Continuous torque regulator

a technology of continuous torque and torque regulator, which is applied in the direction of differential gearings, toothed gearings, fluid gearings, etc., can solve the problems of poor use of input torque, limited torque to be transmitted, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

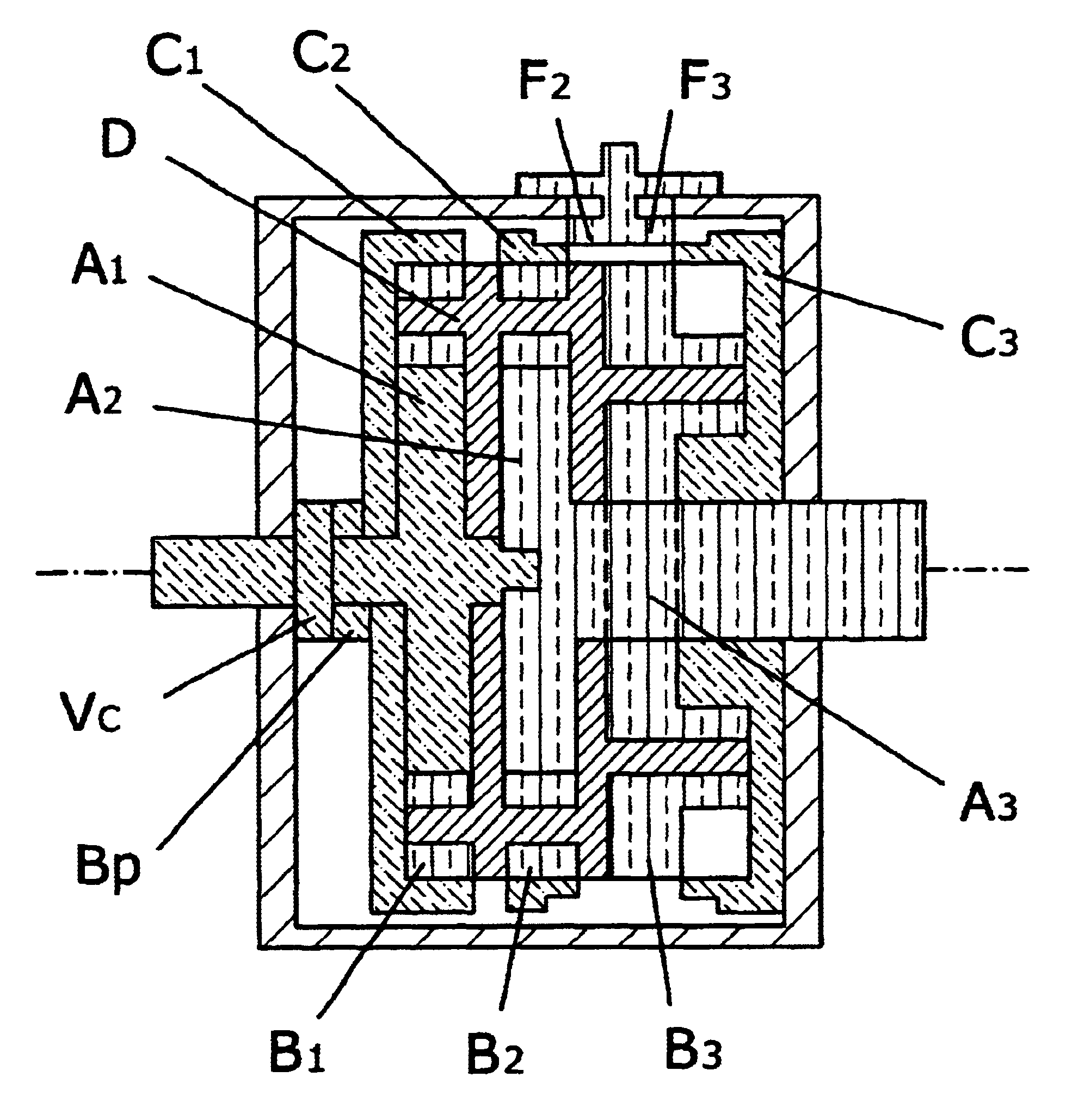

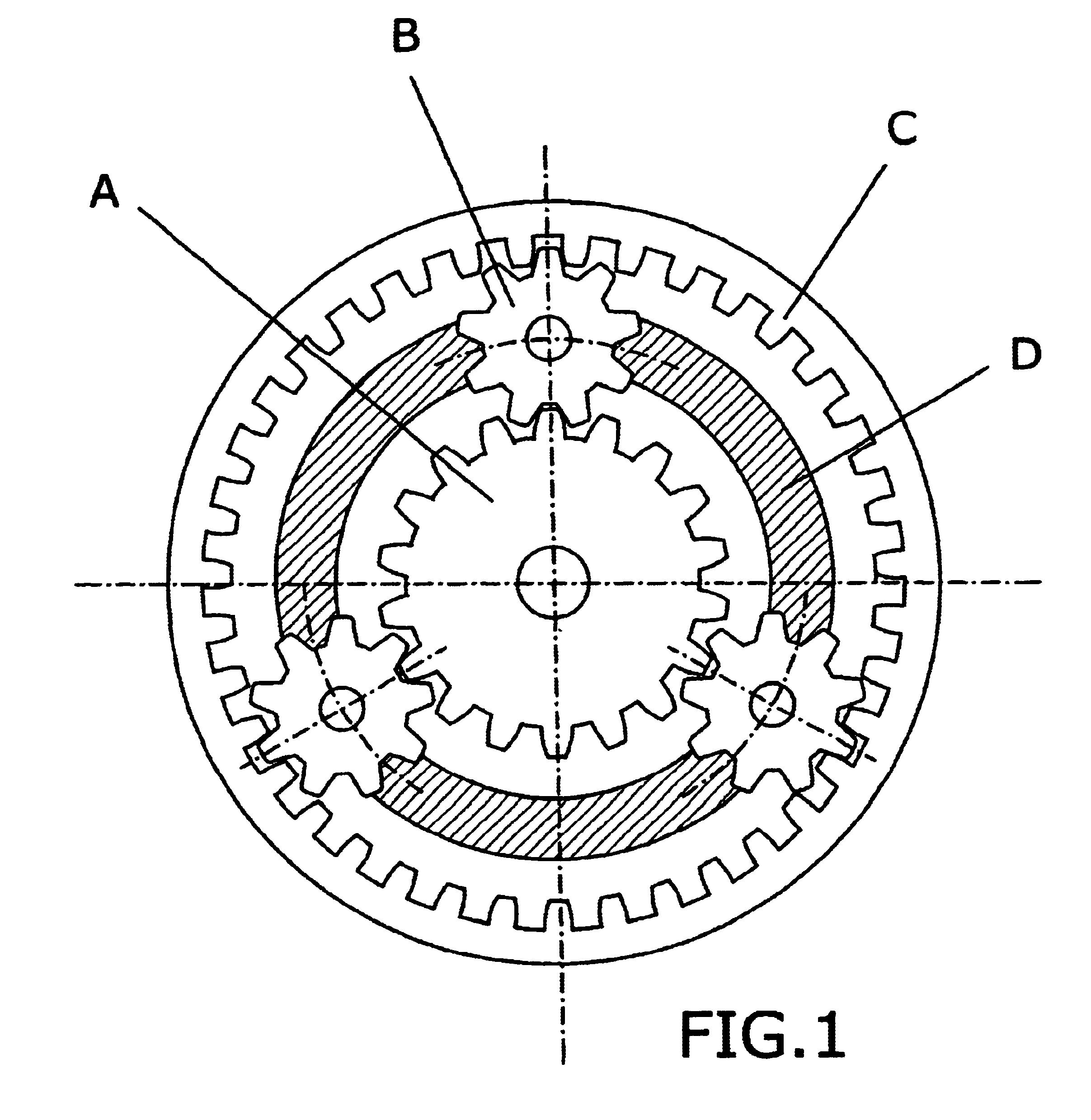

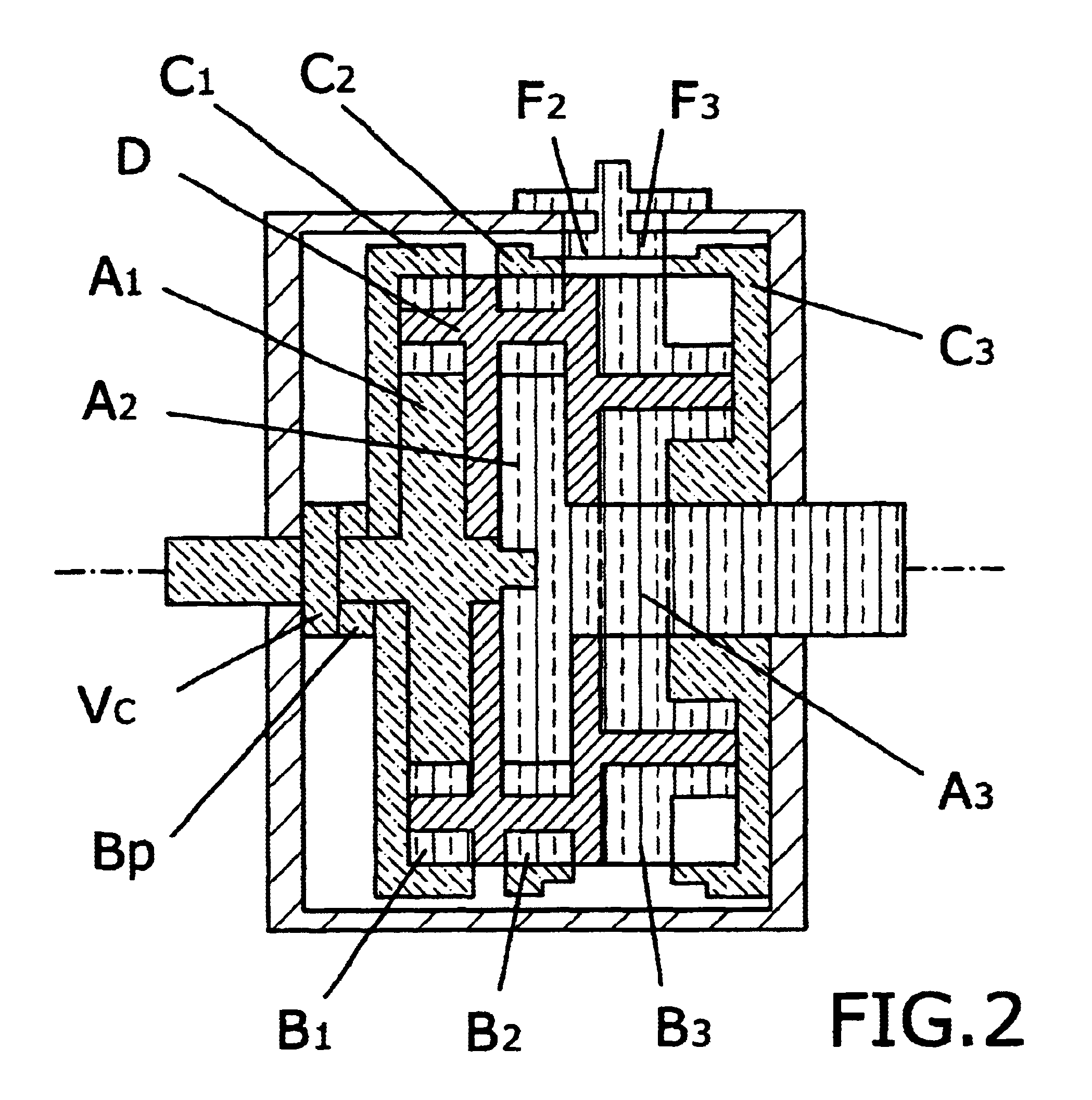

The proposed invention of a continuous torque regulator consists of a mechanism based on a series of epicycloid gears. An epicycloid gear mechanism is formed by a pinion termed planetary gear which engages with two or three pinions arranged on its circumference, which are given the name of satellite pinions. The driving shafts of the satellite pinions are joined to each other through a frame in such a manner that the relative position is maintained of the three satellite pinions. These satellite pinions are located inside a crown wheel which, toothed on the inside, engages with these satellite pinions.

The continuous torque regulator assembly is formed by three epicycloid gears in which the first and second epicycloid gears are tied by means of a frame which joins the shafts of the satellite gears of the epicycloid gears. The third gear likewise has a planetary gear, but which in this case is joined to the planetary gear of the second epicycloid gear. This third gear also has satelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com