Argon ion polishing/scanning electron microscope analyzing and sampling method for shale samples

An argon ion polishing and scanning electron microscope technology, applied in the field of petroleum geology, can solve the problems of inability to analyze shale samples, difficult to obtain bulk samples, easy to break, etc., to improve the success rate of sample preparation, facilitate cutting operations, and reduce cutting times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Argon ion polishing / scanning electron microscope sample preparation of brittle shale core samples

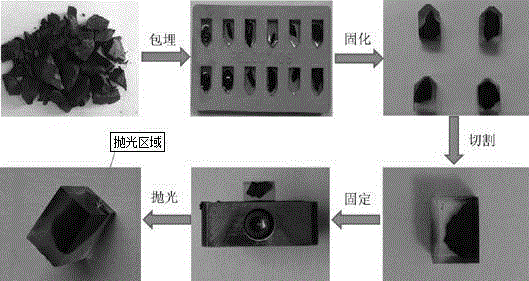

[0021] Such as figure 2 As shown, the steps of argon ion polishing / scanning electron microscope sample preparation for friable shale core samples are as follows:

[0022] (1) Embedding: Mix the embedding agent Eponate12 according to the ratio of resin monomer / DDSA / NMA / DMP-30=1 / 0.2 / 0.49 / 0.01, and remove air bubbles for later use. Place the shale sample in the embedding plate, slowly add the prepared embedding agent, and remove all air bubbles.

[0023] (2) Curing: The embedding plate embedded with the shale core sample was placed in an oven and cured at 60°C for 24 hours.

[0024] (3) Cutting: Take out the solidified shale core embedding sample from the embedding plate, cut it into a regular cuboid shape with a precision slicer, and ensure that the polished section of the shale sample is exposed.

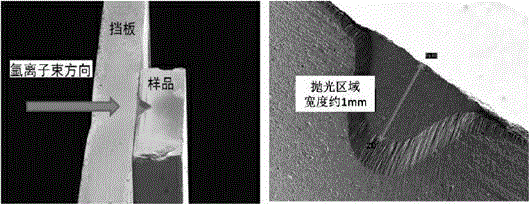

[0025] (4) Polishing: stick the cut shale core embedded sampl...

Embodiment 2

[0026] Example 2 Argon ion polishing / scanning electron microscope sample preparation of shale cuttings samples

[0027] The steps of argon ion polishing / scanning electron microscopy sample preparation of shale cuttings samples are as follows:

[0028] (1) Embedding: Mix the embedding agent Eponate12 according to the ratio of resin monomer / DDSA / NMA / DMP-30=1 / 0.1 / 0.59 / 0.01, and remove air bubbles for later use. Place the shale sample in the embedding plate, slowly add the prepared embedding agent, and remove all air bubbles.

[0029] (2) Curing: The embedding plate embedded with the shale cuttings sample was placed in an oven and cured at 60°C for 16 hours.

[0030] (3) Cutting: Take the solidified shale cuttings embedded sample out of the embedding plate, place it in a precision microtome, cut it into a regular cuboid shape, and ensure that the polished section of the shale sample is exposed.

[0031] (4) Polishing: stick the cut shale cuttings embedding samples on the baffle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com