Unsymmetrical stretching forming mould capable of inducing plate material to rebound

A stretch forming, asymmetric technology, applied in the field of sheet metal forming, can solve problems such as the complexity of the measurement process, the difference, the impact of the springback placement method, etc., and achieve the reduction of cutting times, good similarity, test repeatability and reproducibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

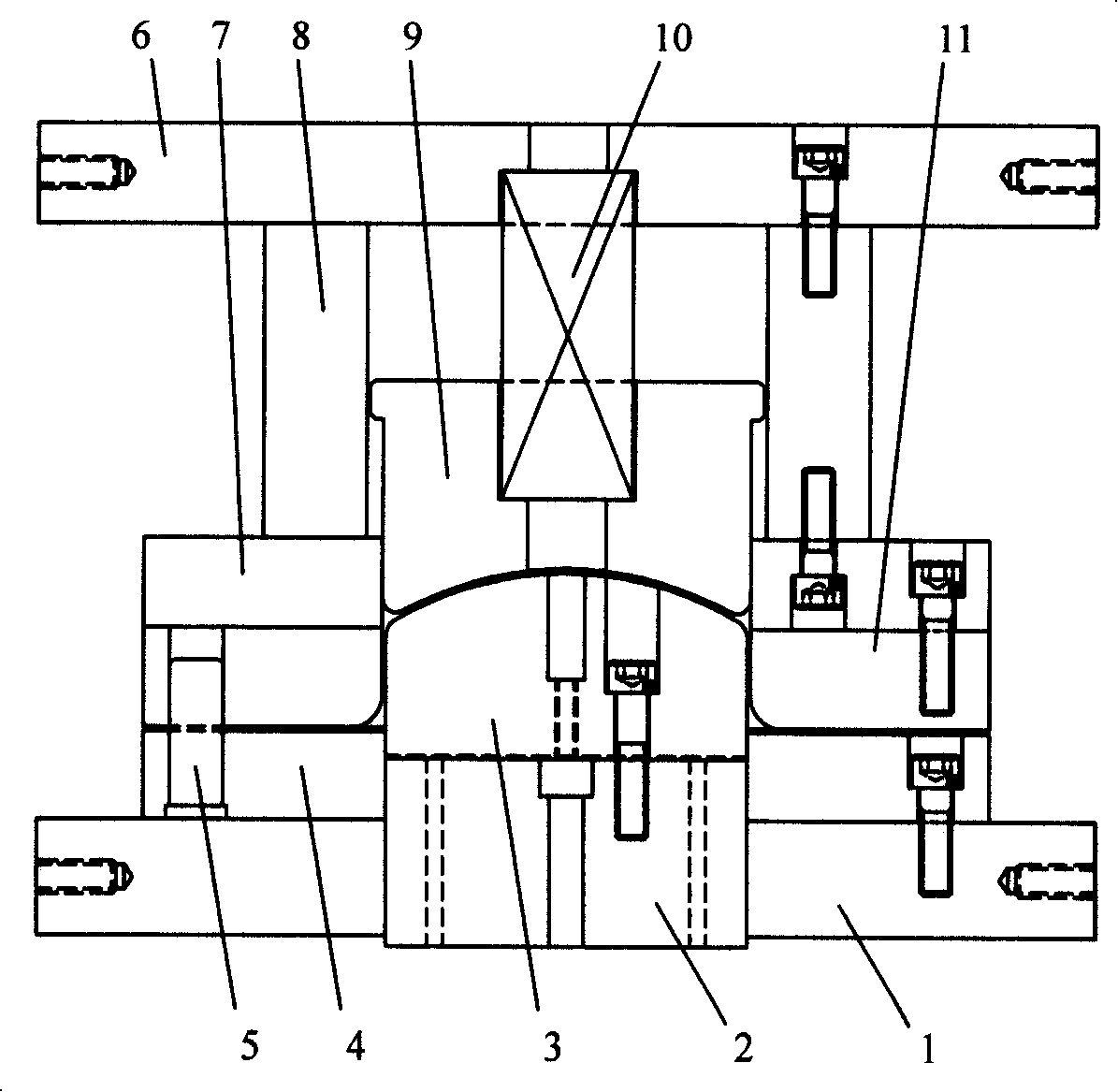

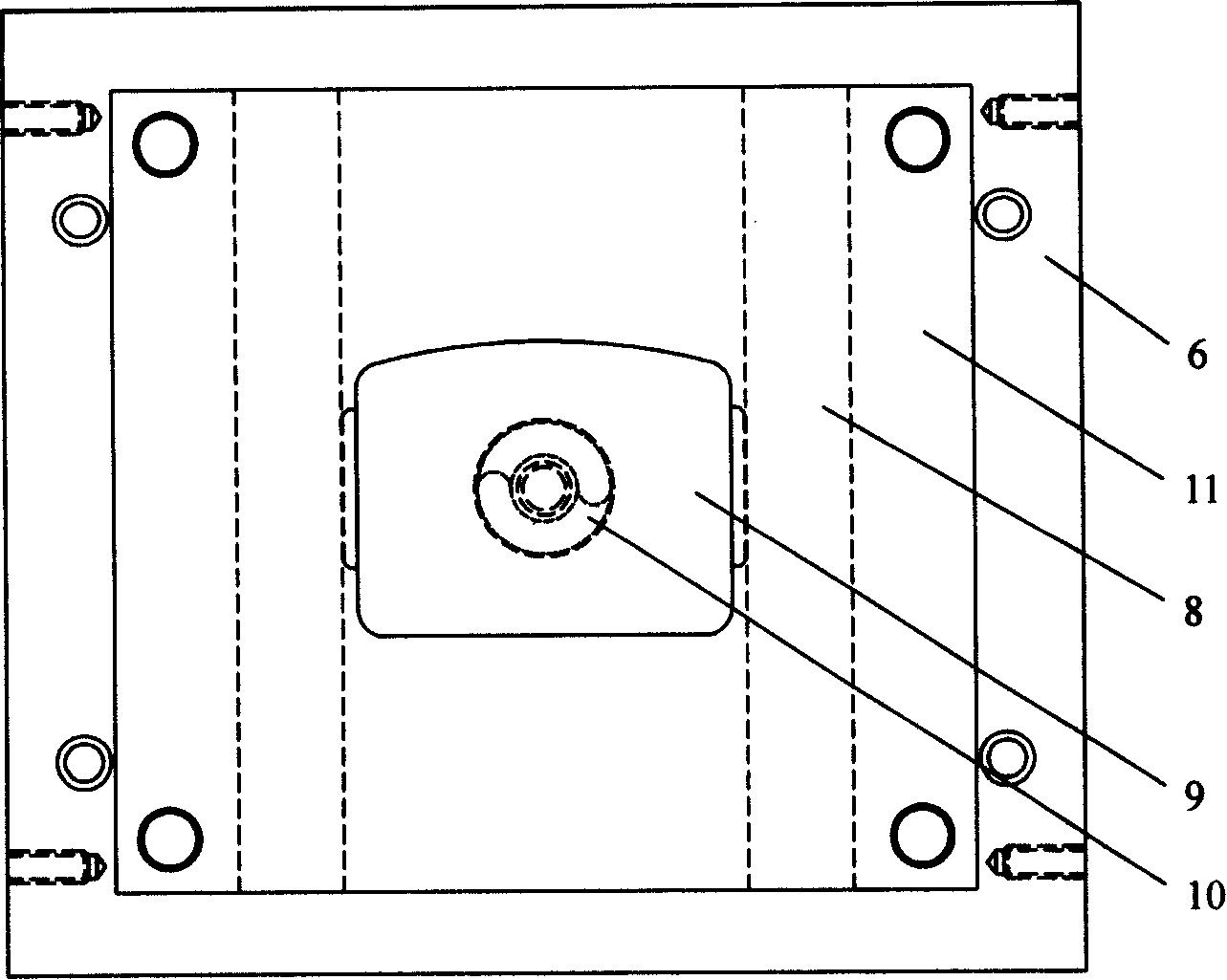

[0015] figure 1 It is a schematic diagram of the structure of the asymmetric stretch forming die for inducing the rebound of sheet metal in the present invention, including: punch 3, die 11, blank holder 4, punch fixing plate 2, die backing plate 7, lower template 1, Upper template 6, upper mold backing plate 8, shoulder-shaped guide post 5, push piece block 9, spring 10. The connection relationship is: the punch 3 is connected with the punch fixing plate 2 through screws, and is connected with the lower moving mechanism of the stamping equipment; the blank holder 4 is connected with the lower template 1 through screws, and is connected with the workbench; Sliding connection with the die 11 through the shoulder-shaped guide post 5; the die 11 is connected with the die backing plate 7, the upper die backing plate 8 and the upper template 6 through screws, and is connected with the upper slider of the equipment.

