Sensing optical fiber and optical fiber sensing device

A technology for sensing optical fibers and optical fibers, which is applied to cladding optical fibers, measuring devices, optical waveguides, etc., can solve problems such as result errors, increased loss of sensing optical fiber interfaces, and increased workload, so as to reduce workload and avoid Increased interface loss and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

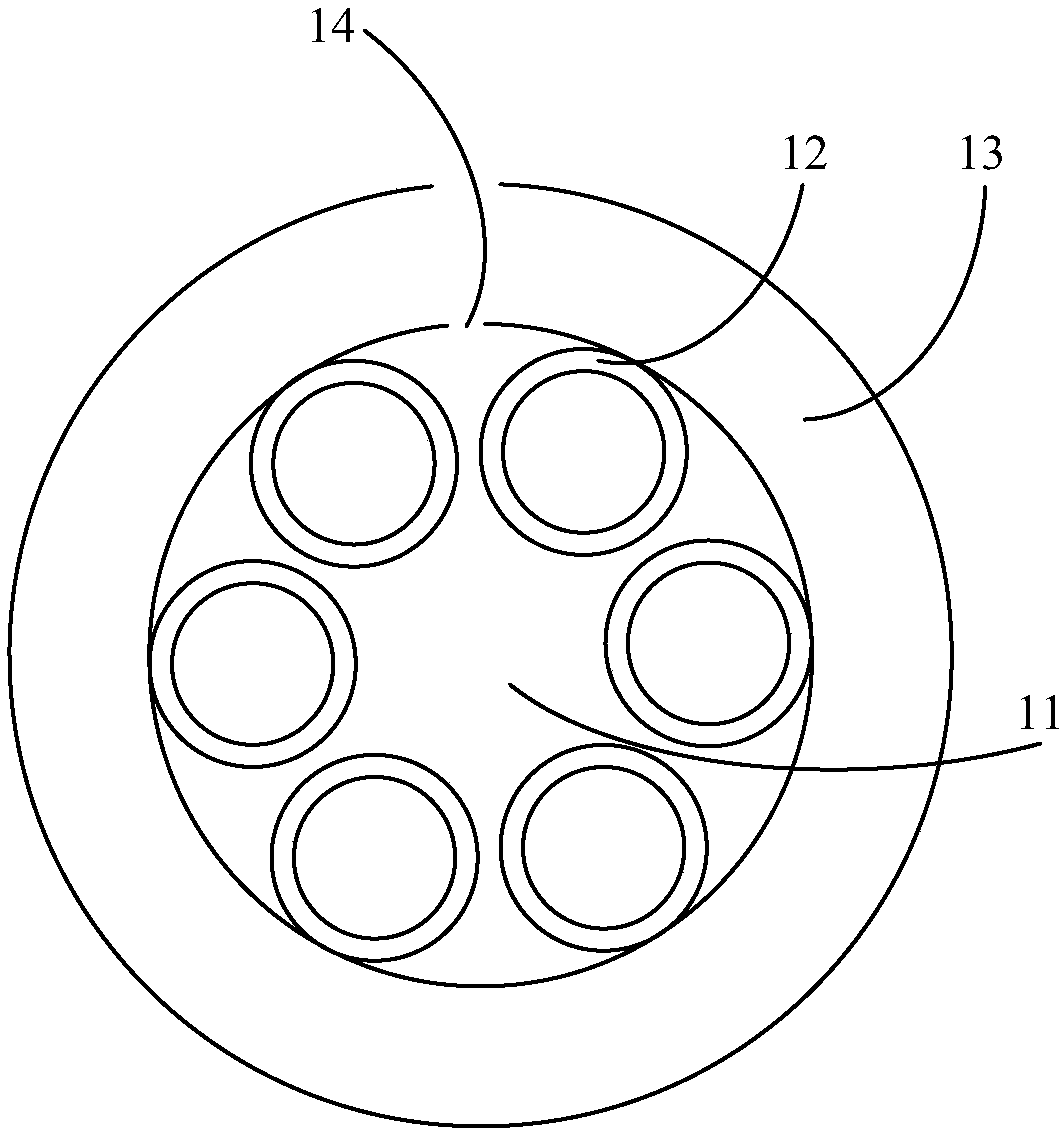

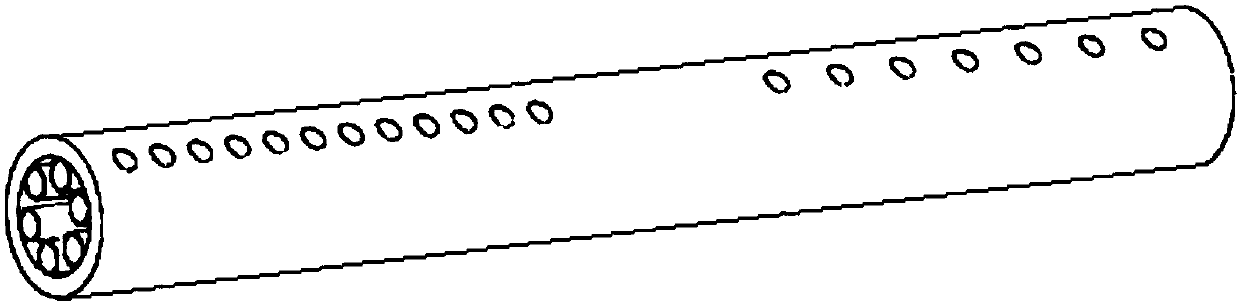

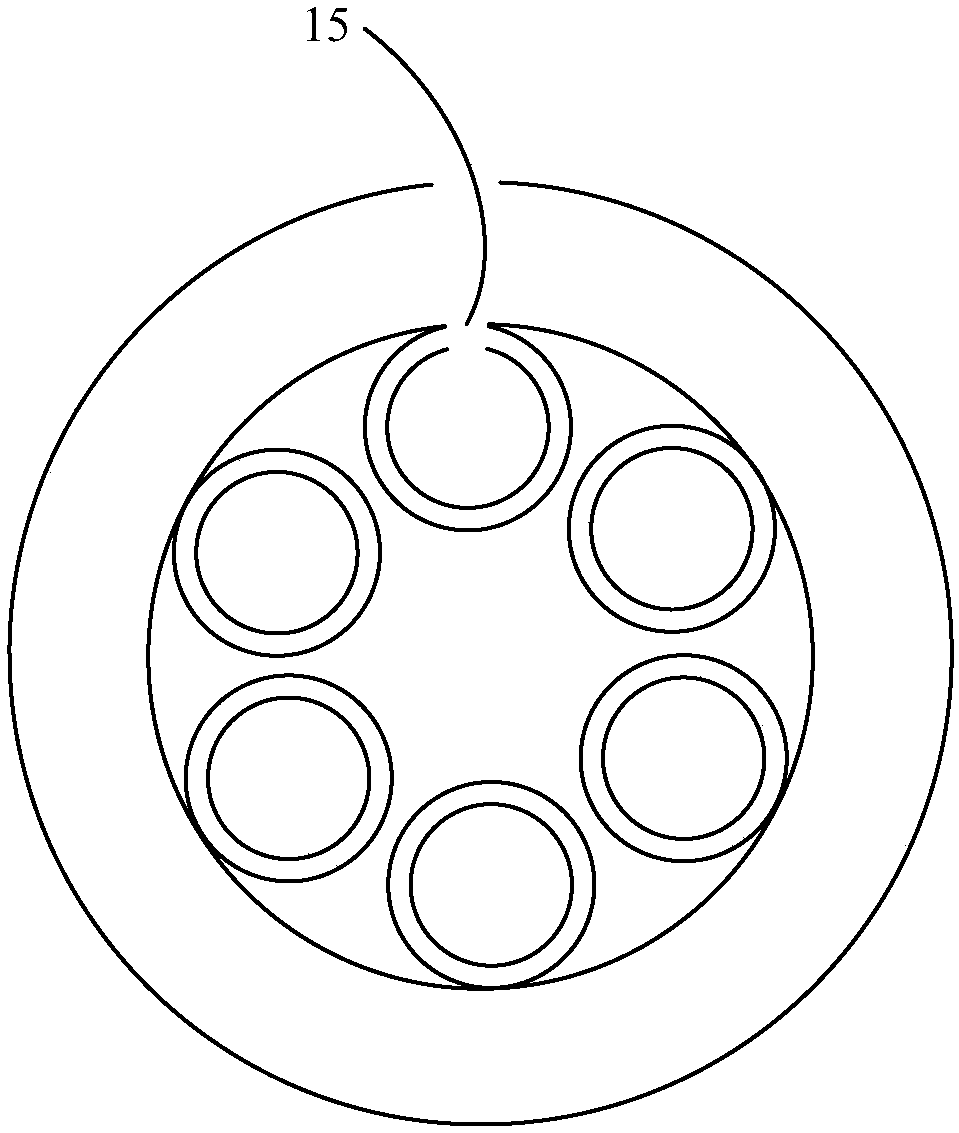

[0025] An embodiment of the present invention provides a sensing optical fiber, the sensing optical fiber is a hollow core antiresonant optical fiber; The core area surrounded by the area; the hollow tube is sleeved on the outside of the cladding area; the refractive index of the core area is lower than the refractive index of the cladding area; for the side of the hollow tube A plurality of preselected position groups, each preselected position group is provided with a through hole, and all preselected positions in each preselected position group are arranged along the central axis direction of the sensing fiber.

[0026] Specifically, the cladding region in the hollow-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com