External soil spraying machine and special two-stage energy-saving high-lift underflow pump for external soil spraying machine

A kind of soil spraying, high lift technology, applied in the direction of spreading seeders, fertilizers and seeding equipment, etc., can solve the problems of damage to the mud pump or diesel engine, reduce the lift and service life of the sprayer, complex structure, etc. Feeding auger, reducing failure prone points, optimizing the effect of the transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

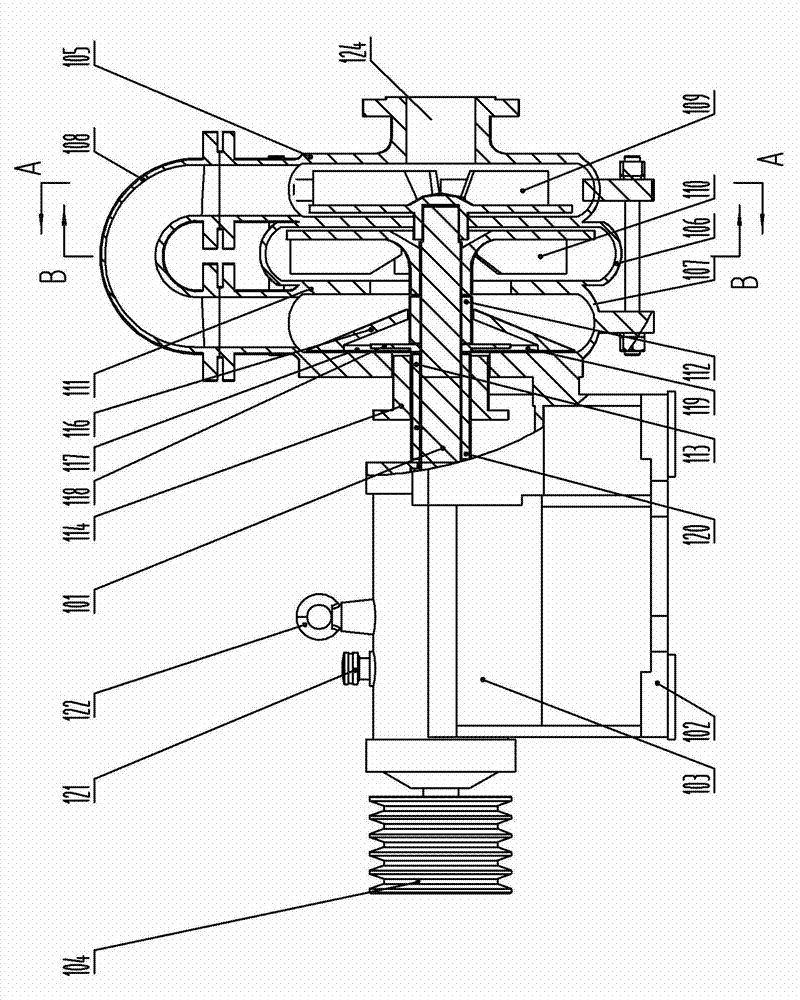

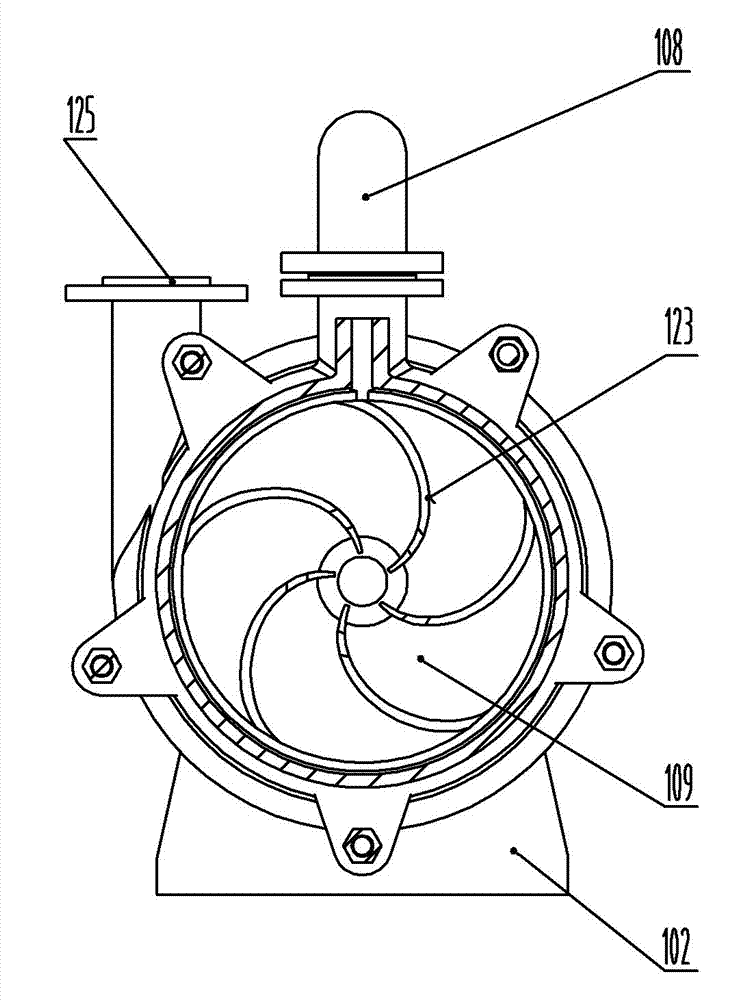

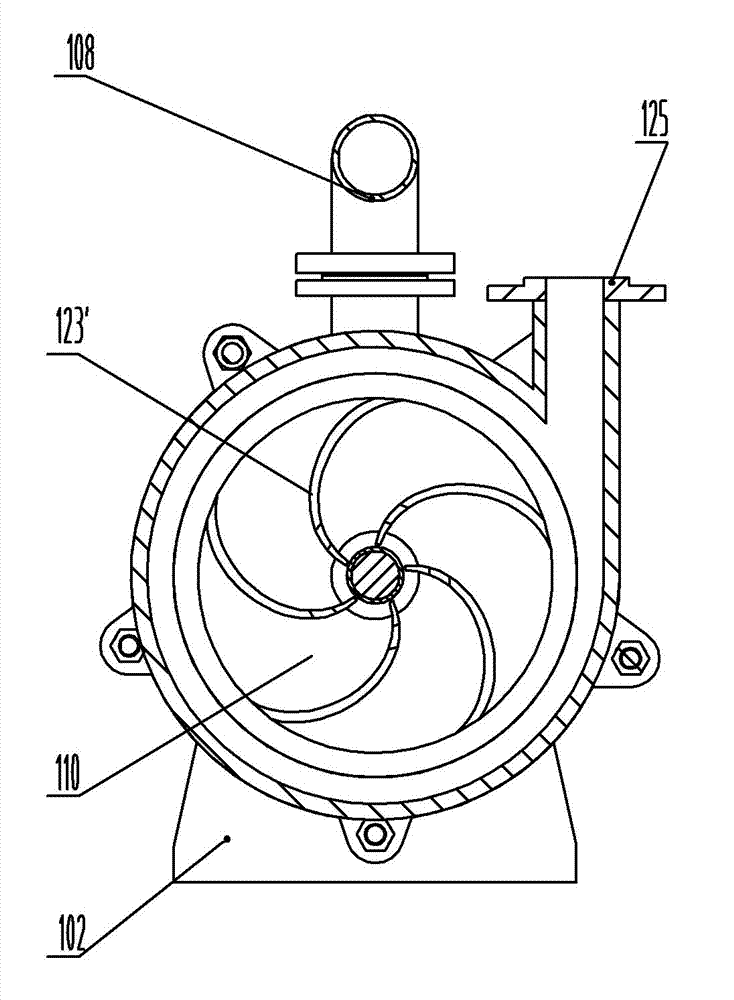

[0035] see Figure 1 to Figure 3 , in the figure, the double-stage energy-saving and high-lift special thick slurry pump 1 for soil seeding machine of the present invention includes a transmission shaft 101, a pump body is installed on the right side of the transmission shaft, and a bearing chamber 103 with a pump seat 102 is installed on the left side, A coupling 104 is installed at the left end, and the pump body includes a first-stage pump body 105, a second-stage pump body 106 and a second-stage feed pump body 107 that are sleeved on the transmission shaft in sequence from right to left. The pump body and the secondary feed pump body are connected by an elbow 108. The primary pump body is provided with a primary impeller 109. The primary impeller is fixedly sleeved on the right end of the transmission shaft, and the secondary pump body is provided with a secondary impeller 110. , a guard plate 111 is fixed between the secondary feeding pump body and the secondary pump body...

Embodiment 2

[0037] see Figure 4 to Figure 7 , in the figure, the double-stage energy-saving high-lift thick slurry pump special-purpose soil seeding machine of the present invention includes the above-mentioned double-stage energy-saving high-lift soil spraying machine special thick slurry pump 1, and also includes a frame 201, which is fixedly installed in the frame. The stirring tank 202 on one side has a stirring system installed inside the stirring tank, a feeding port 203 is arranged on the upper part of the outer side of the stirring tank, and the thick slurry pump is installed on the other side of the frame, which is respectively connected with the thick slurry pump and the stirring tank. The transmission mechanism connected to the system, and the power mechanism connected with the transmission mechanism, the lower part of the inner side of the mixing tank is provided with a water inlet pipe to connect with the thick slurry pump, and the top of the rack is provided with an operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com