Side-channel compressor for a fuel cell system for conveying and/or compressing a gaseous medium

A fuel cell system, gaseous medium technology, applied in fuel cells, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve problems such as increasing operating costs, high energy consumption of driving devices, etc. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

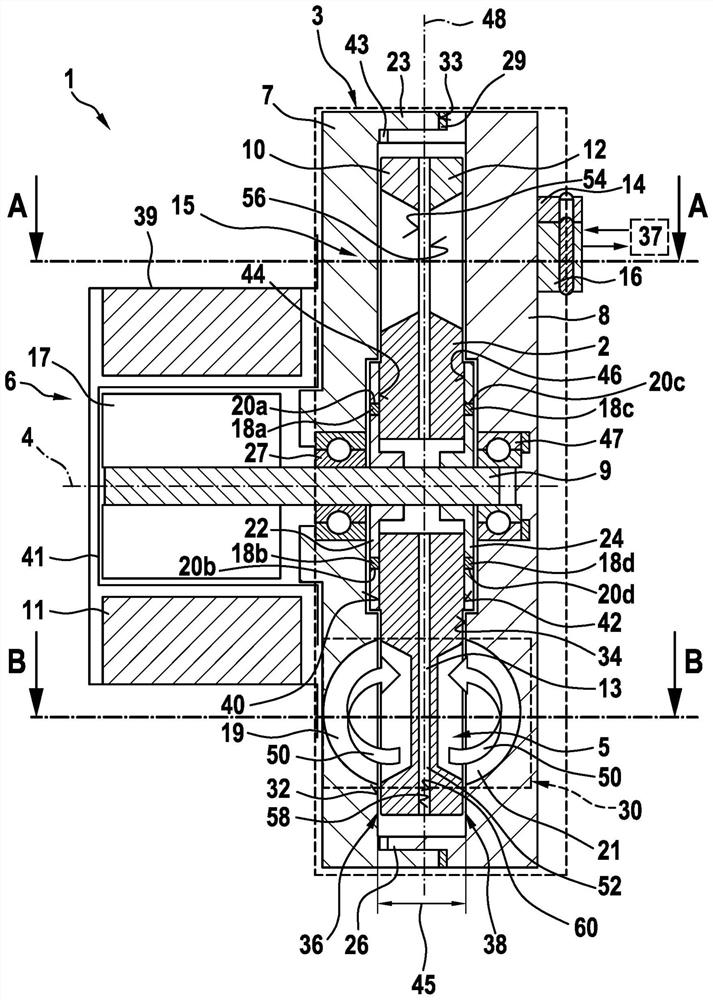

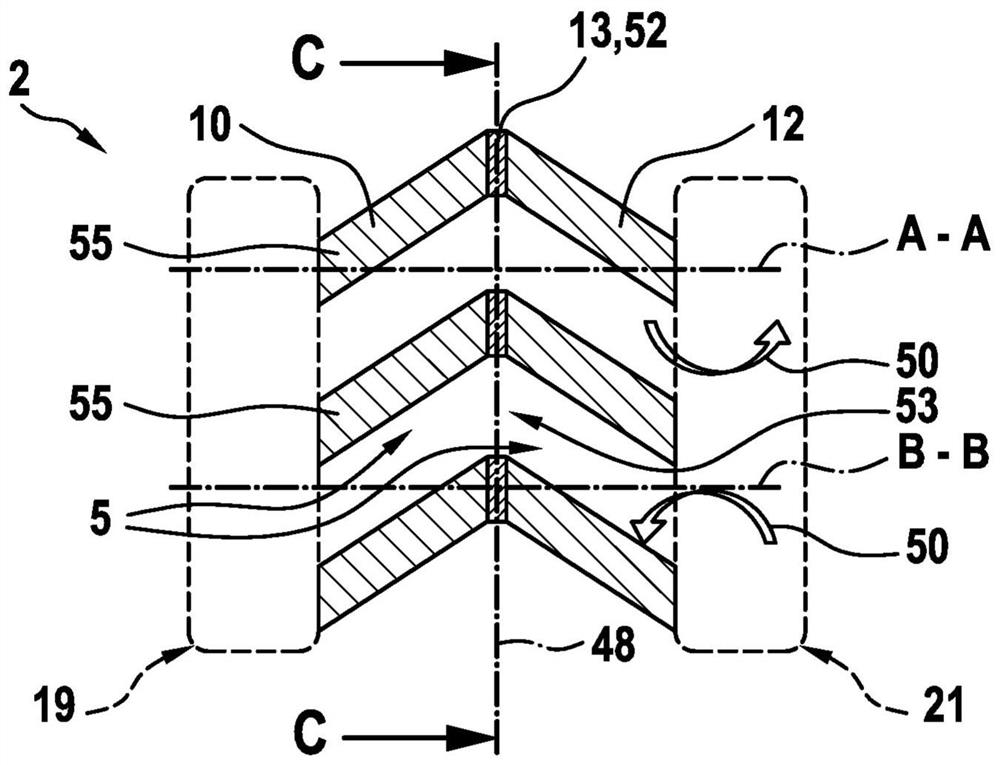

[0024] from according to figure 1 The illustration in FIG. 1 results in a schematic sectional view of a side channel compressor 1 according to the invention and a compressor wheel 2 according to the invention according to a first embodiment.

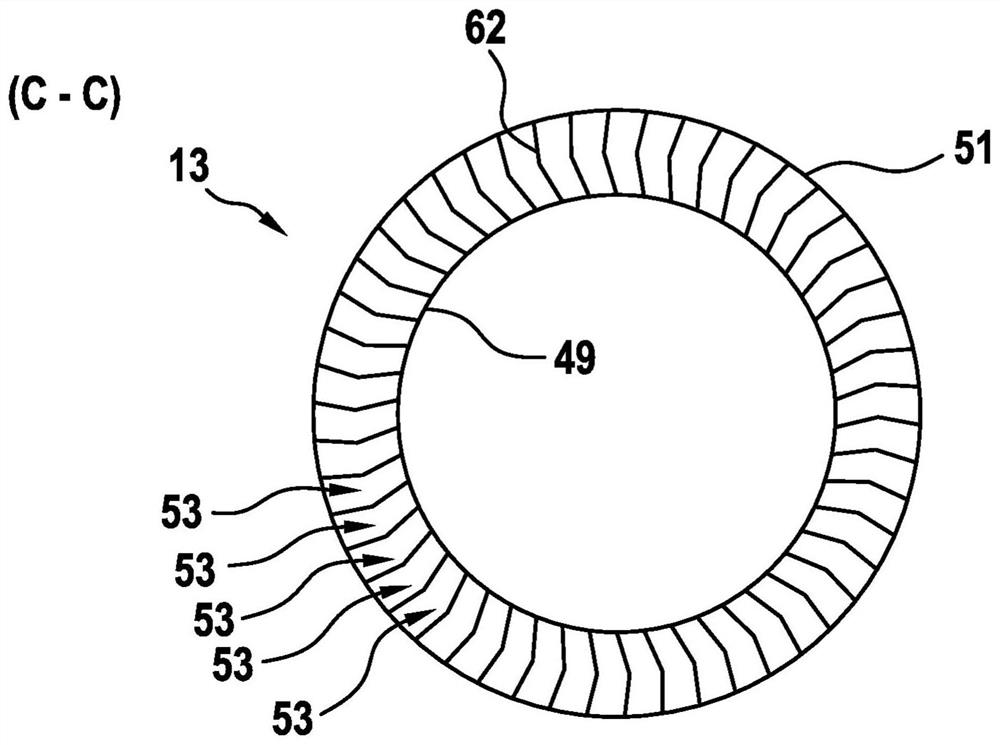

[0025] In this case, the side-channel compressor 1 has a compressor wheel 2 which is mounted rotatably about a horizontally extending axis of rotation 4 in a housing 3 . In this case, a drive 6 , in particular an electric drive 6 , serves as a rotary drive 6 for the compressor wheel 2 , and a torque and / or a rotary movement is transmitted from the drive 6 to the compressor wheel 2 at least indirectly via a drive shaft 9 . Here, according to a first exemplary embodiment, the compressor wheel 2 is constructed in multiple parts and has a first wheel shell 10 and a second wheel shell 12 , wherein they are arranged axially next to each other, in particular with respect to the axis of rotation 4 , and A gap 52 radially surrounding the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com