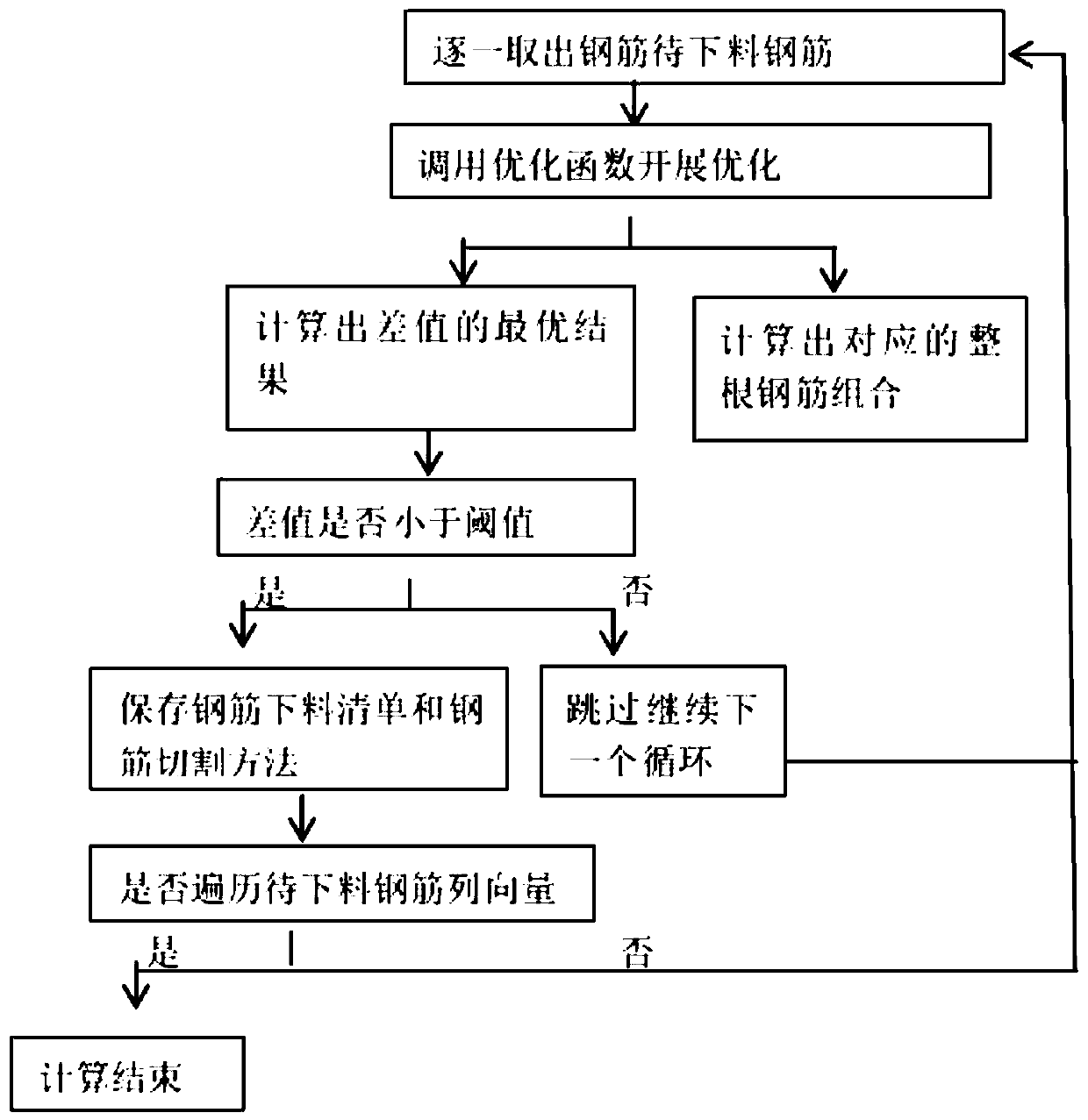

[0090] The reinforcing bar blanking method that the embodiment of the present invention provides, comprises the steps:

[0091] Step 1: Collect the length of steel bar to be cut and the length of raw material steel bar:

[0092] Specifically, you can call th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com