Screw vacuum pump rotor profile

A screw vacuum pump and rotor profile technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of incomplete meshing curve, low wear resistance, poor sealing, etc., to improve wear resistance, The effect of high volumetric efficiency and high area utilization factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

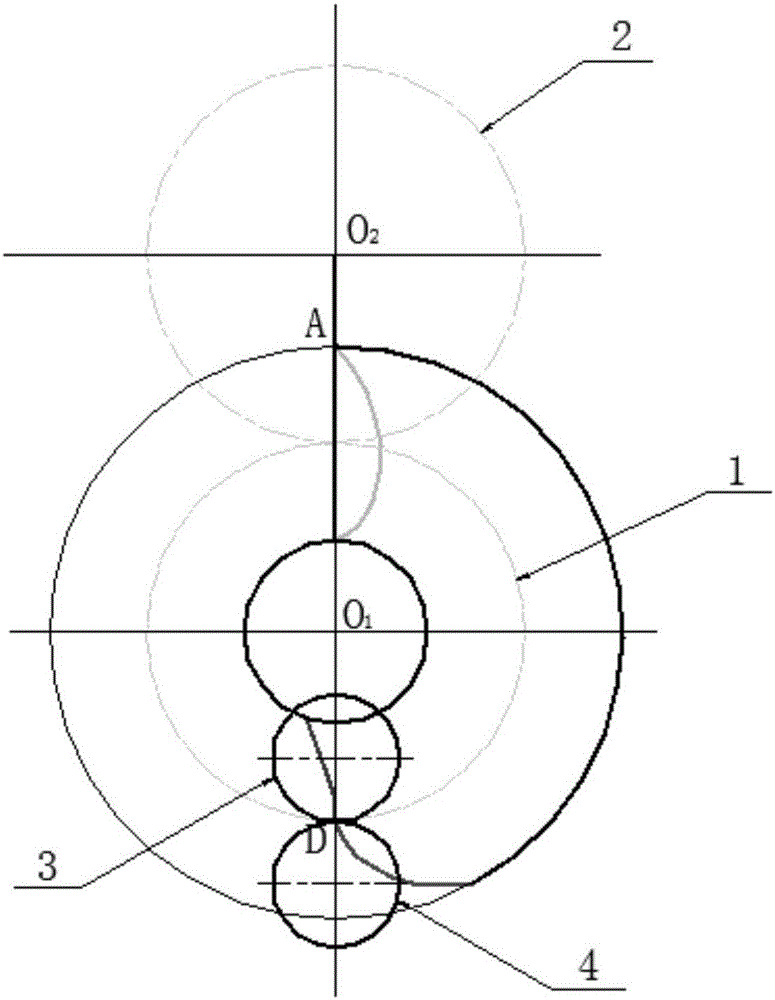

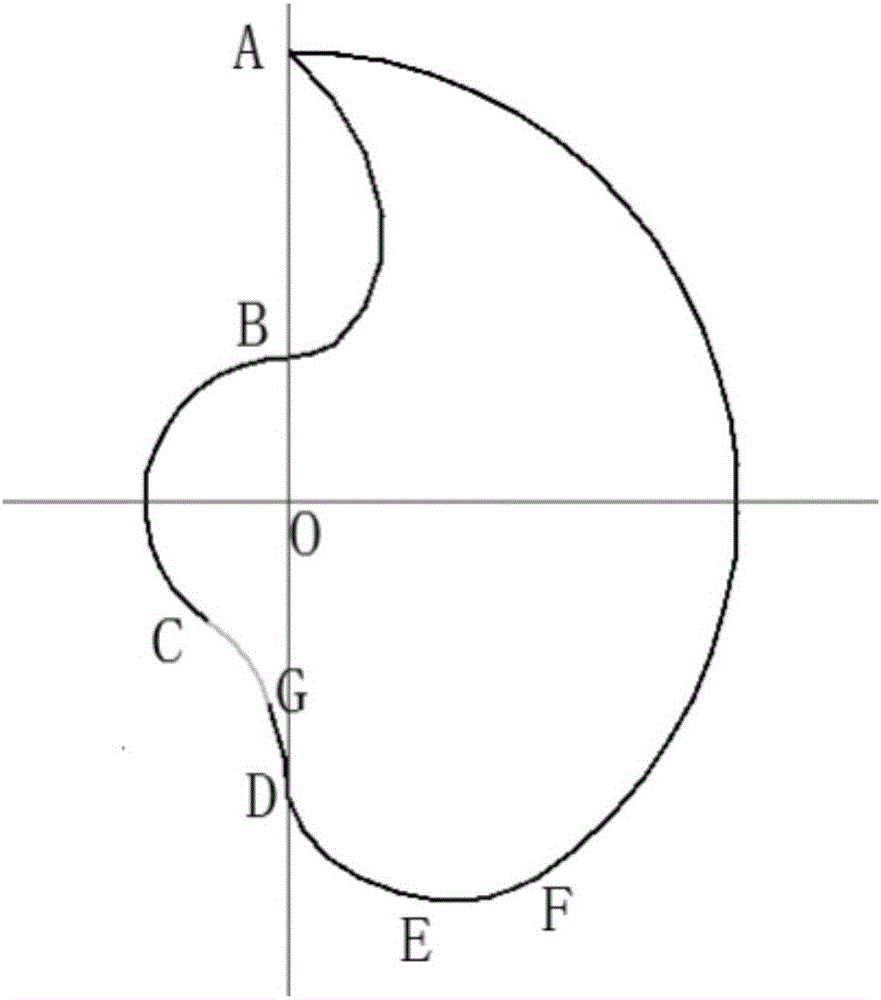

[0017] Attached below Figure 1-2 A specific implementation manner of a screw vacuum pump rotor profile of the present invention is further described.

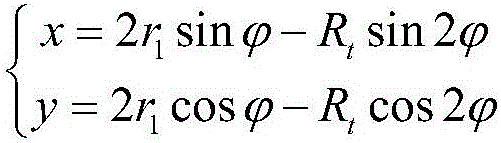

[0018] Depend on figure 2 It can be seen that the tooth profile of the screw section is mainly composed of a long epicycloid AB with a radius of R r The dedendum circle BC of radius r 1 -R r The transition circle CG, hypocycloid GD, epicycloid DE, radius R t -r 1 The transition circle EF and radius R t Composed of the addendum circle FA, and the hypocycloid GD and epicycloid DE are smoothly connected at point D, by figure 1 visible figure 2 The formation mechanism of each segment of the curve.

[0019] The formation mechanism of the long epicycloid AB is: the base circle 1 and the generating circle 2 whose radii are both pitch circles, and when the generating circle 2 rolls counterclockwise along the base circle 1 without slipping, it is fixed at a point A on the generating circle 2 The trajectory of the motion is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com