Loaded tooth surface contact analysis method direct at epicycloid bevel gear errors

A technology of cycloidal bevel gear and contact analysis, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc., and can solve problems such as transmission error loading tooth surface contact analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

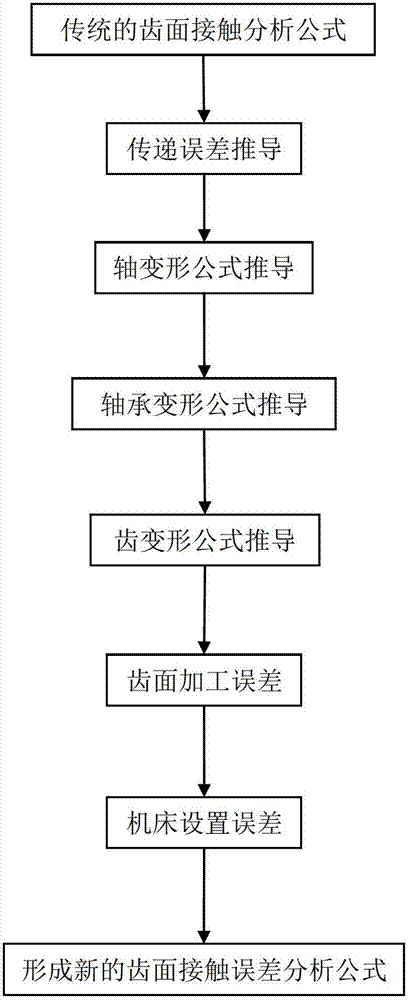

[0070] Such as Figure 1-8 Shown, a kind of method of the present invention is aimed at the tooth surface contact analysis of cycloidal bevel gear error loading, and its specific steps are as follows:

[0071] 1 Tooth surface contact analysis

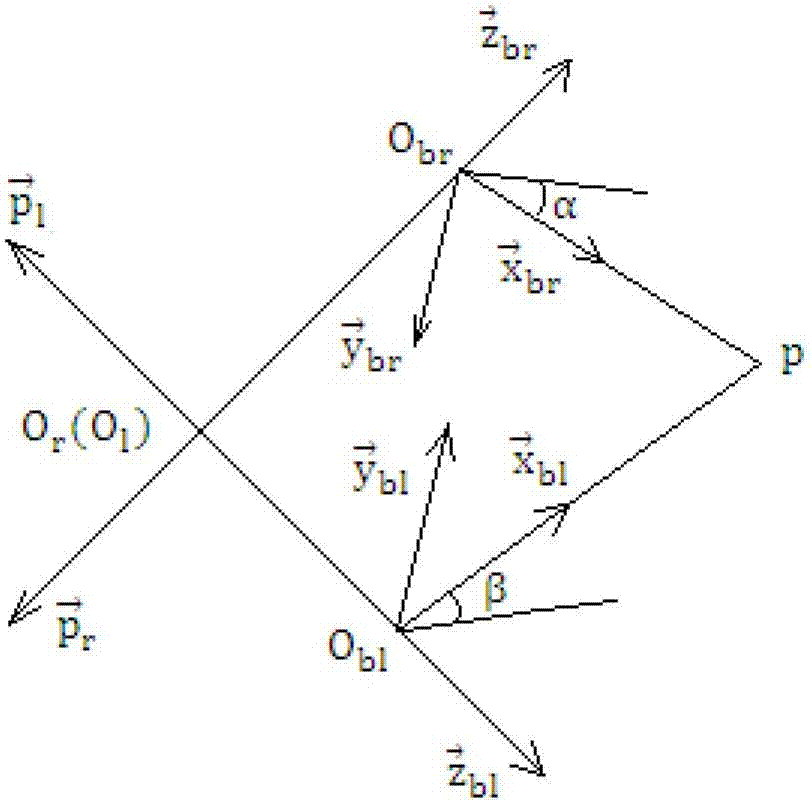

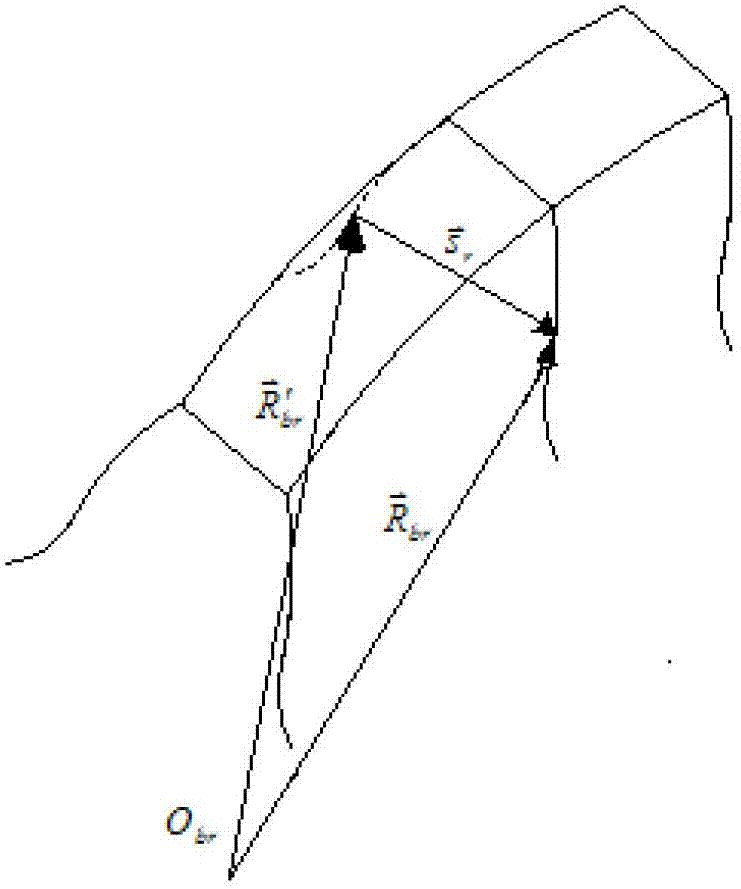

[0072] The three-dimensional space distance vector of the conjugate contact point

[0073] Δ R d → = - H p l → + J p r → + V e l → - - - ( 1 )

[0074] where V is the longitudinal setting parameter of the gear pair, and the upward direction of the pinion is active. H is the coordinate axis setting parameter of the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com