Sludge thickening and dewatering all-in-one machine

A sludge concentration and integrated machine technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of limited sludge concentration effect, large equipment investment, and low work efficiency. Achieve the effects of reducing the moisture content of sludge, increasing the contact area, and increasing the compression speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

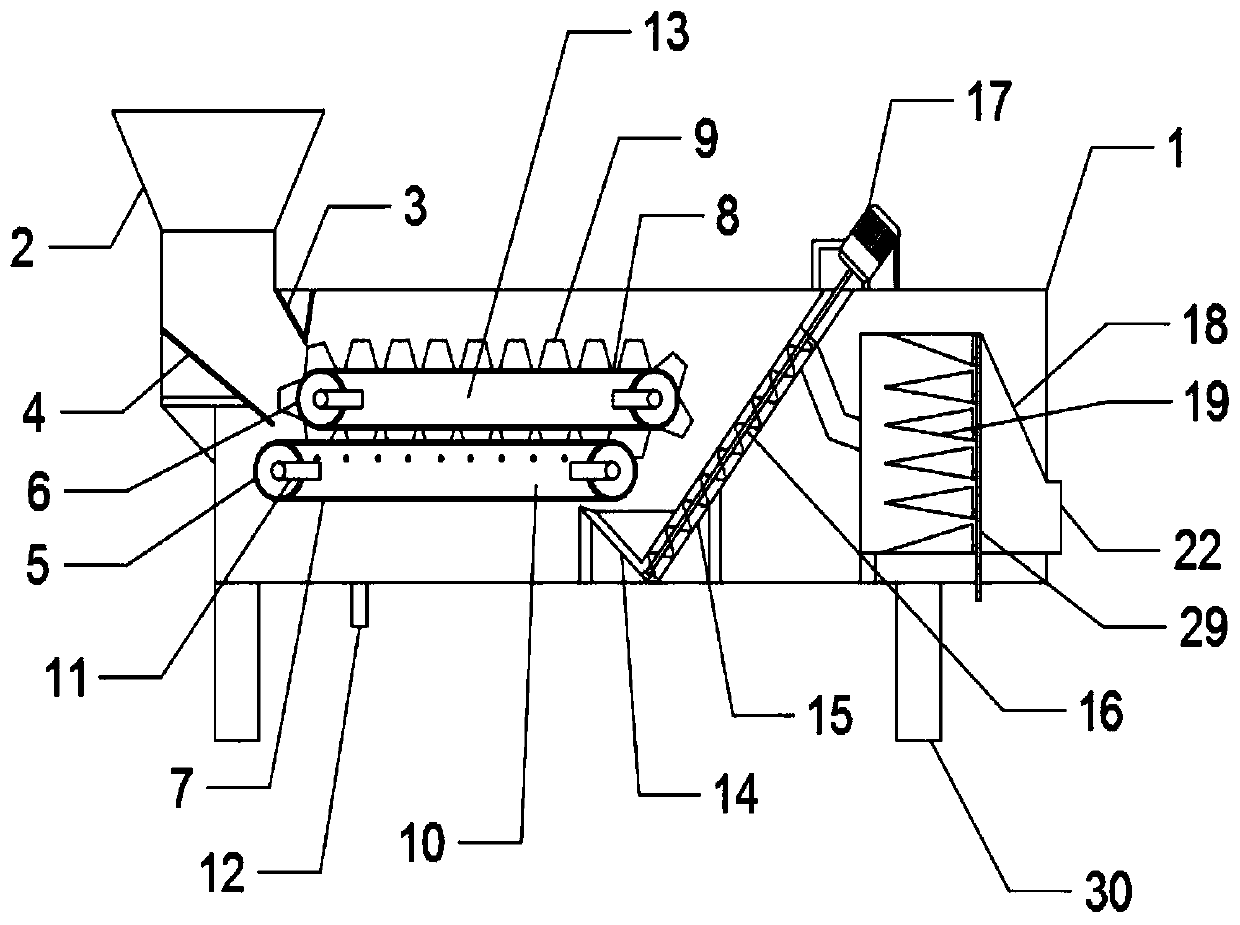

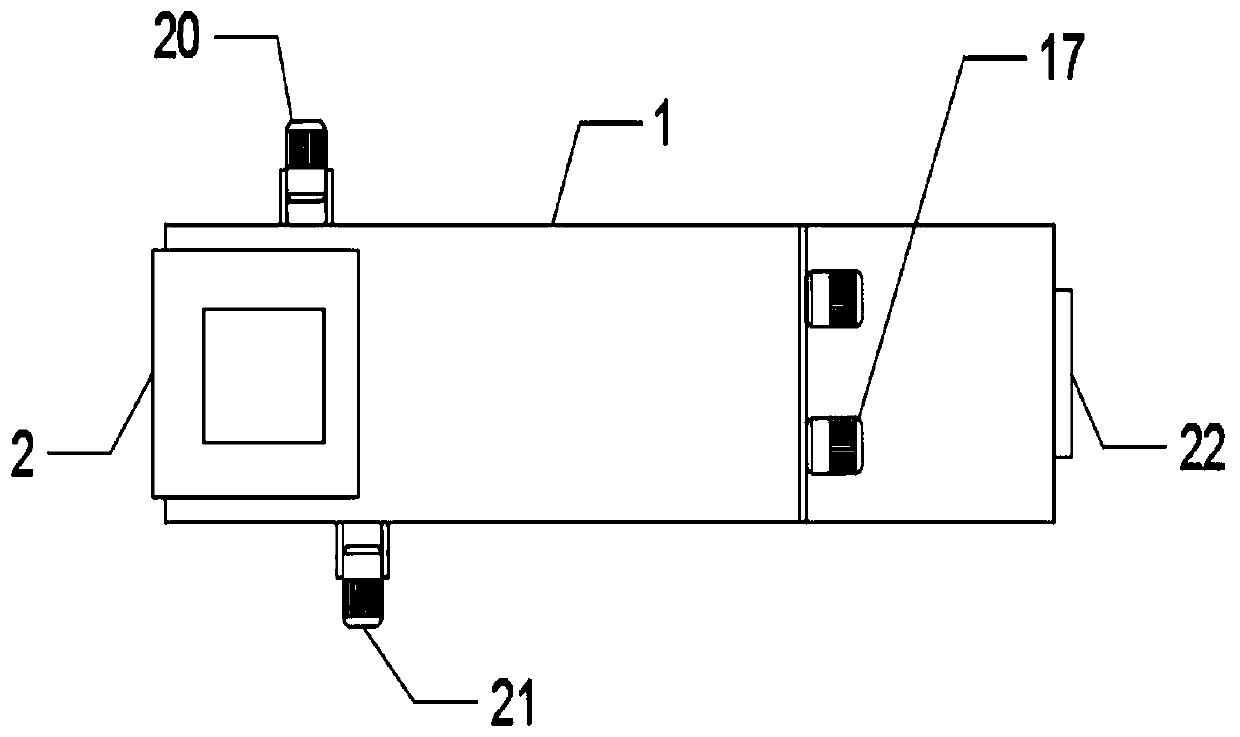

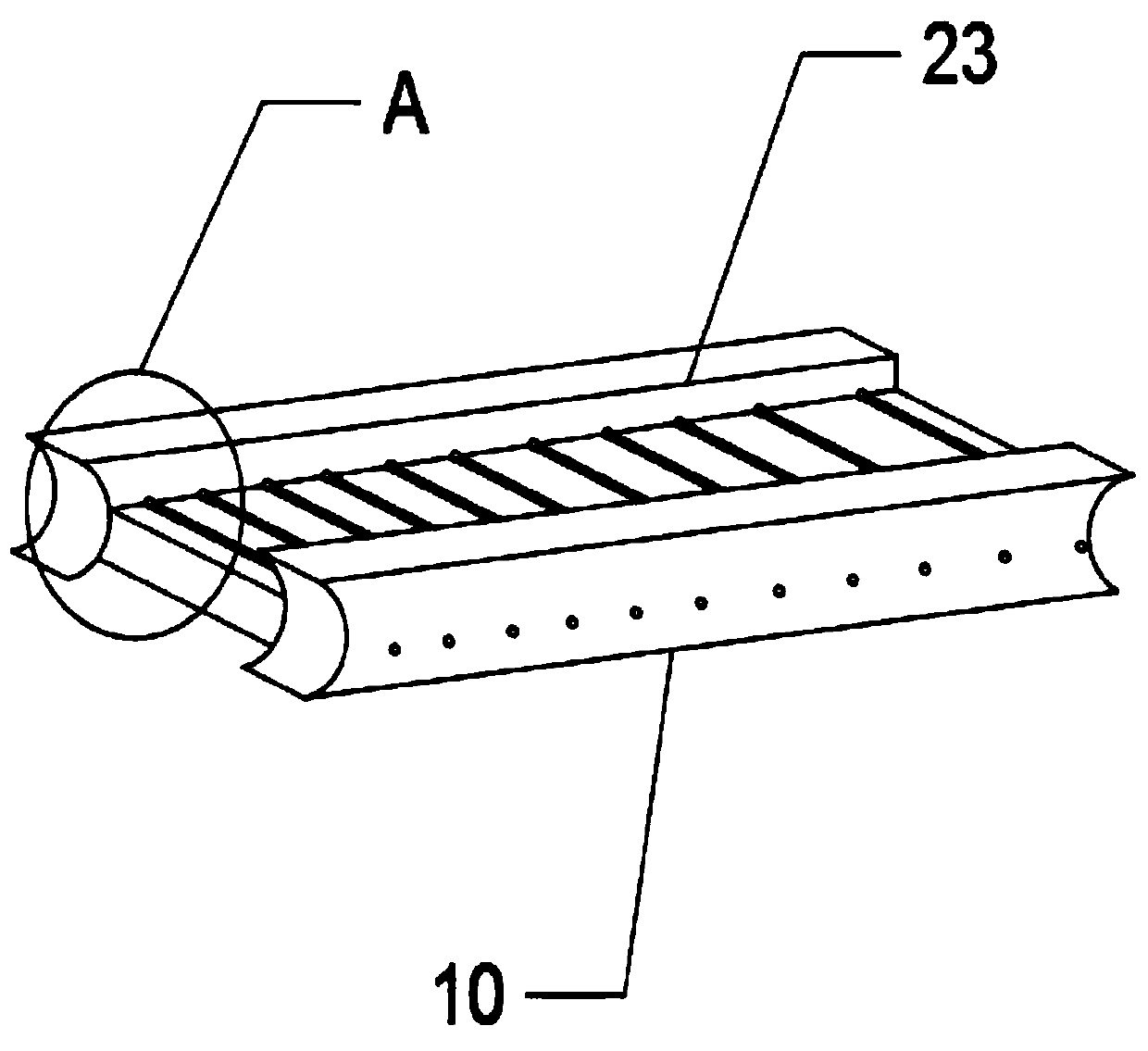

[0024] Such as Figure 1-Figure 7 As shown, the integrated sludge thickening and dewatering machine provided in this embodiment includes a housing 1, and two first driving drums 5 are arranged inside the housing 1, and two second driving drums are arranged above the first driving drum 5. 6. A first conveyor belt 7 is connected between the two first driving rollers 5 . A second conveyor belt 8 is connected between the two second drive rollers 6 , and a plurality of pressing blocks 9 are arranged on the second conveyor belt 8 . The first conveyor belt 7 is provided with a plurality of pressing grooves 28, and the inside of the pressing grooves 28 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com