Cycloid oscillating tooth speed reducer with mechanical balance combined tooth surface raceway

A technology of movable tooth reducer and mechanical balance, applied in the field of movable tooth transmission, can solve the problems of increasing the difficulty of structural design and manufacturing of parts, and achieve flexible configuration, high torque/volume ratio, and improved rigidity of the whole machine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

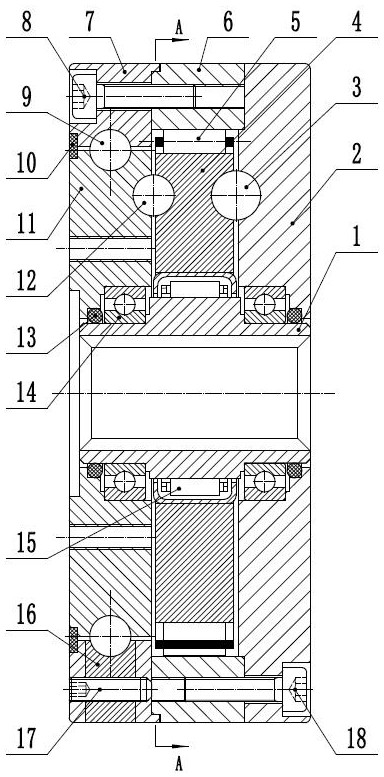

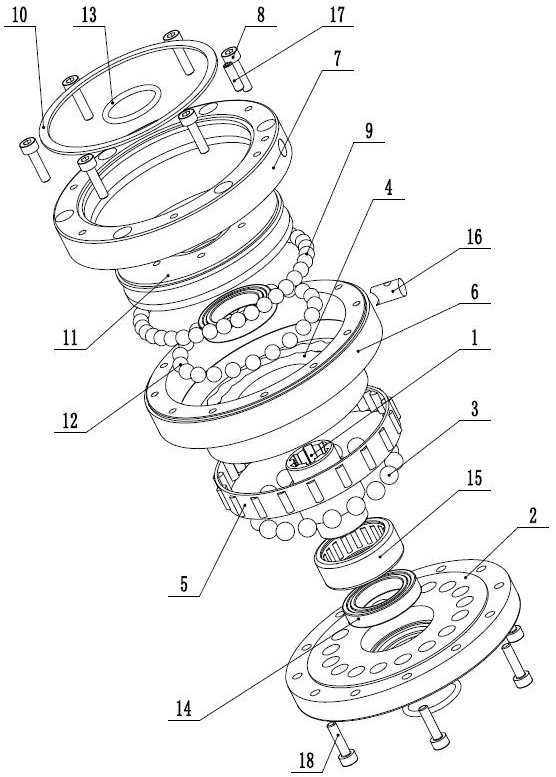

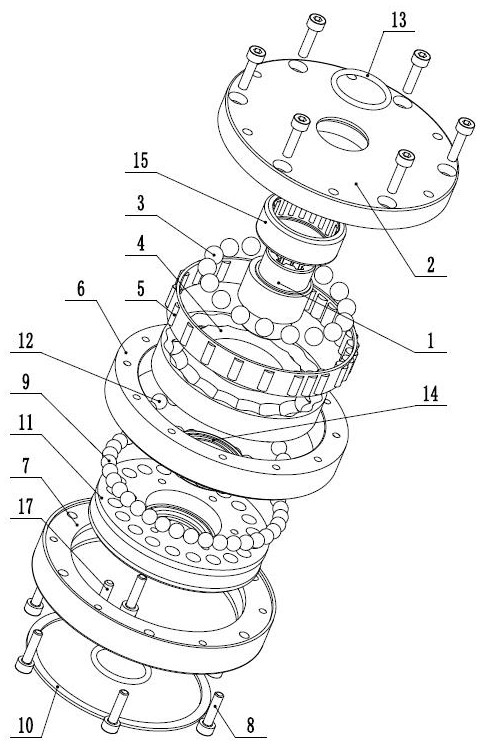

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0032] Figure 1-12 As a preferred embodiment of the present invention, the pictographic method is used to obtain symbolic meanings, the symbol "S" is used to represent the cycloidal raceway of the combined tooth surface, and the symbol "O" is used to represent the movable tooth groove, and S and the corresponding O are connected together to form a The movable tooth meshing pair and the movable tooth constitute a single-stage combined tooth surface raceway cycloid movable tooth transmission unit. As can be seen from the foregoing, the first movable tooth meshing pair, the second movable tooth meshing pair, the third movable tooth meshing pair, and the fourth movable tooth meshing pair, there are four in total, that is, two groups of movable tooth meshing pairs, which are respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com