Rubber screw rotor molding line applicable to screw-type volumetric pump

A technology of rotor profile and positive displacement pump, applied in rotary piston pump, rotary piston machine, pump, etc., can solve the problem that the end profile cannot be applied to rubber screw rotor, the speed of rubber screw rotor cannot be too fast, and the processing of rubber molding die complex problems, to achieve the effect of ideal overall efficiency, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

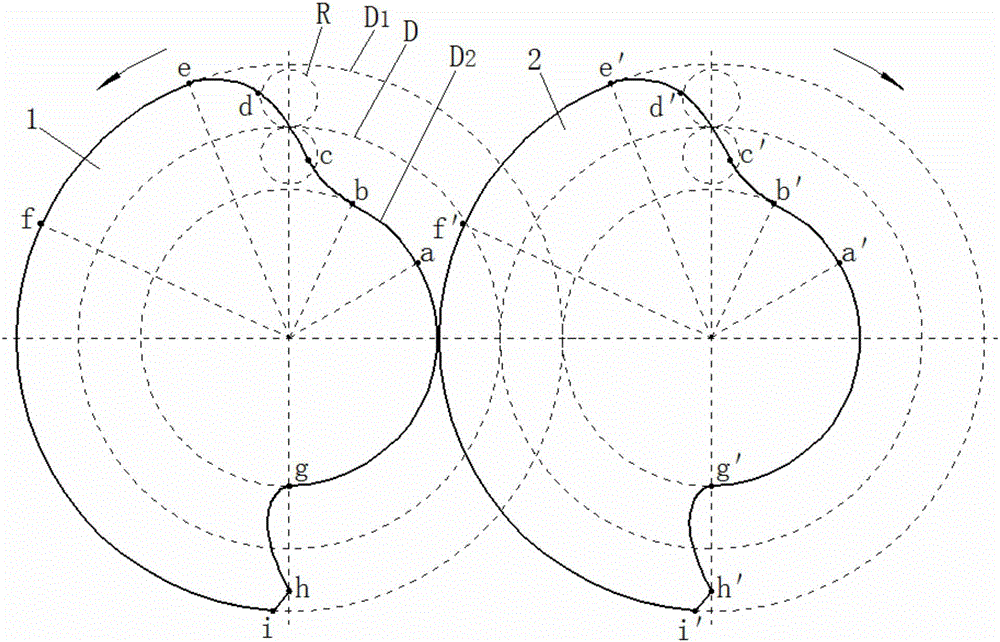

[0011] Example: see figure 1 , a rubber screw rotor profile suitable for screw positive displacement pumps, used for paired screw rotors with parallel shafts and reverse external meshing, of the two screw rotors, one is left-handed and the other is right-handed, and the profile lines of the two screw end surfaces are formed Conjugate relationship, the basic linear shape of the two screws adopts the B-type twin-screw profile, including the same two-section sealing curve g-h-i and five-section force transmission curve a-b-c-d-e-f, and the five-section force transmission curve a-b-c-d-e-f consists of a base circle D2 arc ab, A section of hypocycloid bc with small circle R as the moving circle on the pitch circle D as the fixed circle, a section of involute cd of the base circle D2, and a section with the small circle R as the moving circle on the pitch circle D as the fixed circle The epicycloid de of equal amplitude and the Archimedean spiral ef starting from the highest point e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com