Metal-coated sealing ring

A metal cladding and metal cladding technology, which is used in the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of only one-time use and small rebound amount, and achieves reduction of waste, enhancement of elasticity, and increased flexibility. The effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

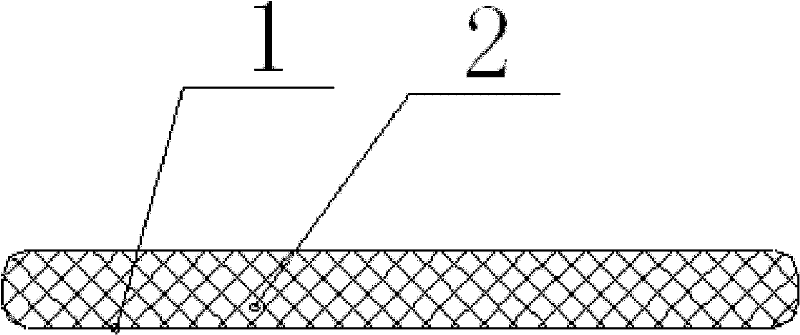

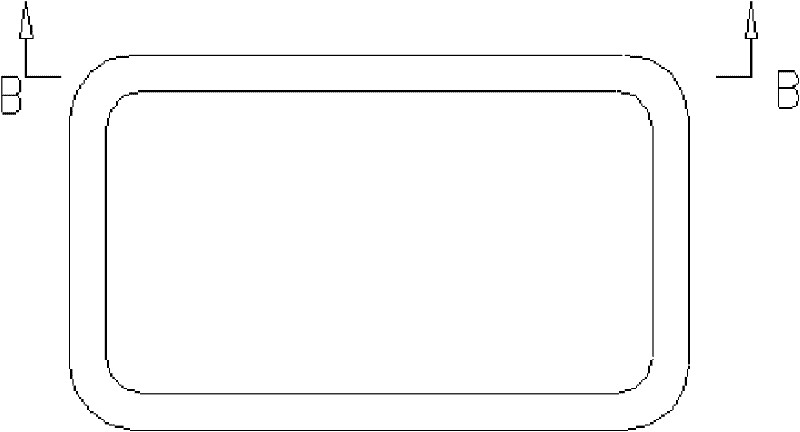

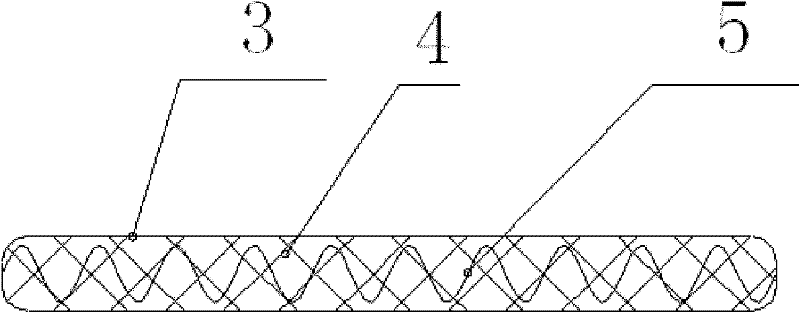

[0025] figure 2 It is a structural schematic diagram of a rectangular metal-clad sealing ring in an embodiment of the metal-clad sealing ring of the present invention, image 3 along figure 2 A schematic cross-sectional view of the B-B line in . Such as figure 2 with image 3 As shown, the metal clad sealing ring provided by the present invention includes a metal cladding layer 3 filler 4, and several layers of elastic skeletons 5 are also arranged in the metal cladding layer 3, and each layer of the elastic skeleton 5 includes several strips Elastic skeleton5. In this embodiment, the metal clad sealing ring is rectangular, and the material of the metal cladding layer 3 can be any material mentioned in Article 3.2 of the metal clad high temperature sealing ring YB / T4059-2007 . The filler 4 can be any material mentioned in Article 3.2 of the metal-clad high-temperature sealing ring YB / T4059-2007. In this embodiment, the elastic skeleton 5 is a layer of corrugated meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com