Tunnel type trimmer for processing textiles

A tunnel-type and trimmer technology, which is applied in the direction of textiles and papermaking, applications, household appliances, etc., can solve the problems of improving the flatness of unsatisfactory clothes, and achieve the effect of improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

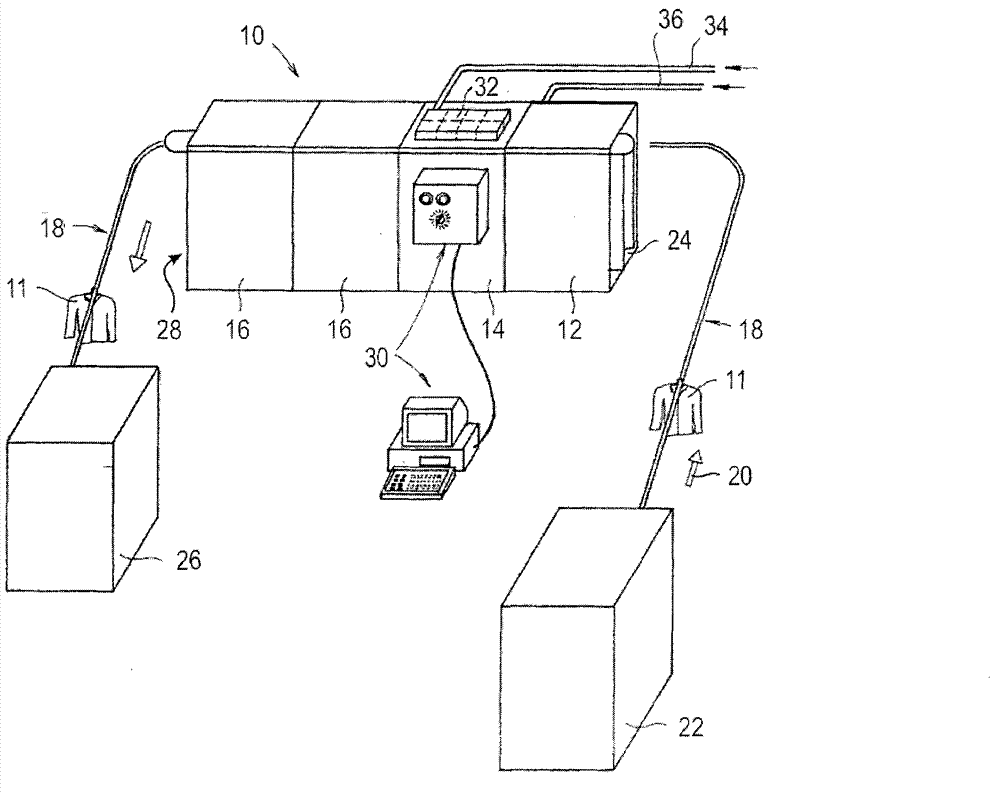

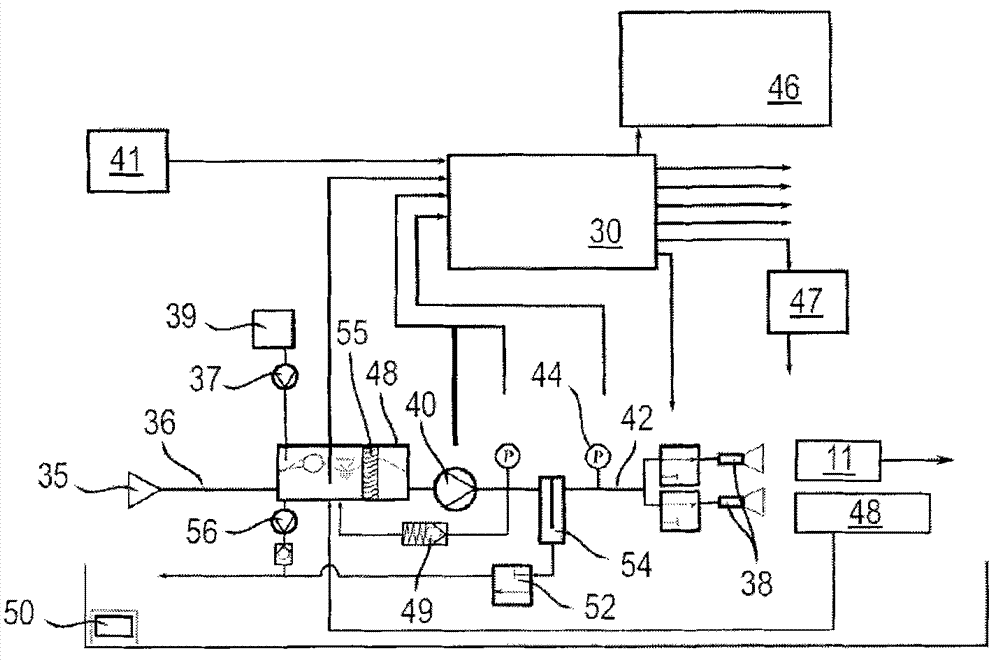

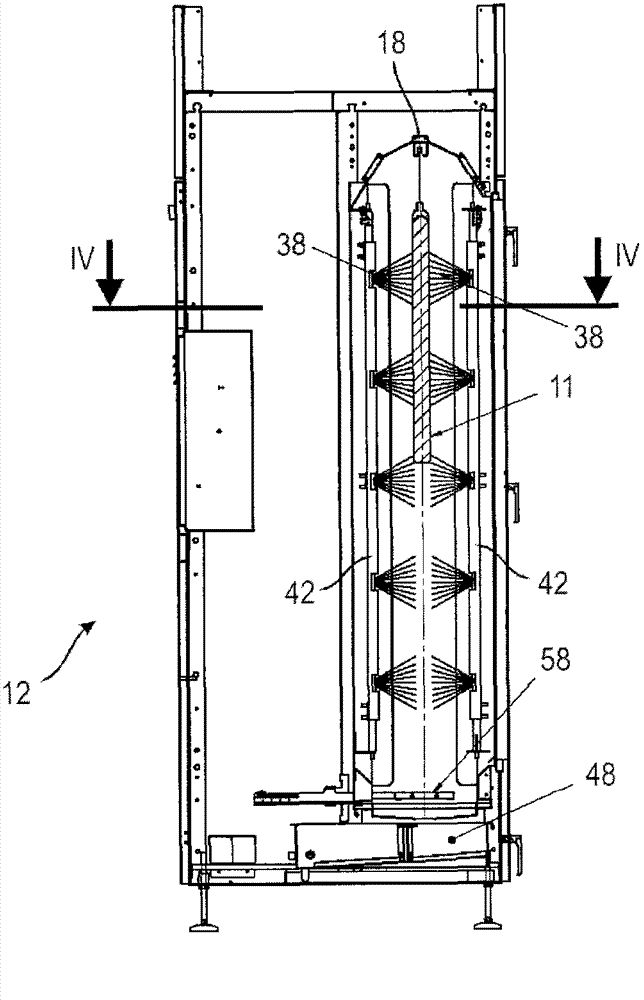

[0024] figure 1 Schematically shows a modularly constructed tunnel finisher 10 for processing textiles 11 with a premoistening module 12, a steam module 14, two drying modules 16 and a conveying system 18 which makes the textiles 11 The modules 12 , 14 , 16 of the tunnel finisher 10 are moved in the direction of passage 20 . The modules are placed next to each other so that they form an integral unit. Furthermore, the tunnel finisher 10 comprises: an output station 22 , which outputs the textiles 11 to be treated via a conveying system 18 to a chamber opening 24 on the input side of the premoistening module 12 ; The chamber opening 28 on the output side of the upper second drying module 16 passes through the processed, "finished" textiles 11 conveyed by the conveying system 18; and the processor control device 30, which can automatically control or adjust various parameters such as humidity, The amount of air and steam delivered, and the delivery speed of delivery system 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com