Bio 3d printing nozzle

A 3D printing and biological technology, applied in the field of biological 3D printing, can solve the problems of high viscosity, poor fluidity, and insufficient pressure of biological tissue fluid, and achieve the effect of uniform cell distribution, reducing inner cell accumulation, and maintaining homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

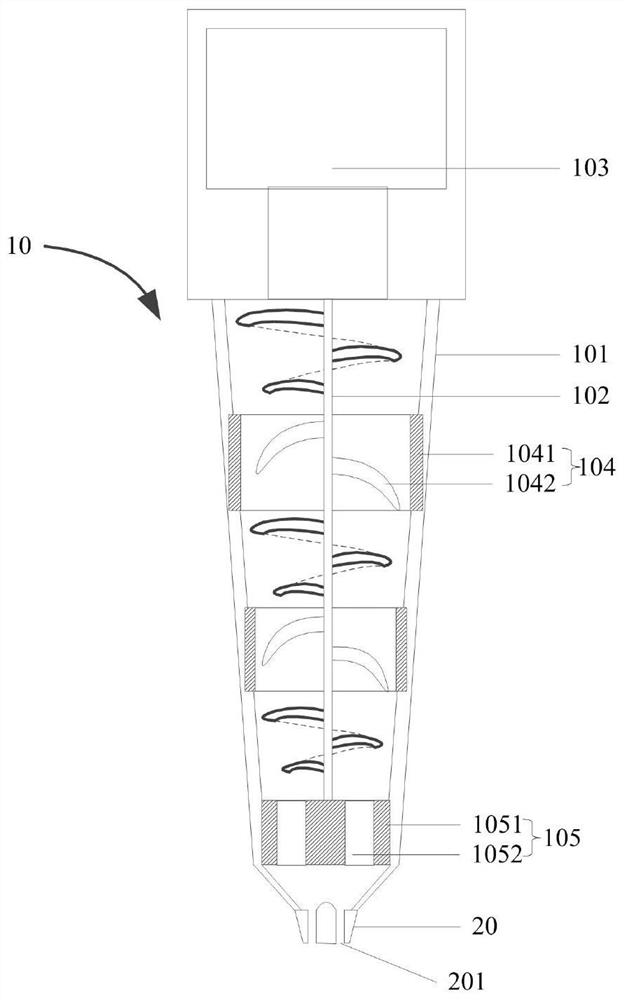

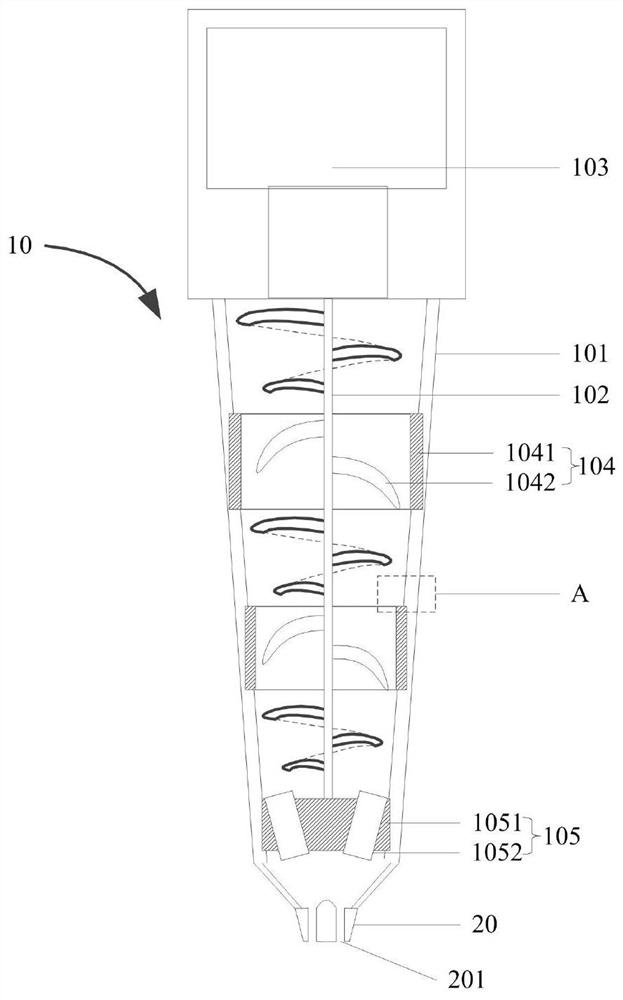

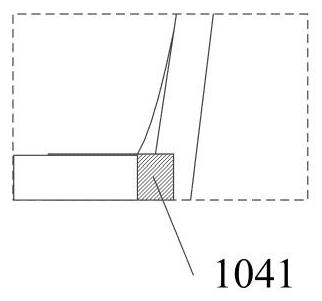

[0035] Such as figure 1 As shown, the present invention provides a biological 3D printing nozzle, comprising:

[0036] The conveying pipe 10 is arranged directly above the 3D printing table, and the conveying pipe also includes: a cylinder 101, which is a vertically arranged hollow pipe, and from the upper end of the cylinder to its lower end, the The cross-section of the cylinder gradually decreases; the shaft 102 is axially arranged in the cylinder, and the screw conveying piece is arranged on the shaft; the motor 103 drives the shaft to rotate; at least two first pressurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com