Powder conveying device

A conveying device and powder technology, which can be used in conveying bulk materials, conveyors, transportation and packaging, etc., and can solve problems such as high failure rate, poor liquid slag discharge, and safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

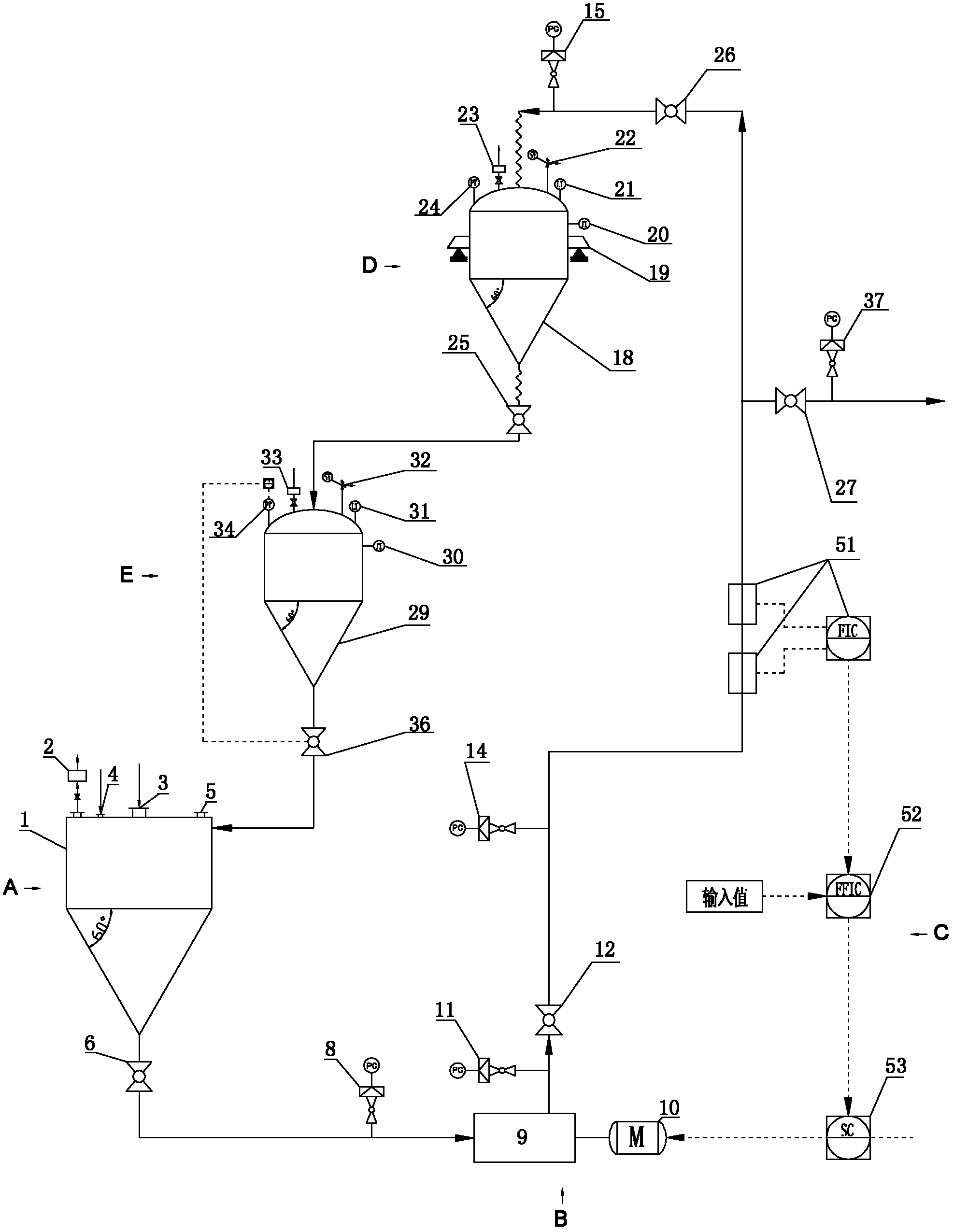

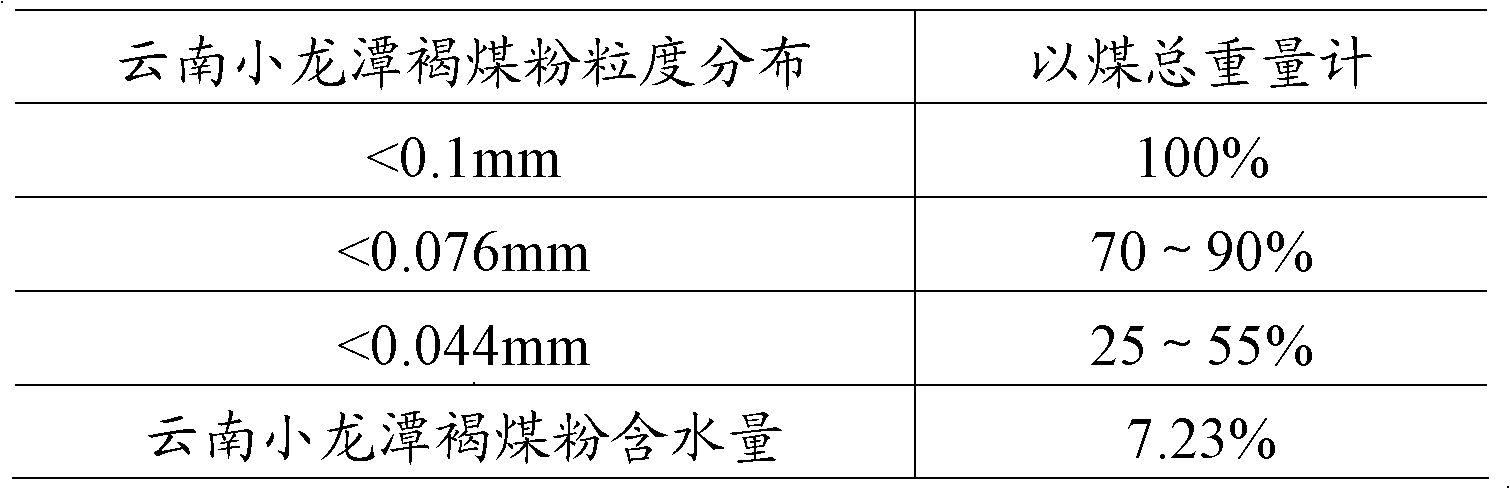

[0071] Example 1 : Use the powder conveying device of the present invention to transport Yunnan Xiaolongtan lignite

[0072] The moisture content of Yunnan Xiaolongtan lignite was determined according to the method of GB / T483-1998 "General Methods for Coal Analysis Test".

[0073] The particle size distribution of Yunnan Xiaolongtan lignite was determined according to the standard sample sieving method.

[0074] The measurement results of moisture content and particle size distribution of Yunnan Xiaolongtan lignite are listed in Table 1.

[0075] Table 1: Moisture content and particle size distribution of Yunnan Xiaolongtan lignite

[0076]

[0077] The implementation is as follows:

[0078] Setting conditions: the flow rate of pulverized coal is 1t / h, and the pressure of pulverized coal discharged from the powder conveying device of the present invention is 5.0MPa.

[0079] The implementation process and its conditions are as follows: about 2t of pulverized coal that ...

Embodiment 2

[0080] Example 2 : use the powder conveying device of the present invention to transport the bituminous coal in Shenfu, Shaanxi

[0081]The moisture content of Shaanxi Shenfu bituminous coal was determined according to GB / T483-1998 "Regulations on General Methods of Coal Analysis Test".

[0082] The particle size distribution of Shaanxi Shenfu bituminous coal was determined according to the standard sample sieving method.

[0083] The measurement results of water content and particle size distribution of Shaanxi Shenfu bituminous coal are listed in Table 1.

[0084] Table 1: Moisture content and particle size distribution of Shaanxi Shenfu bituminous coal

[0085]

[0086] The implementation is as follows:

[0087] Setting conditions: the flow rate of pulverized coal is 20t / h, and the pressure of pulverized coal out of the system is set to 7.0MPa.

[0088] The implementation process and its conditions are as follows:

[0089] Using the system calibrated in Example 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com