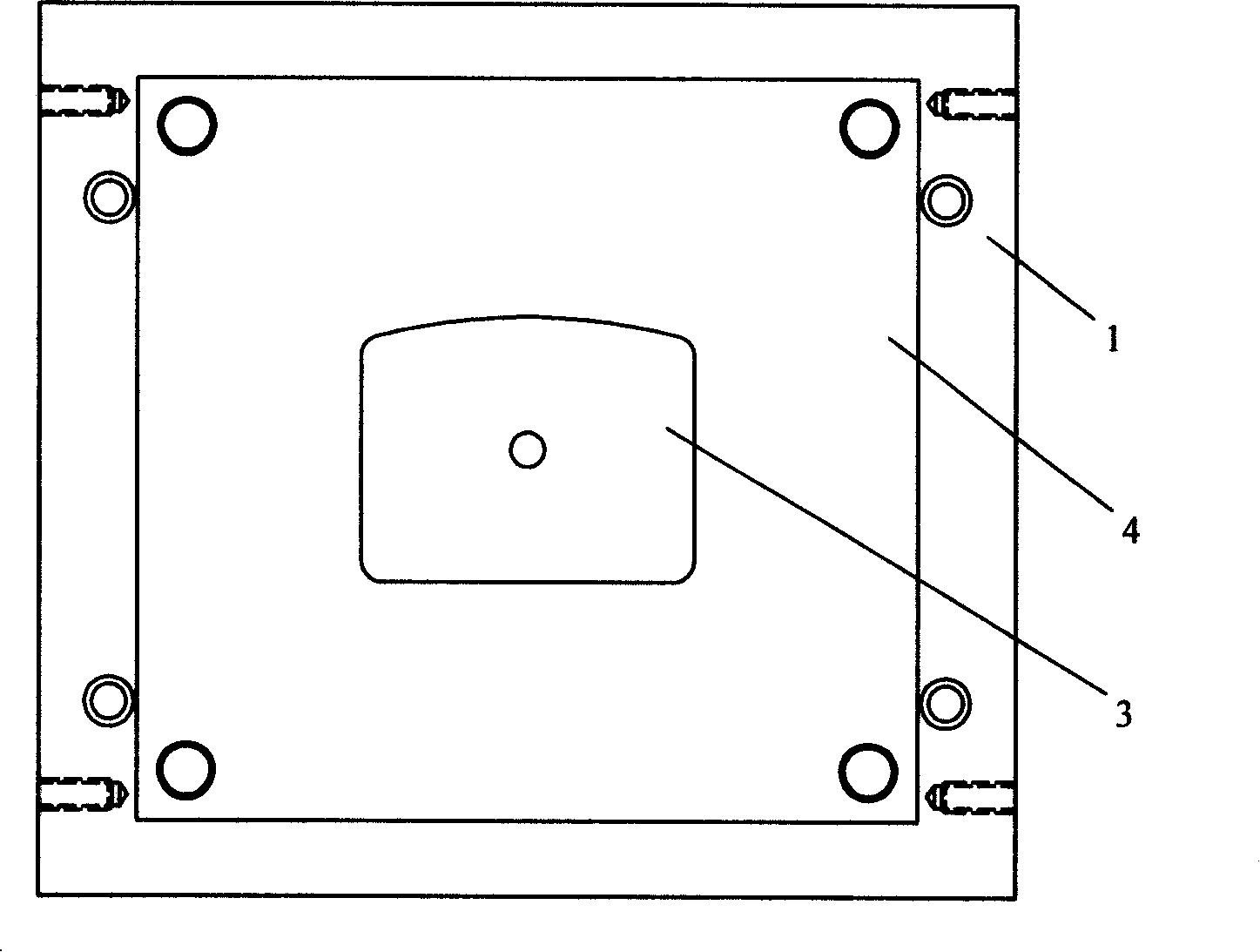

[0016] figure 2 It is a schematic diagram of the lower mold pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com